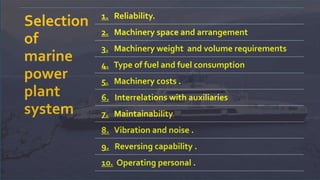

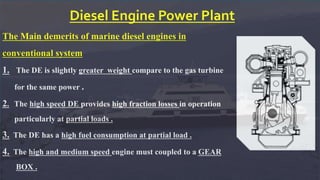

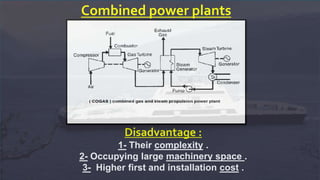

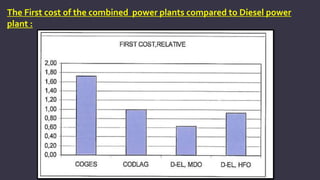

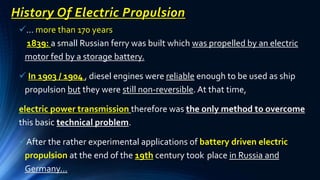

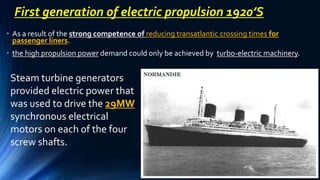

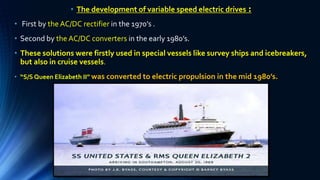

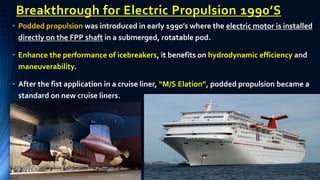

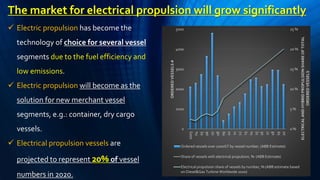

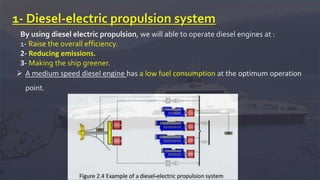

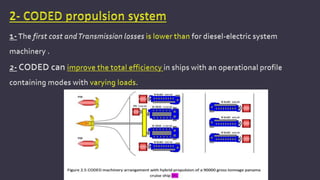

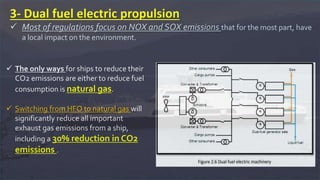

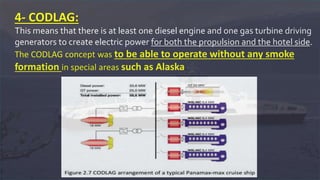

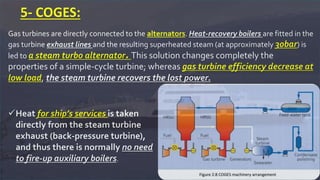

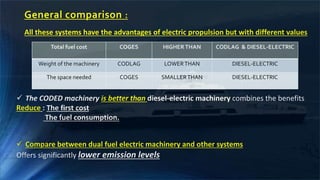

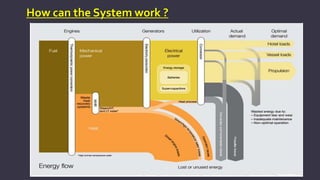

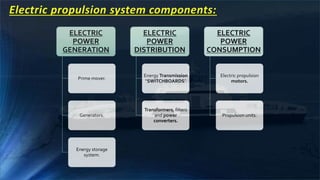

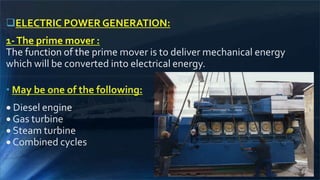

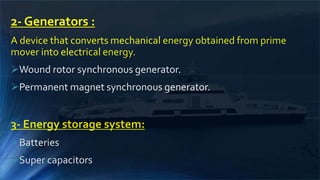

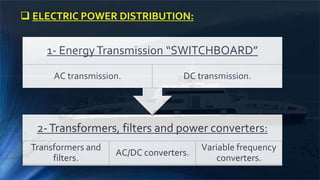

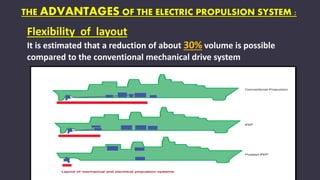

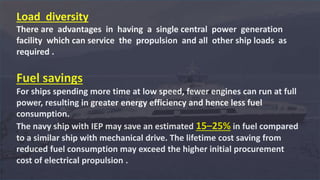

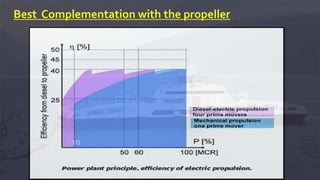

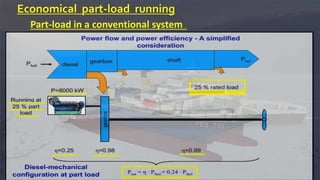

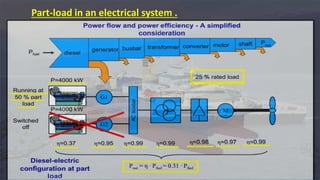

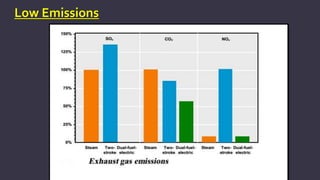

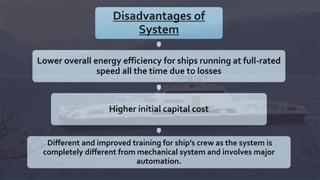

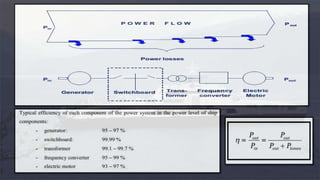

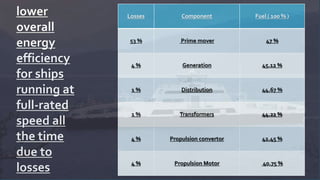

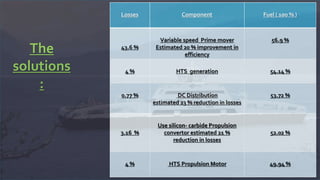

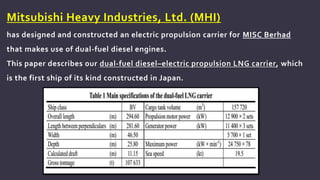

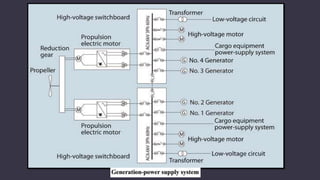

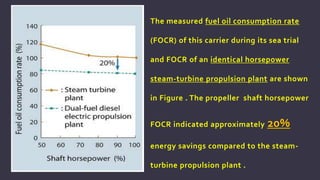

The document discusses electric propulsion systems for marine vessels. It provides an overview of conventional power plants and their disadvantages. It then discusses the history and development of electric propulsion systems, including early experimental systems from the late 19th century through modern commercial applications starting in the 1920s. The document outlines several types of electric propulsion systems and their components. It discusses the advantages of electric propulsion systems, including improved efficiency, emissions reductions, and operational flexibility compared to conventional systems.

![Main Specification of the boat :

- 18 [kWh] lithiumion battery of which

weight is about 400 [kg]

- 80 % of full charge of the battery can be

recharged by the quick charger within

-30 [min]

-The operational time with the full

charged battery is about 45 [min].

- the motor power is about 25 [kW] .

-The maximum speed of “RAICHO-I” is

about 10 [knots] with half load and 8.5

[knots] with full load. Full load means 2

crews and 10 passengers on board.](https://image.slidesharecdn.com/thefinal-151219202813/85/The-Electric-Propulsion-Systems-63-320.jpg)