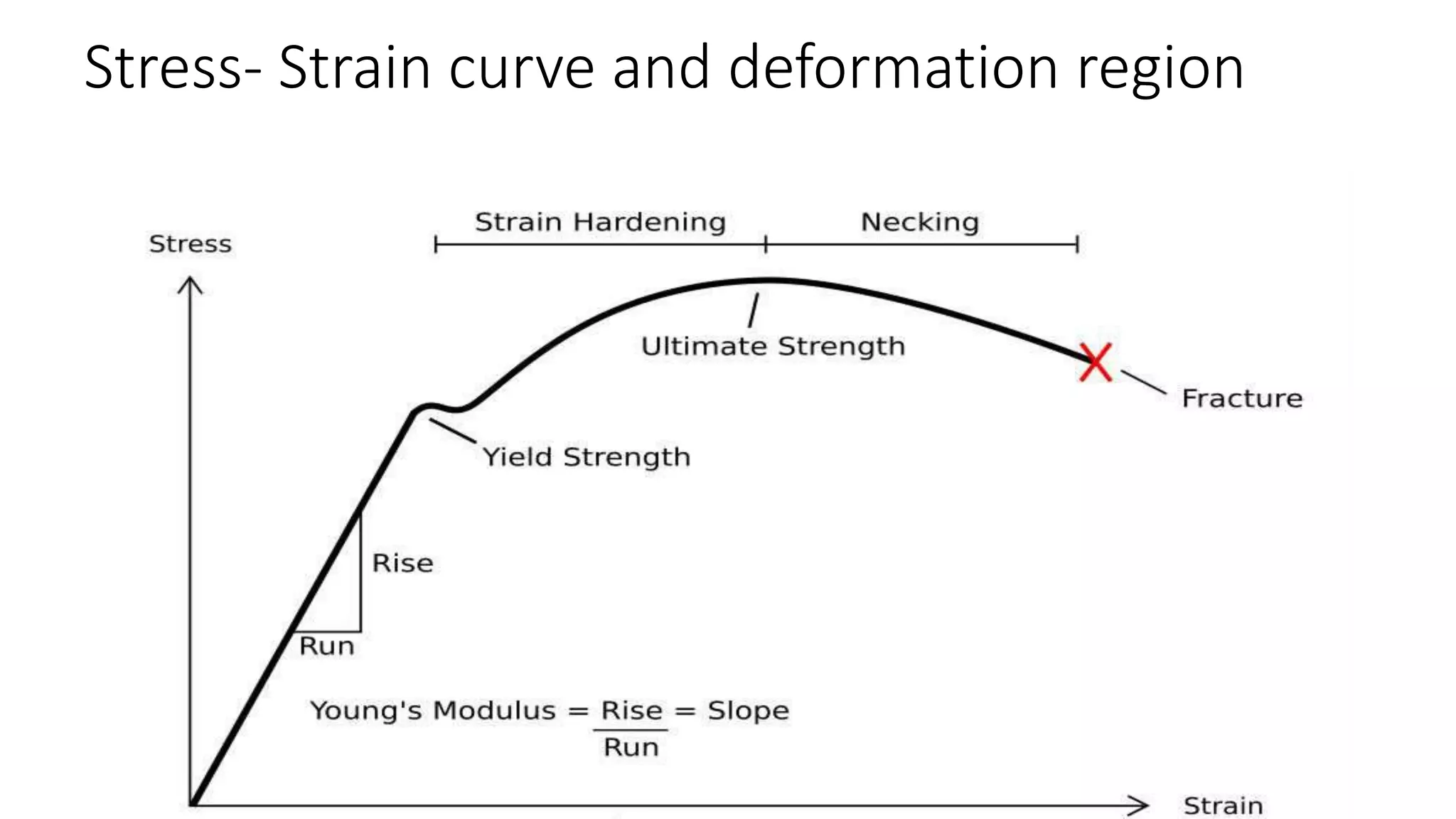

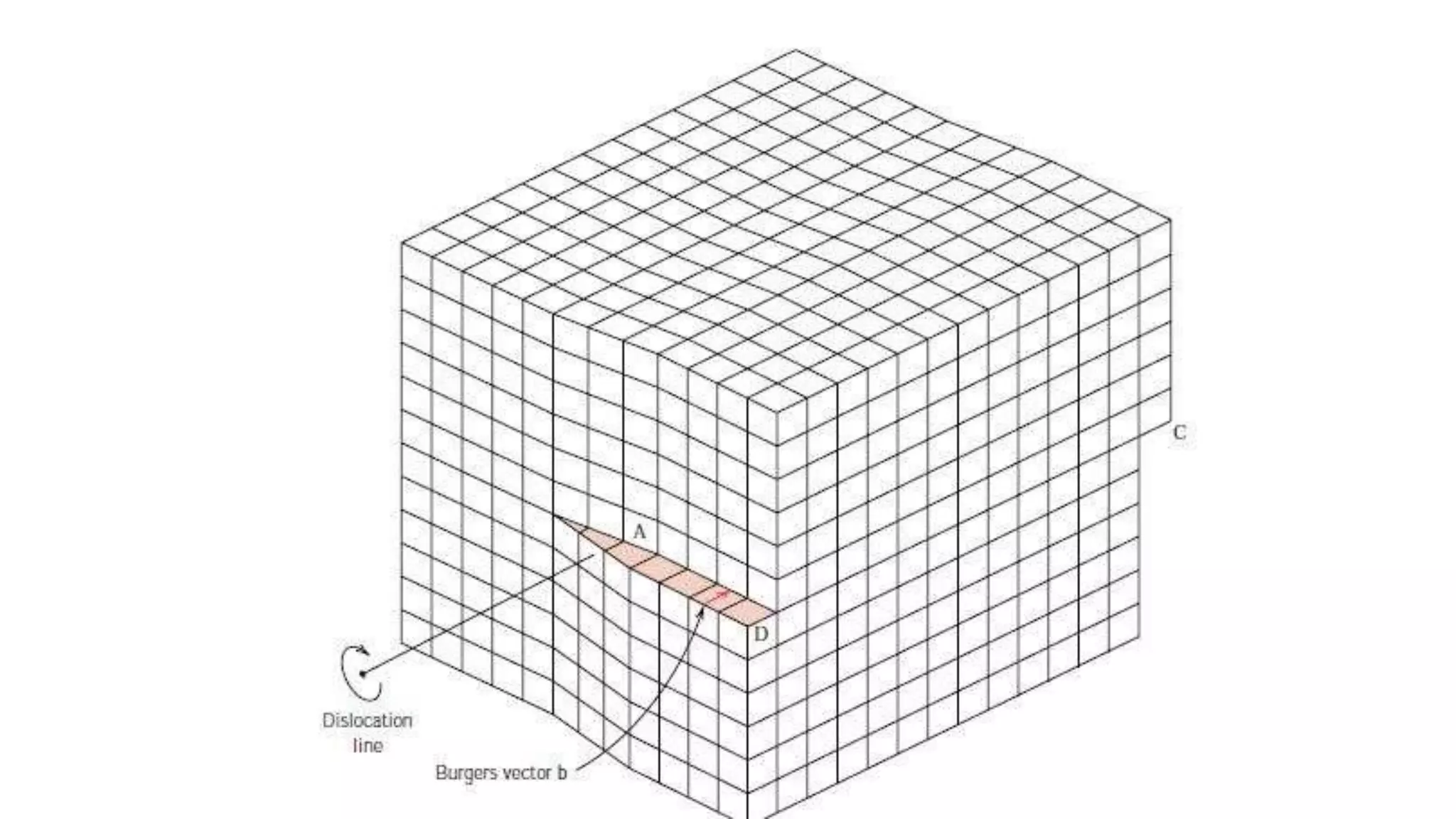

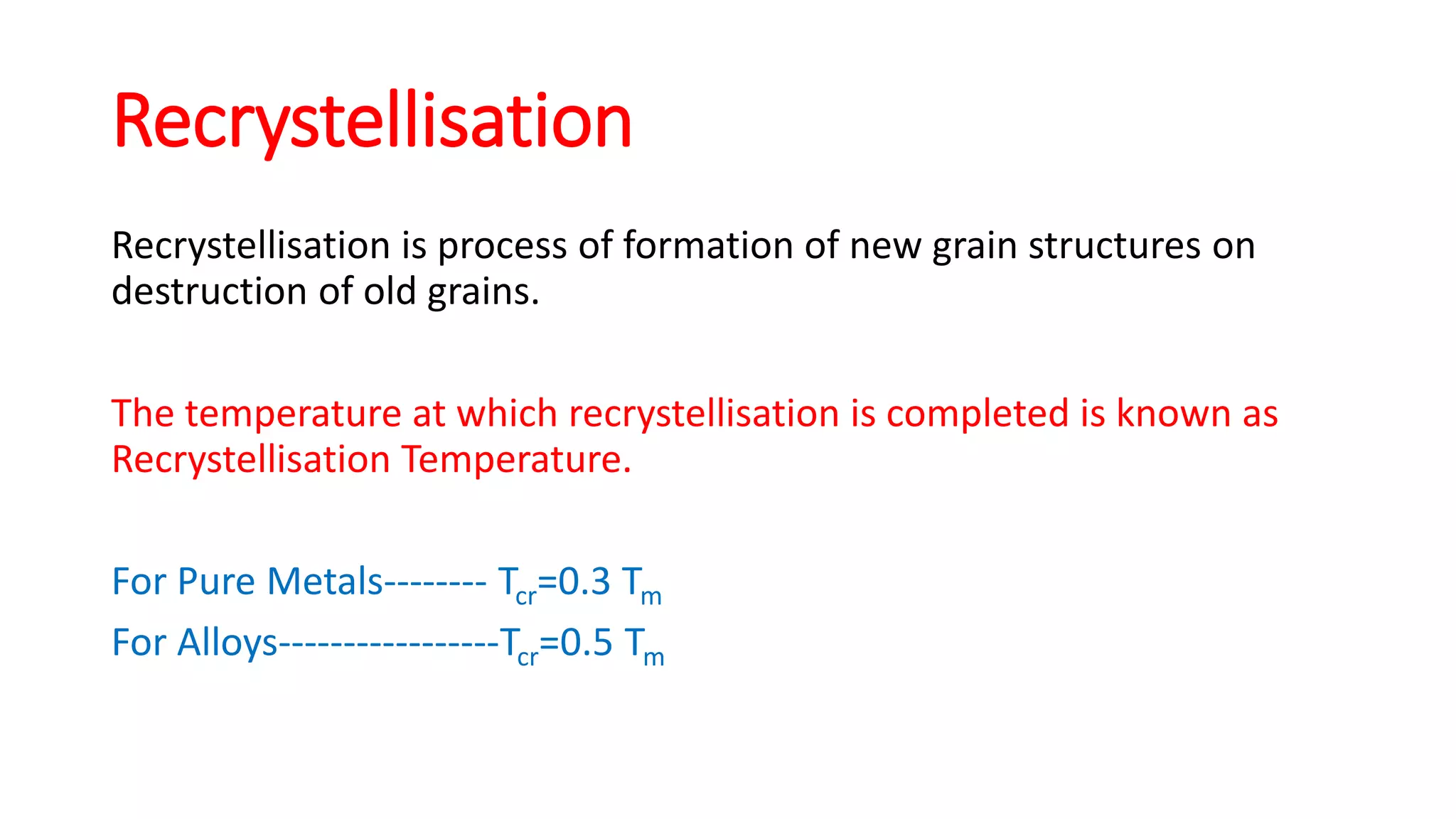

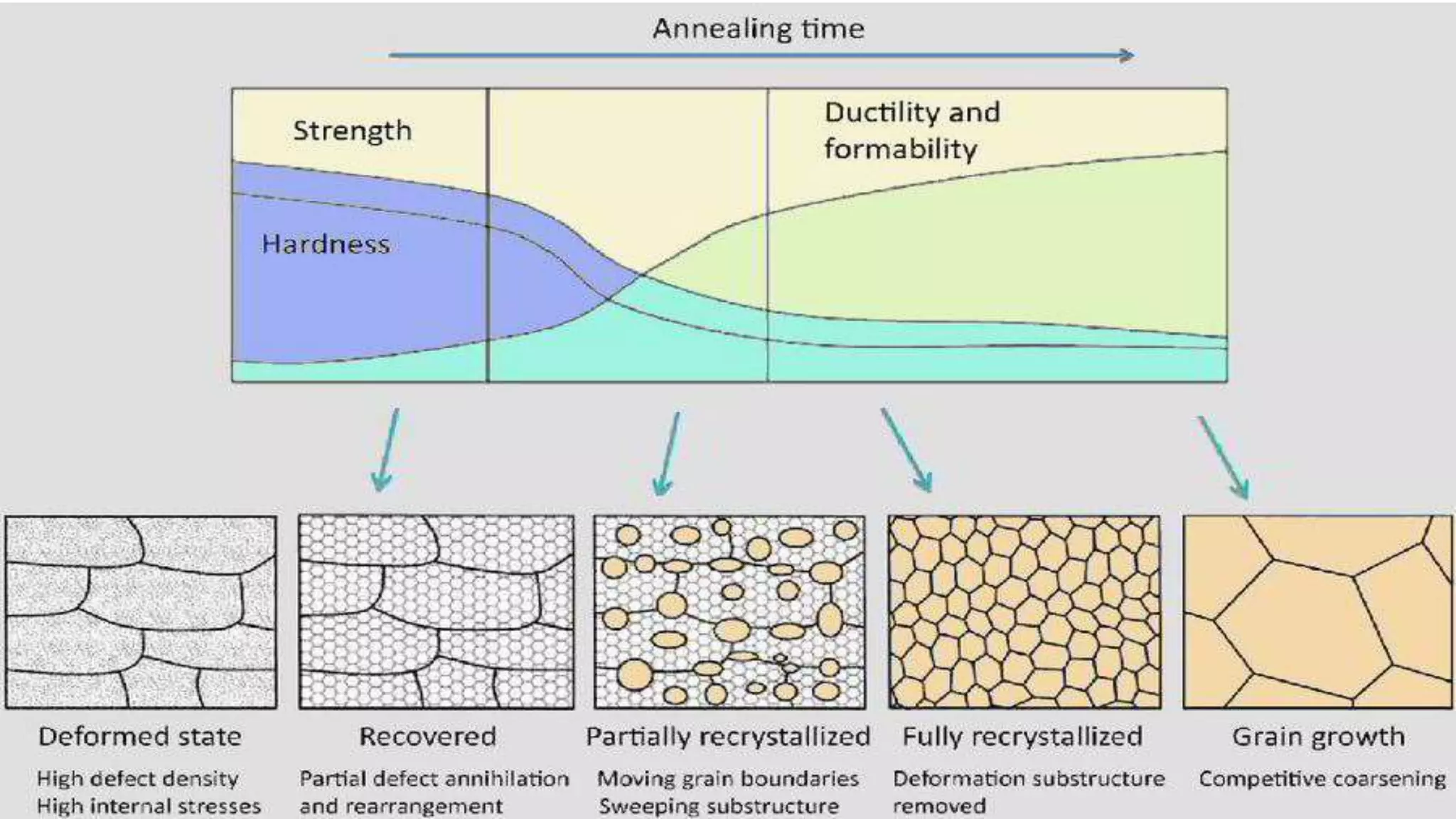

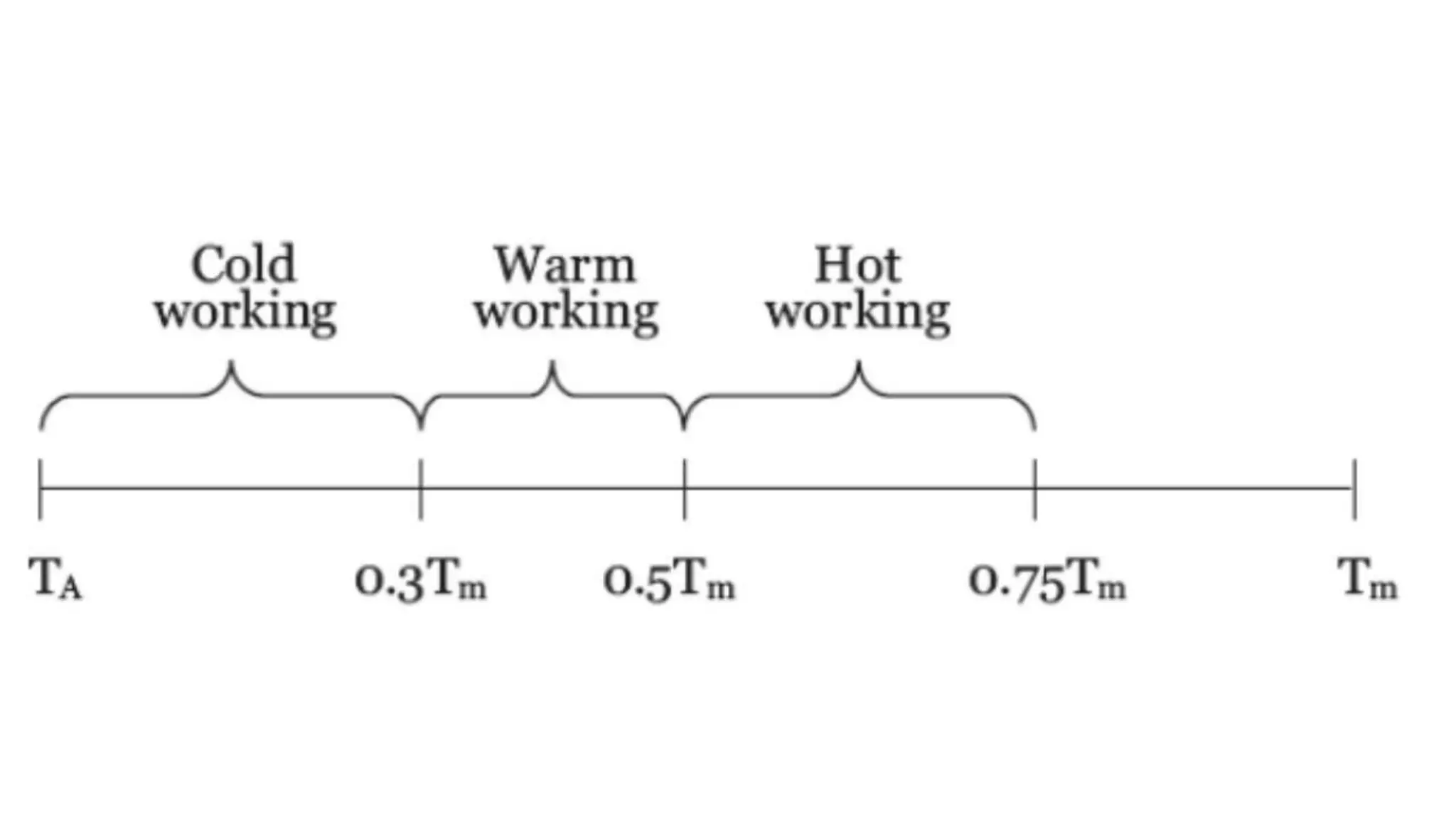

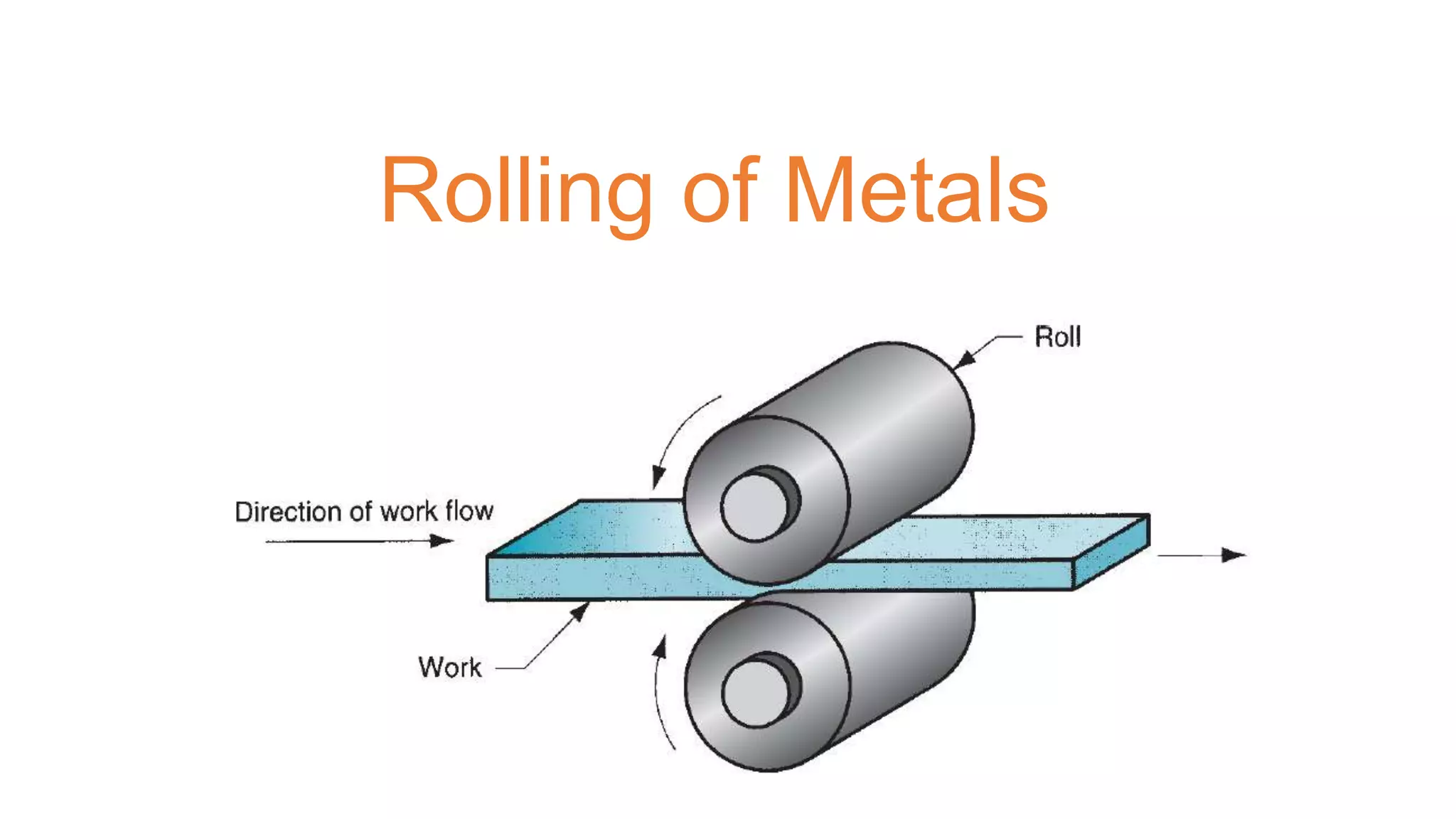

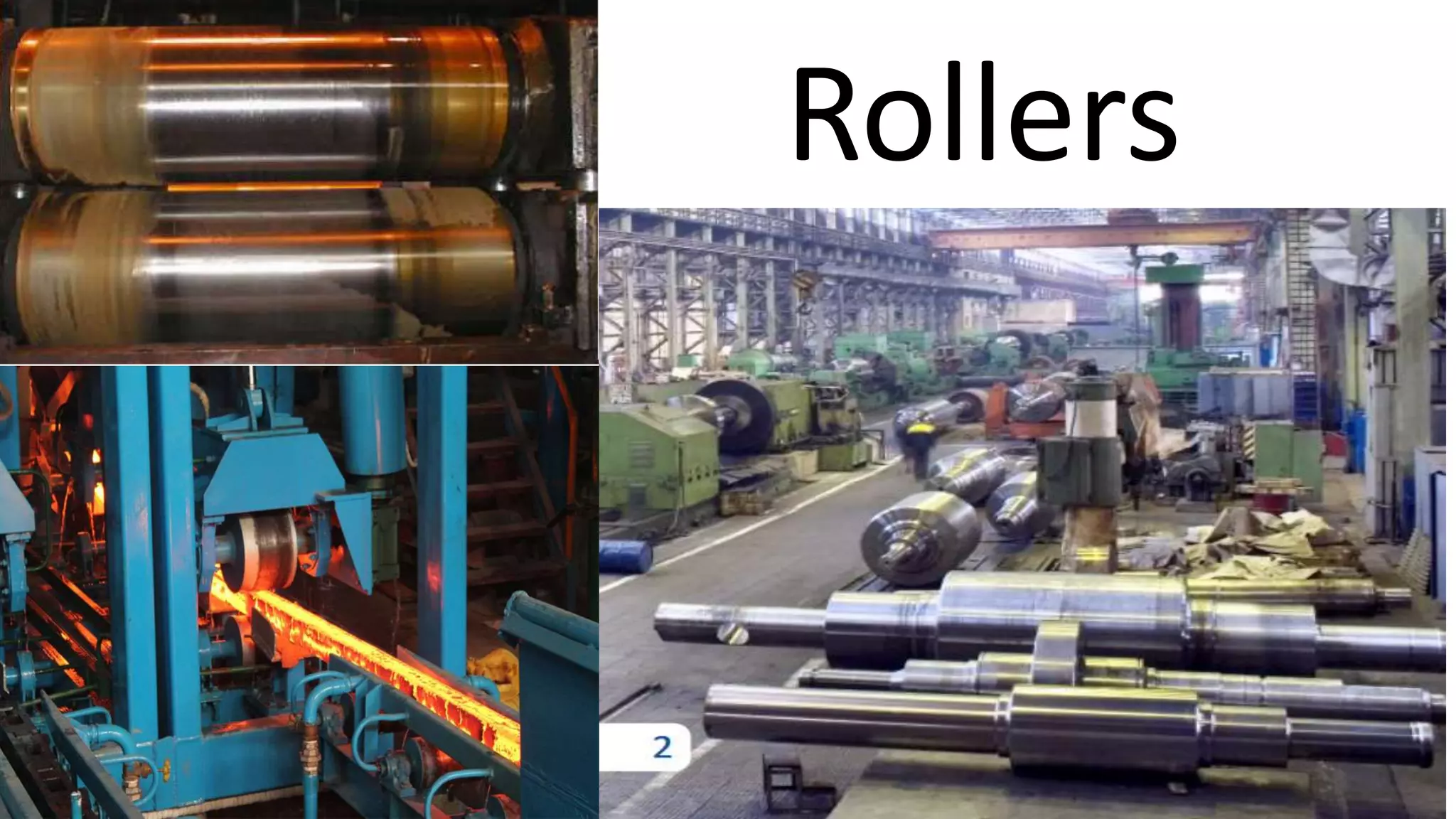

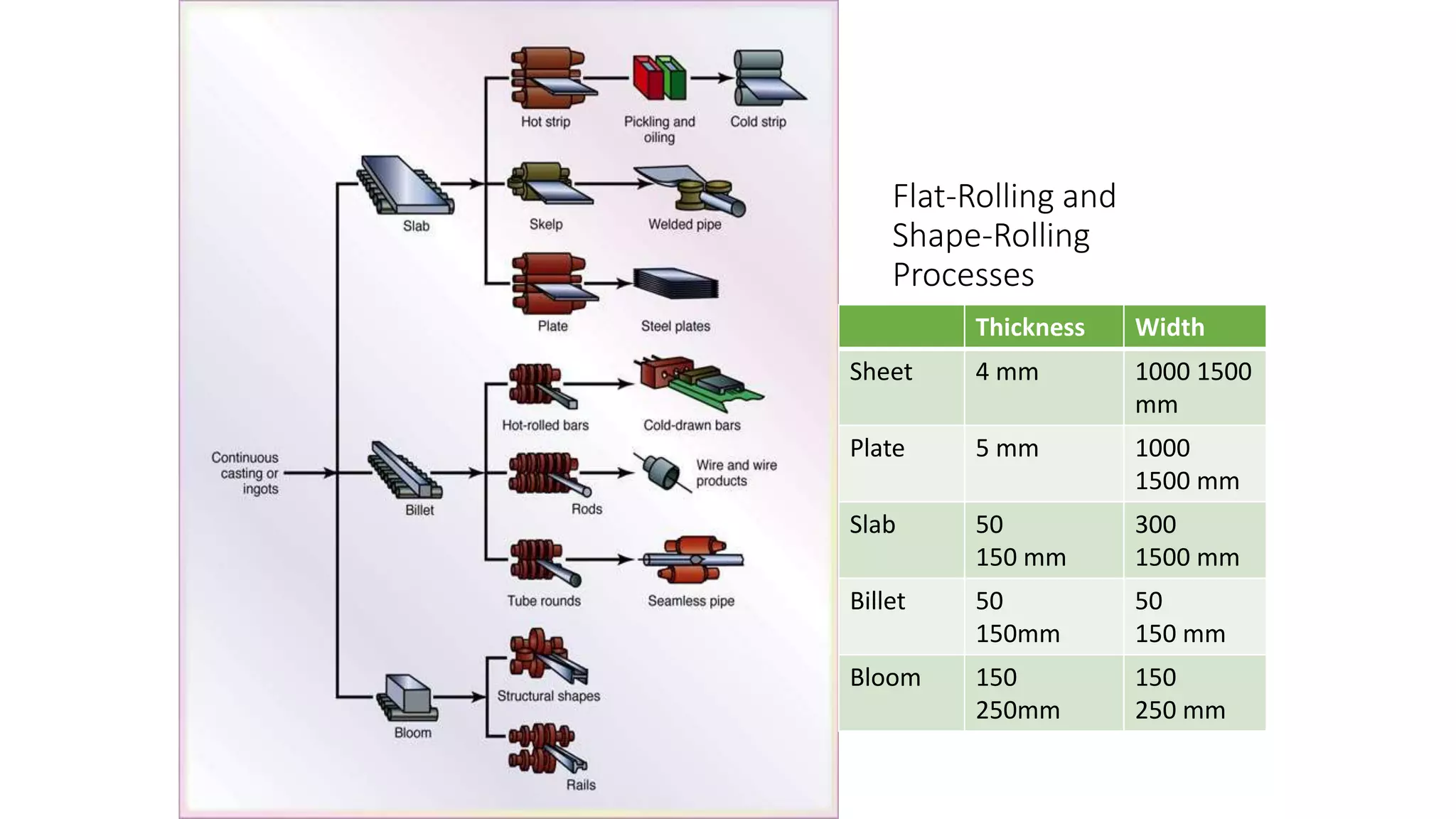

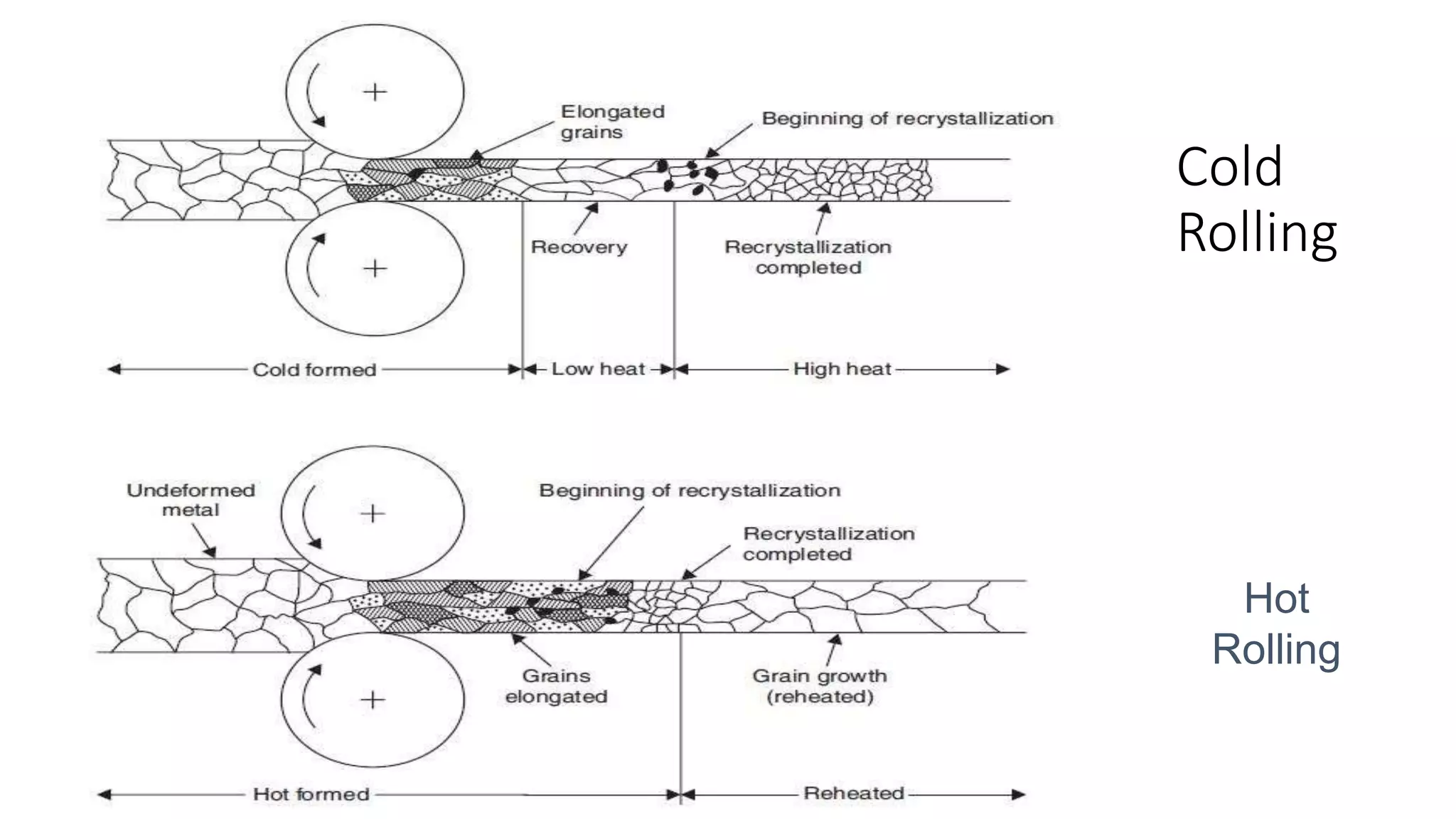

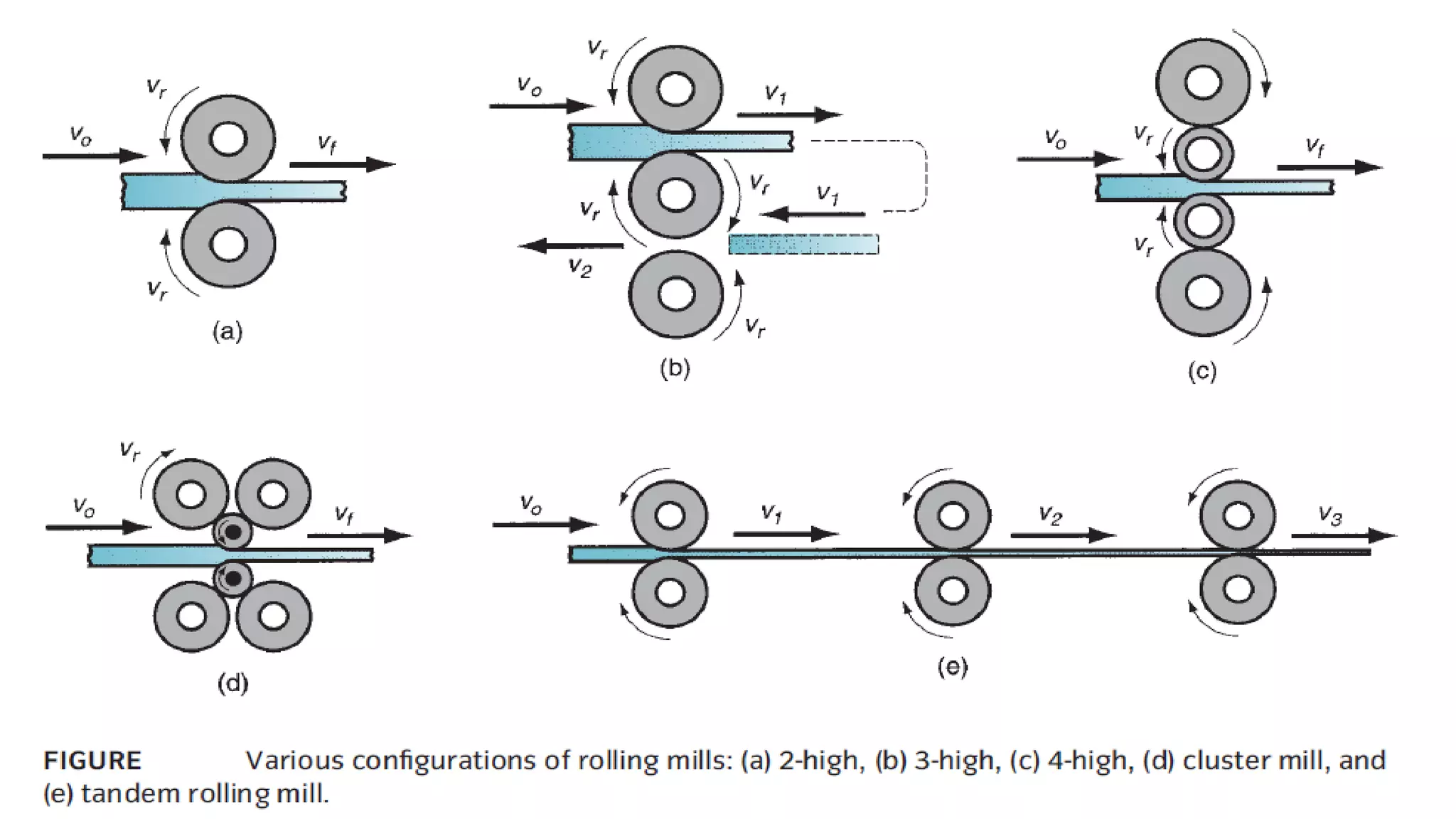

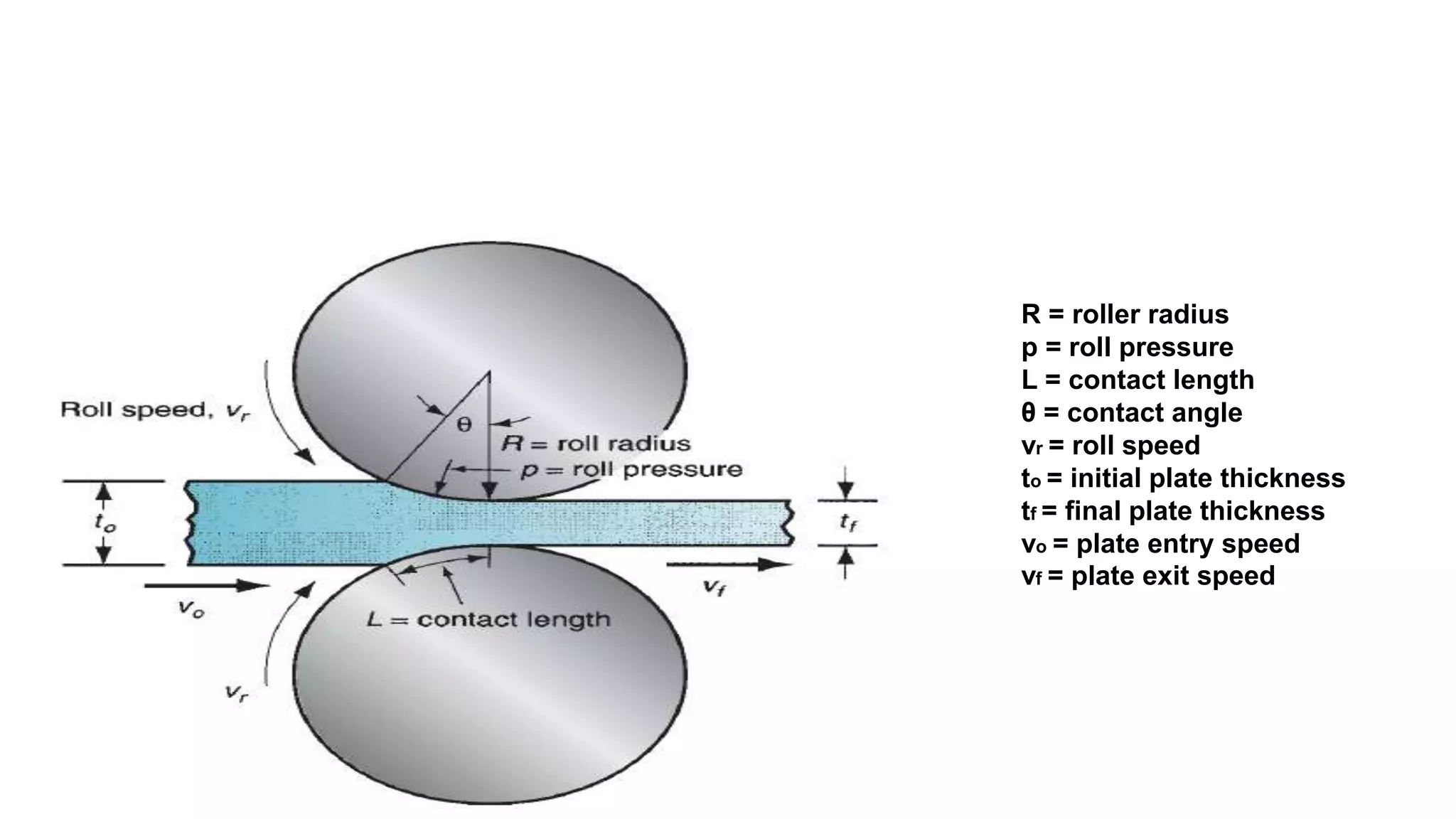

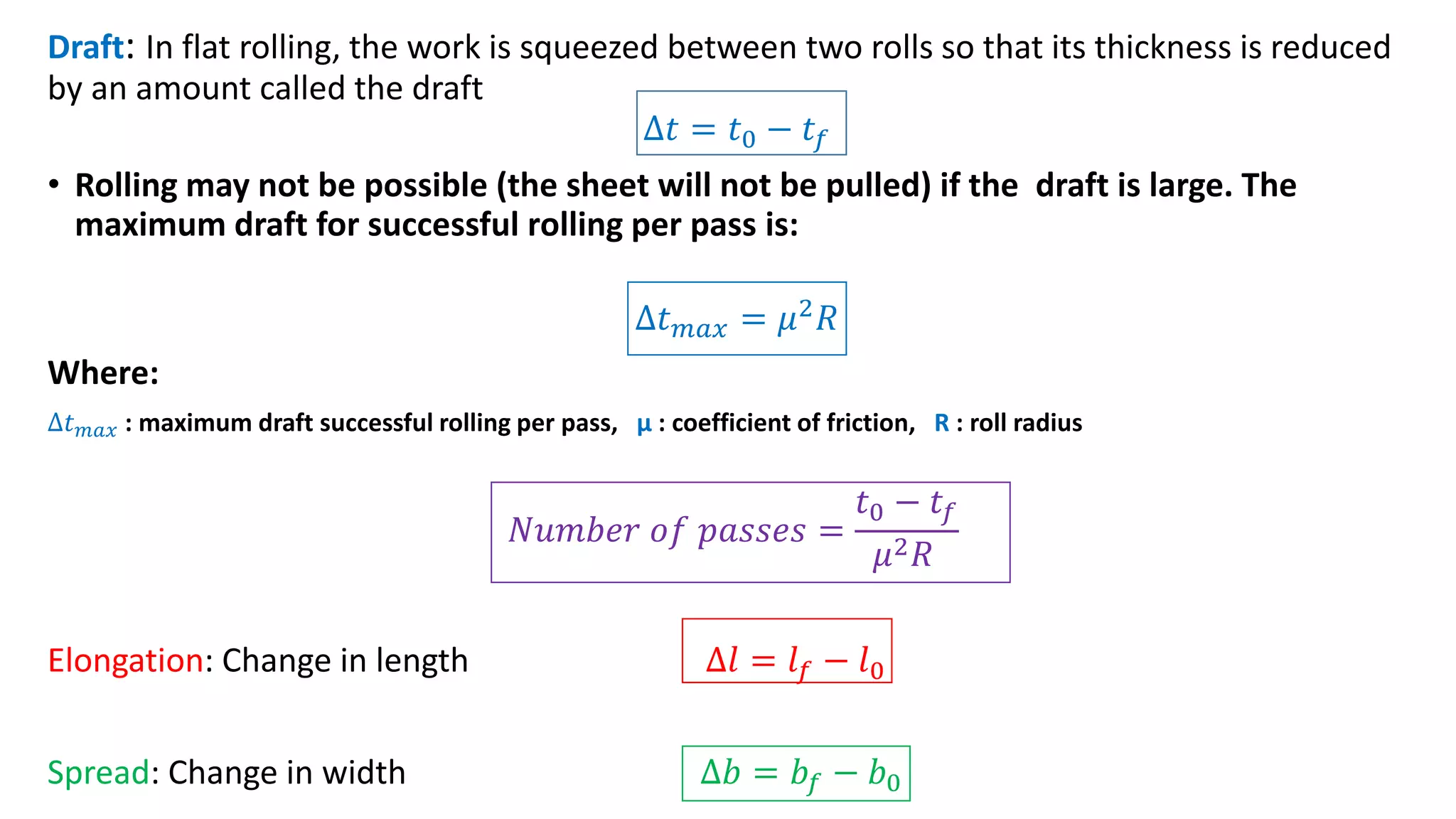

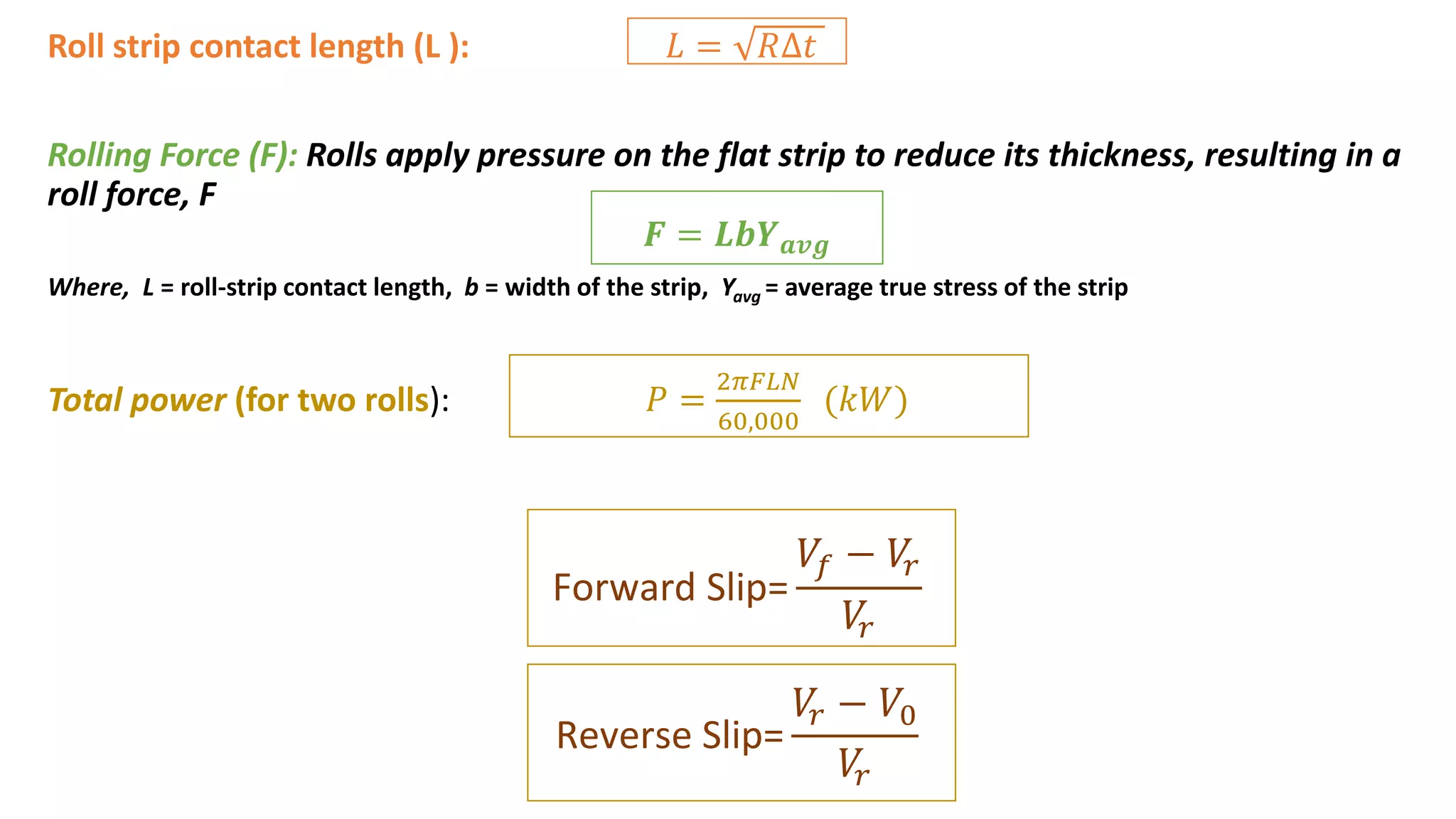

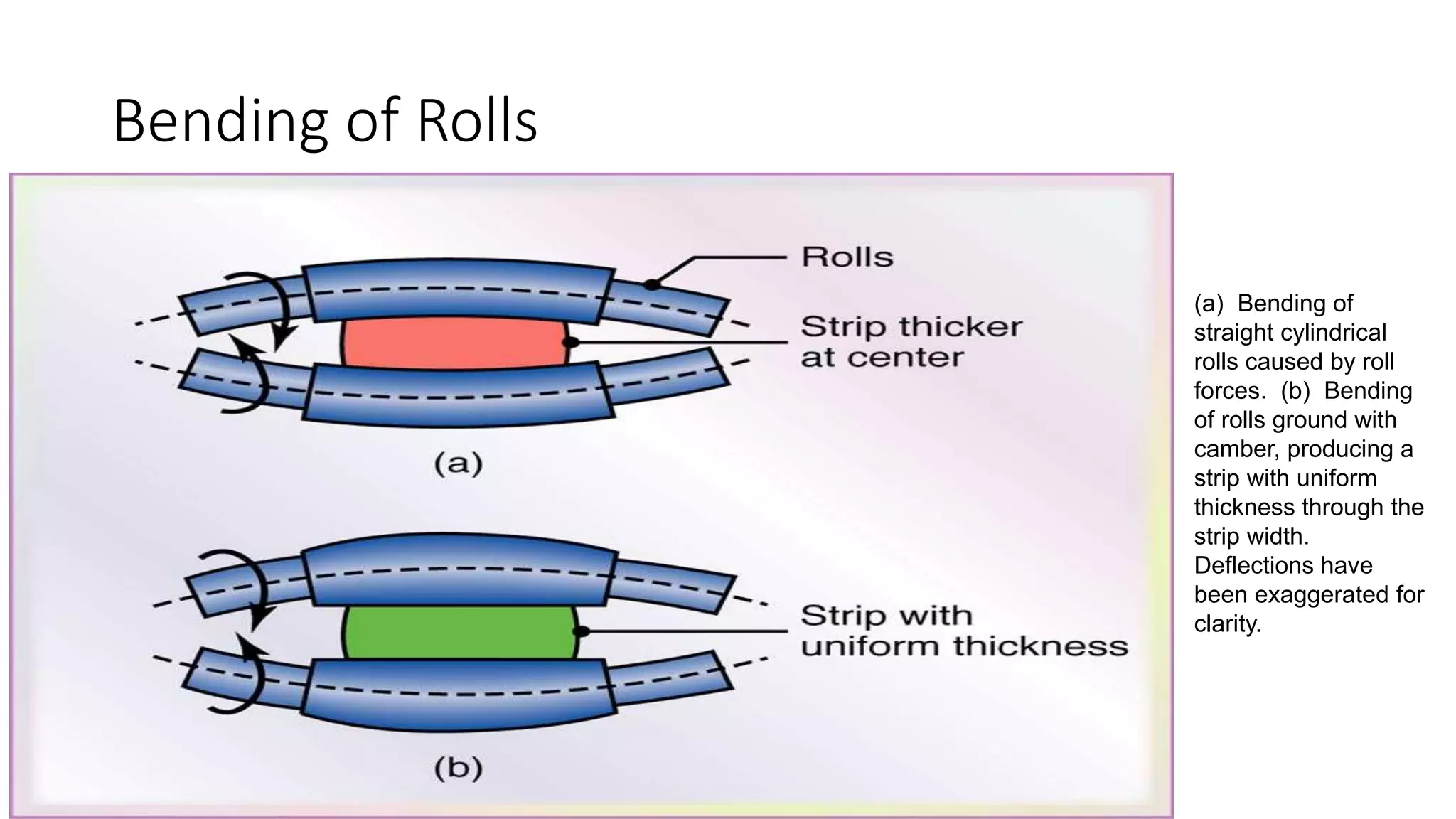

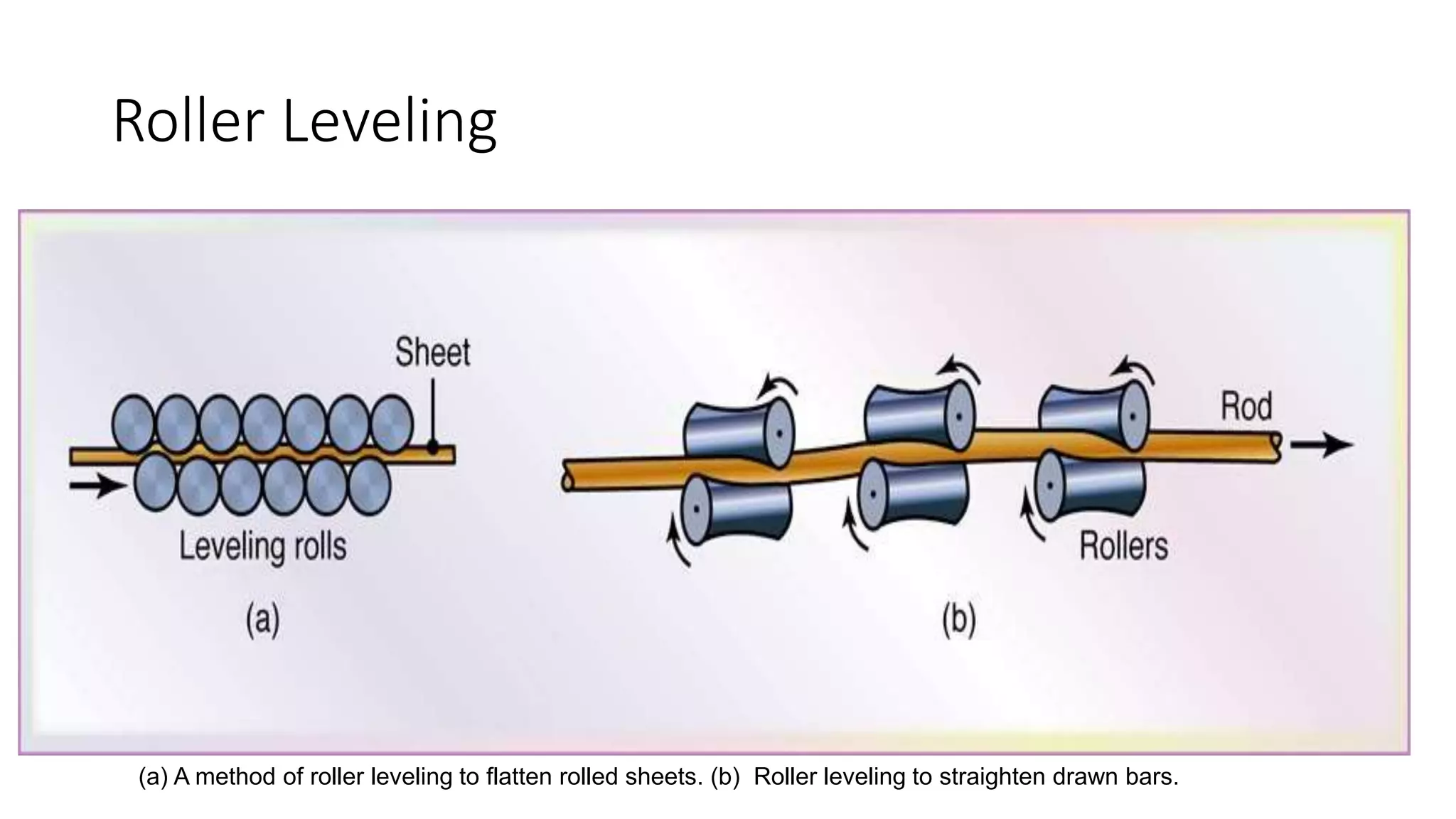

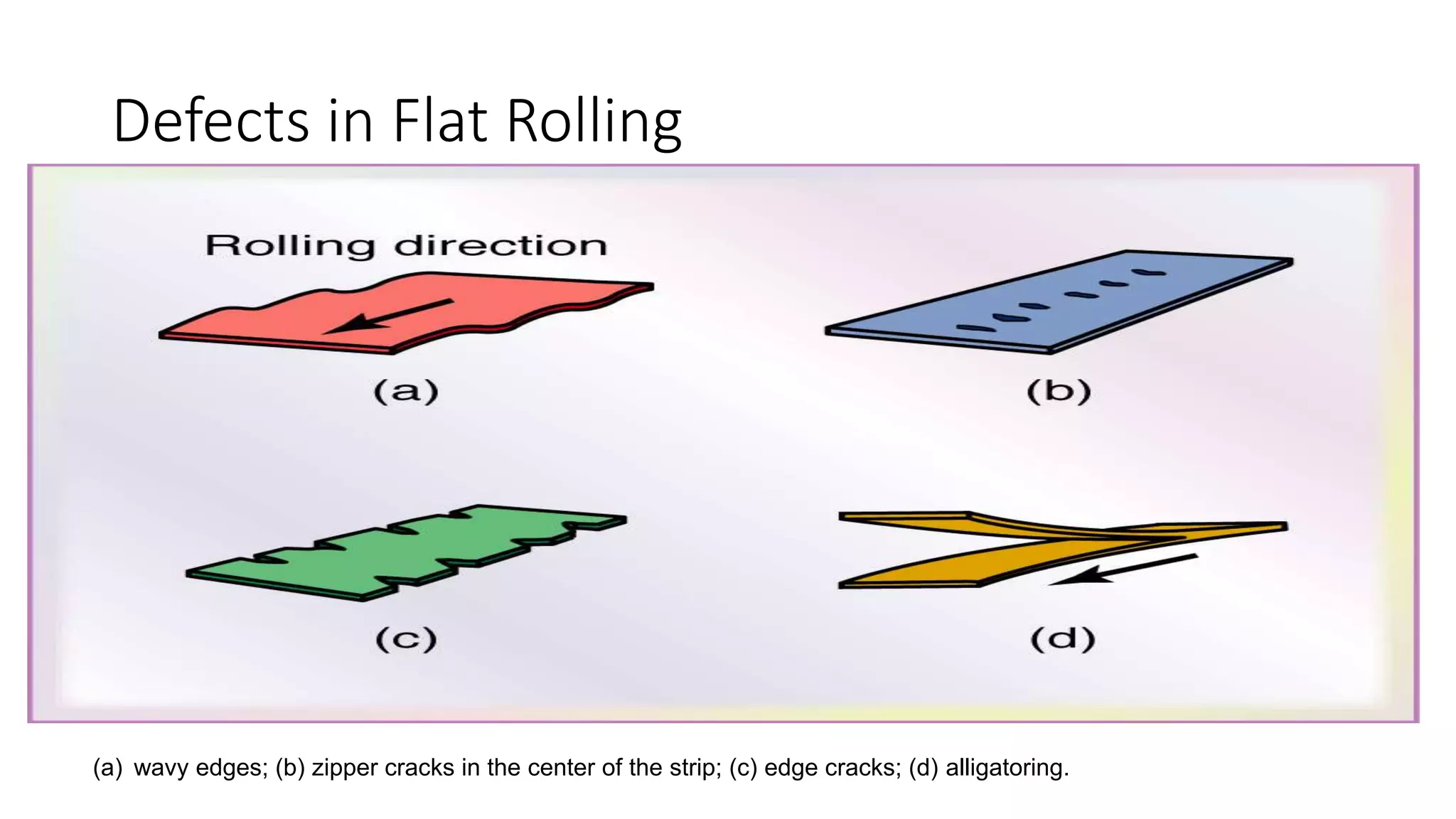

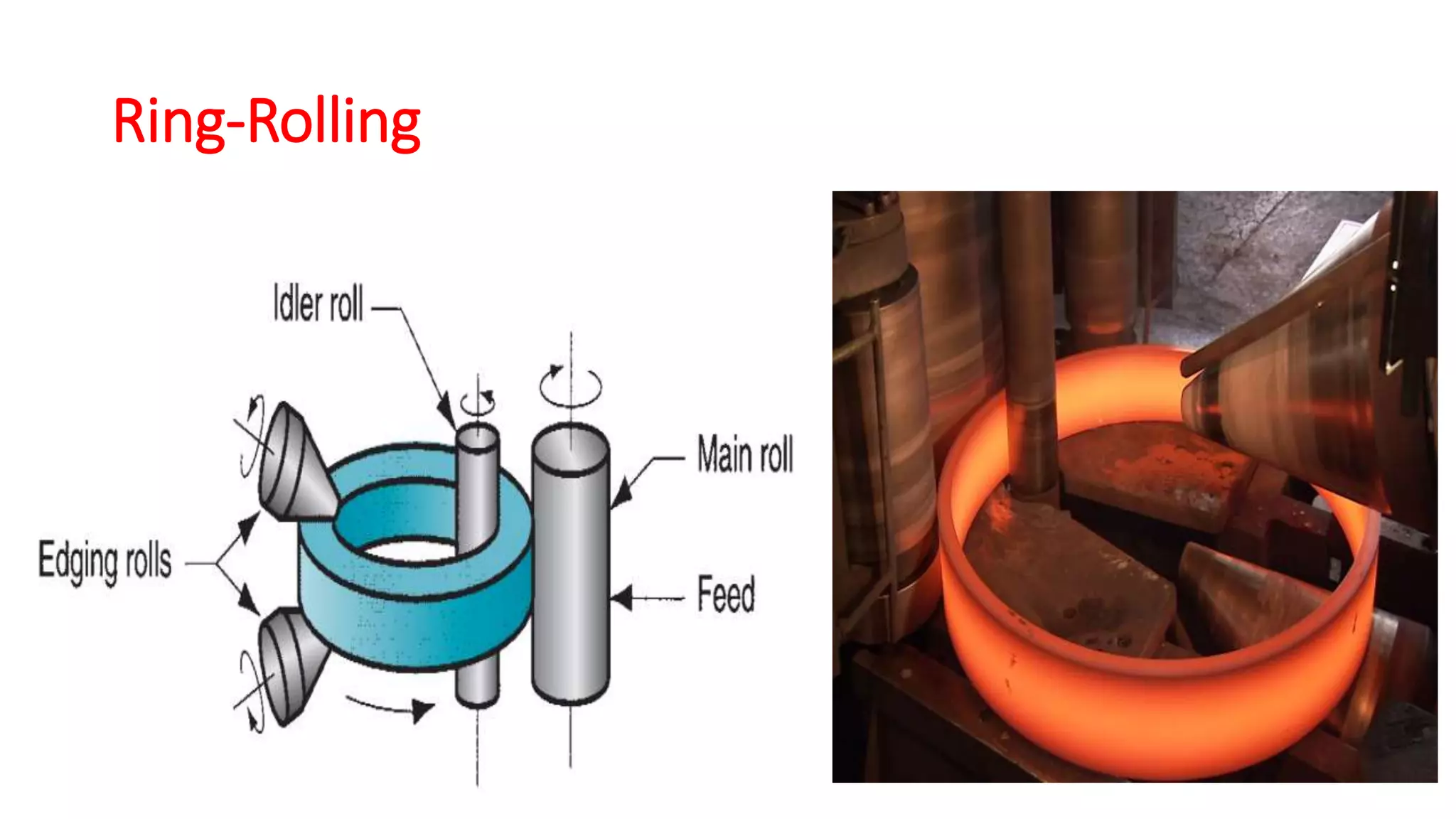

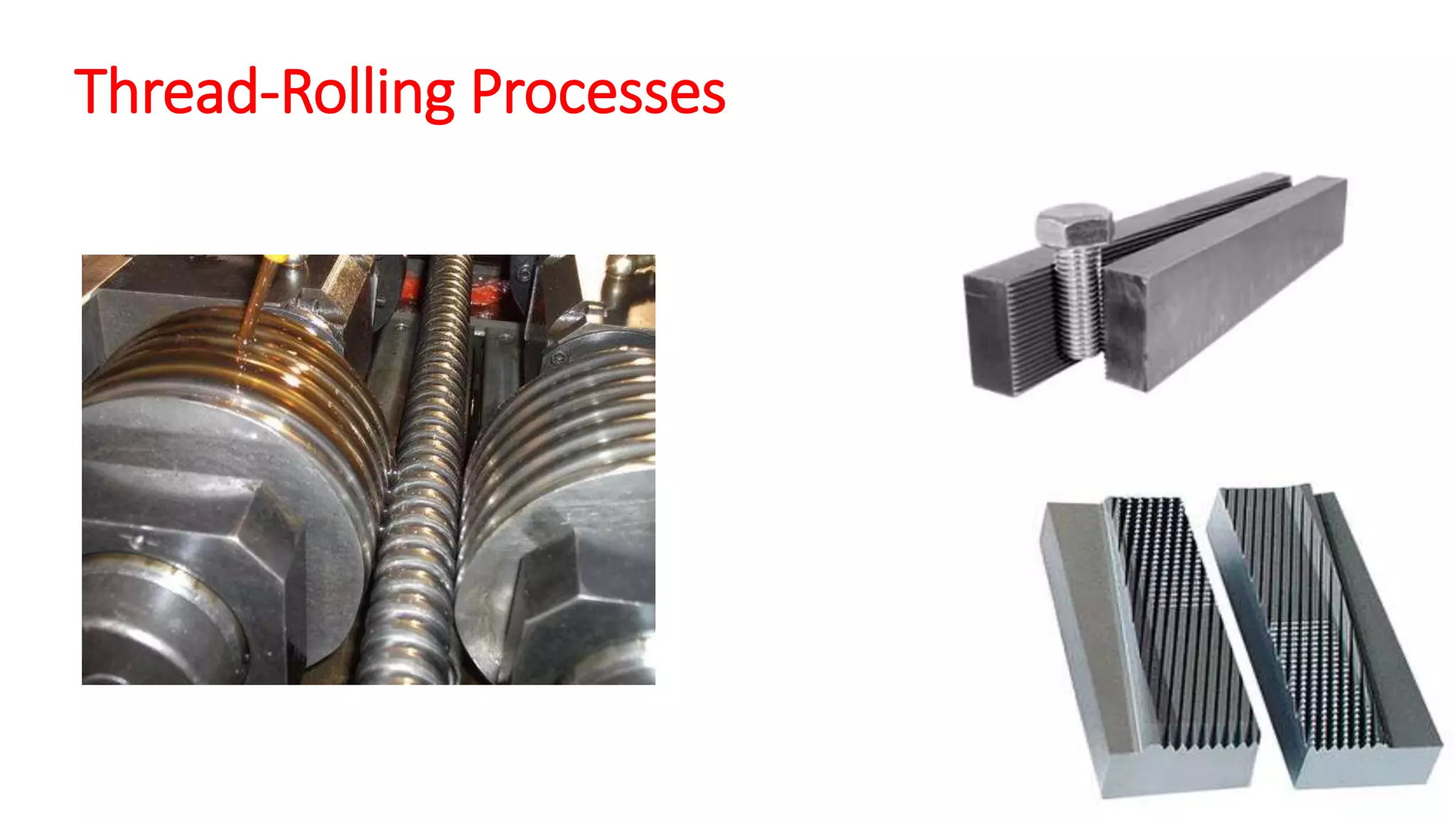

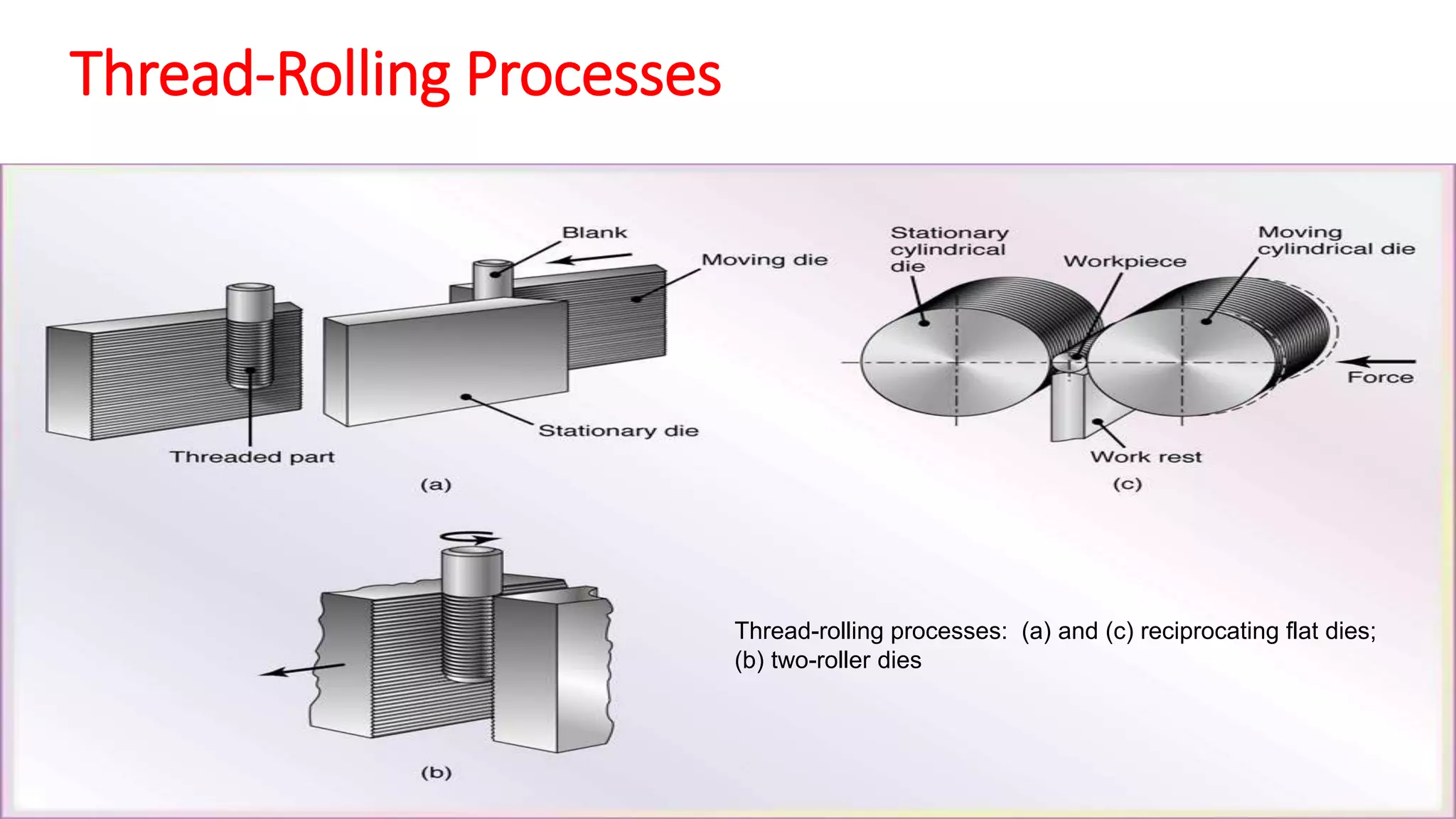

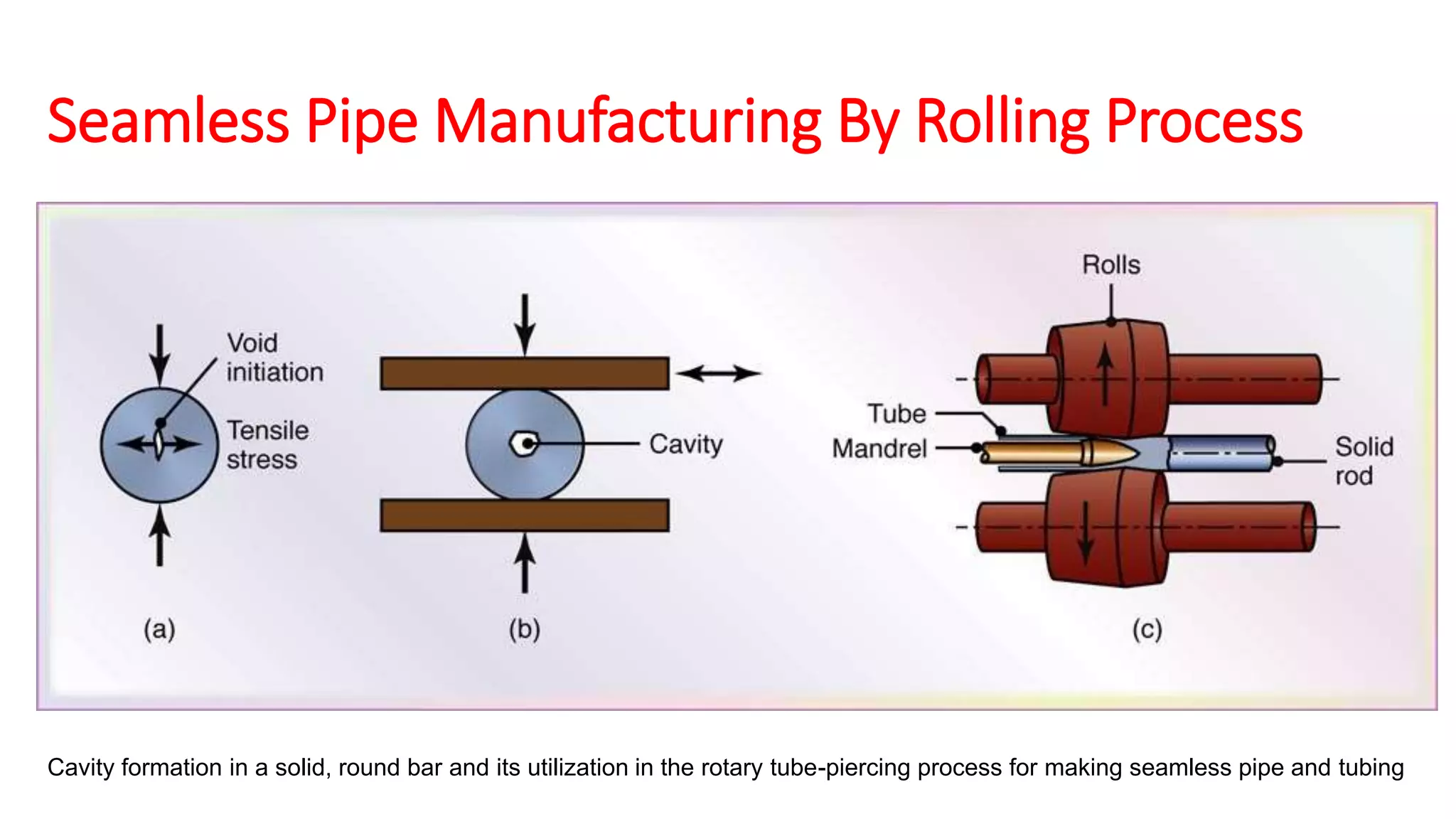

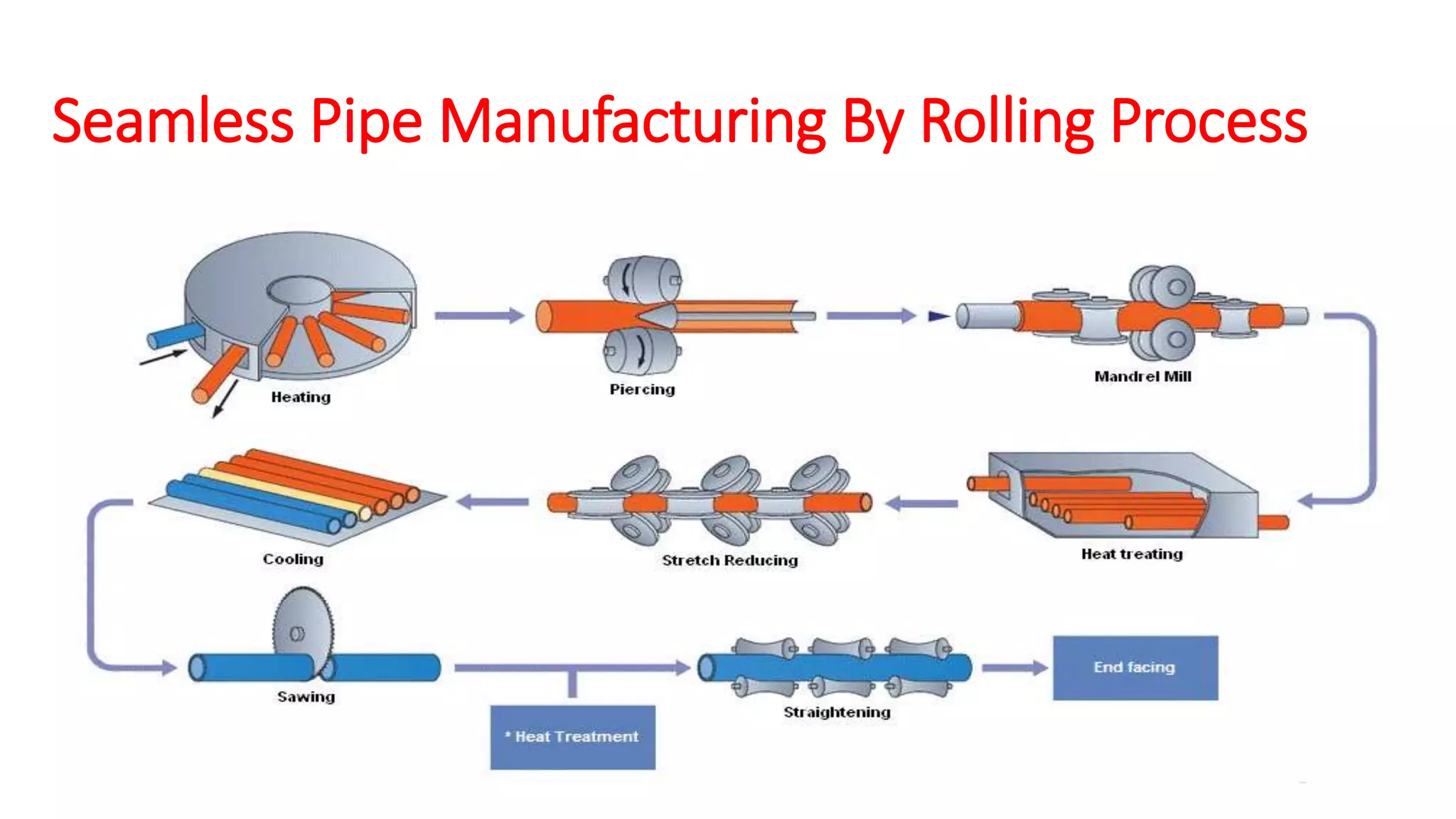

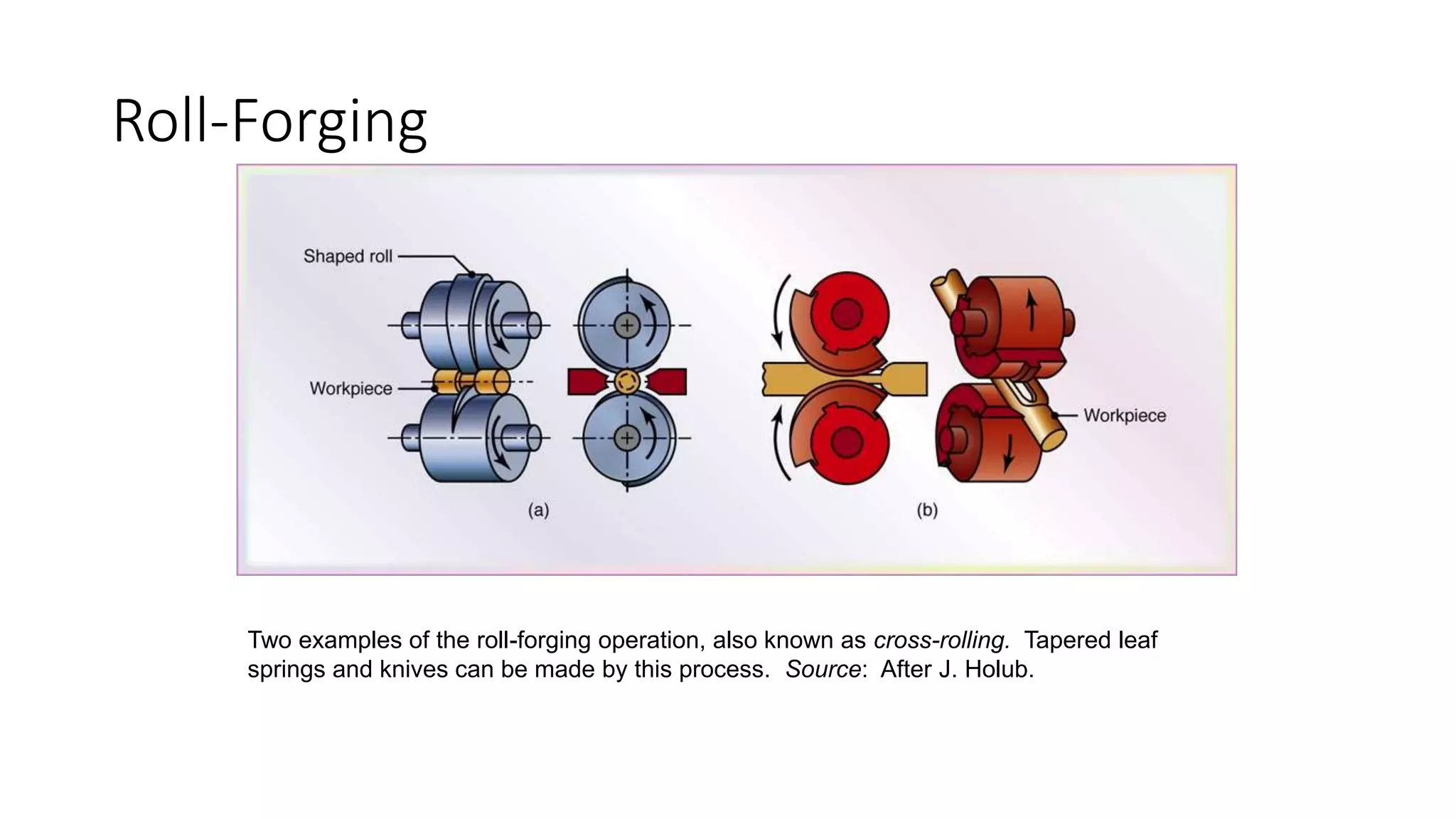

The document discusses the metal forming process, focusing on the rolling process and its variations, including hot working, cold working, and warm working, which are based on temperature and their effects on material properties. It explains concepts like recrystallization, draft in flat rolling, elongation, spread, and rolling forces, as well as the production of seamless pipes, steel balls, and the roll-forging operation. The document also addresses defects in flat rolling and the mechanical properties associated with different forming techniques.