1. Gajra Differential Gears is the largest manufacturer of automobile transmission gears in India, with 130,000 sq ft of machine shop area and 29,000 sq ft heat treatment facility and over 1000 employees.

2. The company produces spiral and hypoid gears, bevel gears, spider kit assemblies, and differential cages and housings. More than 50% of products are exported globally.

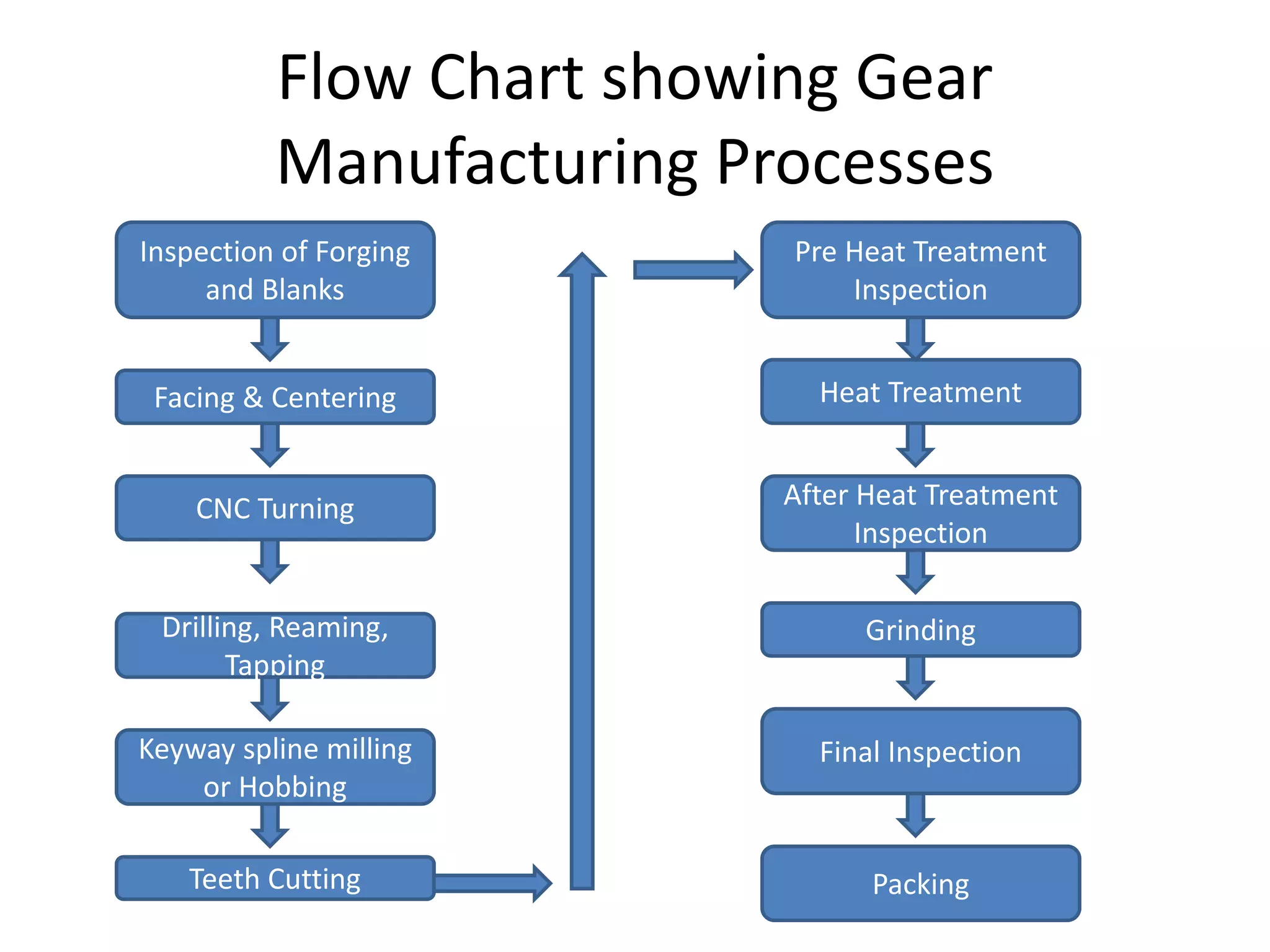

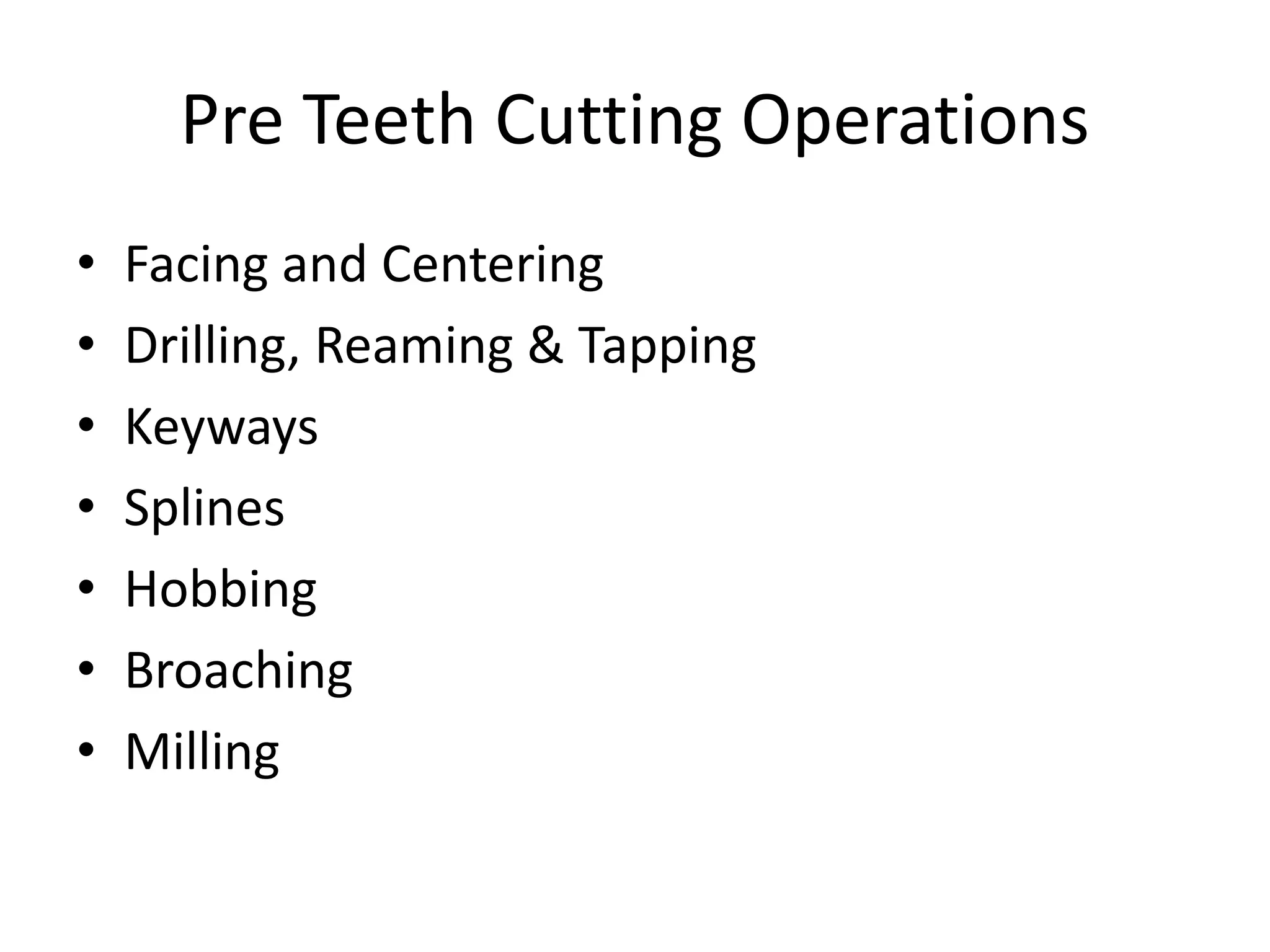

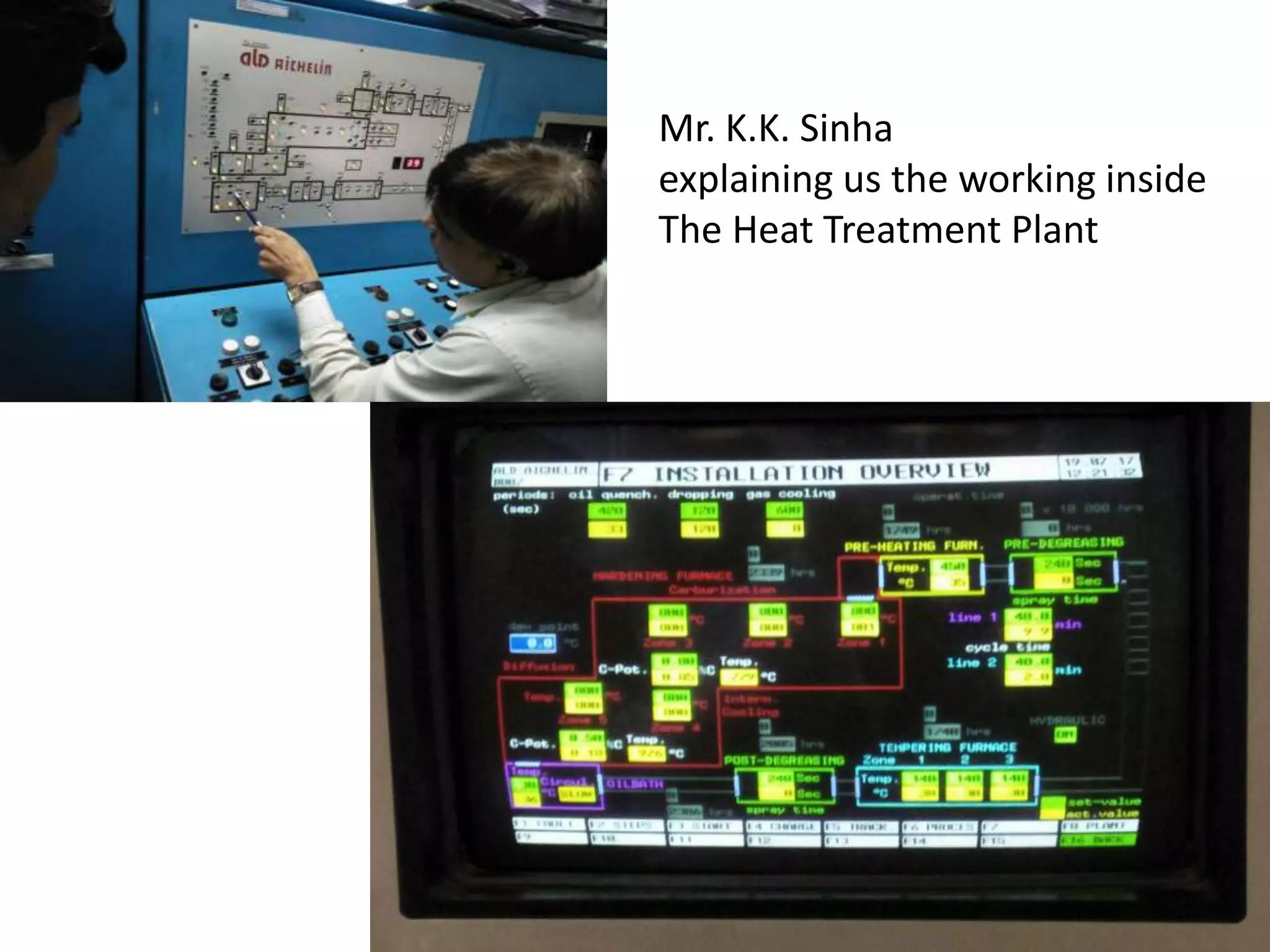

3. The gear manufacturing process involves operations like facing, centering, teeth cutting, heat treatment, grinding, and final inspection to produce precision-cut transmission gears for vehicles.