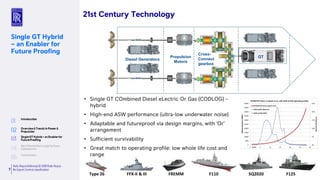

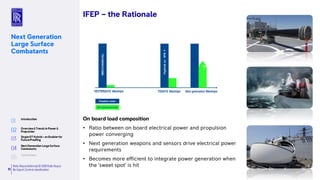

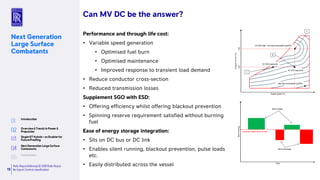

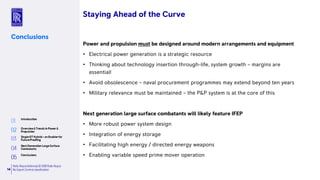

This document discusses trends and future directions in naval propulsion and power systems. It argues that future large surface combatants will likely feature integrated full electric propulsion (IFEP) to meet increasing electrical loads from sensors and weapons. IFEP allows for more efficient power generation by integrating generation when the ratio of electrical to propulsion power converges. Technologies like variable speed generation, energy storage integration, and medium voltage DC distribution could help IFEP systems meet performance and cost requirements for next-generation ships while facilitating new weapon technologies. The document advocates designing propulsion and power around modern arrangements with margins for technology insertion and system growth over a ship's lifespan.