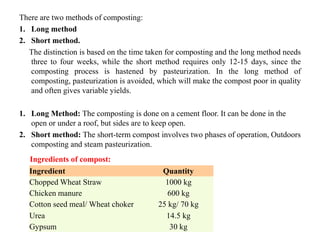

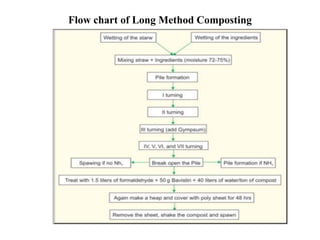

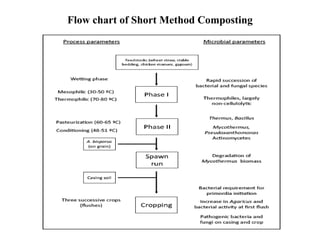

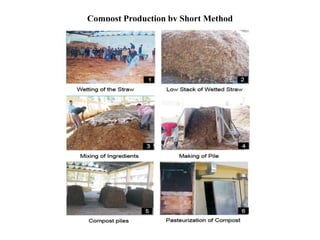

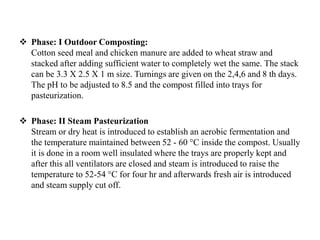

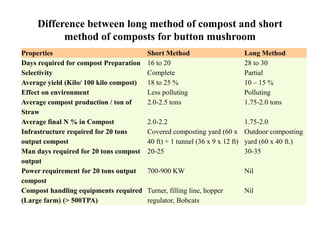

The document discusses methods for compost preparation in the cultivation of white button mushrooms. There are two main methods - the long method and the short method. The long method takes 3-4 weeks without pasteurization, resulting in lower quality compost and variable yields. The short method has two phases - outdoor composting for 12-15 days including turnings, followed by steam pasteurization to raise the temperature to 52-54°C for 4 hours to establish aerobic fermentation. The short method compost takes less time, results in higher and more consistent yields, and is less polluting than the long method.