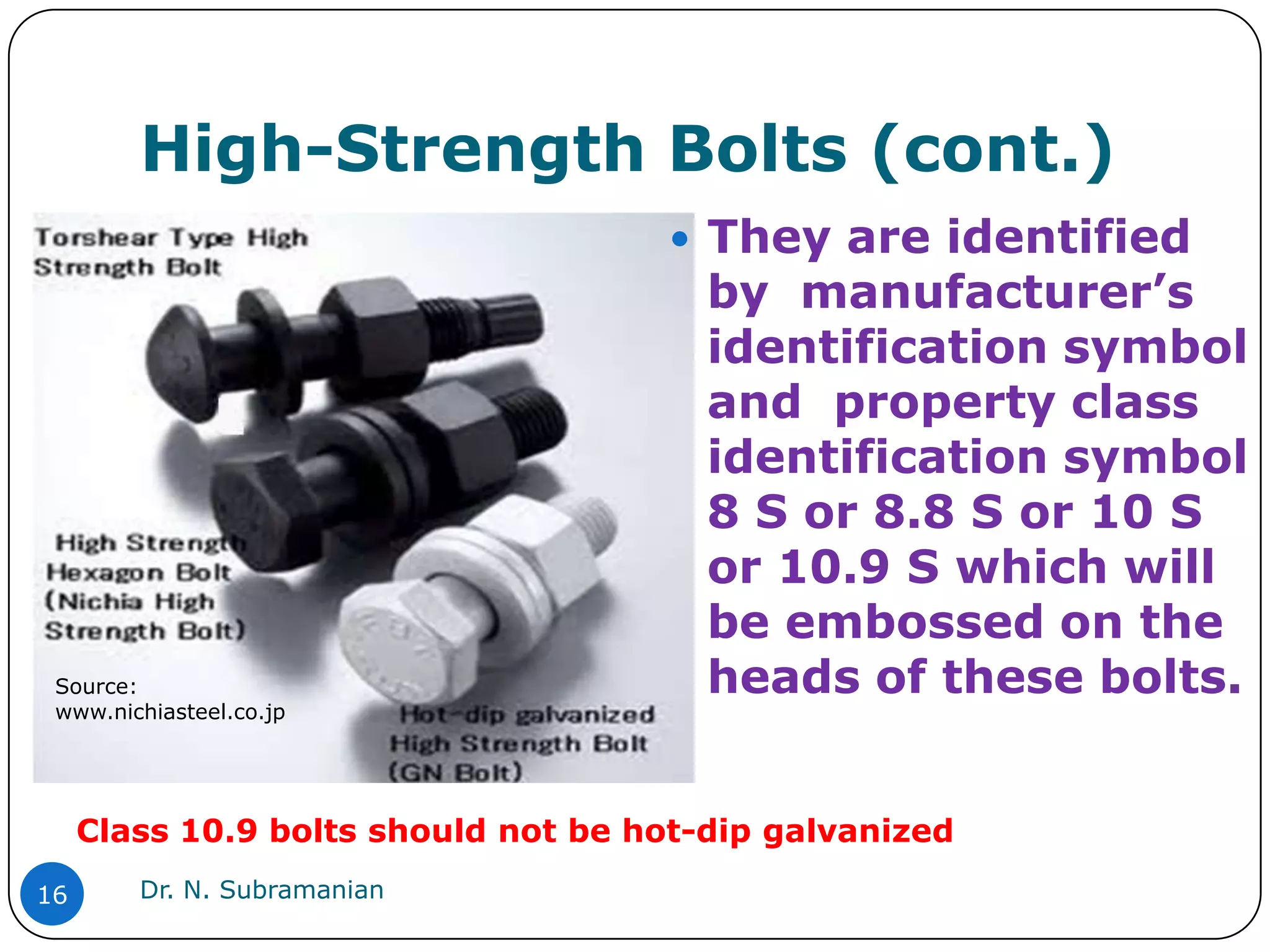

This document discusses bolted connections used in structural engineering. It begins by explaining why connection failures should be avoided, as they can lead to catastrophic structural failures. It then classifies bolted connections based on their method of fastening, rigidity, joint resistance, fabrication location, joint location, connection geometry, and type of force transferred. It describes different types of bolts and bolt tightening techniques used for friction grip connections. It discusses advantages and drawbacks of bolted connections compared to riveted or welded connections. The document provides detailed information on design and behavior of various bolted connections.