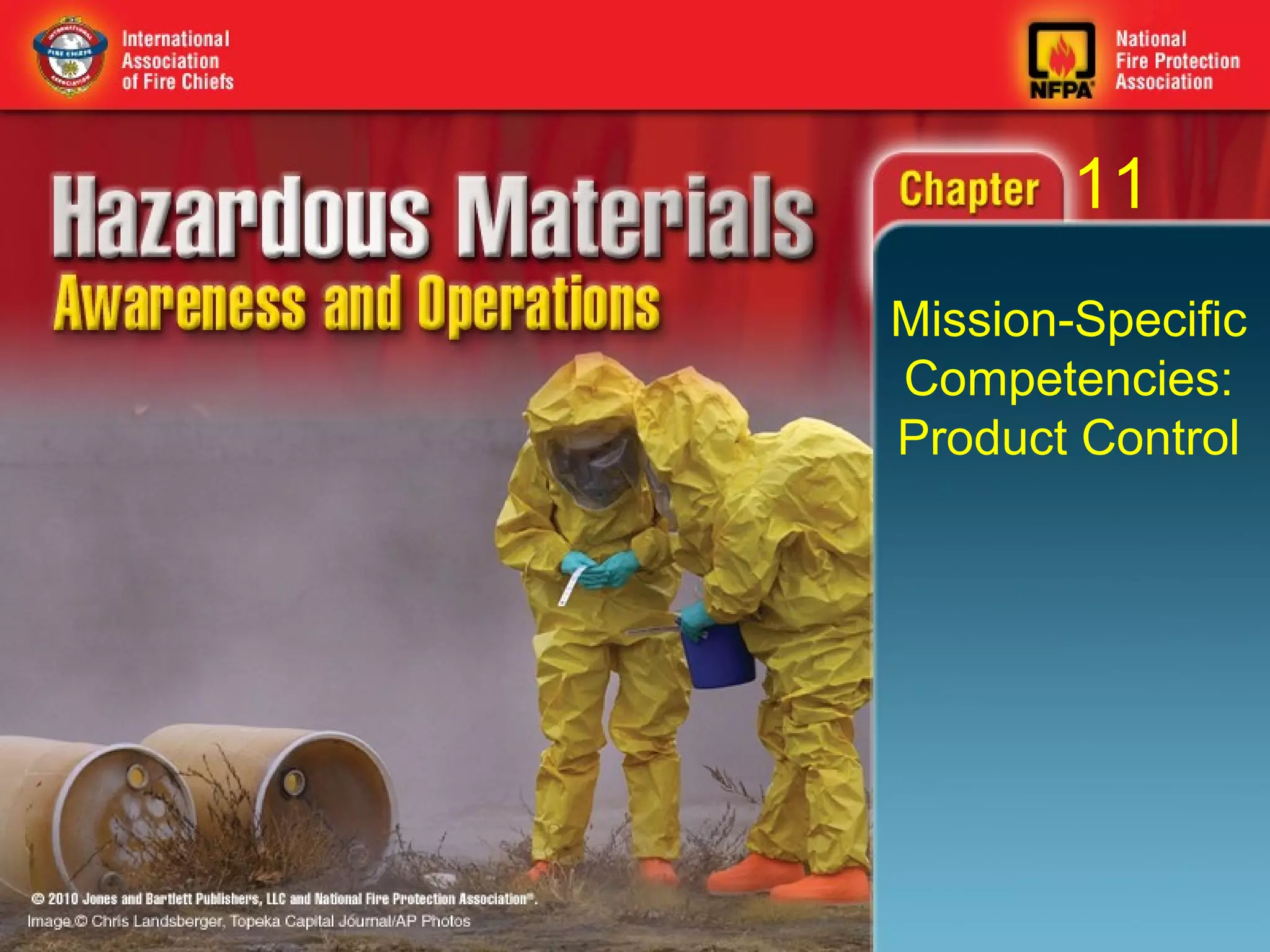

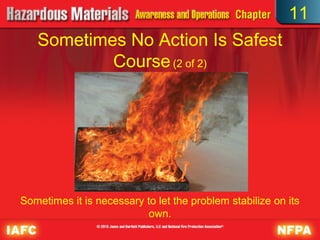

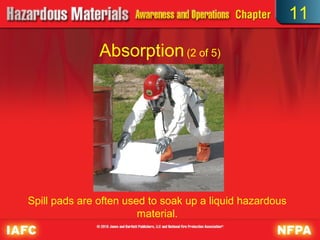

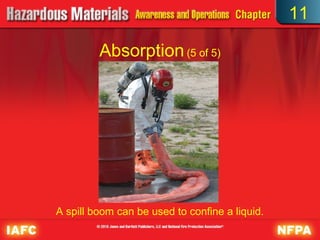

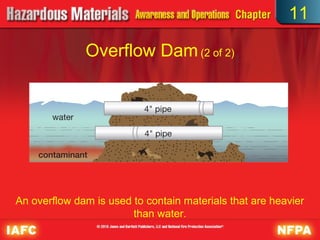

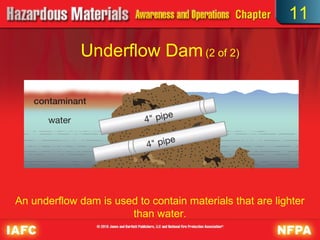

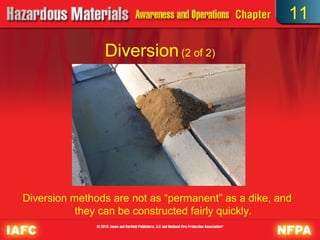

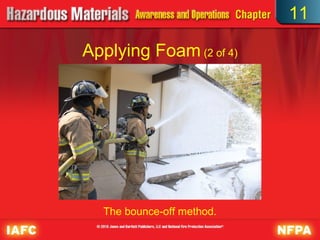

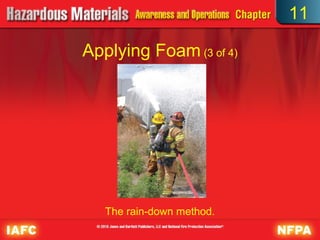

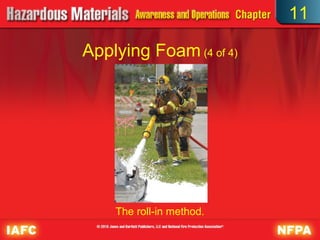

This document discusses control options for hazardous materials incidents. It describes techniques like absorption, diversion, damming, diking, and using special foams to contain, redirect, or lower concentrations of materials. Sometimes the safest approach is to create a perimeter and let the problem stabilize. The recovery phase aims to clean up the area and return it to its original condition.