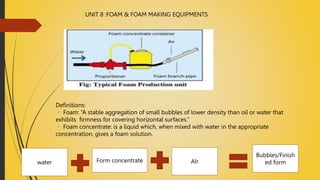

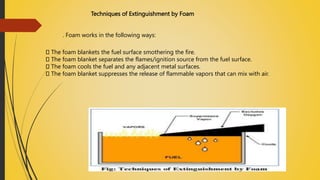

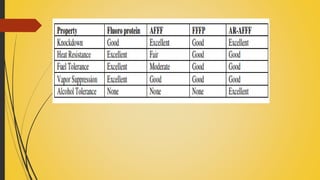

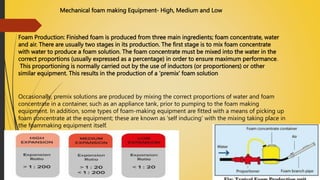

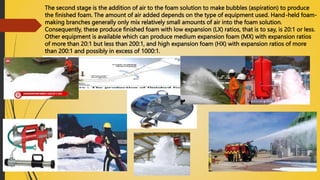

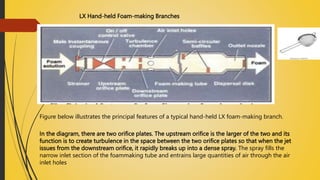

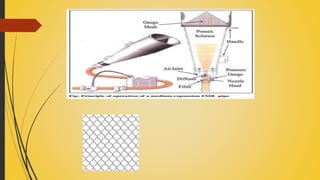

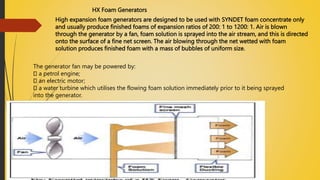

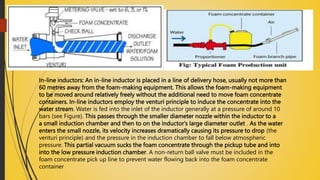

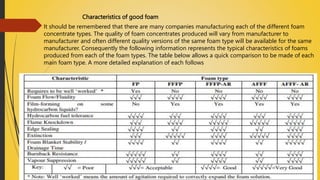

Foam is a stable aggregation of small gas bubbles that provides insulation against heat and fire. There are several types of foam concentrates that produce foam with different properties when mixed with water. Foam works to extinguish fires by coating the fuel, cooling surfaces, and suppressing vapors. Equipment uses the Venturi effect or fans to mix water, foam concentrate, and air to produce low, medium, or high expansion foam. Proper induction of foam concentrate is important for finished foam quality. Handheld wands produce low expansion foam while generators create medium to high expansion foam for firefighting.