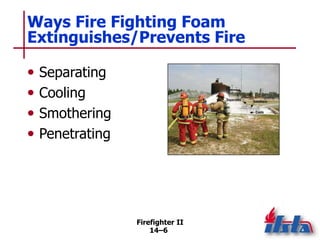

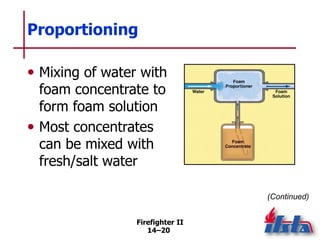

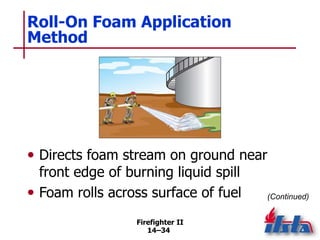

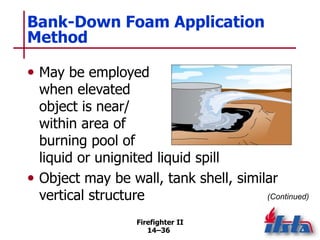

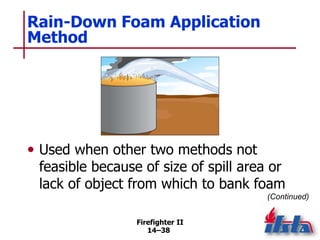

Chapter 14 of the Essentials of Fire Fighting discusses the effective application of fire fighting foam, including its types, concentrates, and delivery devices. It covers specific objectives such as the characteristics of foam, its generation process, proportioning methods, and associated hazards, while detailing application techniques like roll-on, bank-down, and rain-down methods. The chapter emphasizes the importance of understanding foam differences for effective fire suppression, alongside safety considerations for humans and the environment.