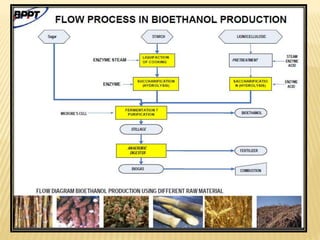

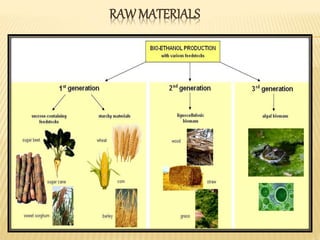

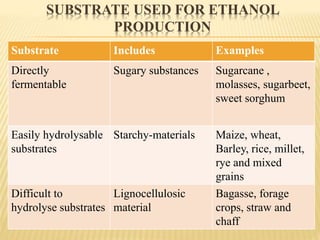

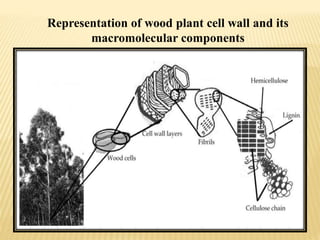

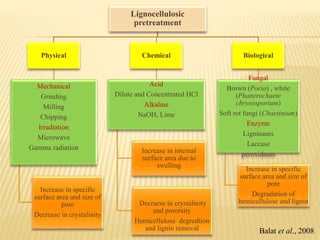

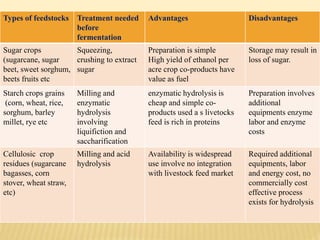

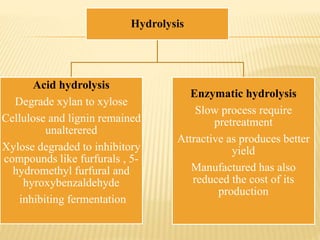

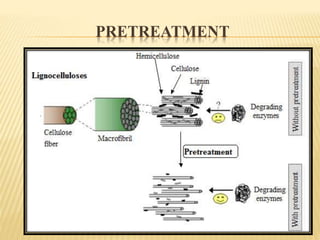

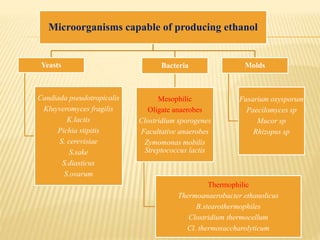

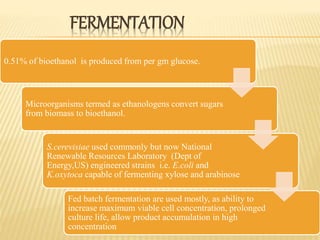

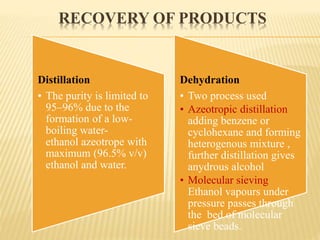

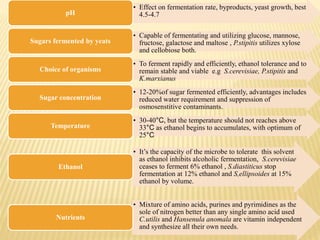

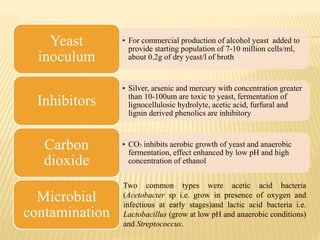

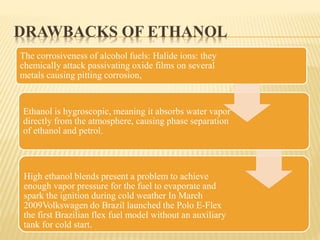

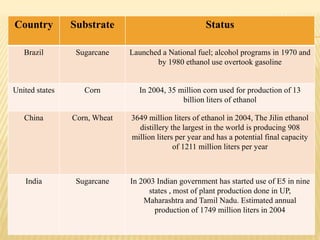

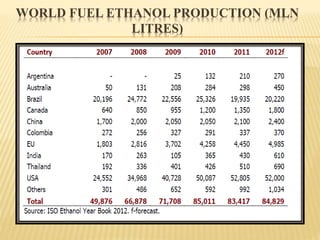

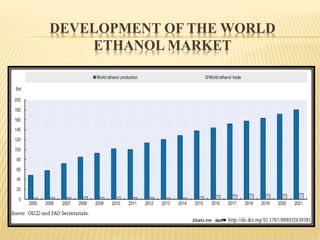

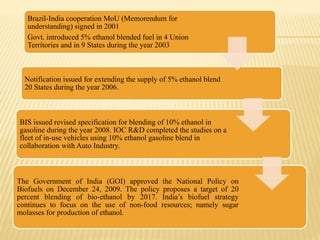

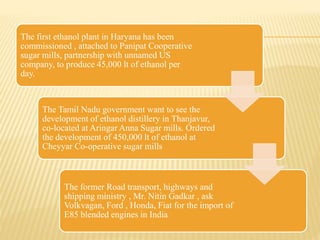

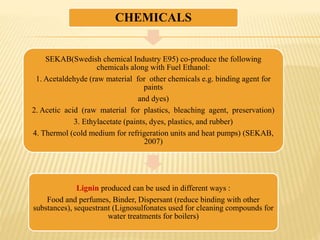

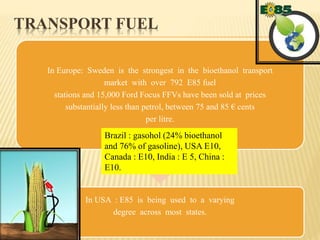

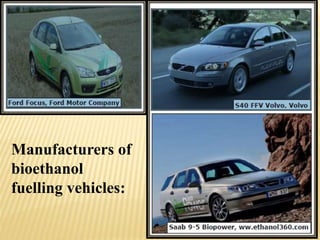

This document discusses bioethanol production. It begins by outlining the history of bioethanol and mentions Henry Ford's interest in it in the 1920s. It then covers the fuel properties of bioethanol, advantages over gasoline, production methods including substrates used, pretreatment, fermentation, and recovery. Factors influencing production and current status of production in countries like Brazil, the US, China, and India are also summarized. End uses of bioethanol in chemicals, transportation fuel, and conclusions on energy security and rural development are presented.