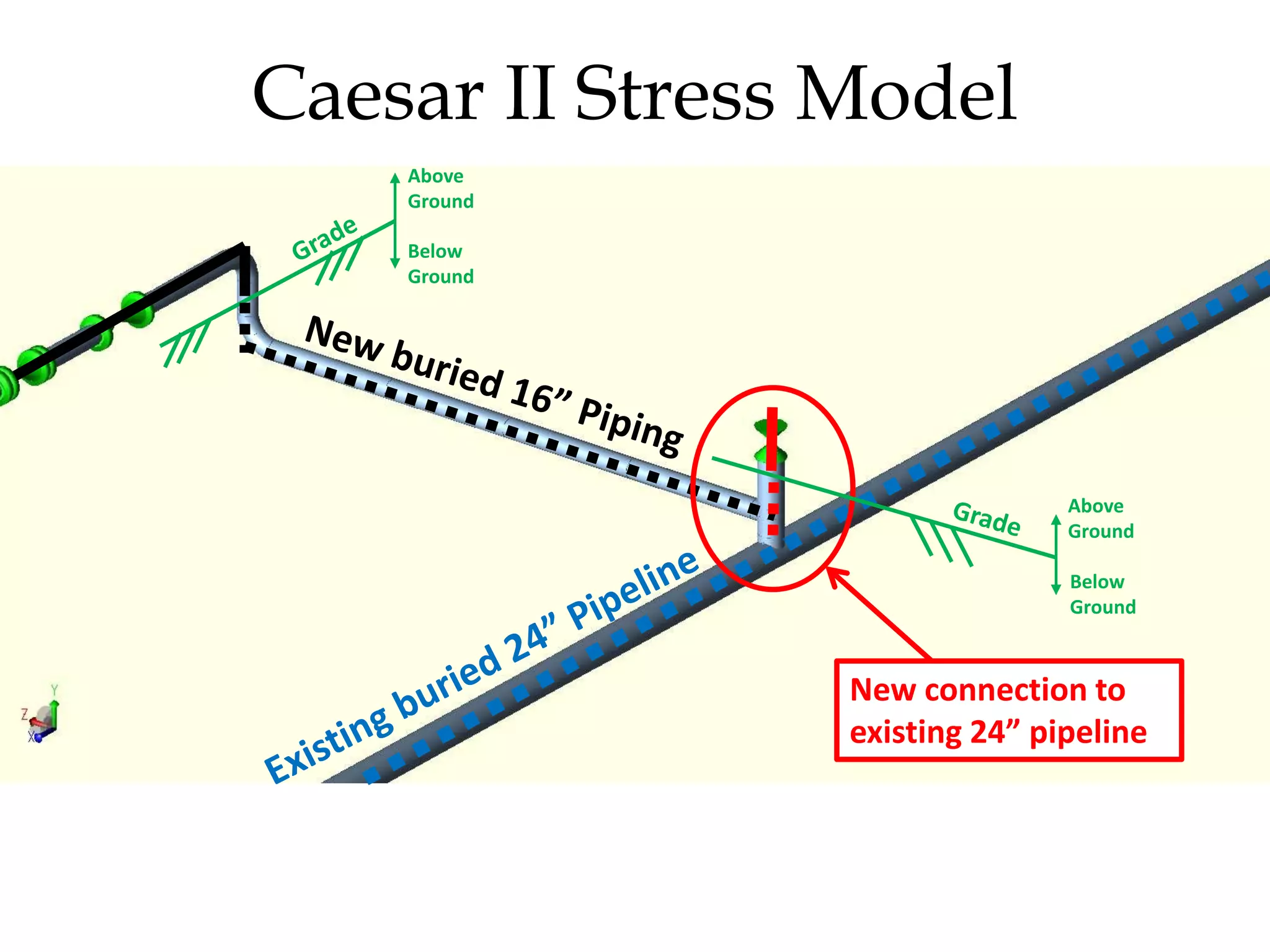

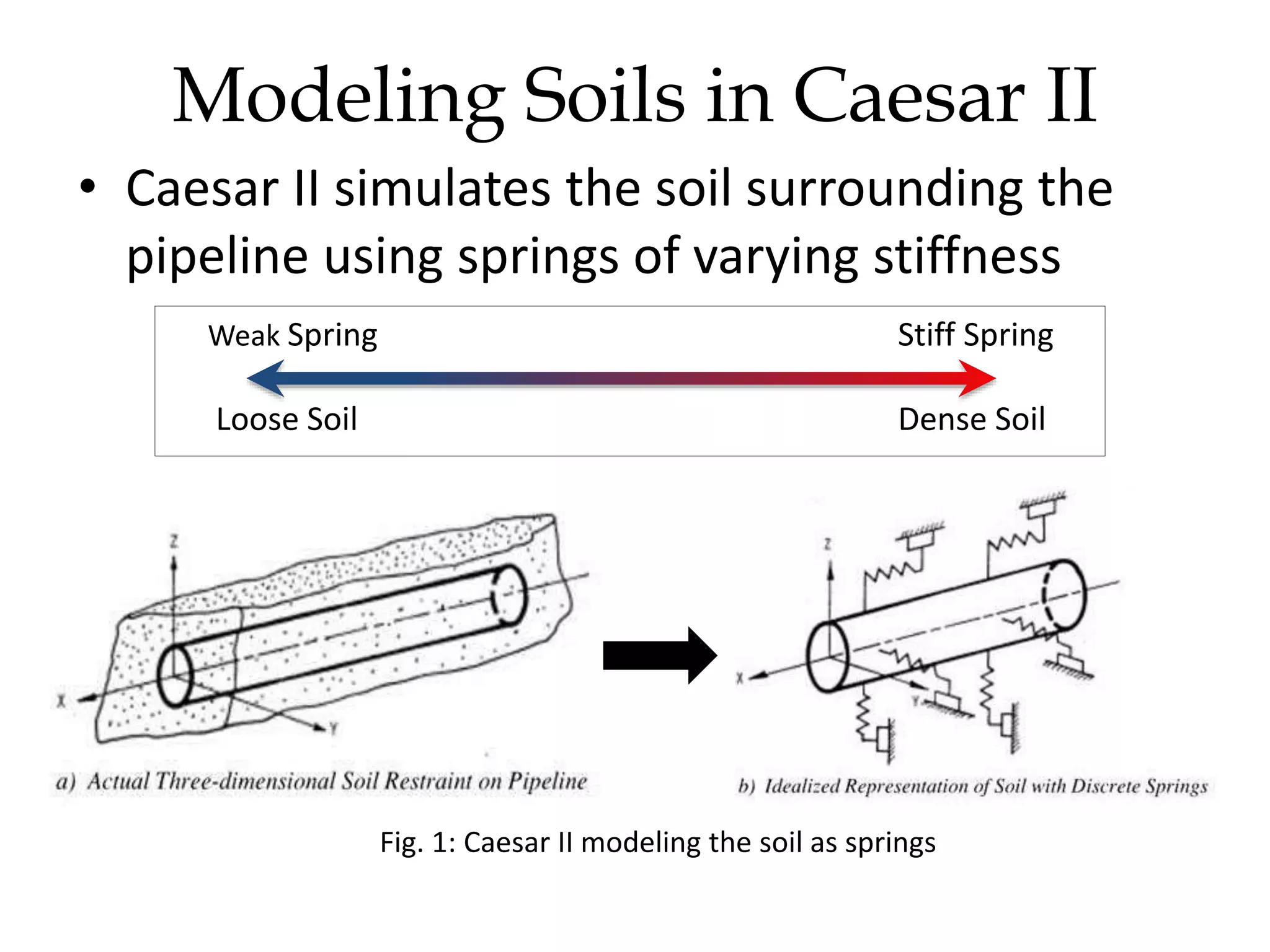

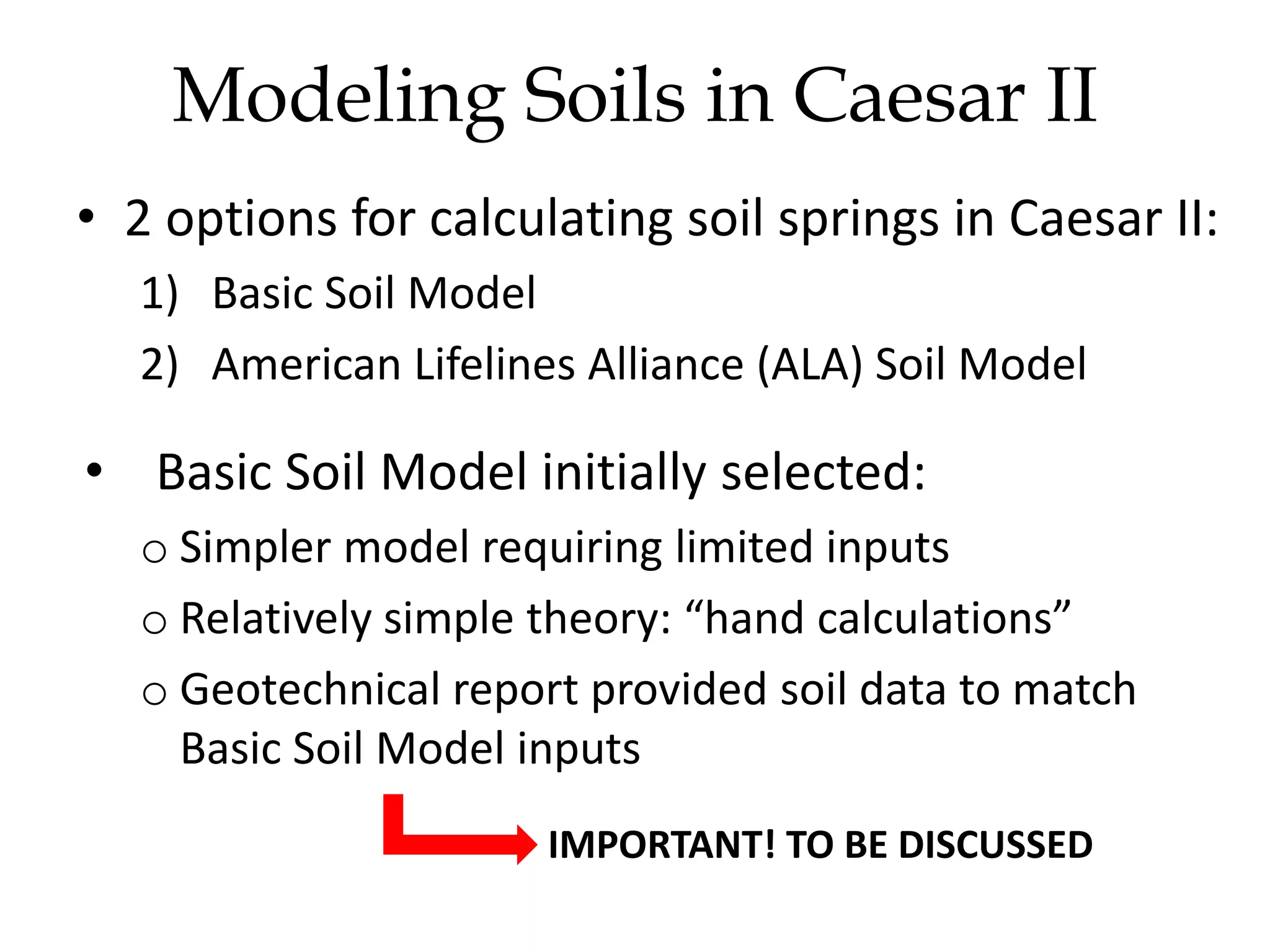

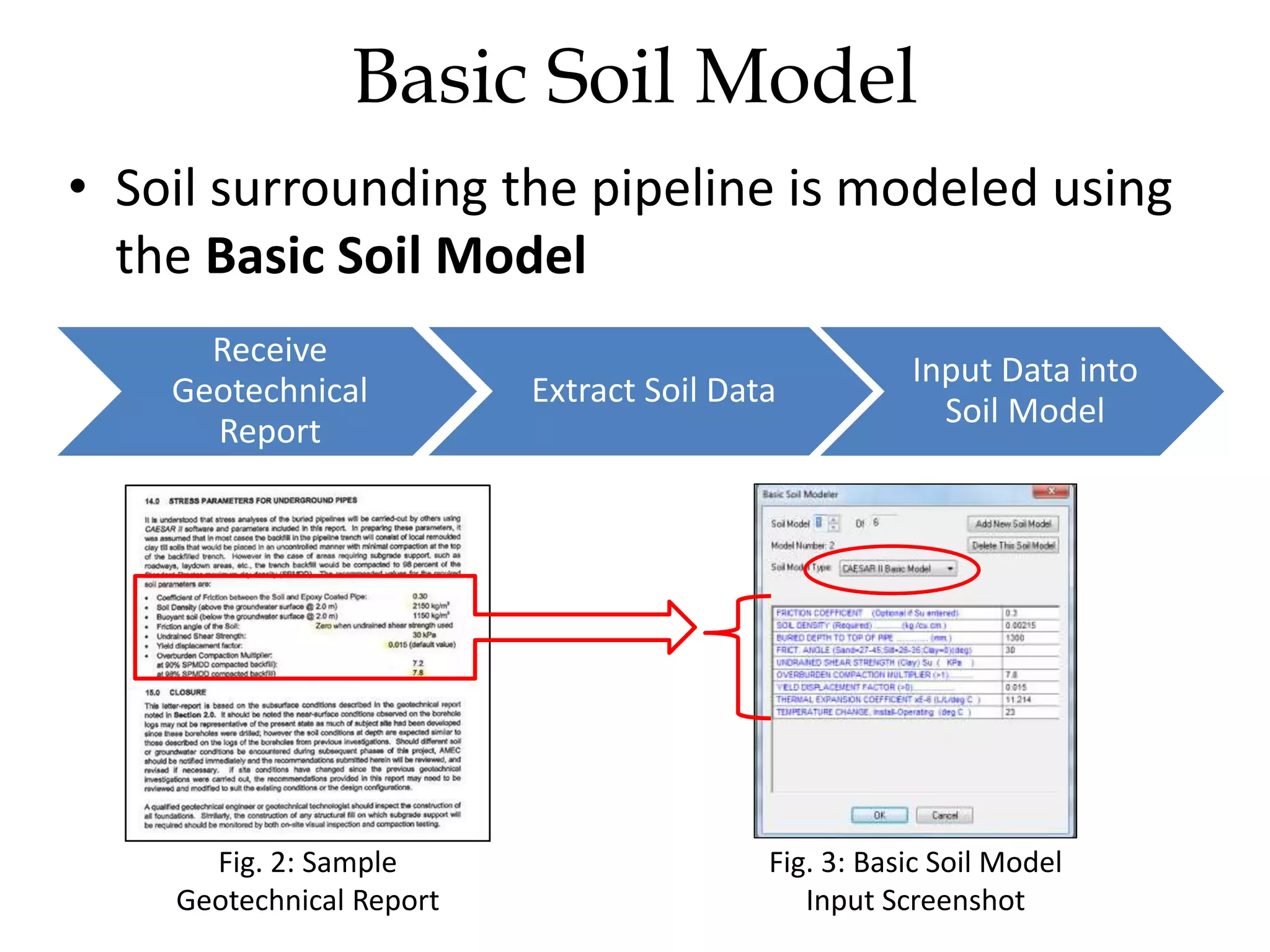

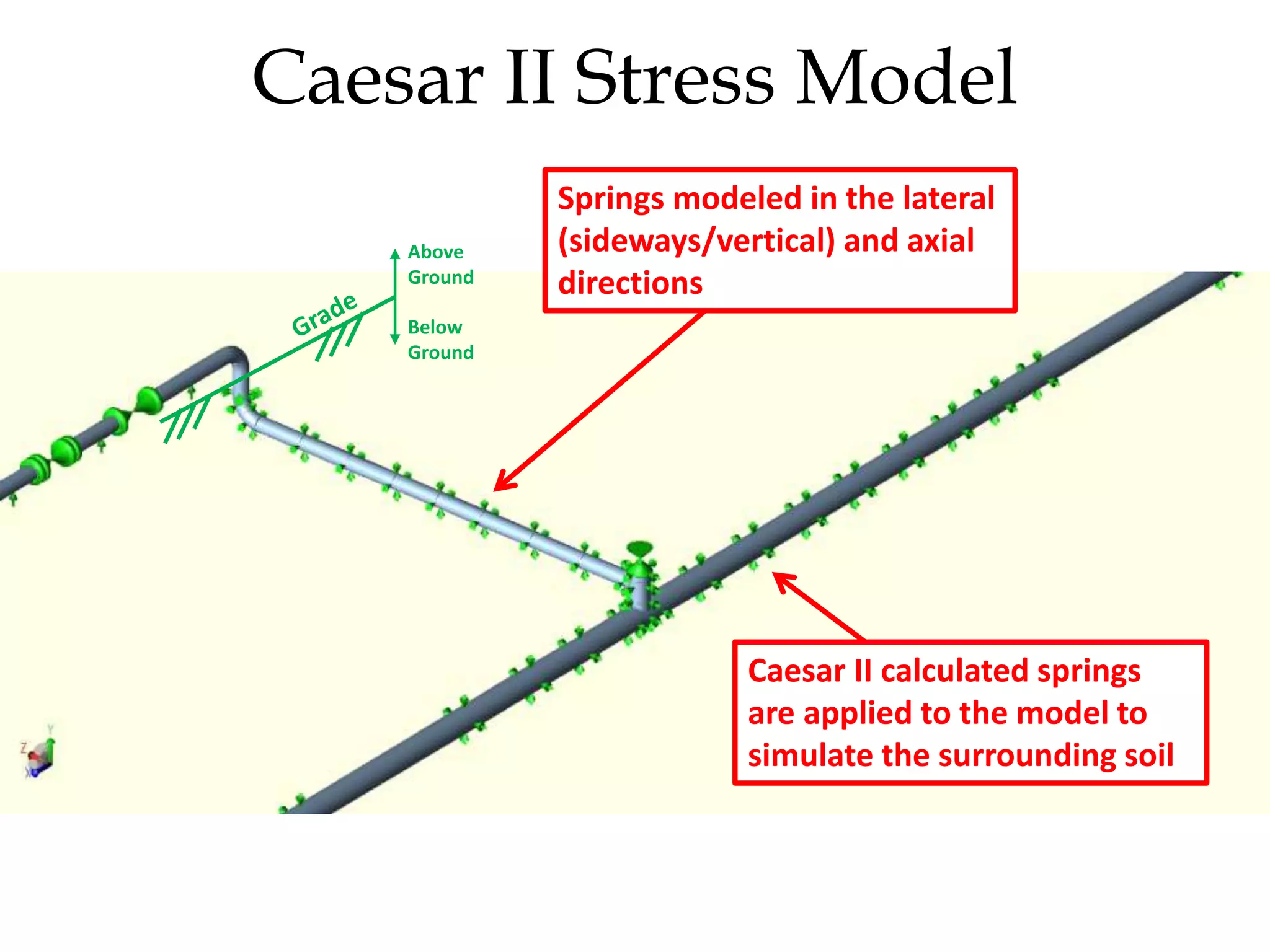

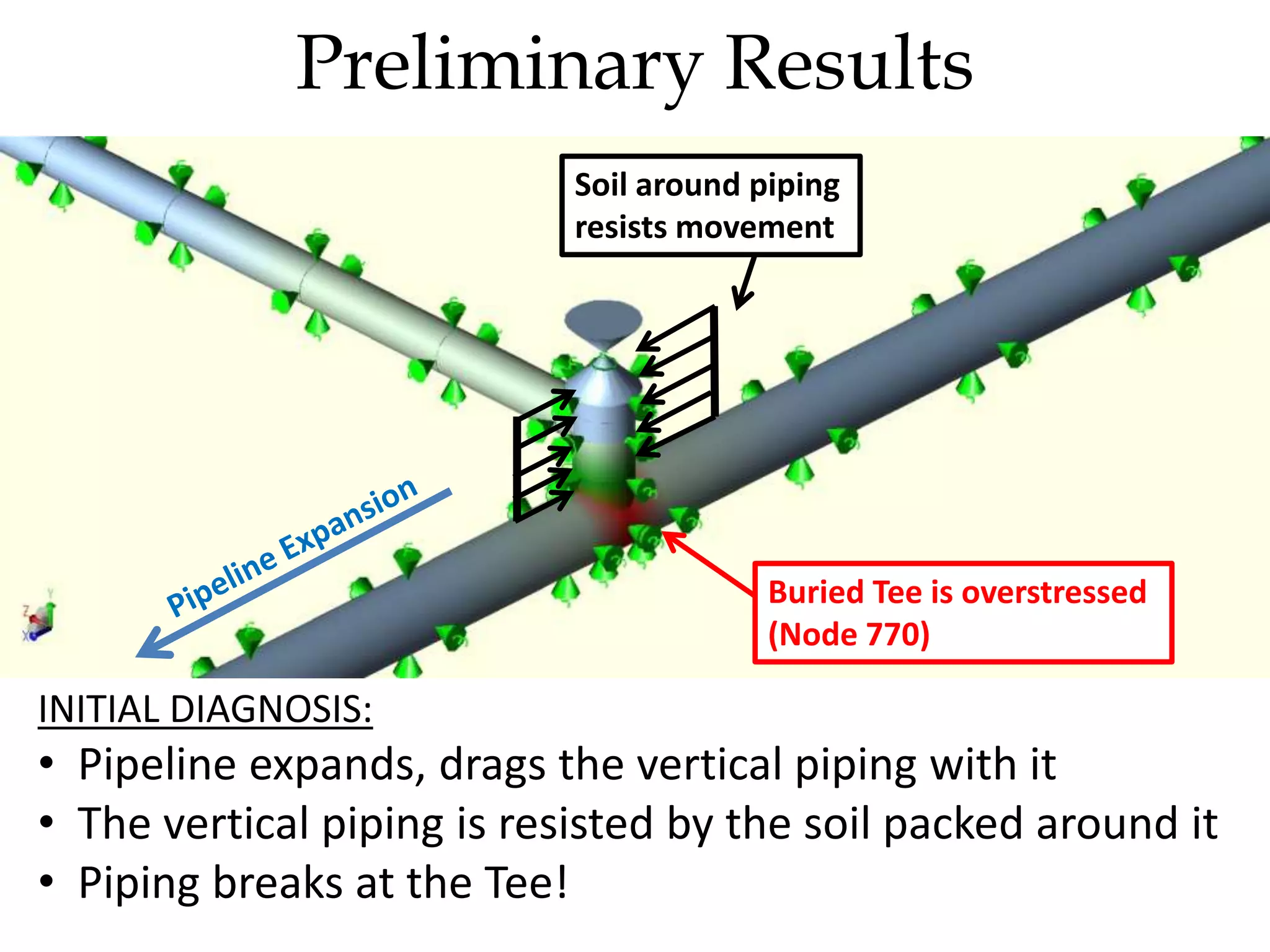

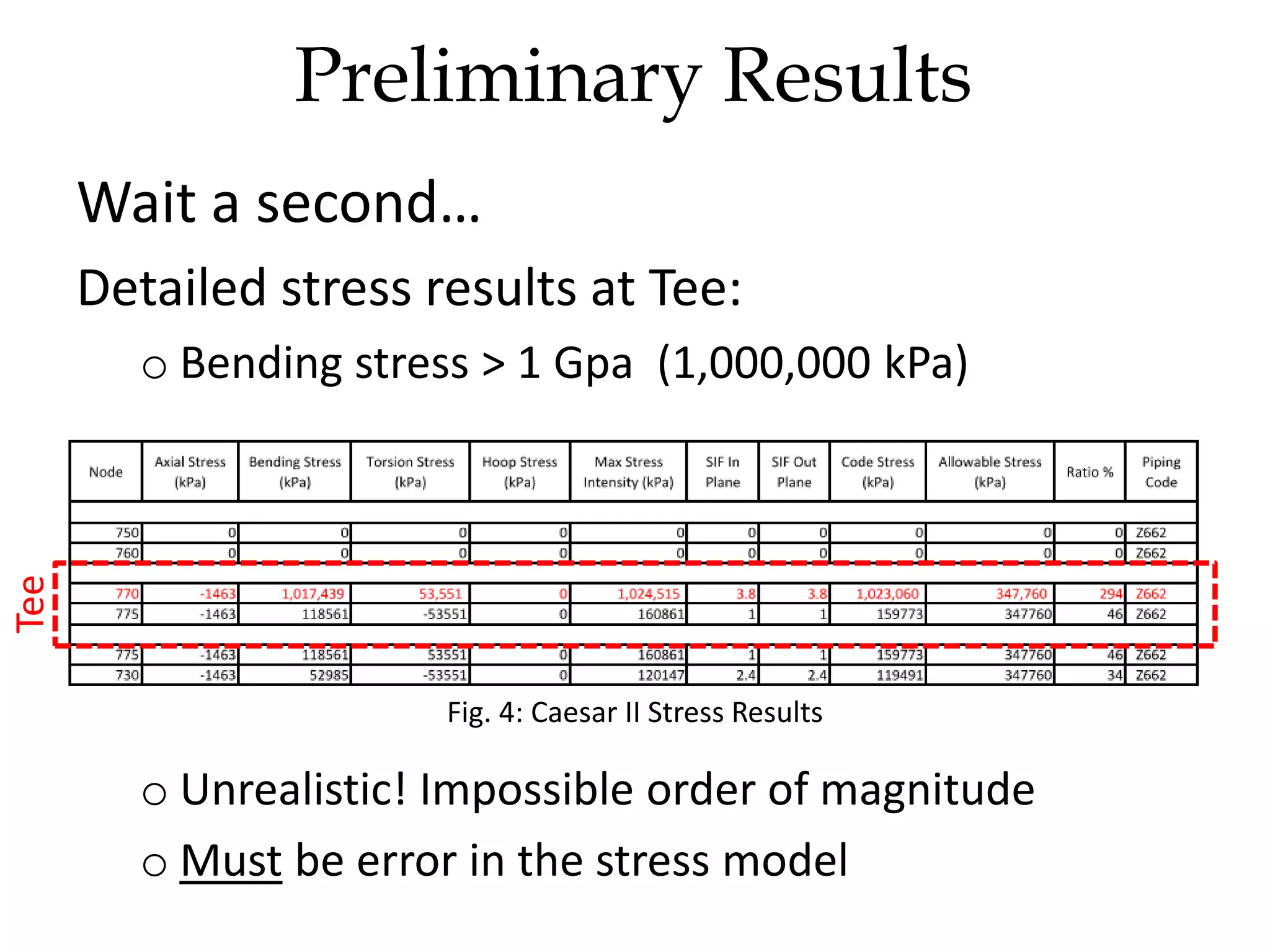

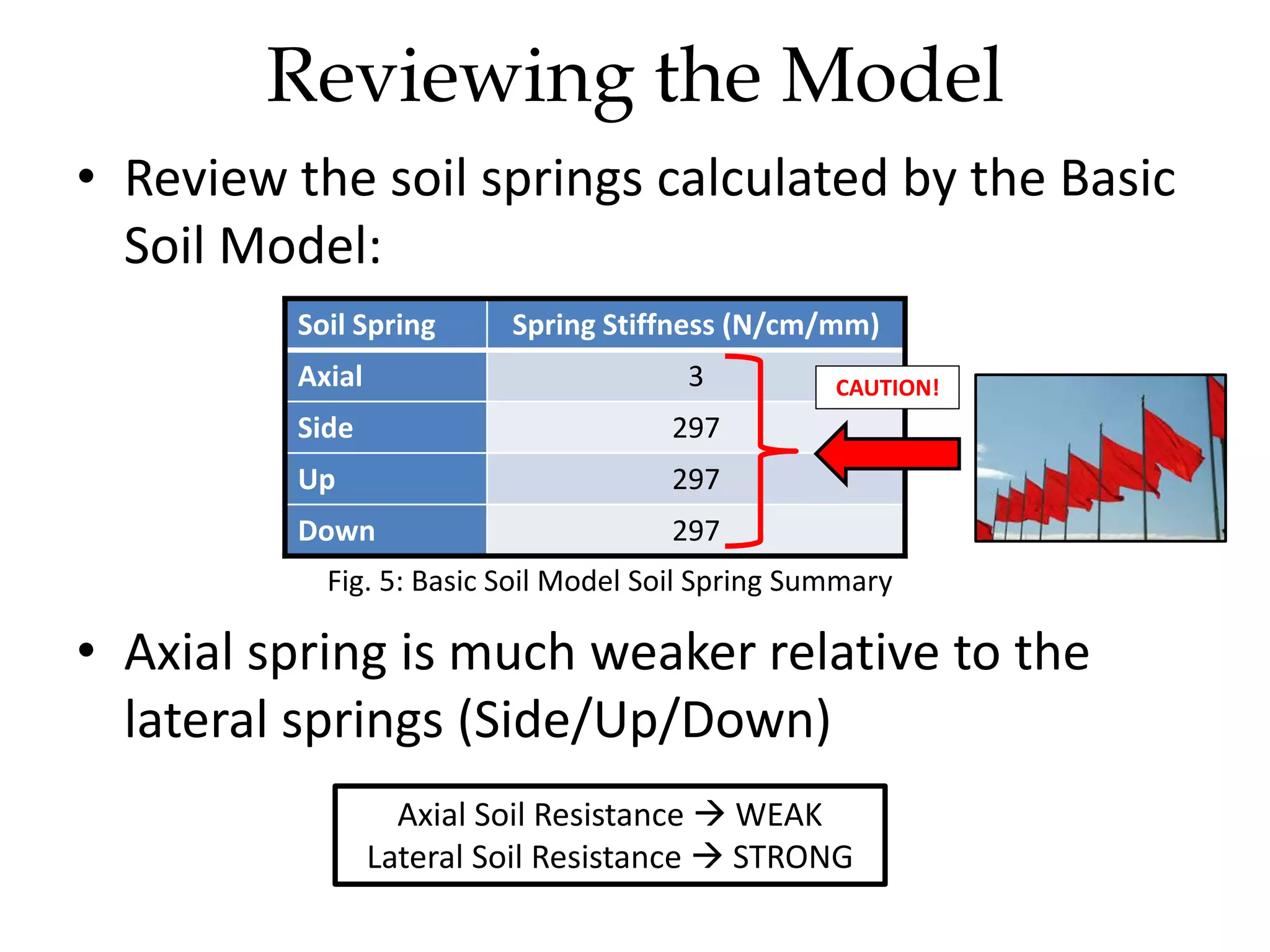

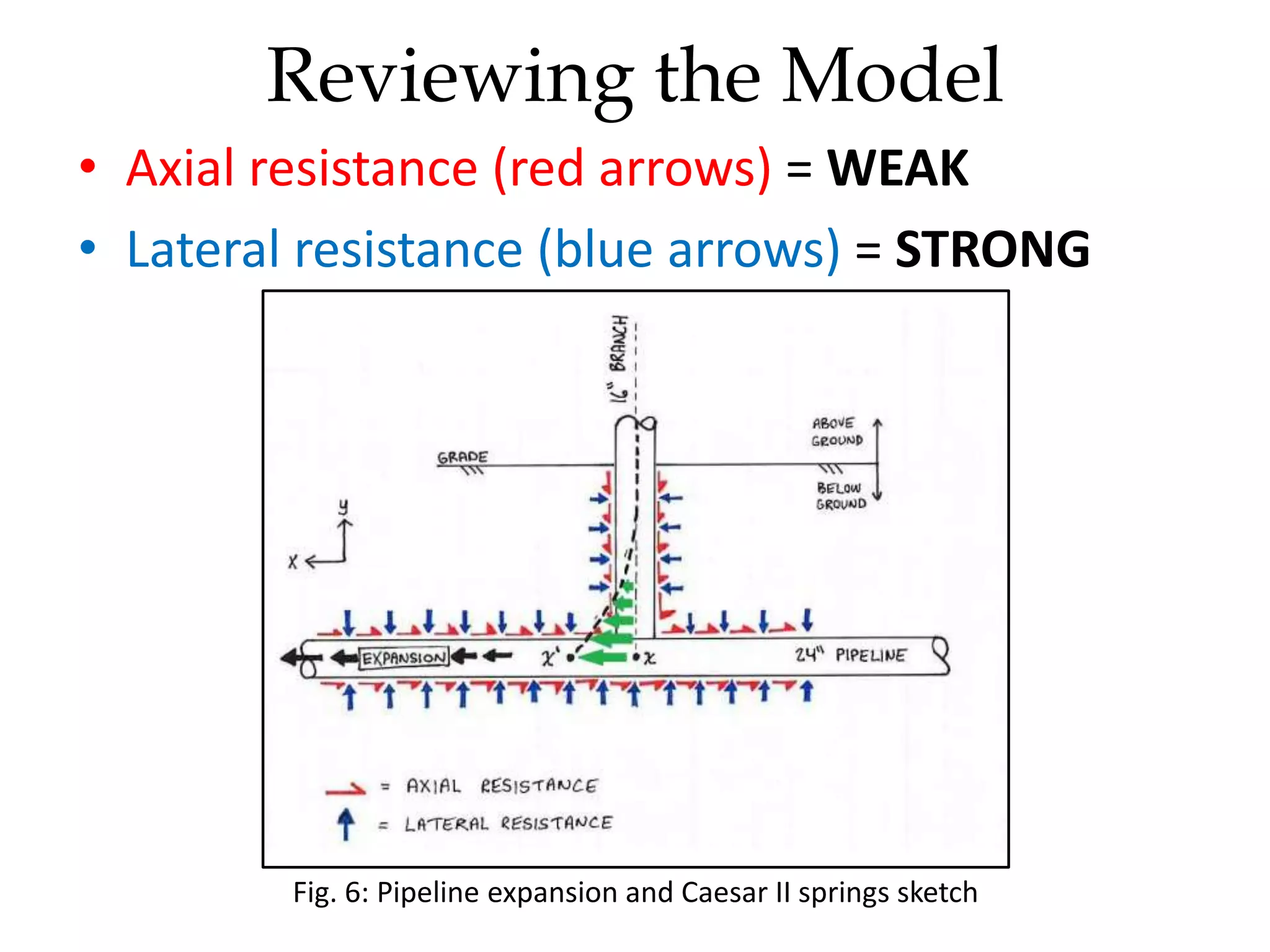

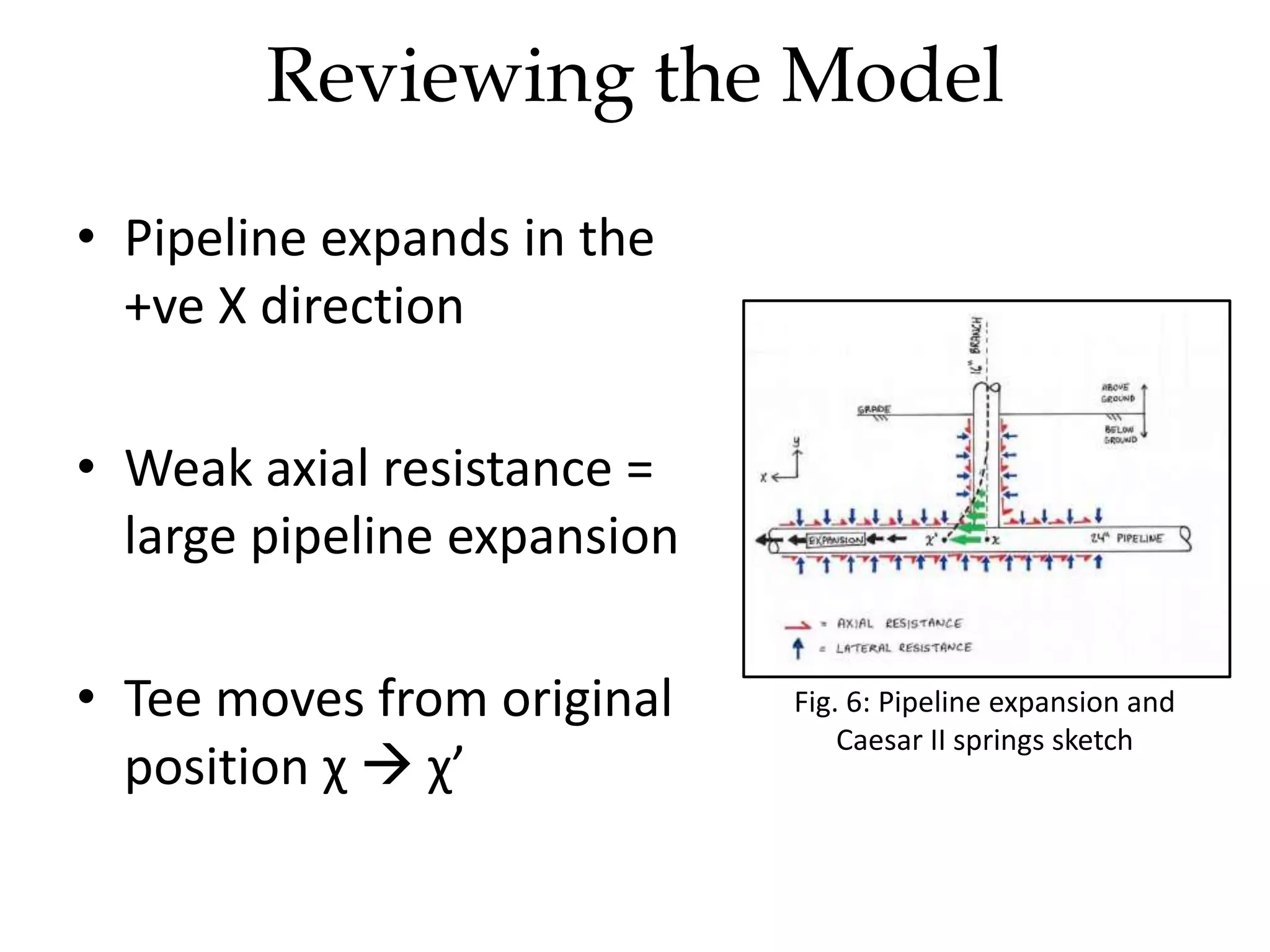

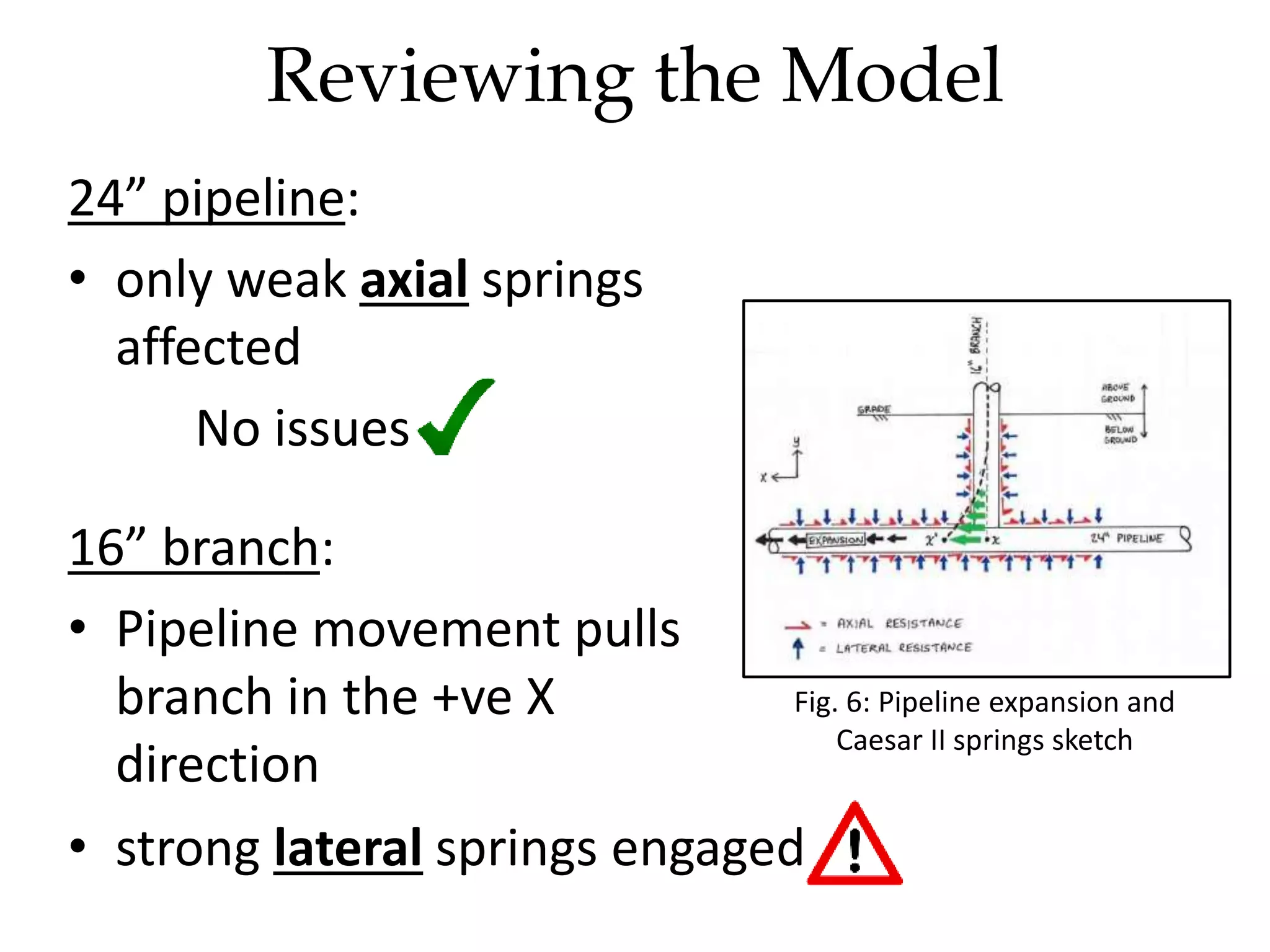

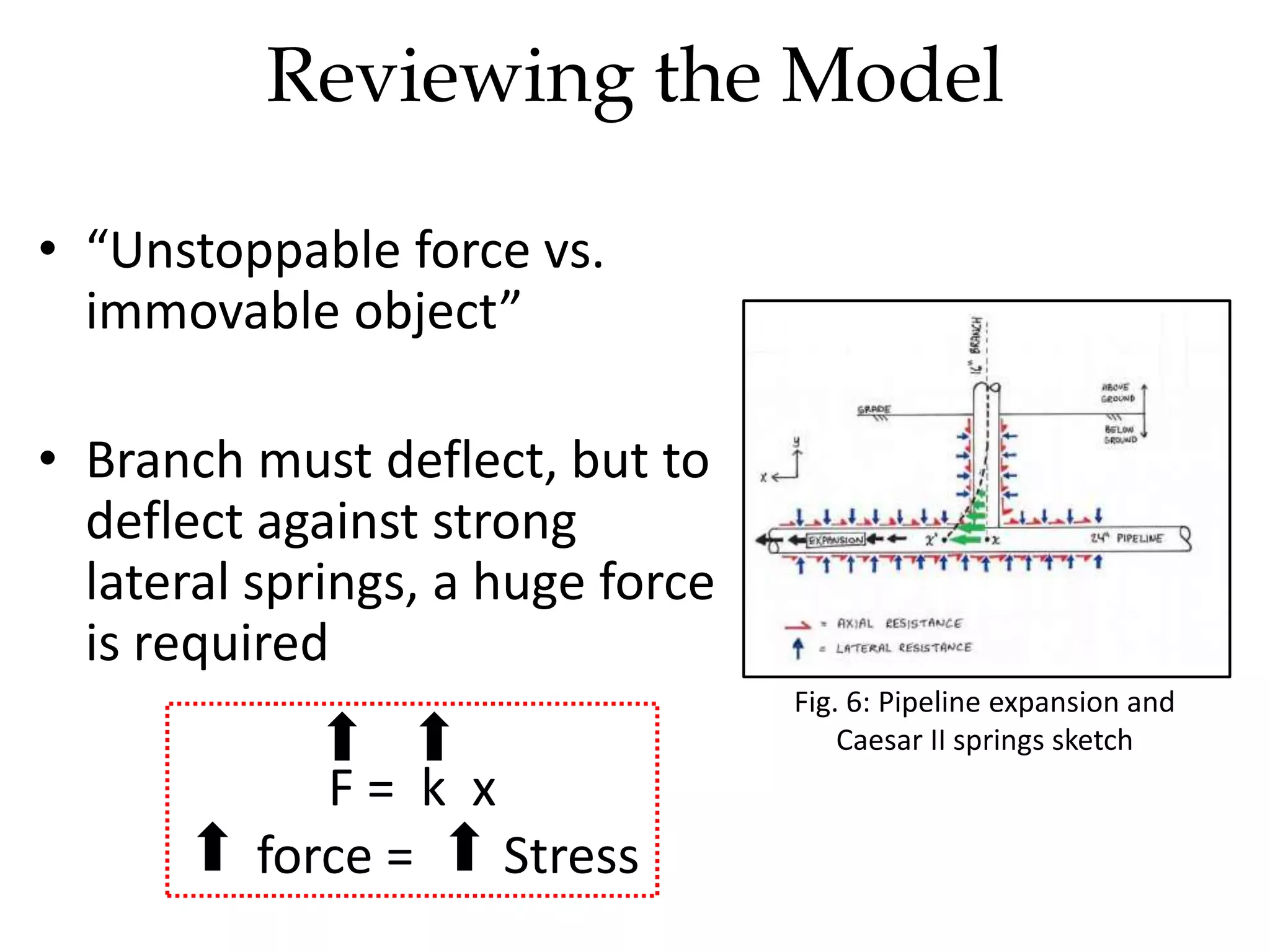

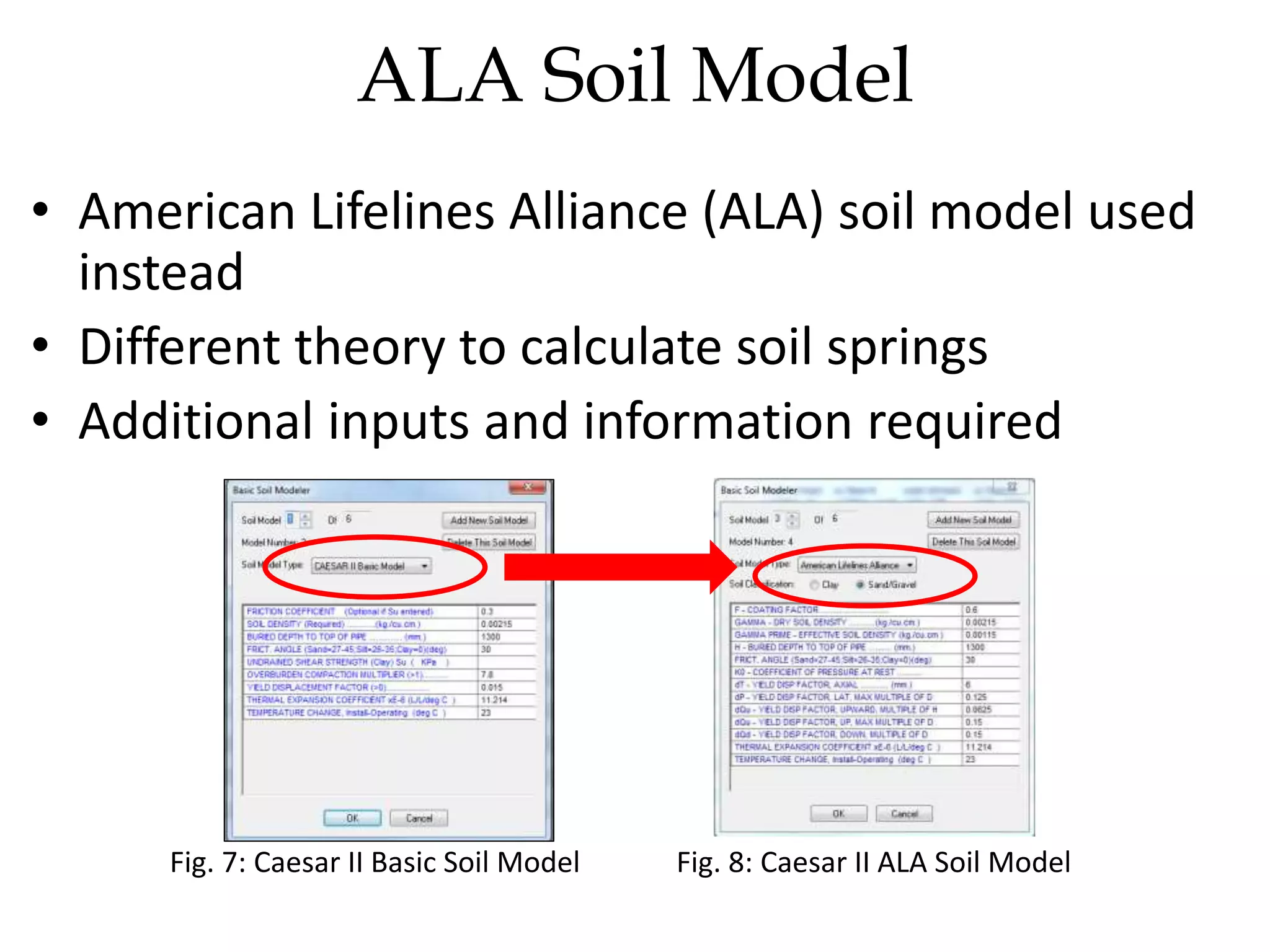

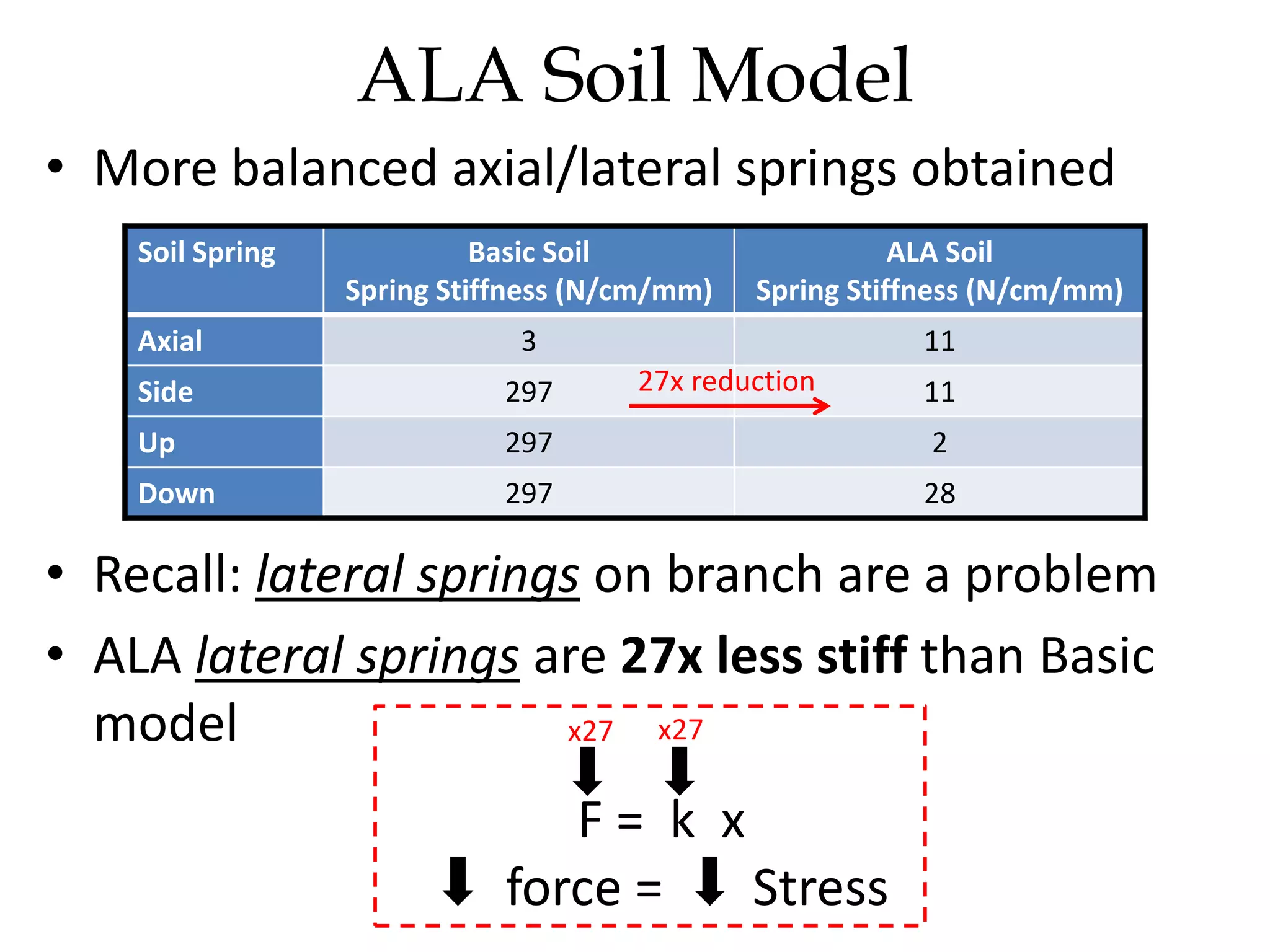

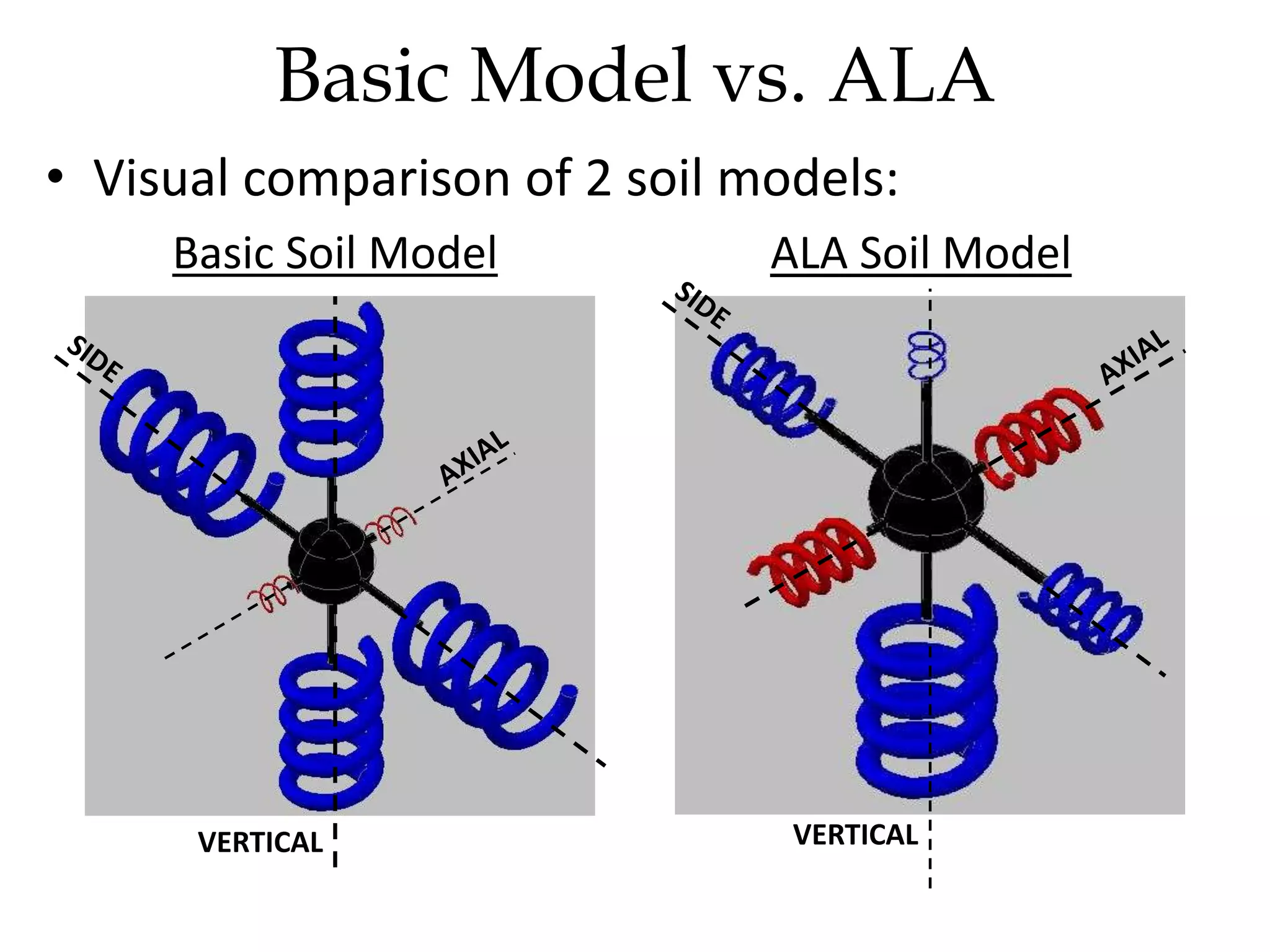

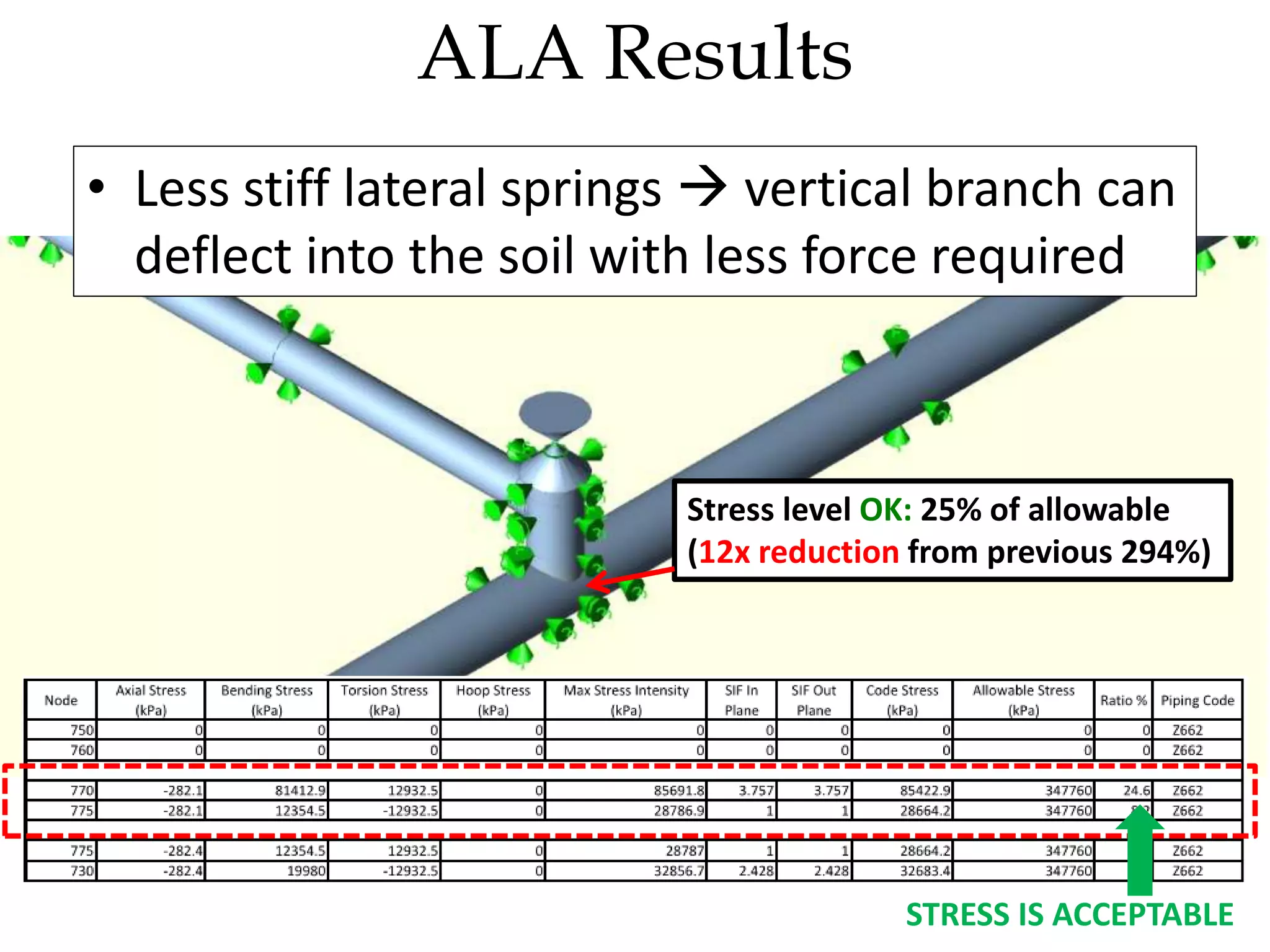

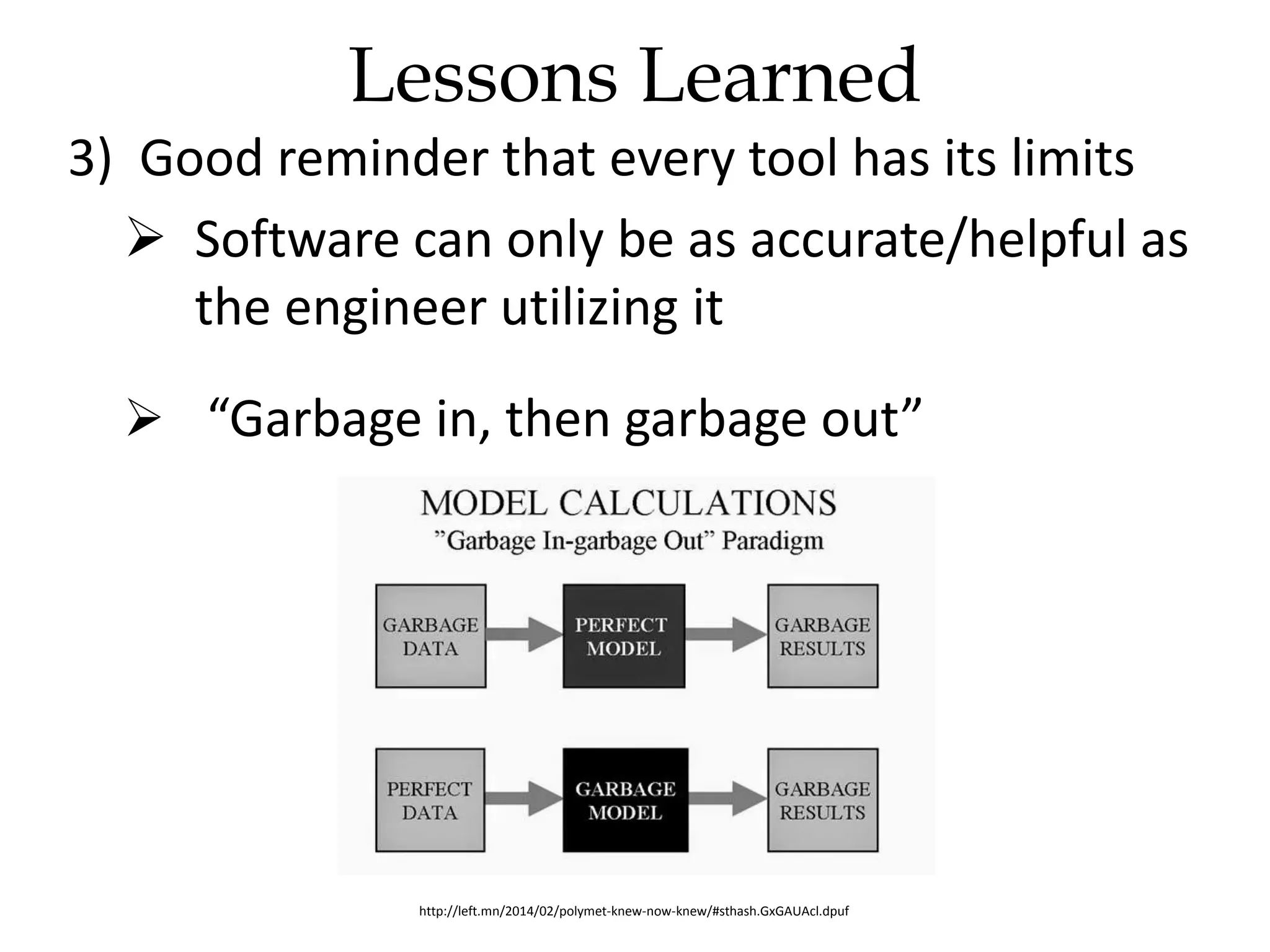

The document discusses analyzing stress in a buried branch connection using pipe stress analysis software Caesar II. The initial results using the basic soil model showed unrealistic high stresses at a tee. Further review found the basic soil model had much weaker axial than lateral soil springs. Switching to the more realistic American Lifelines Alliance soil model resulted in stress levels within acceptable limits by providing more balanced soil resistance. The lessons learned were to not rely solely on software and have a deep understanding of its limitations and assumptions.