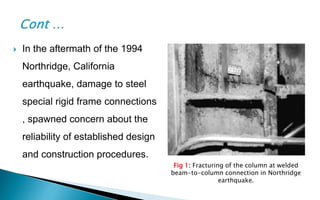

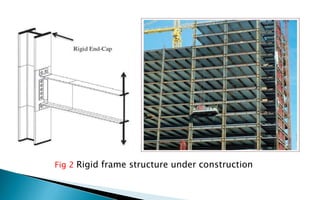

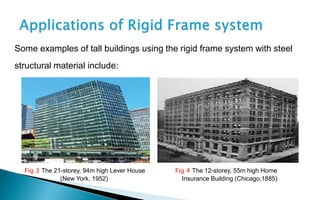

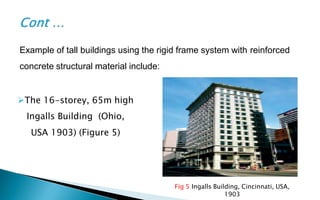

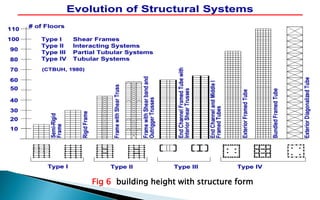

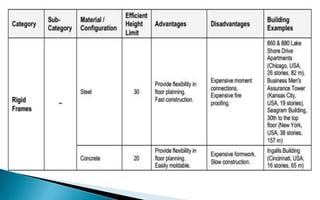

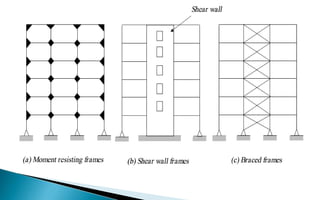

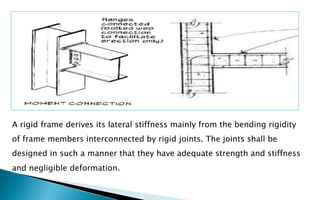

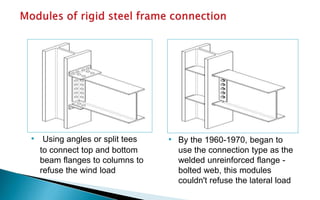

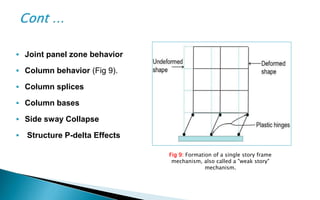

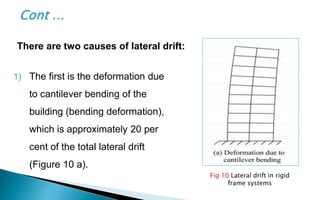

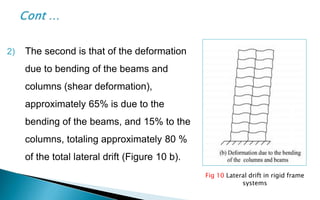

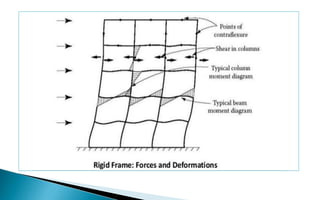

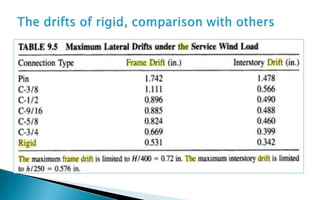

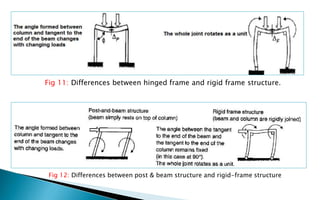

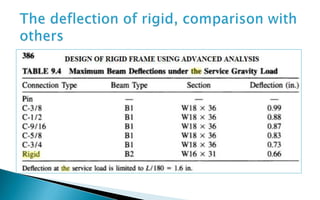

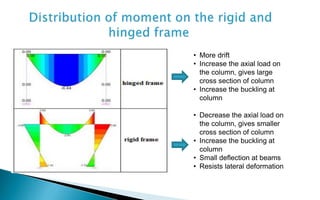

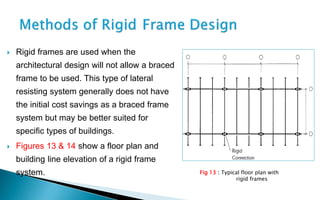

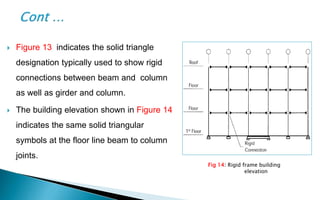

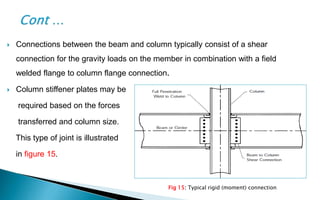

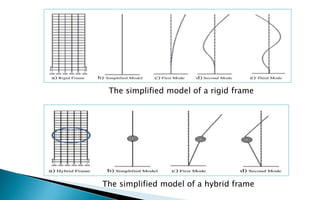

The document discusses rigid frame systems used in high-rise buildings. It provides a history of rigid frames, an introduction to what they are, and examples of their applications. It describes the material properties and connections used. It discusses considerations for rigid frame design like behavior under lateral loads. It notes advantages like architectural freedom but also disadvantages like increased drift. It concludes with a case study on using hybrid rigid/semi-rigid frames to improve seismic performance.