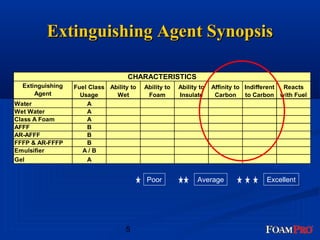

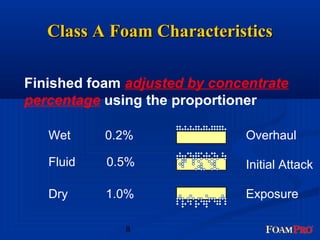

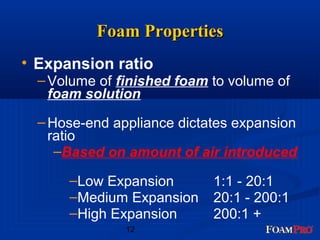

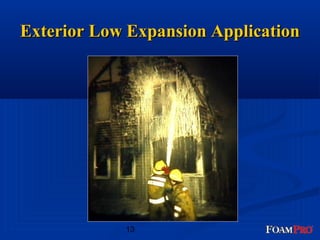

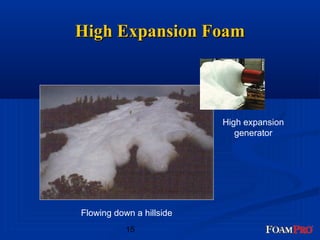

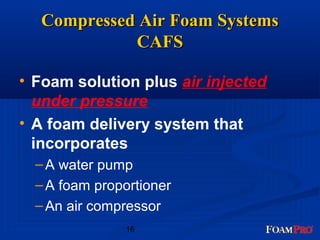

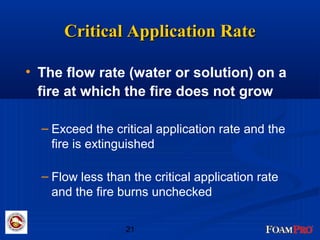

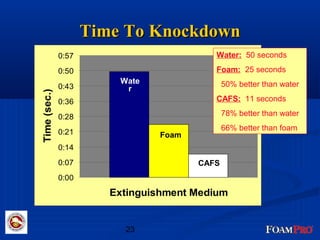

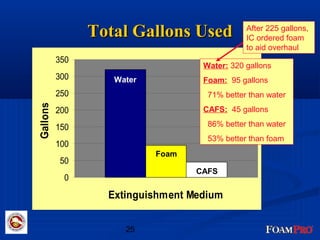

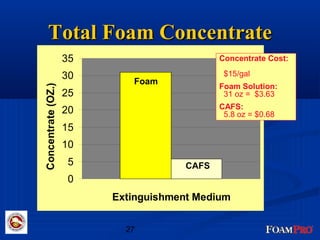

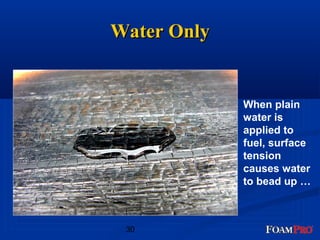

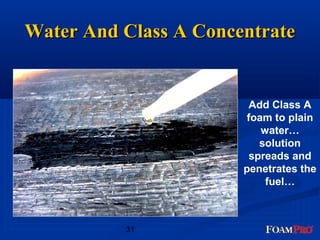

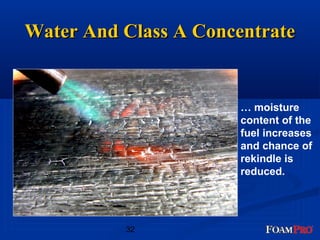

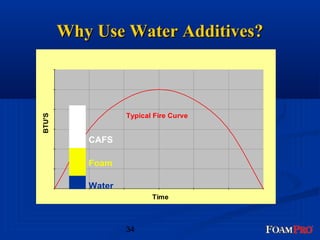

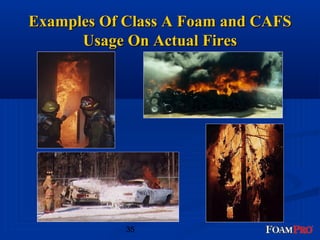

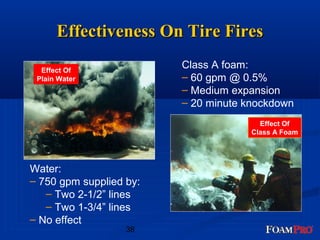

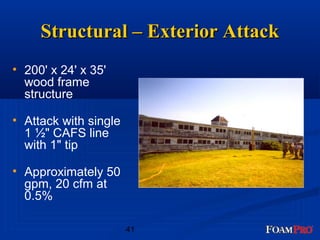

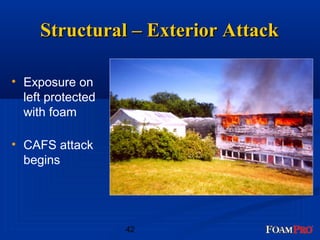

This document provides an introduction to Class A foam and compressed air foam systems (CAFS) for firefighting. It discusses the benefits of Class A foam and CAFS compared to water, citing a study that found CAFS was up to 4 times more effective than water in metrics like time to knockdown, gallons required, and time to cool a structure. The document also covers types of foam concentrates, proper usage, and characteristics of Class A foam. Examples are given of Class A foam and CAFS being effectively used on real fires.