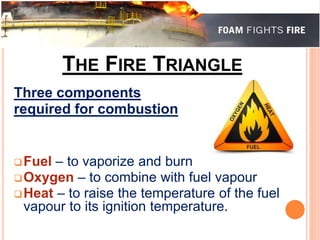

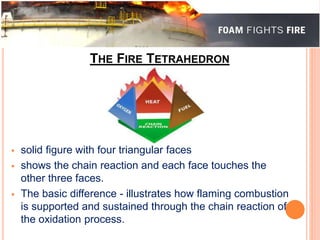

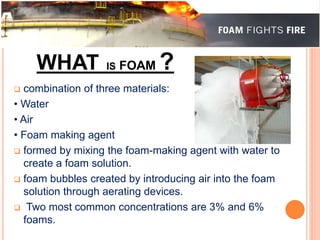

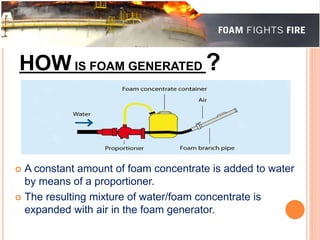

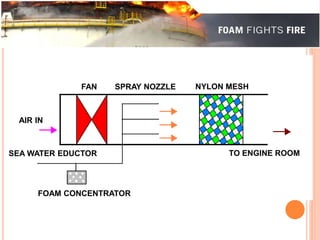

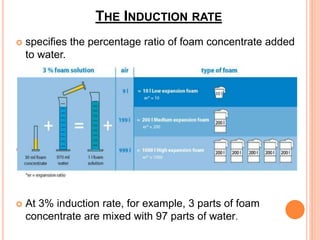

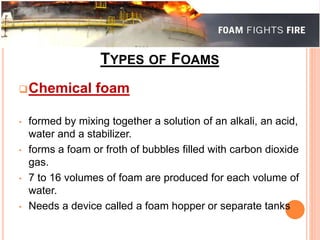

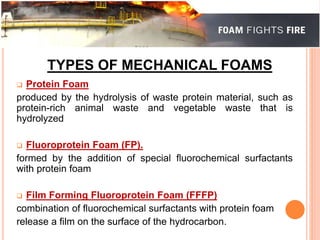

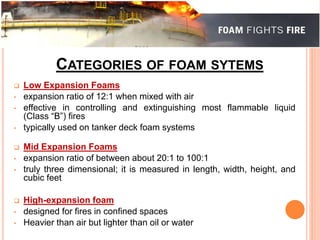

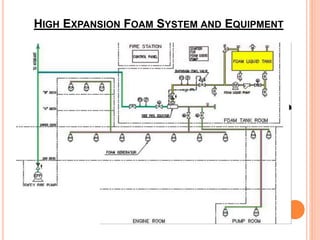

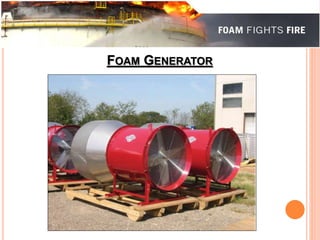

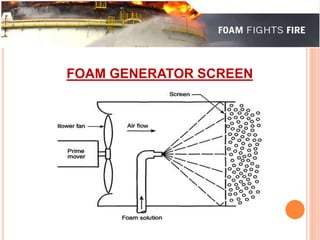

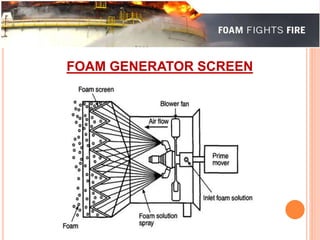

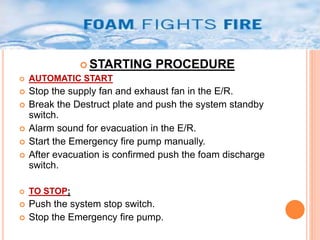

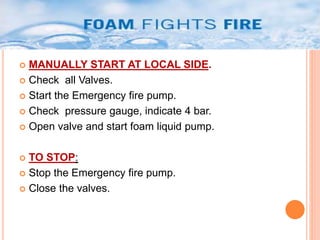

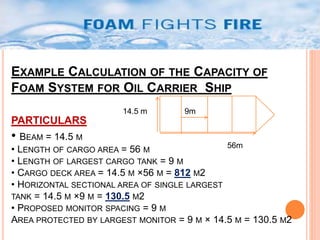

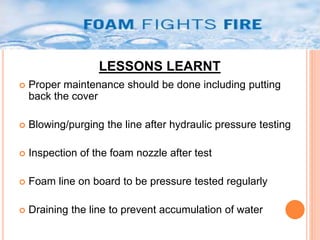

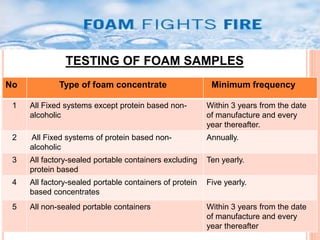

The document details the fire triangle, its components, and various systems for fire fighting, particularly focusing on foam systems used in marine applications. It explains the methods of foam generation, types of foams, their properties, and the systems for application, including SOLAS and ABS requirements for foam extinguishing systems. Additionally, it highlights operational procedures, maintenance, and inspection protocols necessary for ensuring foam systems are ready for use.