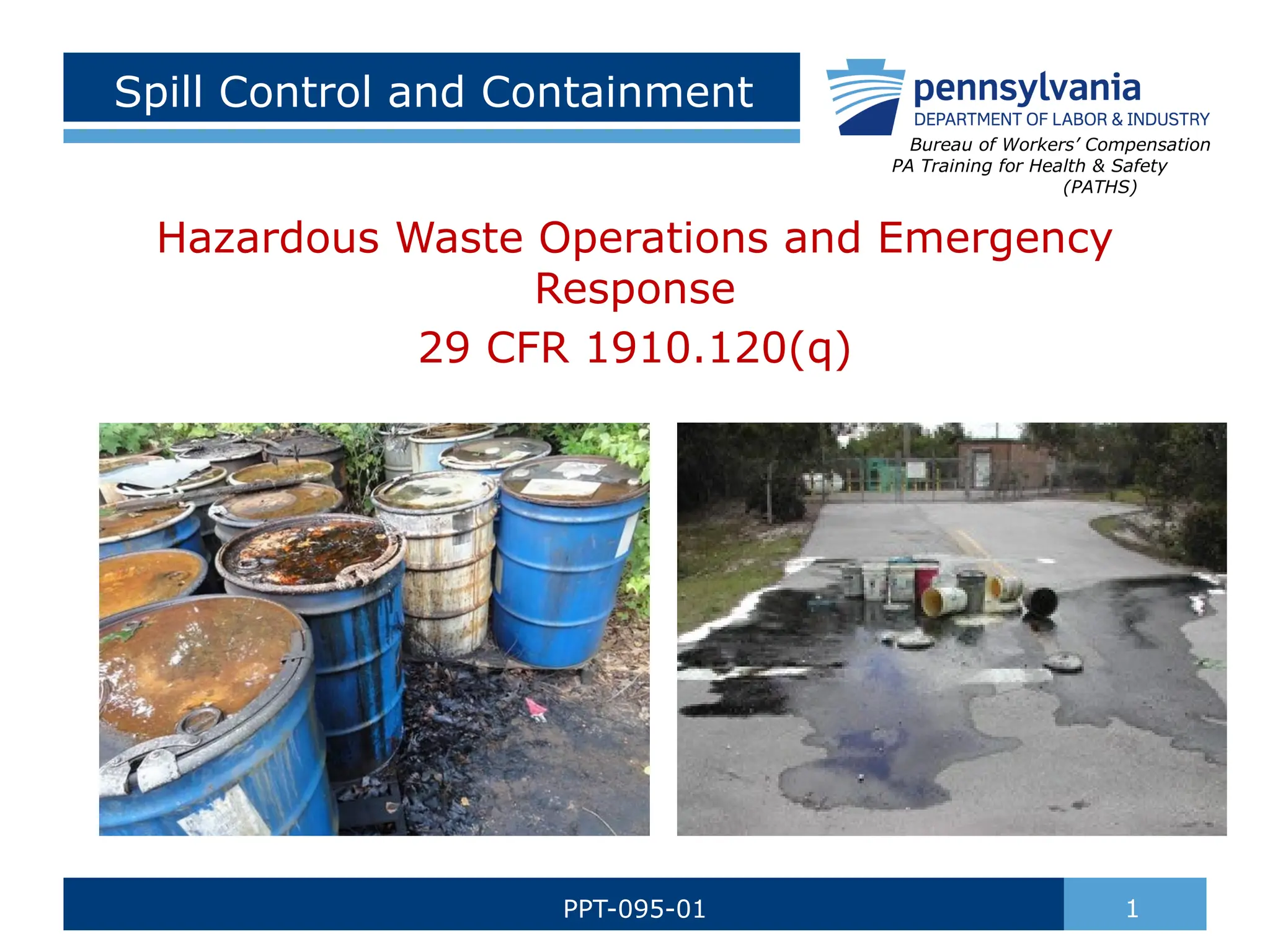

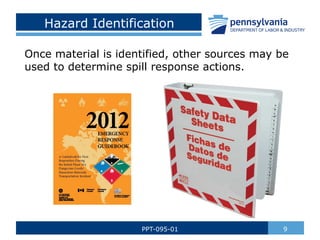

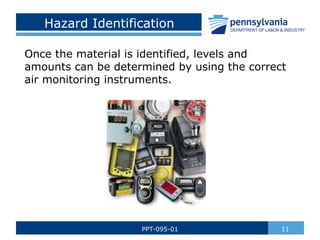

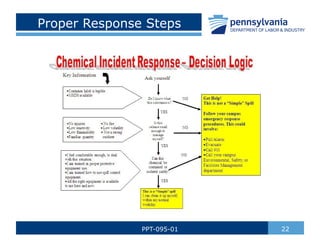

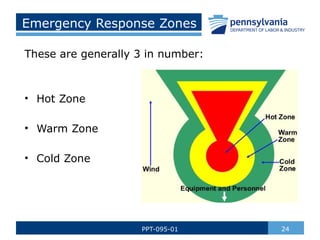

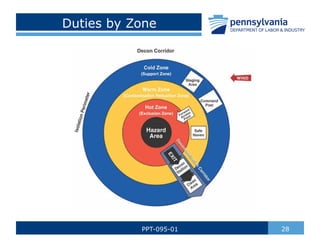

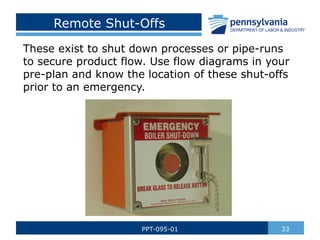

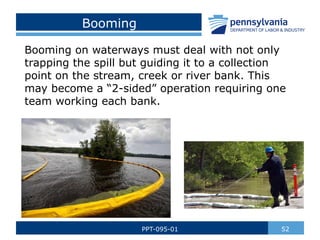

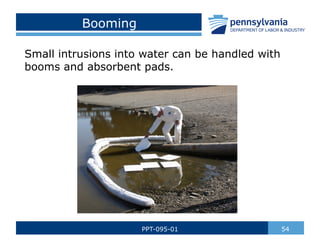

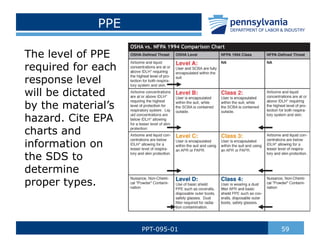

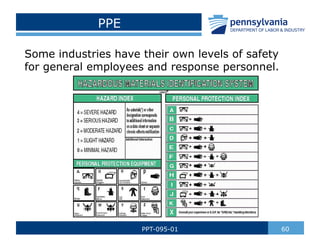

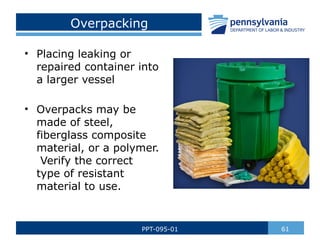

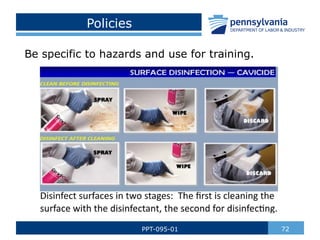

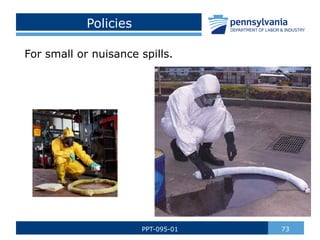

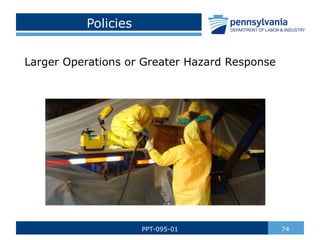

The document focuses on spill control and containment in hazardous waste operations and emergency response, outlining the potential hazards of chemical spills and the response strategies to mitigate them. It discusses methods for hazard identification, containment techniques, and emergency response zones, along with appropriate personal protective equipment (PPE) and response actions. The document emphasizes the importance of training, proper planning, and documentation for effective spill response and decontamination.