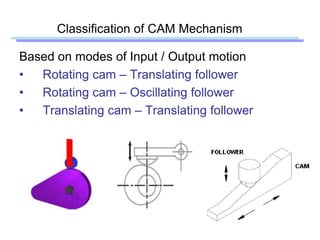

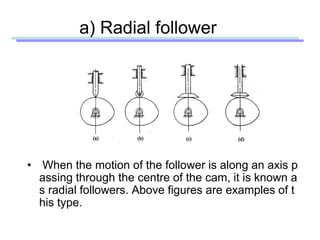

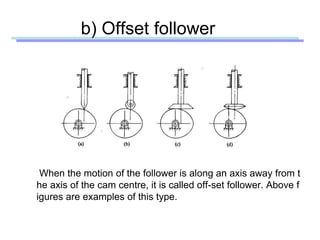

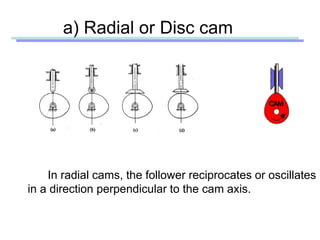

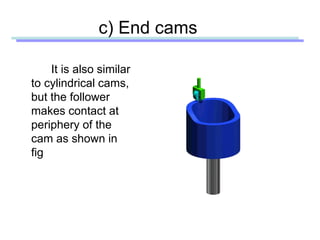

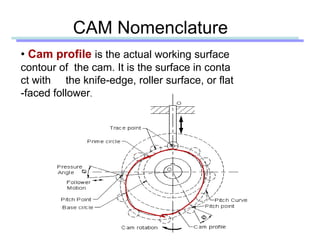

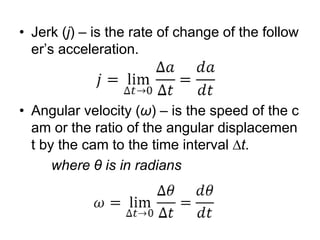

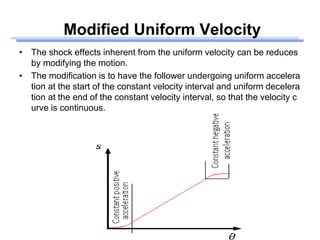

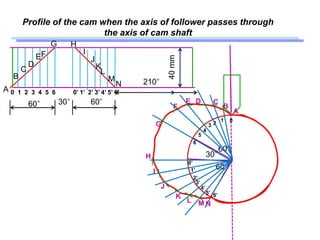

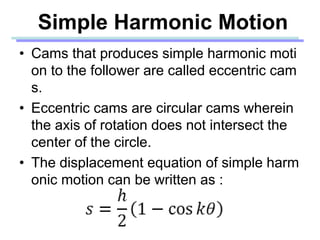

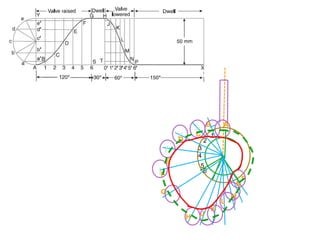

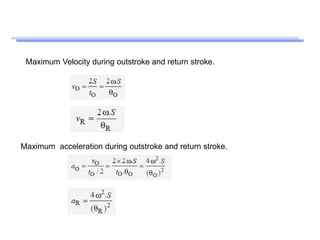

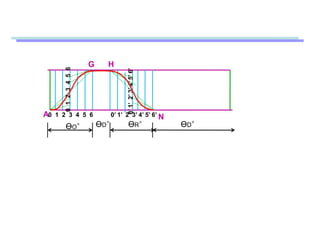

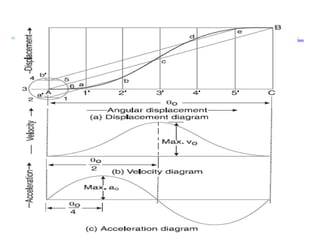

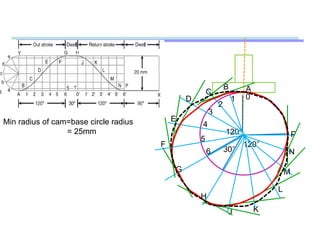

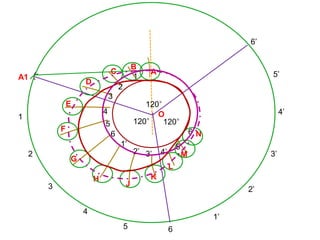

The document provides an in-depth analysis of the kinematics of cam mechanisms, detailing the definitions, classifications, and applications of cams and followers in mechanical systems. It explores the evolution of cam designs, the basic principles of cam movement, types of cam profiles, and the kinematic terminology used in cam and follower motion. Additionally, it includes examples of cam applications, particularly in engine components, and outlines the mathematical relationships governing follower motion and acceleration.