This document provides guidance on designing pipe hangers and supports. It discusses determining hanger locations based on pipe size and configuration. It describes calculating hanger loads based on the weight of pipe, fittings, valves, and insulation. It also addresses calculating thermal movement of piping at hanger locations. The document provides information on selecting appropriate hangers based on the loads and movements, including spring hangers. It includes sample problems demonstrating how to apply the guidance. An extensive section lists the weights of common piping materials to aid in load calculations. The document is intended as a reference for engineers involved in pipe hanger and support design.

![10 Anvil International, Piping & Pipe Hanger Design and Engineering www.anvilintl.com

HANGER LOAD CALCULATIONS

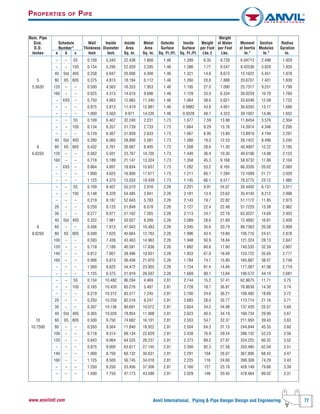

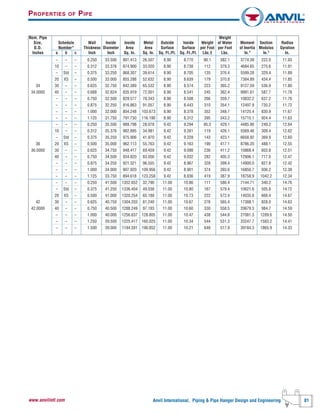

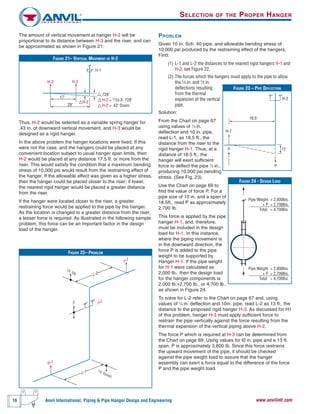

CALCULATED ARC DISTANCES FOR BENDS AND WELDING ELBOWS

0.0

0.2

0.1

0.3

0.4

0.6

0.8

1.0

1.1

1.2

0.5

0.7

0.9

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

"D" Curve

"E" Curve

TE

R

A

D

cg

T

E

D

θ

θ/2

D = R x [TAN(θ/2) + 2/θ - 2 x CSC(θ)]

E = 2 x R x [CSC(θ) 1/θ]

T = R x TAN(θ/2)

CENTER OF GRAVITY OF AN ARC

0.0

0.2

0.1

0.3

0.4

0.6

0.8

1.0

0.5

0.7

0.9

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

"A" Curve

"C" Curve

"B" Curve

B

C

cg

R

A

θ/2

θ

A = [2 x R x SIN(θ/2)]

θ

B = R x [1 - COS(θ)

θ

C = R x SIN(θ)

θ

A,B&CinInchesfor1"Radius

ø in Degrees

D&EinInchesfor1"Radius

ø in Degrees](https://image.slidesharecdn.com/178680732-pipe-hanger-design-141104044635-conversion-gate02/85/178680732-pipe-hanger-design-10-320.jpg)

![28 Anvil International, Piping & Pipe Hanger Design and Engineering www.anvilintl.com

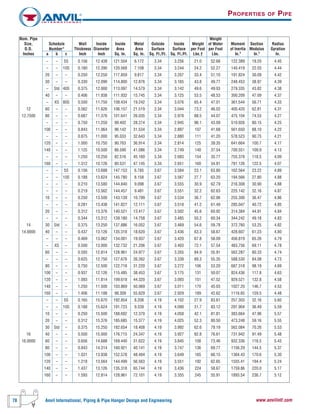

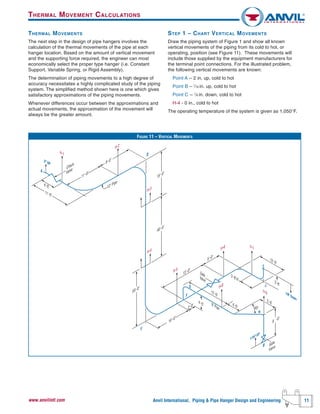

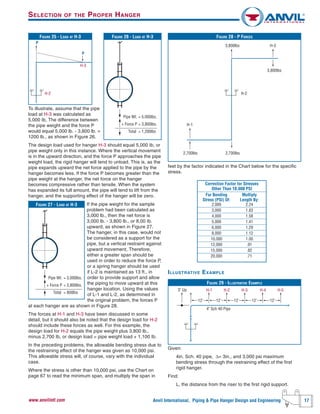

Figure 40 - The coupling joints have been installed butted or

partially open. When pressurized the pipe ends in the coupling

joints will separate to the maximum amount permitted by the

coupling design.

The coupling key sections will make contact with the groove

walls and restrain the pipe from further separation.

The movement at each coupling joint will add with all other

joints and produce ΔL.

Figure 41 - In the system shown here, the pipe will move and

deflect at the elbow joint due to pressure thrust.

The pipe designer must assure himself that the system has the

capability of deflecting sufficiently to absorb this movement

without introducing additional stresses into the pipe system.

In the deflected condition shown, temperature increases would

produce further expansion of the pipe system thus increasing

the deflection.

Figure 42 - To restrain this system provide a pressure thrust

anchor at “R1” to resist the pressure thrust acting through the

tee “D1” at the cap “C”. Provide a hanger at Point “R2”, or a

base support at Point “D2” to support the vertical column. If the

offsets L1, L2, and L3 are of adequate length to handle

expected pipe movements, no additional anchoring is required.

Thermal movement of the pipe system should also be

considered, and intermediate anchors located as required, to

direct the pipe movement so as to prevent introducing bending

stresses into the system.

Figure 43 - Anchor at “A” to support weight of vertical water

column. Use spring hanger at “D” and “E” to allow movement

of vertical piping.

Anchors at “B” and “C” if offsets at L1and L2 are insufficiently

long to handle expected pipe movements.

Figure 44 [Lateral Restraint] - A grooved coupling joint

installed in a partially deflected condition between anchor

locations will deflect to its fully deflected condition when

pressurized. Hangers and supports must be selected with

consideration of the hanger’s capability to provide lateral

restraint.

Light duty hangers, while acceptable in many installations,

may deflect against the application of lateral forces and result

in “snaking” conditions of the pipe system.

FIGURE 40 - PRESSURE THRUST

System With No Pressure

ΔL

System Pressurized

FIGURE 41 - PRESSURE THRUST

ΔM-MOVEMENT DUE

TO PRESSURE THRUST

SUFFICIENT LENGTH

TO OFFSET

PRESSURE THRUST

FIGURE 42 - PRESSURE THRUST

L2

D2

D1

R C

2R1

L3

L1

FIGURE 43 - PRESSURE THRUST

FIGURE 44 - LATERAL RESTRAINT

System with no pressure

partially deflected

System pressurized

fully deflected

PIPE SUPPORTS FOR GROOVED PIPING

L2

L1

E

C

A

D

B

VERTICAL

COLUMN

VERTICAL

COLUMN

HORIZONTAL RUN](https://image.slidesharecdn.com/178680732-pipe-hanger-design-141104044635-conversion-gate02/85/178680732-pipe-hanger-design-28-320.jpg)