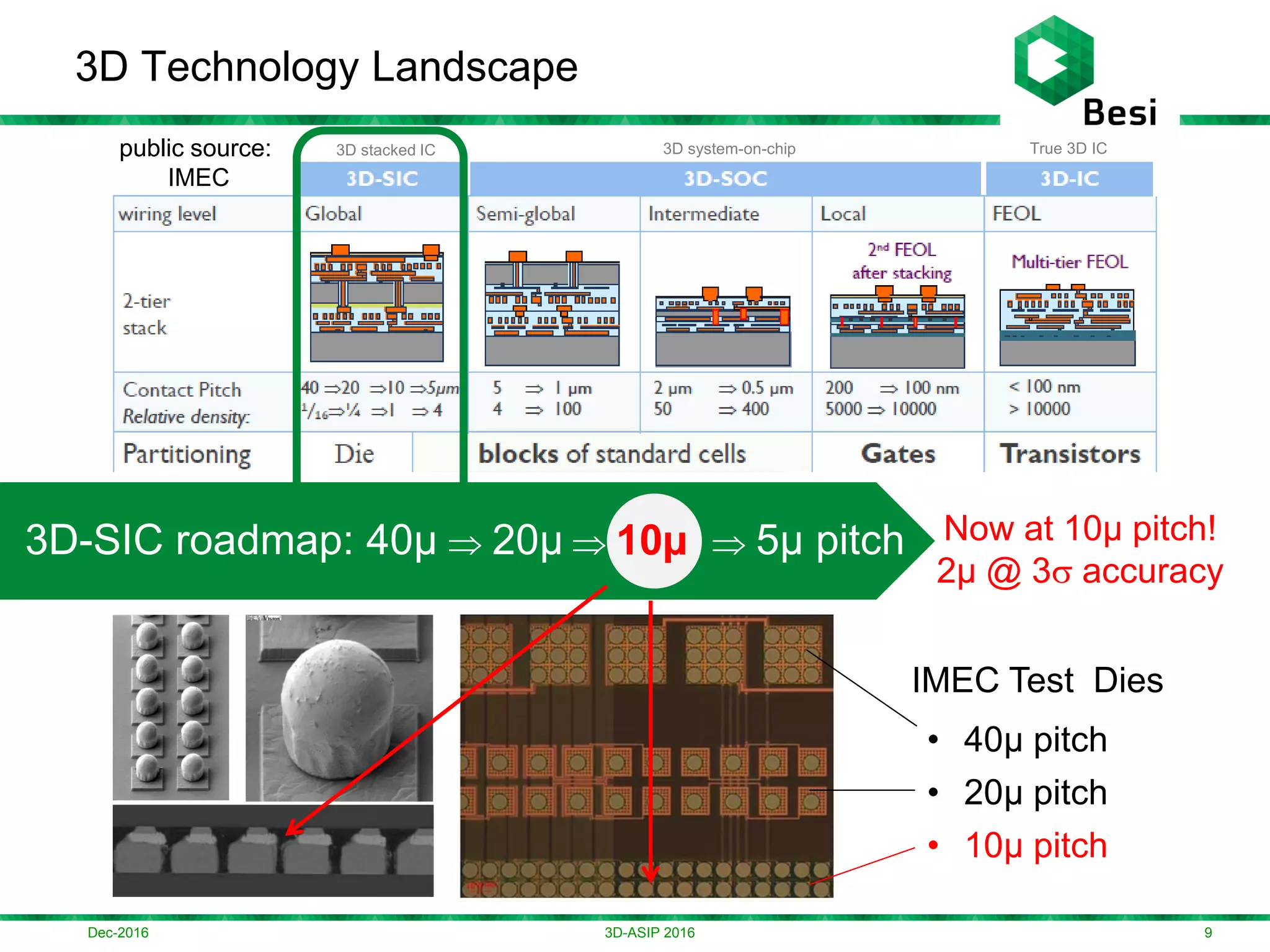

This document summarizes key aspects of thermo compression bonding (TCB) technology from the perspective of a machine vendor. It discusses three core TCB capabilities that are essential for high yield: accuracy, co-planarity, and sophisticated bond control. Maintaining high accuracy during temperature ramping from cold to hot states is critical. Co-planarity must also be maintained during temperature ramping to avoid yield issues. Sophisticated hybrid bond control, as used in the TC-CUF process, tightly controls bond line thickness despite thermal expansion movements.

![0 100 200 300 400 500 600 700 800 900

-2.5

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

2.5

x[µ],y[µ]

@4305.77.Speck Challenge (17:04:43) [stream]: mean = 0.17/0.02, sigma = 0.16/0.12 @ x/y [µ/µ]

Cpk = 3.88/5.57, Cp = 4.24/5.62 @ x/y [2µ/2µ]

Dec-2016

A Closer Look at the Data

193D-ASIP 2016

2µ @ 7

required

Single position GoG application

cold (20°C), low force (30N)

2µ @ 11 sigma

achieved!

(+/- 0.55µ)

Matrix GoG application

hot (380°C), high force (250N)

0 200 400 600 800 1000 1200

-2.5

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

2.5

x[µ],y[µ]

Matrix GoG, T: 100->380°C, 30N [stream]: mean = 0.17/-0, sigma = 0.4/0.4 @ x/y [µ/µ]

Cpk = 1.53/1.68, Cp = 1.67/1.68 @ x/y [2µ/2µ]

2µ @ 4

required

2µ @ 5 sigma

achieved!

(+/- 1.2µ)](https://image.slidesharecdn.com/f0e7e5aa-3ebe-4489-8c30-bc7b0c876c25-161215140611/75/Some-Essentials-of-TCB-19-2048.jpg)

![Accuracy – Essential !

213D-ASIP 2016

Essential - Accuracy

Maintain position accuracy while

ramping from cold to hot state

Dec-2016

single position GoG application

hot (380°C), low force (30N)

2µ @ 5

required weird

behavior !!!

1000 1500 2000 2500 3000 3500 4000 4500

-10

-8

-6

-4

-2

0

2

4

6

8

10

@4305.84.BMC_Test_left_heated_tool_hot (13:51:51)

time

x[µ],y[µ]

Potential Issue

Or: bring accuracy

from bond head down to die

80°C

80°C

80°C->380°C](https://image.slidesharecdn.com/f0e7e5aa-3ebe-4489-8c30-bc7b0c876c25-161215140611/75/Some-Essentials-of-TCB-21-2048.jpg)

,T/10[°C](temp.-red),w[µ](pos.-green)

(C) Time t [s] - (selection by: tasks: All Tasks, types: * gantry: L layer: 0)

100

150

200

250

300

Test:

Run 40 repeatable

temperature ramps

from 80°C to 300°C

0 1 2 3 4 5 6 7 8

-4

-2

0

2

4

6

Residues: kinematic: std = NaNµ (Cpk = NaN), thermal: std = 0.69µ (Cpk = 0.48)

#2.56 Tilt 119G-05 (2015-01-29)

-40

-20

0

20

40

60

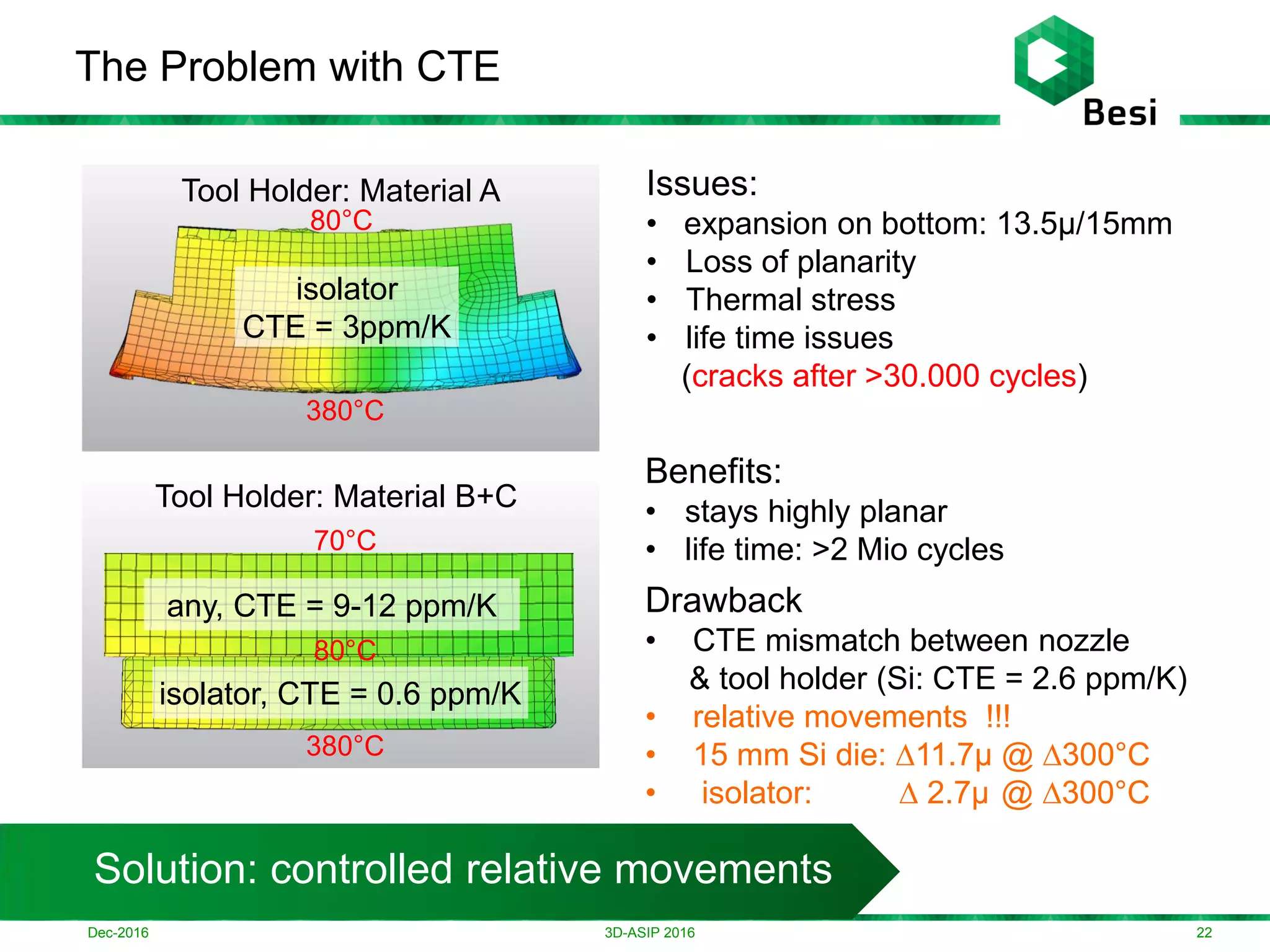

Improper Co-planarity Integrity

Position traces of

4 die corners

Residual analysis out of spec

0 1 2 3 4 5 6 7 8

-4

-2

0

2

4

6

Residues: kinematic: std = 0.03µ (Cpk = 12.29), thermal: std = 0.09µ (Cpk = 3.8)

#2.56 Tilt 119G-05 (2015-01-29)

-40

-20

0

20

40

60

Proper Co-planarity Integrity

Position traces of

4 die corners

Residual analysis in spec +/-1µ

Essential:

Coplanarity Integrity

„Maintain co-planarity during

temperature ramp!“](https://image.slidesharecdn.com/f0e7e5aa-3ebe-4489-8c30-bc7b0c876c25-161215140611/75/Some-Essentials-of-TCB-27-2048.jpg)

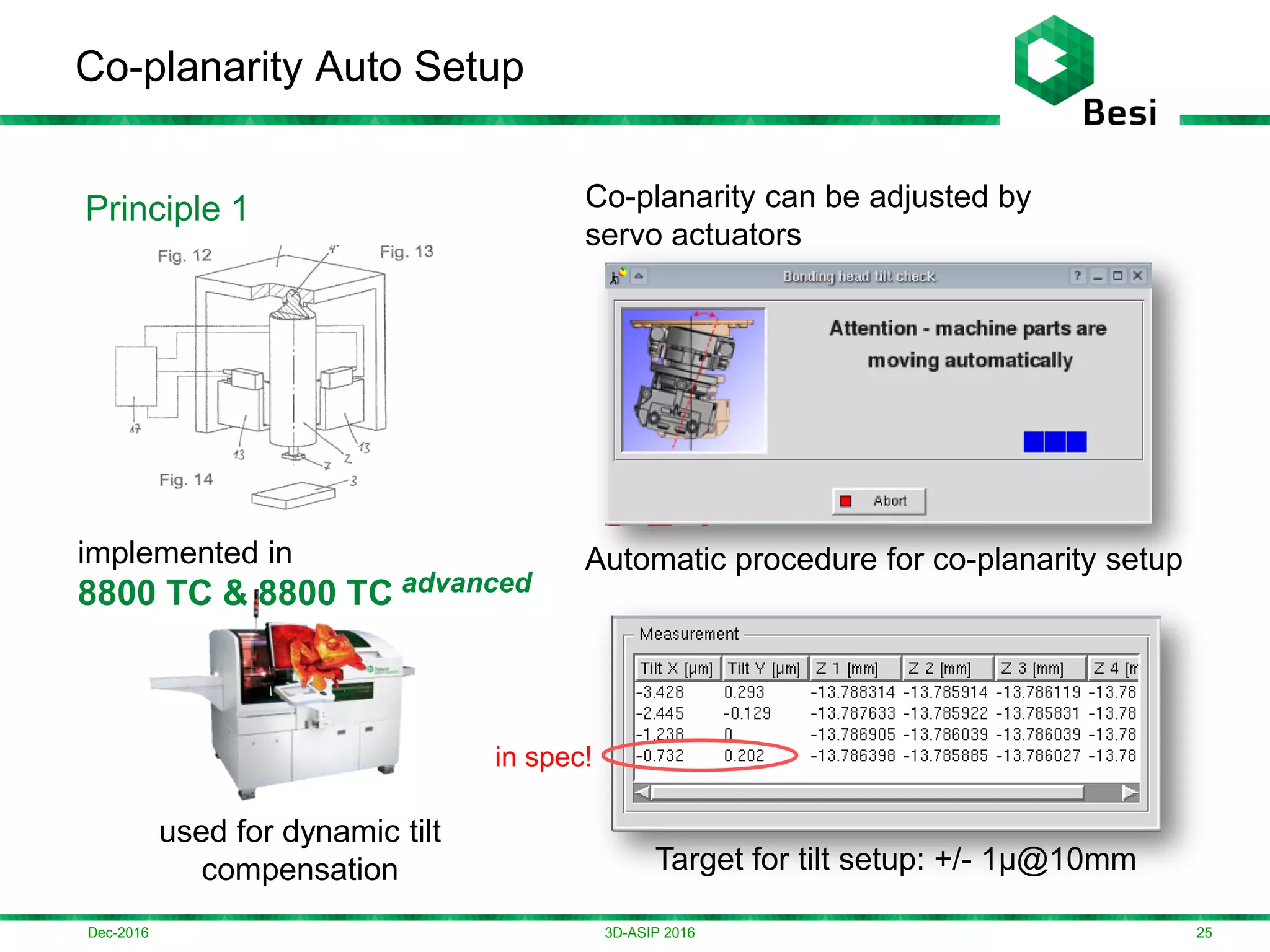

![Dec-2016

Bond Control for TC-CUF Process

303D-ASIP 2016

z (position)

T (temperature)

F (force)

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

-20

-10

0

10

20

30

40

50

-200

-100

0

100

200

300

400

500

Temperature[°C]

Bond Control for CUF Process

Force[N],Position[µm]

time [s]

high temperature

ramping rate

200°C/s

dynamic

z-control

during collapse

thermal

compensation

rapid cooling

-100°C/s

• Challenge 1: How do you teach the position control?

• Challenge 2: How do you move from one tool to another?

T (temperature)

F (force)

z (position)

position control.

force

control](https://image.slidesharecdn.com/f0e7e5aa-3ebe-4489-8c30-bc7b0c876c25-161215140611/75/Some-Essentials-of-TCB-30-2048.jpg)

![Dec-2016

Enhanced Bond Control for TC-CUF Process

313D-ASIP 2016

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

-20

-10

0

10

20

30

40

50

-200

-100

0

100

200

300

400

500

Temperature[°C]

Enhanced Bond Control for CUF Process

Force[N],Position[µm]

time [s]

• By distributing bond control over two position axes the

complexity of the bond control is reduced

w (position)

T (temperature)

F (force)

z (position)

thermal

compensation

@ z-position-axis

w-position axis

used for

BLT control

-7µ@2s

responsibility of

process engineer

kinematic

compensation position control.

force

control](https://image.slidesharecdn.com/f0e7e5aa-3ebe-4489-8c30-bc7b0c876c25-161215140611/75/Some-Essentials-of-TCB-31-2048.jpg)

![Dec-2016

1) Start with Force Ramp

323D-ASIP 2016

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

-20

-10

0

10

20

30

40

50

-200

-100

0

100

200

300

400

500

Temperature[°C]

Enhanced Bond Control for CUF Process

Force[N],Position[µm]

time [s]

w (position)

T (temperature)

z (position)

start with

force ramping

-7µ@2s

responsibility of

process engineer

bond head position (w)

reacts with elastic movement)

F (force)](https://image.slidesharecdn.com/f0e7e5aa-3ebe-4489-8c30-bc7b0c876c25-161215140611/75/Some-Essentials-of-TCB-32-2048.jpg)

![0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

-20

-10

0

10

20

30

40

50

-200

-100

0

100

200

300

400

500

Temperature[°C]

Enhanced Bond Control for CUF Process

Force[N],Position[µm]

time [s]

Dec-2016

2) Start Temperature Ramping

333D-ASIP 2016

w (position)

T (temperature)

z (position)

-7µ@2s

responsibility of

process engineer

start

temperature

ramping

bond head position (z)

will start moving due to

thermal expansion

Shortly before liquification:

switch from force to position

control (to be prepared for the

soon following force collapse)

hold force

start your compensation for

the thermal expansion](https://image.slidesharecdn.com/f0e7e5aa-3ebe-4489-8c30-bc7b0c876c25-161215140611/75/Some-Essentials-of-TCB-33-2048.jpg)

![0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

-20

-10

0

10

20

30

40

50

-200

-100

0

100

200

300

400

500

Temperature[°C]

Enhanced Bond Control for CUF Process

Force[N],Position[µm]

time [s]

Dec-2016

3) Liquification Phase: Hurry up!

343D-ASIP 2016

w (position)

T (temperature)

z (position)

-7µ@2s

responsibility of

process engineer

temperature

exceeds

liquification

threshold

Liquification:

the bump gets

liquid and the

force breaks

down

Luckily you are already in

position mode and you can

control bond head position

for whatever you want!

Hurry up and raise the bond

head position, since by collapse

of the force your compressed

elasticities relax at sudden

don‘t forget: your materials

are thermally expanding!

Compensate with porper

bond head raise movement!

solder climbing

squish

otherwise you get these

nasty results](https://image.slidesharecdn.com/f0e7e5aa-3ebe-4489-8c30-bc7b0c876c25-161215140611/75/Some-Essentials-of-TCB-34-2048.jpg)

![0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

-20

-10

0

10

20

30

40

50

-200

-100

0

100

200

300

400

500

Temperature[°C]

Enhanced Bond Control for CUF Process

Force[N],Position[µm]

time [s]

Dec-2016

4) Relax – Solder Joint Formation

353D-ASIP 2016

w (position)

T (temperature)

z (position)

-7µ@2s

Relax!

Adjust bond head position to

form final solder joint height

and never forget:

your materials are still

thermally expanding!

Compensate with porper

bond head raise movement!

responsibility of

process engineer

temperature

is still in a

transient

phase](https://image.slidesharecdn.com/f0e7e5aa-3ebe-4489-8c30-bc7b0c876c25-161215140611/75/Some-Essentials-of-TCB-35-2048.jpg)

![0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

-20

-10

0

10

20

30

40

50

-200

-100

0

100

200

300

400

500

Temperature[°C]

Enhanced Bond Control for CUF Process

Force[N],Position[µm]

time [s]

Dec-2016

5) Bring to the End

363D-ASIP 2016

w (position)

T (temperature)

z (position)

-7µ@2s

Hold your solder joint thickness!

Especially during solidification

phase, otherwise you will

impact your solder joint strength

And never forget:

your materials are still

thermally expanding, later

on shrinking!

Compensate with porper

bond head movement!

run the rest of

your thermal profile.

solder joints are still

liquid until

solidification](https://image.slidesharecdn.com/f0e7e5aa-3ebe-4489-8c30-bc7b0c876c25-161215140611/75/Some-Essentials-of-TCB-36-2048.jpg)