This document is the second revision of the Indian Roads Congress Manual of Specifications and Standards for Two Laning of Highways with Paved Shoulder, published in November 2018. It provides guidelines for geometric design, pavement structure, drainage, traffic control devices, safety works, and other aspects of two-lane highway projects. The manual contains 14 sections addressing topics such as intersections, road embankments, pavement design, drainage, structures, materials, and special requirements for hill roads and tunnels. It is intended to assist in planning, design, and execution of two-lane highway projects in India.

![IRC:SP:73-2018

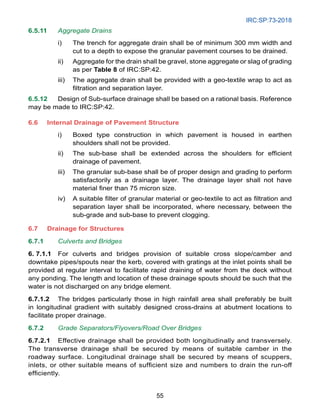

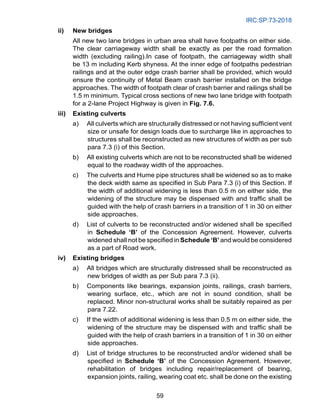

6

SECTION - 1

GENERAL

1.1 This Manual describes the planning, standards, design, construction, maintenance,

operation, safety and environmental requirements to be fulfilled in execution of the works of [ …]

under a concession or contract Agreement and shall be read harmoniously and in conjunction

with the contract. This Manual is applicable for Two Laning of Highways (with or without paved

shoulders) through Public Private Partnership (PPP), EPC or any other mode. The general

planning aspects laid out in this Manual shall be applicable for widening from single/intermediate

lane to two lane or new construction of two lane highways. The scope of the work shall be as

defined in the Concession Agreement. As far as National Highways are concerned, two laning

in this Manual shall mean two lane with paved shoulders as per Ministry’s Guidelines unless

otherwise specified.

1.2 The Project Highway and the project facilities shall conform to the requirements of design

and specifications set out in this Manual, which are the minimum prescribed. The project report

and other information provided by the Authority shall be used by the Concessionaire only for its

own reference and for carrying out further investigations. The Concessionaire shall be solely

responsible for undertaking all the necessary surveys, investigations and detailed designs in

accordance with Authority for any loss, damage, risk, costs, liabilities or obligations arising out of

or in relation to the project report and other information provided by the Authority.

1.3 At least 2 weeks prior to commencement of the work, the Concessionaire shall draw up

a Quality Assurance Manual (QAM) covering the Quality System (QS), Quality Assurance Plan

(QAP) and documentation for all aspects of the bridge and road works, which shall include the

standard operative procedures which the Concessionaire, his personnel, his contractors and their

sub-contractors shall follow during execution and send three copies of each to the Independent

Engineer (IE) for review. The class of quality assurance shall be as per IRC:SP:112-2017 Manual

for Quality Control in Road and Bridge Works.

1.4 The Codes, Standards, Technical Specifications and Guidelines applicable for the design

and construction of project components are:

i) Indian Roads Congress (IRC) Codes, Standards and Guidelines;

ii) Specifications for Road and Bridge Works issued by the Ministry of Road

Transport Highways (MORTH) hereinafter referred to as MORTH or Ministry’s

specifications.

iii) Any other standards referred to in the Manual and any supplement issued

with the bid document.

1.5 The version of the Codes, Standards, Specifications, etc. notified/published at least 60

days prior to the last date of bid submission shall be considered applicable.](https://image.slidesharecdn.com/irc-230519121254-c789ba91/85/irc-073-2018-document-uploaded-by-Priyanshu-Kumar-9608684800-16-320.jpg)

![IRC:SP:73-2018

116

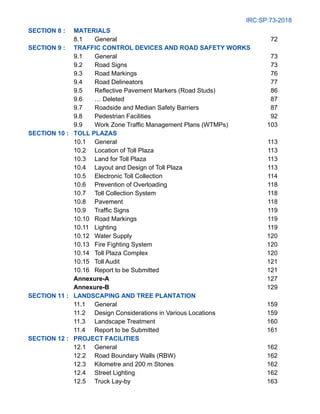

of the Toll Plazas shall not be removed. The installation of Medium Speed Weigh

in Motions (MSWIMs) shall be carried out only on those lanes where there is no

existing Weigh in Motion (WIM) equipment / hardware.

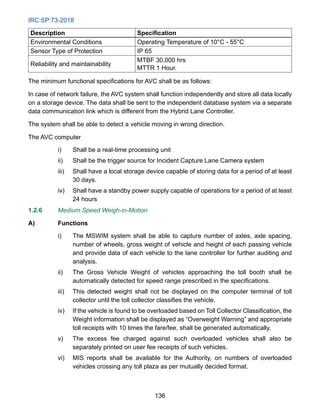

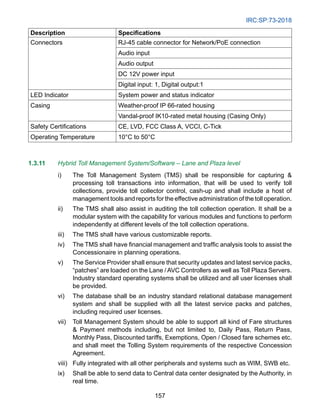

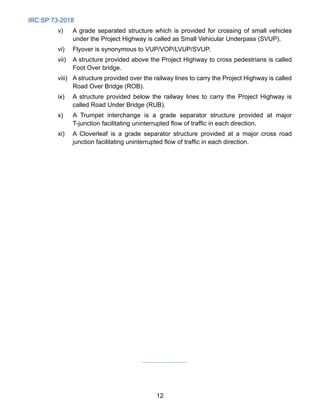

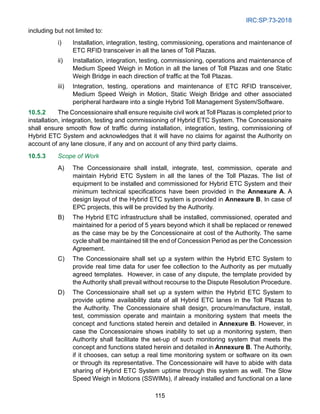

10.5.4 Service Level

i) The uptime availability of all critical components of Hybrid ETC lanes shall be

99% per lane per month for 90% of total lanes in a toll plaza (rounded off to

nearest integer). For the balance 10% lanes, uptime availability of all critical

components shall be 98% per lane per month.

ii) The downtime for a toll lane shall be calculated at a cumulative level when any

of the below mentioned critical component is non-operational for that specific

lane:

a) ETC RFID transceiver

b) Automatic Lane Barrier

c) Lane Incident Camera

d) Automatic Vehicle Classifier

e) Hybrid Lane Controller

f) Any other plaza level or lane level equipment leading to disruption in ETC

transactions

iii) For all other components of Hybrid ETC System, the uptime availability shall be

98% per lane per month.

iv) Scheduled downtime is defined as a period of time when system will remain

unavailable for conducting necessary preventive maintenance, urgent repairs

etc. The maximum scheduled downtime for any Site shall be 4 hours per lane

per month.

v) The formula for calculation of Hybrid ETC System availability shall be as follows:

System Uptime = [1-{A/(B-C)}*100]

Where A = Time for which system is down per month basis scenarios identified

in clause 4B

B = Total time in a month

C = Scheduled downtime basis Clause 4D

vi) The Concessionaire shall maintain adequate inventory to ensure the service

levels prescribed in Clause 4A are adhered. Spares of critical components

of Hybrid ETC System as identified in Clause 4B for at most 2 lanes shall be

included in the cost of change in Scope of Work Order. There shall be no other

provision or payment for additional Hybrid ETC equipment/hardware from the

Authority.

vii) The Concessionaire shall ensure that the Hybrid ETC Systems are operational

as per the service levels defined in Clause A to facilitate payment of user fee

through ETC. In case, a vehicle user with a valid, functional ETC RFID tag with

sufficient balance in the linked account is not able to pay user fee through ETC](https://image.slidesharecdn.com/irc-230519121254-c789ba91/85/irc-073-2018-document-uploaded-by-Priyanshu-Kumar-9608684800-126-320.jpg)

![IRC:SP:73-2018

117

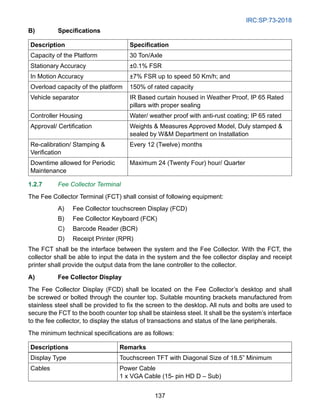

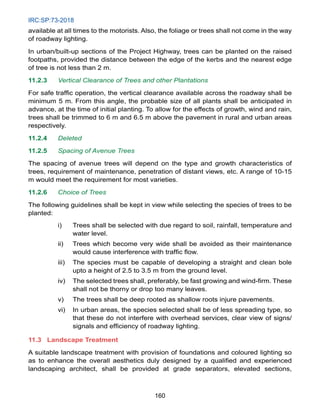

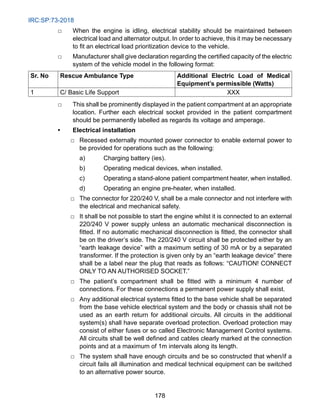

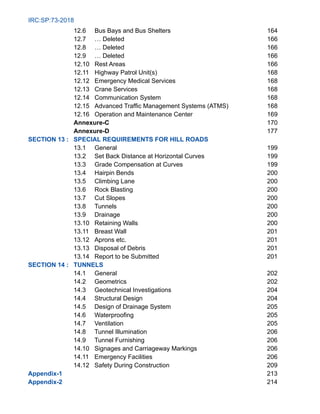

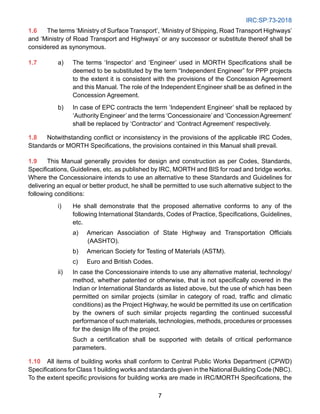

through any lane owing to malfunctioning of Hybrid ETC equipment/hardware,

the vehicle user shall be permitted to pass without payment of any user fee.

viii) In case of non-adherence to service levels as defined in Clause 4A, suitable

damages shall be levied on each lane by the Authority over and above the free

passage of user as described in Clause 4G.

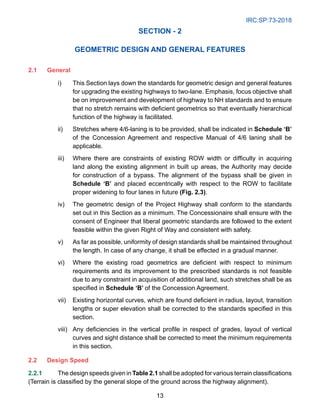

ix) The Concessionaire shall ensure that all transaction files are uploaded as per

defined service levels provided by the Authority or CCH. The service levels are

prescribed in the table below:

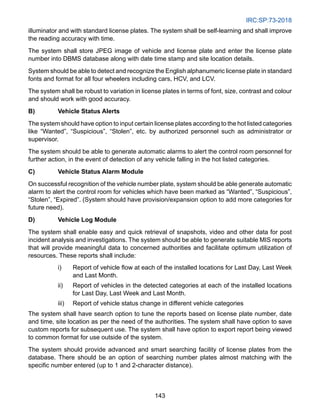

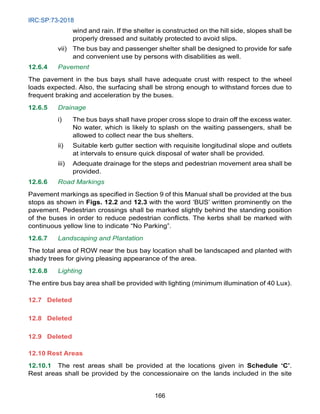

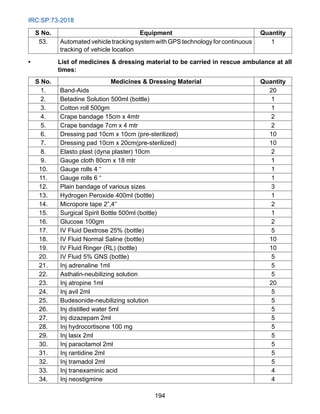

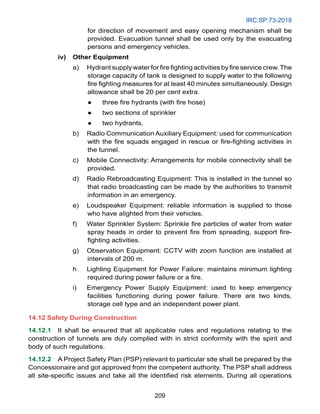

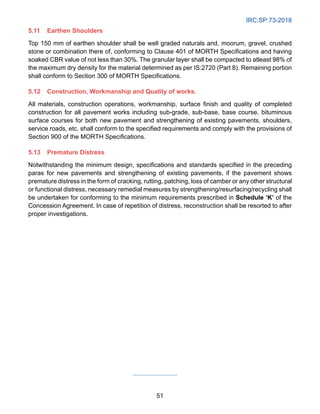

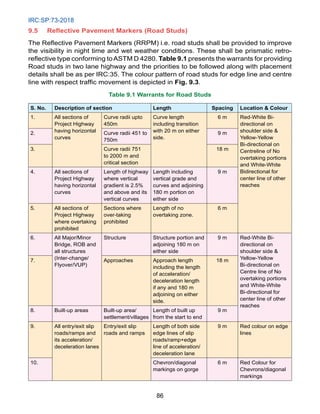

S. No. Description Service Level Damages

1. Sending clean

transaction files in a

specified format to

CCH

•

Within 10

minutes of [ETC

transaction]

•

Up to 3 days of

[ETC transaction.]

•

Transaction post 10 minutes shall

be processed only if the tag account

has sufficient balance. In case of

negative balance, the transaction

shall be rejected.

•

Liability of such transactions (after

10 minutes and before 3 days) shall

lie with the Concessionaire.

Transaction shall be rejected by CCH

after 3 days.

2. Sending violation

transactions post audit

at plaza level along

with clear supporting

images to CCH.

The images should be

clear enough to identify

the vehicle class.

•

Within 10 minutes

of ETC transaction

•

Up to 3 days of

ETC transaction

Transaction post 10 minutes shall be

processed only if the tag account has

sufficient balance. In case of negative

balance, the transaction shall be

rejected.

Liability of such transactions (after 10

minutes and before 3 days) shall lie

with the Concessionaire.

Transaction shall be rejected by CCH

after 3 days.

3. Populating blacklist

file in the Hybrid ETC

system of all the lanes.

•

Within 10 minutes

of receipt from

CCH

Post 10 minutes, any clean/violation

transaction file received by CCH for

the same tag account with inadequate

balance shall be rejected.

10.5.5 A) The Concessionaire shall be provided a list of Acquiring parties by the Authority

or a representative of the Authority amongst which the Concessionaire shall

select one for the processing of ETC transactions. The list of Acquiring parties

may be updated or modified from time to time by the Authority or a representative

of Authority and the Concessionaire shall abide by all the terms and conditions

of such directives.

B) The Concessionaire shall effect and maintain at its own cost, adequate

insurance cover for any case of accidental damage to Hybrid ETC Systems. The

Concessionaire shall indemnify the Authority against any claims whatsoever on

this account.](https://image.slidesharecdn.com/irc-230519121254-c789ba91/85/irc-073-2018-document-uploaded-by-Priyanshu-Kumar-9608684800-127-320.jpg)