Binder jet 3D printing is an additive manufacturing process that applies a liquid binder to layers of powder to create parts and tooling, which can include metals and ceramics. It offers advantages like compatibility with various powdered materials and larger build volumes, but also faces challenges such as the need for post-processing and lower relative density compared to other methods. The process involves multiple steps including printing, curing, depowdering, and densification, often requiring careful handling to achieve desired mechanical properties and surface finishes.

![ADVANTAGES OF BINDER JETTING

• 1. Unlike PBF technologies, binder jetting is compatible with virtually any powdered material, and because numerous powdered

• metals and ceramics are sintered to full density in many current industries, binder jetting has a real potential to surpass PBF and

• have the widest selection of materials of all AM processes [53].

• 2. Another merit of binder jetting compared with other AM methods is that the shaping process occurs at room temperature and

• atmosphere, avoiding issues related to oxidation, residual stress, elemental segregation, and phase changes, making the powder

• around the parts in the build box (the area where the powder bed is ready for printing) highly recyclable. Furthermore, by avoiding

• the use of expensive sealed chambers for vacuum or inerting, the build volume of binder jetting machines is among the largest

• compared with all AM technologies (up to 2200 × 1200 × 600 mm) while still maintaining the high resolution afforded by inkjet.

• Important features of AM processes are the maximum size and complexity of the produced parts, production times, and part

• qualities such as dimensional accuracy and defects of the final product.

• 3. In fusion-based AM, support material must be produced alongside the part and attached to a build plate for stability during

printing

• and therefore requires more time and material than in binder jetting, where the part is supported by loose powder in the job box.

• Additionally, no support structure is required for any part geometry produced by BJ3DP during printing, whereas other AM

• methods ultimately need support structures for overhanging features](https://image.slidesharecdn.com/binderjet3dprinting-240924023523-070c3abf/85/BINDER-JET-3D-PRINTINGmanufacturing-technology-pptx-6-320.jpg)

![BINDER 3D JET PRINTING

• A 3D model is required using a designed, modeled, or scanned 3D model attained from an actual

specimen. A digital CAD model is obtained and sliced into thin layers and saved as an STL file that can be

used for printing (Fig. 4(A)).

• A thin layer of powder is spread on the build box and a traversing counter-rotating roller spreads and

loosely compacts the new layer of powder.

• A liquid binder (such as polymer in solvent or aqueous solution) is jetted from the printhead onto the

powder layer where the object is to be formed [115]. Binder saturation is calculated based on the

estimated powder bed density and used as an input by the user.

• After the binder is deposited, an electrical heater passes over the powder bed to partially dry/cure the

layer and prepare it for spreading the subsequent layer, which also helps to maintain a uniform

temperature. Curing time after printing of each layer is an important factor in which enough drying time

is required to let binder fully bind with powder to avoid cracking of the powder bed or agglomeration and

sticking of powder on the roller’s surface during printing.](https://image.slidesharecdn.com/binderjet3dprinting-240924023523-070c3abf/85/BINDER-JET-3D-PRINTINGmanufacturing-technology-pptx-10-320.jpg)

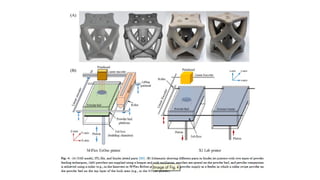

![BINDER 3D JET PRINTING

• • After the binder is deposited and dried, a piston that supports the powder bed lowers the build by the height of

one layer, which

• typically ranges from 50 to 200 μm. The roller spreads powder onto the powder bed from the powder supply. The

powder supply

• can be a gravity-fed hopper-style bin and in some cases, feed is induced by exciting the powder through the bin for

powders with

• undesirably flow characteristics [116]. Once the powder is deposited onto the surface, a recoater, which typically is

in the form of

• an oscillating or rotating bar, spreads the powder over the surface and/or smooths and lightly compacts the

powder in the case of a roller [117]. Schematics of two types of binder jet 3D printers are shown in Fig. 4(B).

• As in PBF, a powder layer is spread by mechanisms such as a blade, comb, or roller. However, with binder jetting, a

counter-rotating roller is almost exclusively used to the roller’s ability to encourage powder flowability. With PBF,

the welding of the metal powder bed can create solid raised features in the bed, which would collide with a roller

and cause damage to either the roller or print or both.

• Thus, by using a counter-rotating roller, binder jetting can spread a wider variety of powder shapes and sizes than

most PBF technologies.](https://image.slidesharecdn.com/binderjet3dprinting-240924023523-070c3abf/85/BINDER-JET-3D-PRINTINGmanufacturing-technology-pptx-11-320.jpg)

![BINDER 3D JET PRINTING

• (ii) Curing and depowdering –

• Once the printing step is complete, some binder jet technologies require a post-cure to dry the binder and give the printed

powder its green strength. To do this curing, the bed is removed from the printer and heated until the binder is adequately

dried and resulting green shapes can be manually removed from the powder bed (although the curing step requires little

operator involvement, it is still an extra step in the process that manufacturers are working to avoid in the future).

Commonly, the build box that contains the powder bed and printed parts are moved to an oven for curing by heating to

180 to 200 ◦C for a prescribed number of hours based on the build box volume and binder characteristics [118]. Watters et

al. proposed a curing protocol including vacuum, heat, visible light, and pressure for improved strength of binder jet 3D

printed parts [119].

• After curing, the green parts have enough strength to be handled and moved to the densification furnace. At this step, the

loose powder in the build box is removed via a vacuum and careful, manual brushing by an operator. The individual parts

are further cleaned, typically by hand, using a brush from the surface of the parts or gently vacuumed/air-blasted, for parts

with internal details.

• For printed parts with small features and overhanging structures, significant attention is required to prevent breaking the

parts. The loosely bound, green metal powder parts that result from the binder jet print process are then densified either

by sintering to full density or infiltration with another material to achieve full density and desirable mechanical properties](https://image.slidesharecdn.com/binderjet3dprinting-240924023523-070c3abf/85/BINDER-JET-3D-PRINTINGmanufacturing-technology-pptx-12-320.jpg)

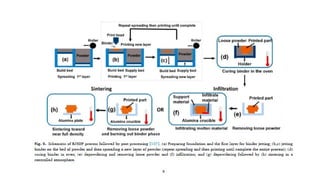

![BINDER 3D JET PRINTING

(iii) Sintering and/or infiltration –

• After curing and depowdering, the relative density of the green part is typically in the range of 50 to 60%. If viewed with a microscope,

the individual powder particles could be observed and simply bound together with polymer at thecontact points of the particles. To

achieve desired density and perhaps target mechanical properties, further densification can beachieved with various methods such as

infiltration (see Fig. 5 path #1 after curing step (d)) [120] or sintering (see Fig. 5 path #2 aftercuring step (d)) [115,121], (see Fig. 5).

• Regardless of the densification method chosen, a burnout step is needed at ~600 to 700 ◦C to fully pyrolyze the binder before sintering

or infiltration can occur. In determining the proper post-processing cycle, factors to consider include material composition, powder size,

sintering atmosphere, temperature, and holding time [122]. Because every material has specific sintering characteristics, controlling

sintering using sintering aids, mixed powder with various powder sizes, and coated particles is sometimes practical [123,124].

• Densification strategies are different for ceramics, metals, and polymers [125,126]. Because ceramics have significantly higher sintering

temperatures and lower potential for densification compared with metal powders, infiltrating ceramics with metals is a common

strategy for densification of binder jetted ceramics. In contrast, polymers have low melting temperatures and densification occurs using

polymerization after printing each layer.

• Certain design factors to must be considered at this stage of consolidating the printed part. A part being able to meet certain

• tolerances and dimensions after undergoing densification is not an insignificant challenge for some materials and processes.

Infiltration, for instance, usually produces highly accurate features, whereas sintering of single alloys to full density results in highly

warped geometries. Design considerations such as section size are important to consider and will determine whether bind can be

effectively removed and not left in the part. Similarly, gravity tends to affect slumping in the sintering step, so orientation of the part

requires consideration](https://image.slidesharecdn.com/binderjet3dprinting-240924023523-070c3abf/85/BINDER-JET-3D-PRINTINGmanufacturing-technology-pptx-14-320.jpg)

![BINDER 3D JET PRINTING

(iv) Finishing

• The average roughness of binder jetted parts has traditionally been around 6 μm (Ra) after sintering, and postprocessing to

improve surface finish is a common practice [17]. The most common techniques for improving surface finish arebead

blasting and tumble polishing; however, plating, machining [128], extrude-honing [129], surface infiltration [130], and

handpolishingare used, as well. Bead blasting can reduce the surface roughness to a max of 7.4 μm, whereas tumble

polishing can result inthe average roughness of 1.25 μm [17,40].

• For all powder bed processes, the particle size and layer thickness used in printing directly affect the surface finish of the

final part (e.g., coarser powders and thicker layers produce rougher surfaces than finer powders and thinner layers).

However, the drawback offiner powders is that they are less flowable in powder hopper systems and can be more difficult

to spread during the creation of the layer.

• Thicker layers take less time to print, which directly influences the economics of the process. Challenges in spreadability

can result in inconsistent deposition in the powder bed and, therefore, nonuniform density throughout.

• Industries familiar with MIM are familiar with fine powders (i.e., <30 mm) but increasingly, other industries are examining

larger powders and thicker layers to meetbusiness objectives [131].](https://image.slidesharecdn.com/binderjet3dprinting-240924023523-070c3abf/85/BINDER-JET-3D-PRINTINGmanufacturing-technology-pptx-15-320.jpg)