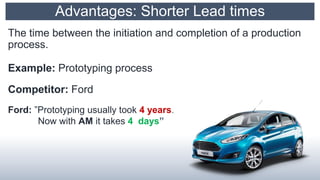

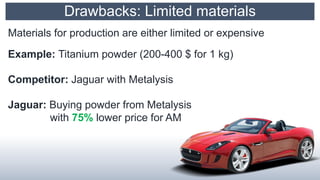

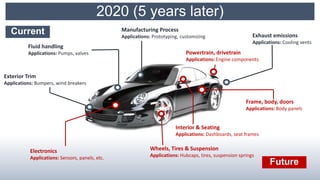

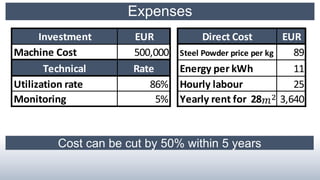

Additive manufacturing (3D printing) provides several advantages for the automotive industry, including new design possibilities, lighter and safer products, shorter lead times, and lower costs. However, challenges remain around manufacturing large parts, a lack of talent, intellectual property concerns, and limited materials. The automotive industry's use of additive manufacturing is expected to grow significantly by 2020 to include more interior, exterior, and powertrain components. For companies like Porsche, the recommendation is to start implementing additive manufacturing now for prototyping while continuing to monitor innovations, in order to integrate the technology and stay competitive in the future as it develops further.