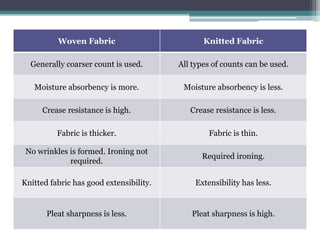

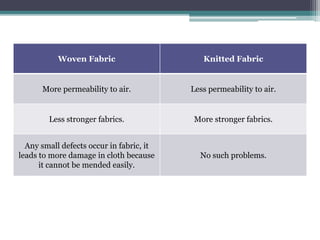

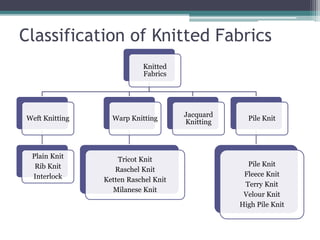

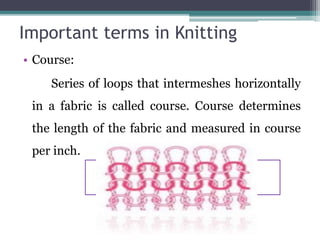

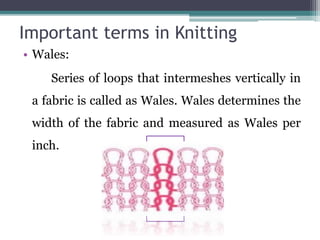

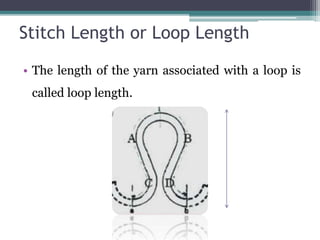

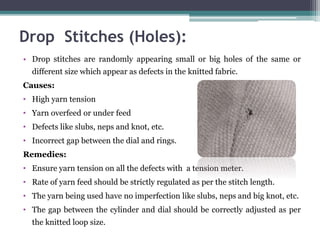

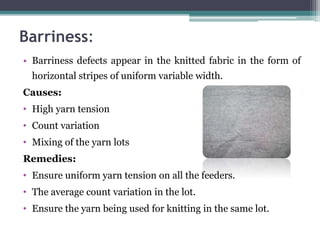

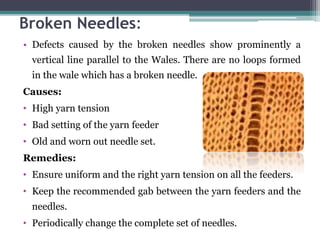

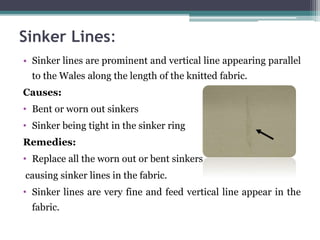

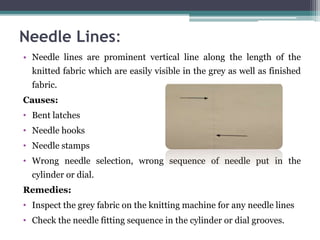

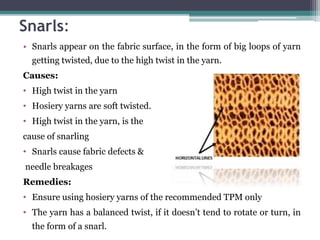

This document provides information about knitting and common knitting defects. It begins by defining knitting as a technique that uses intermeshed loops of yarn to form fabric. It then compares characteristics of woven and knitted fabrics. The document classifies types of knitted fabrics and defines important knitting terms. Finally, it describes and provides causes and remedies for several common knitting defects such as drop stitches, barriness, imperfections, and contamination.