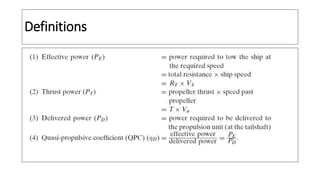

This document discusses methods for estimating the propulsive power required to propel a ship at a given speed. It explains that the power estimate is needed to determine machinery masses and fuel consumption. The power can be estimated from tests of similar existing vessels or models. Scaling laws must be applied when estimating power for a different sized craft. The effective power required to drive the ship is less than the power delivered to the propulsion unit due to efficiency losses. Common propulsion systems include diesel, gas turbine, steam turbine and electric, each with their own advantages and limitations. The overall assessment requires knowledge of the required thrust at a given speed, available propulsion engines, and propulsor options.

Human: Thank you, that is

![• A fundamental requirement of any ship propulsion system is the

efficient conversion of the power (P) available from the main

propulsion engine(s) [prime mover] into useful thrust (T) to propel

the ship at the required speed (V),

• There are several forms of main propulsion engines including:

• Diesel.

• Gas turbine.

• Steam turbine.

• Electric.

• (And variants / combinations of these).](https://image.slidesharecdn.com/2-propulsivepower-220724115617-0328fa8c/85/2-Propulsive-Power-pptx-6-320.jpg)

![propeller detail main engine

D(m) = 4.000 Pm(kW) = 1750 1750

Ratio= 7.200 Nm(RPM)= 900

Np(RPM)= 125 DUCTED PROPELLER

Vs Pe Pd Pbmin N Nmak

(knots) (kWs) (kWs) (kWs) (RPM) (RPM)

10.0 585 0.279 0.248 1.044 0.624 1.015 0.661 885 917 107 768

10.5 688 0.279 0.248 1.044 0.624 1.015 0.661 1041 1079 113 811

11.0 809 0.279 0.248 1.044 0.623 1.015 0.660 1226 1270 119 855

11.5 950 0.279 0.248 1.044 0.622 1.015 0.659 1442 1494 125 900

12.0 1114 0.279 0.248 1.044 0.620 1.015 0.657 1696 1758 132 948

12.5 1307 0.279 0.248 1.043 0.618 1.015 0.655 1997 2069 139 998

Not: %100 MCR ve deniz marjini olmaksızın asgari makina gücü Pbmin; h tr = 0.965 olarak hesaplanmıştır.

wt t H 0 r d

0

500

1000

1500

2000

2500

3000

3500

4000

7.0 8.0 9.0 10.011.012.013.014.015.0

Power

[kW]

Speed [knots]

Pe

Pbmin](https://image.slidesharecdn.com/2-propulsivepower-220724115617-0328fa8c/85/2-Propulsive-Power-pptx-18-320.jpg)