Machine Design Board Review part1.pdf

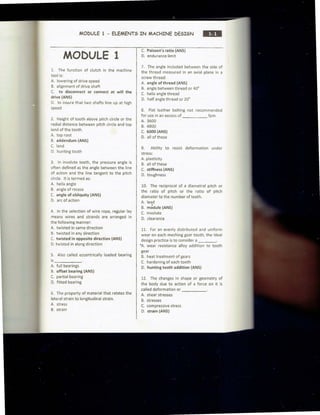

- 1. MODULE 1 - ELEMENTS IN MACHINE DESIGN ••• MODULE 1 1. The function of clutch in the machine tool is: A. lowering of drive speed B. alignment of drive shaft C. to disconnect or connect at will the drive (ANS) D. to insure that two shafts line up at high speed 2. Height of tooth above pitch circle or the radial distance between pitch circle and top land of the tooth. A. top root B. addendum {ANS) C. land D. hunting tooth 3. In involute teeth, the pressure angle is often defined as the angle between the line of action and the line tangent to the pitch circle. It is termed as: A. helix angle B. angle of recess C. angle of obliquity {ANS) D. arc of action 4. In the selection of wire rope, regular lay means wires and strands are arranged in the following manner: A. twisted in same direction B. twisted in any direction C. twisted in opposite direction (ANS) D. twisted in along direction 5. Also called eccentrically loaded bearing is ___ _ _ A. full bearings B. offset bearing (ANS) C. partial bearing D. fitted bearing 6. The property of material that relates the lateral strain to longitudinal strain. A. stress B. strain C. Poisson's ratio (ANS) D. endurance limit 7. The angle included between the side of the thread measured in an axial plane in a screw thread: A. angle of thread (ANS) B. angle between thread or 40" C. helix angle thread D. half angle thread or 20° 8. Flat leather belting not recommended for use in an excess of fpm. A. 3600 B. 4800 C. 6000 (ANS) D. all of these 9. Ability to resist deformation under stress: A. plasticity B. all of these C. stiffness (ANS) D. toughness 10. The reciprocal of a diametral pitch or the ratio of pitch or the ratio of pitch diameter to the number of teeth. A. lead B. m~dule (ANS) C. involute D. clearance 11. For an evenly distributed and uniform wear on each meshing gear tooth, the ideal design practice is to consider a ____ 'A. wear resistance alloy addition to tooth gear B. heat treatment of gears C. hardening of each tooth D. hunting tooth addition (ANS) 12. The changes in shape or geometry of the body due to action of a force on it is called deformation or _ ____ A. shear stresses B. stresses C. compressive stress D. strain (ANS)

- 2. ORDILLO '° for high speed ,·mum number of uld be: e ratio of pitch - mber of teeth: n of the profile rn of the tooth • which is equa endum: dent of loaos . ouiry mo· C" ·: MODULE 1 - ELEMENTS IN MACHINE DESIGN ••• C. 5 times D. 6 times 27. The motion of an object diminished/decreased speed: A. deceleration B. all of the above C. retarded motion (ANS) D. negative impulse 28. Most popular soldering material: A. 10/80 B. 45/ 55 C. 50/50 (ANS) D. 60/40 29. The following pertain to joining of metals except: A. welding B. soldering C. casting (ANS) D. brazing 30. Killed steel is always associated with: A. silicon (ANS) B. manganese C. phosphorous 0. sulfur 31. The usual ratio of water to soluble oil used as cutting fluid: A. 50% water to 500A. oil B. 2 water to 1 oil C. 3 water to 1 oil D. 4 to 80 water to 1 oil (ANS) 32. The good deoxidizer in steel melting: A. manganese B. silicon C. all of these (ANS) D. aluminum 33. Good stabilizer in stainless steel: A. columbium B. titanium C. all of these (ANS) D. tantalium 34. What is/are the common cutting fluids used for cutting metals? A. all of these (ANS) B. water with soda or borax C. light mineral oil D. soluble oil 35. It is considered semi-solid lubricant: A. all of these B. lube oil C. graphite D. grease (ANS) 36. Metals are conductive because: A. the electrons are loosely bound to the nuclei and therefore mobile (ANS) B. having a characteristics metallic luster C. they are on the left side of the periodic table D. they have extra electrons as exhibited by normally possible balance state 37. The purpose of these parts in application are to have better bearings to seal the guard against marring, etc. A. bearing journal B. metallic seal C. washer (ANS) D. shaft seal 38. The yield strength of a regular yellow brass (65 to 70% Cu, 30 to 35% Zn) can ··be increased/improved by: A. cold working (ANS) B. tempering C. chill casting D. heat treatment 39. Used in as cast condition steel casting with carbon content less than % C. A. 0.26 B. 0.15 to 0.18 C. 0.20 (ANS) D. 0.25 40. Liners normally are made of: A. cast iron (ANS) B. alloyed bronze C. alloyed steel D. alloyed aluminum

- 3. ••• MACHINE DESIGN REVIEWER BY J AS TORDILLO 13. Could be defined as simply push or pull. A. work B. force (ANS) C. inertia D. power 14. The differential of the shear equation is which one of the following: A. bending moment of the beam B. tensile strength of the beam C. slope of the elastic curve D. load of the beam (ANS) lS. Gear used to transmit power at high velocity ratios between non-intersecting shafts that are usually but not necessarily at right angle. A. helical gear B. bevel gear C. worm gear (ANS) D. spiral gear 16. The ratio of the moment of inertia of the cross section of the beam to the section modulus: A. equal to the radius of gyration B. equal to the area of the cross section C. measure of a distance (ANS) D. dependent on the modulus of elasticity of beam measure 17. Opposite direction parallel forces: A. concurrent B. coplanar C. couple (ANS) D. non-coplanar 18. Which of the following is the structural class of steel? A. high speed steel B. tool and die (ANS) C. low carbon D. high carbon 19. Continuous stretching under load even if the stress is less than the yield point: A. plasticity B. elasticity C. creep (ANS) 0. ductility 20. It is recommended for high speed application that the minimum number of teeth in small sprocket should be: A. 26 to 30 B. 12 to16 C. 26 to 28 D. 18 to 24 (ANS) 21. In gear design, the ratio of pitch diameter in inches to the number of teeth: A. module B. diametral pitch C. English module (ANS) D. circular 22. The concave portion of the profile where it joins the bottom of the tooth space: A. fillet curve (ANS) B. fillet radius C. bottom curve o. fillet 23. The distance of the tooth which is equal to the addendum and dedendum: A. full B. whole depth (ANS) C. working depth D. dedendum 24. Stresses that are independent of loads: A. working stress B. operating stress C. residual stress (ANS) D. shear stress 25. It is used to change rotary motion to reciprocating motion: A. helical gear B. rack gear (ANS) C. worm gear D. spur gear 26. it is recommended not to have a direct drive and sprockets if the ratio of their teeth exceeds use two or more step combination. A. lOtimes B. 8 times (ANS) MODULE 1 - E C. S times D. 6 times 27. The motion of an diminished/decreased speed: A. deceleration B. all of the above C. retarded motion (ANS) 0. negative impulse 28: Most popular soldering materi< A. 10/80 B. 45/55 C. 50/50 (ANS) 0. 60/40 29. The following pertain to j< metals except: A. welding B. soldering C. casting (ANS) D. brazing 30. Killed steel is always associate1 A. silicon (ANS) B. manganese C. phosphorous 0. sulfur 31. The usual ratio of water to s.i used as cutting fluid: A. 50% water to 50% oil 8. 2 water to 1 oil C. 3 water to 1 oil D. 4 to 80 water to 1 oil (ANS) 32. The good deoxidizer in steel m1 A. manganese B. silicon C. all of these (ANS) D. aluminum 33. Good stabilizer in stainless ste A. columbium B. titanium C. all of these (ANS) 0. tantalium 34. What is/are the common cut1 used for cutting metals?

- 4. ••• MACHINE DESIGN REVIEWER BY J AS TORDILLO 41. Endurance strength is nearly proportional to the ultimate strength but not with ______ A. yield strength (ANS) B. design stress C. shear stress D. all of the above 42. A furnace used in melting non-ferrous metals: A. cupola furnace B. crucible furnace C. induction furnace (ANS) D. normalizing furnace 43. Alloy that improves strength of steel at high temperature application: A. tungsten B. molybdenum C. all of these (ANS) D. chromium 44. In a gear design, the total work load must be equally shared by its arms. Rim must be rigid to support these arms and also the bead is recommended for its stiffening value. The assumption in the detailed design of rim thickness and depth of bead is ___ circular pitch. A. 0.65 B. 0.50 C. 0.56 (ANS) D. 0.44 45. Tooth width measured along the chord at the pitch circle: A. flank B. face width C. width of space D. chordal thickness {ANS) 46. The best instrument for measuring a thousand of an inch: A. Micrometer (ANS) B. Tachometer C. Caliper D. Pyrometer 47. All are associated with standard material specification, EXCEPT: A. American Iron and Steel Institute B. Society of Automotive Engineers C. Southeast Asia Iron and Steel Institute (ANS) D. American Society for Testing Materials 48. The allowable stresses that are generally used in practice are 4 ksi for main power transmitting shaft, 6 ksi for lineshaft carrying pulleys and 8.5 ksi for small, short shaft/countershaft, etc. With these allowable stresses what will be simplified formula to determine transmitted HP diameter of the shaft or even the rpm(N)? A. HP =D 3 N/80 B. HP = D 3 N/53.S C. all of these (ANS) D. HP = D 3 N/38 49. Machine tool used for laying straight lines on metal surfaces made of sharp tool steel is called: A. plain scriber (ANS) B. a trammel C. hermaphrodite D. divider SO. It is the difference of addendum and dedendum which is equivalent to the whole depth less working depth. A. fillet space B. fillet radius C. clearance (ANS) D. backlash 51. A lathe machine threading mechanism: A. reverse gear and lever B. spindle gear (ANS) C. all of these D. change stud gear 52. Separate forces which can be so combined are called: A. non-concurrent forces B. couple C. combined forces D. concurrent forces (ANS) MODULE 1 53. That property of matter w resist any change in its motit est: - brake :; friction :. inertia (ANS) ;J. impulse 54. Negative allowance is also 1 ~ interference of metal (ANS) 3 clearance :::.. advance :J. allowance of positive fit 55. Which of the following is ·esemble the shape of tool bit? "'" round nose 6. center cut (ANS) C square nose 9. thread cutting 56. A kind of thread in which he thread is approximately e depth of the thread and the sp; threads are approximately equa A. square thread (ANS) B. acme thread C. buttress thread D. whitworth thread 57. A shaft is to be c concentricity. A suitable performing the check is: A. bench centers and dial indic B. bench bottom and caliper C. bench top and tachometer D. bench vise and planer 58. For moderate speed of m the ideal ratio of contact is: A. 1.25 - 4 {ANS) B. 1.2 -1.45 c. 1.0-1.3 D. 1.35 -1.45 59. Nominal diameter of bolts i! A. major diameter (ANS) B. minor diameter C. mean diameter D. average diameter 60. A lathe wit h multiple cuttin!

- 5. TORDILLO 'lStitute ~ gineers d Steel Institute :sting Materials tresses that are are 4 ksi for main 6 ksi for linesha"- ;s or small, shor: With these ,; be simplifiea ansmitted HP en the rpm(N)? r aying straig· : aee of sharp too c' addendum a c ra" to the wh e ea g mechan.s ch can be ~ MODULE 1 - ELEMENTS IN MACHINE DESIGN S3. That property of matter which causes it to resist any change in its motion or state of rest: A. brake B. friction C. inertia (ANS) 0. impulse 54. Negative allowance is also called: A. interference of metal (ANS) B. clearance C. advance 0. allowance of positive fit SS. Which of the following is not used to resemble the shape of tool bit? A. round nose B. center cut (ANS) C. square nose D. thread cutting S6. A kind of thread in which the width of the thread is approximately equal to the depth of the thread and the space between threads are approximately equal. A. square thread (ANS) B. acme thread C. buttress thread D. whitworth thread 57. A shaft is to be checked for concentricity. A suitable method of performing the check is: A. bench centers and dial indicator (ANS) B. bench bottom and caliper C. bench top and tachometer D. bench vise and planer 58. For moderate speed of mating gears, the ideal ratio of contact is: A. 1.25 - 4 (ANS) B. 1.2 -1.4S c. 1.0-1.3 D. 1.35 -1.4S 59. Nominal diameter of bolts is the: A. major diameter (ANS) B. minor diameter C. mean diameter D. average diameter 60. A lathe with multiple cutting stations: A. turret lathe (ANS) B. lathe machine C. milling machine D. grinding machine 61. Major and minor diameters are commonly used in: A. screw thread (ANS) B. bolts C. gear 0. all of these 62. The distance a helical gear or worm would thread along its axis in one revolution if it were free to move axially is called: A. length of action B. line of action C. land D. lead (ANS) 63. Length of contact between two mating parts in a screw and nut threads meas1,1red axially is called: A. arc of contact B. depth of engagement (ANS) C. length of engagement D. axis of contact 64. If the velocity of a mass is the same all the time during which motion takes place is called: A. deceleration B. uniform motion (ANS) C. acceleration D. none of these 65. Device used to measure accurately speed: A. speedometer B. dial indicator C. tachometer (ANS) D. dial gauge 66. When the hole is smaller than the shaft, it will take pressure to put the parts together. The allowance is said to be negative and is termed as: A. negative tolerance B. negative allowance

- 6. RDILLO s.;ally do the e ed and the excessive or e point of c 1 ded by the a (ANS) IS ltant of all time that g is not a 'of. e strain ~strain I limit (ANS) imit e grade of MODULE 1 - ELEMENTS IN MACHINE DESIGN ••• 80. The property of material which relates the lateral strain to the longitudinal strain: A. stress B. strain C. Poisson's ratio {ANS) D. strength 81. The maximum stress to which a material may be subjected before failure occurs: A. ultimate strength B. ultimate stress (ANS) C. endurance limit D. tensile stress 82. Hypoid gear is a special type of gear like: A. worm gear B. spur gear C. herringbone gear D. bevel gear (ANS) 83. Considered a maximum safe center distance of sprockets should be __ pitches. Very long center distance cause catenary tension in the chain. A. 70 B. 80 (ANS) c. 60 D. 50 84. Cold working of steel plates makes the metal: A. tougher B. more ductile C. harder (ANS) D. more malleable 85. Recommended best cutting angle of drill for work on steel or cast iron is ____ degrees. A. 48 B. 63 C. 59 (ANS) D. 50 86. In shear pin or breaking pin design, we may use the data experienced by link-belt for 1/8 inch to 1 pin and the breaking stress is ksi. A. 40 B. 55 C. 50 (ANS) D. 48 87. Deals only with the motion of bodies without reference to the forces that causes them: A. dynamics B. kinetics C. statics D. kinematics (ANS) 88. the property that characterizes a material ability to be drawn into a wire: A. ductility (ANS) B. thermal conductivity C. tensile strength D. endurance limit 89. The three-moment equation may be used to analyze: A. tapered column B. continuous beam (ANS) C. composite beam D. axially end loaded beam 90. What is the common shop practice to prevent solder from running away from its surface to be joined? A. all of these (ANS) B. surround the work with clay C. introduce around the work rolled with cloth D. put asbestos sheeting around the work 91. Non-ferrous filler metal is melted into grooves or as fillet on the mother metal; the base metal is not melted. This commonly used for joining iron based machine parts or in repair works of some materials. It is called: A. spot welding B. braze welding (ANS) C. brazing D. gas welding 92. It is advised that in rubber belts application/mounting, it should have an initial tension of inch/ply.

- 7. ••• MACHINE DESIGN REVIEWER BY JAS TORDILLO C. negative fits D. interference of metal (ANS) 67. When two elastic bodies collide, which of the following laws can be used to solve for the resulting velocity? A. Dalton's law B. Avogradro C. Conservation of energy D. Conservation of momentum and Conservation of energy (ANS) 68. The ability of a metal to be deformed considerably without rupture is called: A. Plasticity (ANS) B. all of these C. Ductility D. Malleability 69. Permanent deformation or strain may occur without fracture: A. malleability B. elasticity C. ductility D. plasticity (ANS) 70. It is the science of motion that can be solved in terms of scalar or vector algebra: A. Kinematics (ANS) B. curvilinear translation C. projectiles D. acceleration 71. A system of forces in space is in equilibrium. If two equal and opposite collinear forces are added, which of the following if any is true? A. equilibrium is destroyed B. equilibrium is maintained (ANS) C. none of these is true D. an unbalance of moment exist 72. Metal that assists lubrication or lubricant itself: A. zinc B. antimony C. Babbitt (ANS) D. lead 73. A mechanism which is usually do the indexing in a machine tool: A. universal chuck B. slotter C. dividing head (ANS) D. indexing 74. It equalizes the energy exerted and the work done thus preventing excessive or sudden changes of speed: A. flywheel B. balance wheel C. all of these (ANS) D. flywheel pulley 75. The smallest area at the point of rupture of a tensile specimen divided by the original area is called: A. percentage elongation B. lzod test C. Charpy test D. Percentage reduction of area (ANS) 76. The product of the resultant of all forces acting on a body and the time that the resultant acts: A. angular impulse B. angular momentum C. linear impulse (ANS) D. linear momentum 77. Which of the following is not a · structural class of steel? A. low carbon steel B. tool and die steel (ANS) C. high chrome alloy steel D. high strength low alloy steel 78. Poisson's ratio is the ratio of: A. shear strain to compressive strain B. elastic limit to compressive strain C. lateral strain to longitudinal limit (ANS) D. elastic limit to proportional limit 79. All are associated with the grade of steel, EXCEPT: A. SAE 43XX B. SAE 13XX C. SAE lOXX D. SAE 74XX (ANS) MODULE 1 - ELEME . The property of material which relat :. e lateral strain to the longitudinal strain "' stress 3. strain :. Poisson's ratio (ANS) ) . strength 31. The maximum stress to whic material may be subjected before fa occurs: "- ultimate strength 3. ultimate stress (ANS) C. endurance limit ;). tensile stress 82. Hypoid gear is a special type of ge ike: A. worm gear B. spur gear C. herringbone gear D. bevel gear (ANS) 83. Considered a maximum safe cen distance of sprockets should be __ pitches. Very long center distance caU! catenary tension in the chain. A. 70 B. 80 (ANS) c. 60 D. 50 84. Cold working of steel plates makes metal: A. tougher B. more ductile C. harder (ANS) D. more malleable 85. Recommended best cutting angle c drill for work on steel or cast iron ____ degrees. A. 48 B. 63 C. 59 (ANS) D. 50 86. In shear pin or breaking pin design, may use the data experienced by link-be for 1/8 inch to 1 pin and the breaking stres is ksi.

- 8. MACHINE DESIGN REVIEWER BY J AS TORDILLO A. 18 to 24 B. 15 to 20 (ANS) c. 12 to 15 0. 10 93. Normal stress relieving temperature for cast steel: A. 200 to 350°F B. 400 to 500, F C. 300 to 400°F 0. 450 to 550°F (ANS) 94. Most effective alloying element for reducing brittleness of steel at very low temperature: A. manganese B. molybdenum C. silicon D. nickel (ANS) 95. Statement that a given body is in static equilibrium means that the body cannot: A. have any type of motion (ANS) B. be acted upon by more than one force C. undergo any displacement D. have any acceleration 96. Ordinary steel begins to lose strength and elasticity significantly at about ___ •F. A. 900-1000 B. 800-900 c. 750 - 850 0. 600- 700 (ANS) 97. Clearance to a new boiler installation to the existing or old plant building should follow a minimum clearance of ___ between top of the boiler proper and the ceiling as stated in the PSME Code. A. 2000 mm (max) B. 1000 mm (max) C. 2130 mm (max) (ANS) 0. 2150 mm (max) 98. For a high corrosion resistant stainless steel, what minimum chromium content is required? A. 8% (ANS) B. 4.3% c. 1.1% 0 . 5.8% 99. V-belts operate efficiently at speed of about: A. 4500 (ANS) B. 4400 c. 4200 0. 3600 100. What type of gear is used for high speed operation? A. helical (ANS) B. spur C. bevel D. worm MODULE 2 - EL MODULE _ 'l a pair of gears, _____ - .a'le perpendicular to the axial pla ".:a"'gent to the pitch surface. prtch :. pitch plane (ANS) - pitch circle ; pitch point The phenomenon of cont stretching under load even if the S' ess than the yield point: elasticity 3. ductility c. plasticity O. creep (ANS) 3. The machinery operation whereb• with the work accurately fastened reciprocating (forward and bad motion and the tool head is stationa11 A. shaping B. planing (ANS) C. turning 0. reaming 4. Finding the resultant of two or forces is called: A. coplanar forces B. non - coplanar C. couple O. composition (ANS) 5. The capacity of metal to withstam without breaking is: A. strength (ANS) B. stress C. elasticity 0. strain 6. Outstanding safety record contri to: A. High productivity and quality of wor B. Outstanding performance that ex reward from management

- 9. DRDILLO a speed of ..sed for high MODULE 2 - ELEMENTS IN MACHINE DESIGN ••• MODULE 2 1. In a pair of gears, is the plane perpendicular to the axial plane and tangent to the pitch surface. A. pitch B. pitch plane (ANS) C. pitch circle 0. pitch point 2. The phenomenon of continuous stretching under load even if the stress is less than the yield point: A. elasticity B. ductility C. plasticity D. creep (ANS) 3. The machinery operation whereby done with the work accurately fastened has a reciprocating (forward and backward) motion and the tool head is stationary. A. shaping B. planing (ANS) C. turning D. reaming 4. Finding the resultant of two or more forces is called: A. coplanar forces B. non - coplanar C. couple D. composition (ANS) 5. The capacity of metal to withstand load without breaking is: A. strength (ANS) B. stress C. elasticity D. strain 6. Outstanding safety record contributes to: A. High productivity and quality of work B. Outstanding performance that expects reward from management C. Confidence in foremen's ability to perform well D. Pride and enthusiasm to one-self (ANS) 7. A type of coupling that allows slight amount of torsional/angular flexibility due to introduction ~ith some elastic material cylindrically wrapped around the bolts in the flange. A. simple elastic bonded coupling B. elastic-material bushed coupling (ANS) C. elastic material bonded coupling D. all of these 8. In a uniformly loaded beam, the maximum vertical shearing force occurs A. at the center B. at the section of maximum moment C. at beam bottom fiber D. at either end support (ANS) 9. Copper and most of Its alloys can be hardened by: A. patenting B. cold working (ANS) C. case hardening D. soaking 10. What happens to a drill if the operating speed is too fast? A. drill will crack B. drill will become overheated and will bend C. drill will become overheated and will be drawn from the steel (ANS) D. drill will become ~ery dull and wear dust 11. Which of the following is not a structural steel class? A. low carbon steel B. stainless steel C. medium carbon steel D. tool and die steel (ANS) 12. The section modulus of a rectangle of base "b" and height "h" about its base is: A. bh 2 /6 (ANS) B. bh 3 /3 c. bh 2 /12

- 10. ••• MACHINE DESIGN REVIEWER BY J AS TORDI LLO D. bh 3 /12 13. A material that should be avoided in constructing wood pattern: A. sap wood (ANS) B. kiln dried wood C. heart wood D. core portion of wood 14. The gradual chemical reaction by other substance such that metal is converted to an oxide or other compounds: A. corrosion (ANS) B. Cheaping C. Rusting D. Weathering 15. The center of gravity of a solid pyramid or cone with a total height of H is: A. X H (ANS) B. 3/5 H C. 1/3 H D. Y, H 16. Which do not belong to foundry or metal casting shop? A. shake-out machine B. molding machine C. coremaking D. forging machine (ANS) 17. What is the property of a material which resists forces acting to pull the material apart? A. shear strength B. tensile strength (ANS) C. torsional strength D. compressive strength 18. The reciprocal of diametral pitch equivalent to the ratio of pitch diameter to the number of teeth: A. lead B. clearance C. module (ANS) D. involute 19. What is the difference between brass and bronze? A. Brass is composed of copper and zinc while bronze is composed of copper and tin (ANS) B. Brass is composed of copper and zinc while bronze is basically copper and tin plus non-ferrous alloy such as manganese aluminum and chromium. C. Bronze is reddish in color while brass is a mixture of copper and antimony D. Bronze is mostly an alloy of copper and tin while brass is a mixture of copper ano antimony. 20. The first derivative with respect to velocity of kinetic energy is: A. power B. energy C. momentum (ANS) D. none of these 21. The arbitrary modification by removing a small portion of a tooth material at the tip of the gear tooth is called: A. tip removal B. tip undercut C. tip relief (ANS) D. pressure angle cut 22. Types of v-belts to use in a driving pulley with speed of 360 rpm and transmitting 5 hp: A. Type Cbelts B. Type B belts (ANS) C. Type A belts D. Type D belts 23. What type of gears that can transmit power at an angle? A. helical gear B. worm gear C. bevel gear (ANS) D. herringbone gear 24. A liquid metal: A. Mercury (ANS) B. Lead C. Zinc D. Aluminum MODULE 2 - E -~- An object thrown upward wil !2rth with the magnitude of thE ~ ocity equal to: zero = one-half of the initial velocity ::. twice the initial velocity ::>. the initial velocity (ANS) :s. Used in conjunction with ciri sectional members to retain oil ar ::lit, foreign particles, moistur :iermit pressure differential exterior and interior of the applie A. Seal (ANS) B. Gasket C. Safety shield D. Packing 27. Commonly used in pa transmission especially when , continuous section is essential speed drives up to 12,000 fpm: A. bevel gear B. herringbone gear (ANS) C. spur gear D. helical gear 28. The hardness of h1 herringbone gear teeth a· treatment is 210 to 300 Brinell for gear and pinion is at: A. 360 Brinell min B. 400 Brinell max C. 340 - 360 normally (ANS) D. all of the above 29. The path of contact in inv where the force/power transmitted. It is a straight im passing through the pitch point ; to the base circle. A. principle reference plane B. pitch point C. front angle D. line of action (ANS) 30. What is the difference shaper and a planer?

- 11. a c .. :: ....s ~s s a ;: :: a - MODULE 2 - ELEMENTS IN MACHINE DESIGN ••• 25. An object thrown upward will return to earth with the magnitude of the terminal velocity equal to: A. zero B. one-half of the initial velocity C. twice the initial velocity D. the initial velocity (ANS) 26. Used in conjunction with circular cross sectional members to retain oil and prevent dirt, foreign particles, moisture and to permit pressure differential between exterior and interior of the applied part: A. Seal (ANS) B. Gasket C. Safety shield D. Packing 27. Commonly used in parallel-shaft transmission especially when a smooth, continuous section is essential as in high speed drives up to 12,000 fpm: A. bevel gear B. herringbone gear (ANS) C. spur gear D. helical gear 28. The hardness of helical and herringbone gear teeth after heat treatment is 210 to 300 Brinell Hardness, for gear and pinion is at: A. 360 Brinell min B. 400 Brinell max C. 340 - 360 normally (ANS) D. all of the above 29. The path of contact in involute gears where the force/power is actually transmitted. It is a straight imaginary line passing through the pitch point and tangent to the base circle. A. principle reference plane B. pitch point C. front angle D. line of action (ANS) 30. What is the difference between a shaper and a planer? A. the tool of the shaper moves while on the planer is stationary (ANS) B. the shaper can perform slotting operation while the planer cannot C. the shaper handles large pieces while the planar handles only small pieces D. the tool of the shaper moves in reciprocating motion while the tool in the planar moves in rotary motion 31. What is the metal characteristics to withstand forces that cause twisting? A. torsional strength (ANS) B. modulus of elasticity C. twisting moment D. elasticity 32. In greater quantity this element is harmful to the ferrous metal: A. Sulfur (ANS) B. Silicon C. Zinc D. Aluminum 33. To prevent leakage in dynamic seal: A. gaskets B. seals C. felts D. packings (ANS) 34. It has molybdenum alloy except: A. SAE 43xx B. SAE 41xx C. SAE 6xxx (ANS) D. SAE 2xxx 35. A type of gear tooth cut inside a cylinder or ring: A. rack gear B. ring gear C. miter gear D. internal gear (ANS) 36. Flexible material used to seal pressurized fluids, normally under dynamic condition: A. nylon B. seal C. teflon

- 12. ••• MACHINE DESIGN REVIEWER BY J AS TORDILLO D. packing (ANS) 37. Cast alloy steel for very high temperature application: A. manganese-nickel steel castings B. high chrome steel casting C. chrome-nickel steel castings (ANS) D. high manganese casting 38. What heat treatment process can cast steel materials of high chrome, high manganese, etc. type of stele be subjected for the purpose of machining process? A. Annealing (ANS) B. Tempering C. Normalizing D. Quenching 39. Galvanized steel plate is a plate coated with: . A. Aluminum B. nn C. Zinc (ANS) 0. Manganese 40. Major component of bronze casting: A. Copper (ANS) B. Manganese C. Zinc 0. Lead 41. Split pulley or pulley made of separate sections bolted together at the rim, the maximum speed should be limited to about % of the maximum speed of solid pulley. A. 65 to 75% B. 45 to 50% C. SS to 60% (ANS) 0. 80to 90% 42. Fillet radius in machine parts is usually introduced to: A. improve the look of the parts B. reduce concentration of stress and extend life of the parts (ANS) C. to avoid obstruction D. necessary to lessen casting weights 43. Type of bolt commonly used in the construction that is threaded in both ends: A. stud bolts (ANS) B. acme threaded bolts C. square threaded bolts D. hex bolts 44. Heating of the metal to a temperature above the critical temperature and then cooling slowly usually in the furnace to reduce the hardness and improve the machinability is called: A. Annealing (ANS) B. Tempering C. Normalizing 0. Quenching 45. A hydrostatic bearing is one which: A. the lube oil Is supplied under pressure (ANS) B. lube oil is not pressurized C. there is no lube oil 0. bearing is lightly loaded 46. One of the following materials is unsuitable as a bearing: A.Teflon B. Low carbon steel (ANS) C. Cast iron D. Nylon 47. Safety features that must be placed and maintained at machine, blacksmith, welding and foundry shop: A. safety goggle B. walkaway guide C. safety notices in markings (ANS) D. all of these 48. The angle, at the base cylinder of an involute gear, that the tooth makes with the gear axis: A. base helix angle (ANS) B. pressure angle C. arc of recess D. arc of approach 49. A kind of thread that is generally used: A. UNEC B. UNC (ANS) C. UNF 0. UNEF MODULE 2 - ELEMEN1 SO. Which is not the generally used standard: A. ASTM B. SAE C. IPS (ANS) 0. AISI 51. Alloy steel known for its resistance to corrosion, abrasion and wear that is usually ideal for mill grinding of ore in cement and concentrator application. It is usually combined with molybdenum to increase the depth hardening: A. manganese chromium steel B. chromium molybdenum steel (ANS) C. chrome-nickel-moly steel D. manganese-moly steel 52. Commonly utilized/cheapest shaft material available in the market w· carbon content of 0.28 to 0.34%C. A. SAE 4132 B. SAE 4320 C. SAE 1030 (ANS) 0. SAE 4130 53. In a pair of gears it is the plane tha contains the two axis, in single gear, it ma be any plane containing the axis and the given point. A. axial plane (ANS) B. pitch plane C. normal plane D. all of the above 54. Accident prevention is: A. an association of employers, organization and individuals B. a job of a safety director C. the foreman's responsibility just ii! much as production (ANS) D. the responsibility of top management

- 13. MODULE 2 - ELEMENTS IN MACHINE DESIGN .., A. UNEC B. UNC (ANS) C. UNF D. UNEF SO. Which is not the generally used standard: A. ASTM B. SAE C. IPS (ANS) D. AISI Sl. Alloy steel known for its resistance to corrosion, abrasion and wear that is usually ideal for mill grinding of ore in cement and concentrator application. It is usually combined with molybdenum to increase the depth hardening: A. manganese chromium steel B. chromium molybdenum steel (ANS) C. chrome-nickel-moly steel D. manganese-moly steel 52. Commonly utilized/cheapest shaft material available in the market with carbon content of 0.28 to 0.34%C. A. SAE 4132 B. SAE 4320 C. SAE 1030 (ANS) D. SAE 4130 53. In a pair of gears it is the plane that contains the two axis, in single gear, it may be any plane containing the axis and the given point. A. axial plane (ANS) B. pitch plane C. normal plane D. all of the above S4. Accident prevention is: A. an association of employers, organization and individuals B. a job of a safety director C. the foreman's responsibility just as much as production (ANS) D. the responsibility of top management 55. Heating of metal above the critical temperature and then cooling slowly usually in the furnace to reduce the hardness and improve the machinability is called: A. normalizing B. annealing (ANS) C. tempering D. quenching 56. A type of welding whereby a wire or powder from the nozzle of a spray gun is fused by a gas flame, arc or plasma jet and the molten particles are projected in a form of a spray by means of compressed air or gas. A. electro-slug welding B. electro-beam welding C. plasma-arc welding D. metal spray welding (ANS) 57. Killed steel is very much associated with: A. manganese 8. sulphur C. phosphorous D. silicon (ANS} S8. The concave portion of the tooth profile where it joins the bottom of the tooth space. A. fillet curve (ANS) B. fillet C. undercut D. plane 59. The length of arc between the two sides of a gear tooth on the pitch circle: A. circular thickness (ANS} B. axial plane C. helix angle D. chordal angle 60. It is hardening treatment whereby a cast metal is being heated to a very high temperature then suddenly subjected to rapid cooling to improve hardenability or wear resistance is called: A. normalizing

- 14. ••• MACHINE DESIGN REVIEWER BY JAS TORDILLO B. tempering C. quenching (ANS) D. annealing 61. To reduce cost in the manufacturing of large worm gears the materials to utilize: A. alloyed aluminum rim with cast iron spider B. bronze rim with cast steel spider (ANS) C. all of these D. cast iron rim with bronze spider 62. The differential of the shear equation is which one of the following: A. bending moment of the beam B. load of the beam (ANS) C. tensile strength of the beam D. slope of the elastic curve 63. SAE steel that responds to heat treatment: A. SAE 1060 B. SAE 1117 (ANS) C. SAE 1030 D. SAE 1020 64. A circle bounding the bottoms of the teeth: A. addendum circle B. addendum cylinder C. pitch circle D. dedendum circle {ANS) 65. A unit deformation is called: A. torsion B. strain (ANS) C. stress D. shear 66. An oil storage roof formed to approximately a spherical surface, supported only at its periphery: A. self-supporting umbrella roof {ANS) B. self-supporting cone roof C. self-supporting D. supporting cone roof 67. Test sometimes referred to as an upsetting test: A. bend (ANS) B. flaring C. flange D. crush 68. An oil storage roof formed to approximately the surface of a right cone, supported only at its periphery: A. self-supporting umbrella roof B. self-supporting doem roof C. supported cone roof D. self-supporting cone roof (ANS) 69. Have the same thermal and minimum film thickness limitation as sleeve bearing: A. ball bearing B. roller bearing C. thrust bearing (ANS) D. oil whip 70. Test is designed primarily for application to electric-welded tubing for detection of lack of penetration or overlaps resulting from flash removal in the weld: A. butt weld B. paste C. lap weld (ANS) D. double butt weld 71. Is a form of correction that develop on a highly localized areas on a metal surfac~: A. crevice B. erosion C. galvanic D. apltting (ANS) 72. The deterioration of organic coating characterized as completely: A. chalking (ANS) B. rusting C. checking D. fritting 73. A gear is one which is 90 deg that is the pitch cone has become a plane: A. angular gear B. crown gear (ANS) C. miter gear D. spiral bevel gear MODULE 2 - ELEMEN:l 74. A machine used for the testing of ve thin steel or surface layers: A. Charpy test B. lzod test C. Description D. Rockwell superficial {ANS) 75. A cone formed by elements which are perpendicular to the elements of the p· cone at the large end: A. cone distance B. back cone (ANS) C. root cone D. cone center 76. The temperature above which the all is liquid and will run: A. melting point {ANS) B. flow point C. pour point D. liquidus 77. A weld made to hold the parts of a weldment in proper alignment until e final welds are made: A. butt weld B. tack weld (ANS) C. fillet weld D. full fillet weld 78. Is used to enable milling machine to take climb milling cuts: A. helical driving mechanism (ANS) B. spindle C. read out D. backlash eliminator 79. The total amount of permanent extension of the gage length measured after the specimen has fractured and is expressed as percentage increase of the original gage length: A. elongation (ANS) B. strain C. stress D. elastic limit

- 15. 0 ed :o p on ce: is the MODULE 2 - ELEMENTS IN MACHINE DESIGN -- 74. A machine used for the testing of very thin steel or surface layers: A. Charpy test B. lzod test C. Description 0. Rockwell superficial (ANS) 75. A cone formed by elements which are perpendicular to the elements of the pitch cone at the large end: A. cone distance B. back cone (ANS) C. root cone 0. cone center 76. The temperature above which the alloy is liquid and will run: A. melting point (ANS) B. flow point C. pour point D. liquidus 77. A weld made to hold the parts of a weldment in proper alignment until the final welds are made: A. buttweld B. tack weld (ANS) C. fillet weld 0. full fillet weld 78. Is used to enable milling machine to take climb milling cuts: A. helical driving mechanism (ANS) B. spindle C. read out D. backlash eliminator 79. The total amount of permanent extension of the gage length measured after the specimen has fractured and is expressed as percentage increase of the original gage length: A. elongation {ANS) B. strain C. stress D. elastic limit 80. It refers to any layer or deposit of extraneous material on a heat-transfer surface: A. low line B. pressure drop C. fouling (ANS) D. scaling 81. Steels containing large amounts of mild nickel and chromium: A. carbon steel B. stainless steel {ANS) C. alloy steel D. cast steel 82. The corrosion of iron or iron-base- alloys: A. rusting (ANS) B. crazing C. chalking D. fritting 83. The ratio of stress to the corresponding strain below the proportional limit A. stress-strain diagram B. gage method C. modulus of elasticity (ANS) D. tensile st rength 84. A fillet weld whose size is equal to the thickness of the thinner joint member: A. butt weld B. tack weld C. lapweld D. full-fillet weld (ANS) 85. A bevel gear of the same size mounted on a shafts at 90 deg: A. crown gear B. spur gear C. angular gears D. miter gears {ANS) 86. Gearing in which the motion or power that is transmitted depenqs upon the friction between the surface in contact: A. bevel cones B. spur friction wheels

- 16. MACHINE DESIGN REVIEWER BY JAS TORDILLO C. evans friction cones 0 . friction gearing (ANS) 87. Wheels are sometimes used for the transmission of high power when an approximately constant velocity ratio is desired: A. bevel cones B. friction gearing C. spur friction wheels (ANS) D. evans friction cones 88. A corrosion occurs within the or adjacent to a crevice formed by contact with another piece of the same or another metal: A. pitting B. galvanic (ANS) C. erosion D. crevice 89. A weld of approximately triangular cross-section that join two surface at approximately right angles as in lap joint, tee-joint, corner joint: A. single welded lap joint B. fillet weld (ANS) C. tack weld D. buttweld 90. An alloy of tin, copper, antimony, or sometimes lead: A. gold B. babbitt (ANS) C. aluminum D. cast iron 91. A weld place in a groove between two abutting members: A. full-fillet weld B. tack weld C. butt weld (ANS) D. fillet weld 92. A test for pipe used for coiling in sizes 2 inches: A. flaring B. crush C. flange 0. bend (ANS) 93. The follower reciprocates or oscillates in a plane parallel to the axis of rotation: A. cam curves B. cylindrical cam (ANS) C. tangential cam D. radial cam 94. Strength of a material that is of a stress intensity determined by considering the maximum test load to act over the original area of the test specimens: A. yield point B. ultimate strength (ANS) C. breaking strength D. elastic limit 95. The follower reciprocates or oscillates in a plane perpendicular to the axis of rotation of the cam: A. cam curves B. cylindrical cam C. tangential cam O. radial cam (ANS) 96. Impacts of reciprocating motion to a single-point cutting tool: A. dividing head B. slotting attachment (ANS) C. circular pitch D. circular milling attachment 97. A joint between two overlapping members in which the overlapped edge of one member is welded with a fillet weld: A. a single welded lap joint (ANS) B. double-welded lap joint C. a single-welded lap joint with backing D. tack weld 98. Weld-metal impact specimen shall be taken across the weld face substantially parallel to and within: A. Y. in B. 1/32 in C. Y. in (ANS) D. 1/16 in MODULE 2 - ELEMENTS 99. The maximum stress which is reached during a tension test: A. stress B. elasticity C. strain 0. tensile strength (ANS) 100. If gears cannot connect parallel shafts, they are called: A. cycloidal gears (ANS) B. helical gears C. spur gears 0 . toothed gears

- 17. MODULE 2 - ELEMENTS IN MACHINE DESIGN 99. The maximum stress which is reached during a tension test: A. stress B. elasticity C. strain D. tensile strength (ANS) 100. If gears cannot connect parallel shafts, they are called: A. cycloidal gears (ANS) B. helical gears C. spur gears D. toothed gears •••

- 18. MODULE 3 - ELEMENTS IN MACHINE DESIGN ••• MODULE 3 1. The size of an equal-leg length fillet weld shall be based on the length of the largest: A. Isosceles right triangle {ANS) B. square C. right triangle D. rectangle 2. Milling machine accessories are used to hold milling cutter in the milling machine: A. spindle-nose tooling B. milling machine vise C. vertical milling attachment O. milling machine arbors 3. The cheapest and the most abundant engineering material: A. steel B. aluminum C. cast iron (ANS) D. babbitt 4. They are usually the steel or steel casting: A. mild steel B. carbon steel {ANS) C. firebox steel D. drop-forge-dies 5. An important accessories of milling machines: A. milling machine vise B. cutters {ANS) C. ram D. vertical milling attachment 6. Gears used to transmit power between shafts axis of which intersect: A. spur gear B. bevel gear (ANS) C. helical gear D. straight gear 7. An Iron has physical properties closely resembling those of mild steel: A. malleable cast iron (ANS) B. malleable iron C. white iron D. gray iron 8. The space between the adjacent teeth: A. tooth B. backlash C. flank D. width (ANS) 9. An iron in which most of the carbon is chemically combined with the iron: A. cast iron B. gray iron C. white iron (ANS) D. malleable iron 10. A machine used in testing steel generally strike the specimen with an energy from 220 to 265 ft-lb: A. lzod test B. Charpy test (ANS) C. Rockwell test D. Test blocks 11. The area in the machine shop whose metal is being melted to form a new shape is the: A. foundry area (ANS) B. tool and die C. welding area D. mass production area 12. Which of the following is not the work of the machinist: A. reboring B. overhauling (ANS) C. grinding D. boring 13. The machine which can flatten surface on a horizontal, vertical or angular plane is: A. drilling machine B. shaper machine (ANS) C. power saw D. lathe machine 14. Which of the following is not part of a lathe machine: A. fan (ANS) B. carriage

- 19. ••• MACHINE DESIGN REVIEWER BY JAS TORDILLO C. headstock D. tailstock 15. One important skill that operators of machine tools must have an understanding of measurement which demands: A. speed B. neatness C. precision (ANS) D. sociability 16. Which of the following metals is non- magnetic? A. manganese steel (ANS) B. cast steel C. alloy steel D. cast iron 17. Which tool does not belong to the group? A. vise grip B. feeler gage (ANS) C. torque wrench D. adjustable wrench 18. What process does not belong to the group? A. brazing B. soldering C. hardening (ANS) D. resistance welding 19. A machinery operation whereby the tool rotates while the feed is stationary: A. shaping B. milling (ANS} C. turning D. reaming 20. Which of the following is not a kind of cast iron? A. gray iron B. white iron C. malleable iron D. lead iron {ANS} 21. Which of the following is not used to temper steel? A. oil bath B. brine/salt bath C. steam bath (ANS) D. water bath 22. Which of the following is not a part of a headstock? A. anvil (ANS) B. spindle C. motor 0. back gear 23. The ability of material or metal to resist being crushed is: A. fatigue strength B. bending strength C. torsional strength D. compressive strength (ANS) 24. Which of the following metal is easy to chisel? A. alloy steel B. manganese steel C. stainless steel D. cast iron (ANS) 25. Ferrous metals contain a relatively large amount of: A. manganese B. carbon (ANS) C. sulfur D. phosphorous 26. Which of the following is not a classification of iron ore: A. siderite B. hematite c. sulfurite (ANS} 0. magnetite 27. The ability of metals to stand loads without breaking down is: A. strain B. stress C. elasticity D. strength (ANS) 28. Herringbone gears are gears which: A. do not operate on parallel shafts B. have line of contact between the teeth (ANS) MODULE 3 - ELEME C. tend to produce end thrust on the s a D. consists of two left handed helical gea 29. In general, the design stress and fad of safety are related as follows: A. Design = ultimate stress divided factor of safety (ANS) B. Design =ultimate stress times fact ' safety C. Ultimate = stress factor for sa'e divided by design stress D. factor of stress = design stress div' by ultimate stress 30. The internals stresses existing i welded connection are: A. relieved by x-ray analysis B. may be relieved when weld is peenec C. not relieved when the weld is pe (ANS) D. not relieved by heat treatment 31. In the usual spur gearing the: A. pitch circle and base circle are the sam B. working depth includes the clearance C. tooth outline are always cycloidal cu D. tooth outline are usually invo curves (ANS) 32. One of the following is not corn terms relating to the classification of fits A. tunking B. snug C. medium force fit 0. bound (ANS) 33. Galvanized iron is a term referring iron coated with: A. tin B. zinc (ANS) C. magnesium D. aluminum 34. Stainless steel is obtained principally the use of which alloying element: A. chromium (ANS) B. nickel C. carbon D. tungsten

- 20. n.LO ::iart of a I ·o reslSt MODULE 3 - ELEMENTS IN MACHINE DESIGN ••• C. tend to produce end thrust on the shafts D. consists of two left handed helical gears 29. In general, the design stress and factor of safety are related as follows: A. Design = ultimate stress divided by factor of safety (ANS) B. Design = ultimate stress times factor of safety C. Ultimate stress factor for safety divided by design stress D. factor of stress = design stress divided by ultimate stress 30. The internals stresses existing in a welded connection are: A. relieved by x-ray analysis B. may be relieved when weld is peened C. not relieved when the weld is peened (ANS) D. not relieved by heat treatment 31. In the usual spur gearing the: A. pitch circle and base circle are the same B. working depth includes the clearance C. tooth outline are always cycloidal curves 0. tooth outline are usually involute curves (ANS} 32. One of the following is not common terms relating to the classification of fits: A. tunking B. snug C. medium force fit D. bound (ANS} 33. Galvanized iron is a term referring to iron coated with: A. tin B. zinc (ANS) C. magnesium 0. aluminum 34. Stainless steel is obtained principally by the use of which alloying element: A. chromium (ANS) B. nickel C. carbon O. tungsten 35. One of the following is not a tap used for cutting threads in holes: A. tapping tap (ANS) B. plugtap C. taper tap 0. bottoming tap 36. A machining operation whereby the tool reciprocates and the feed is stationary, is called: A. planning B. shaping (ANS) C. turning D. reaming 37. One of the following metals which respond to heat treatment: A. cast iron B. wrought iron C. medium carbon steel (ANS) 0. low carbon steel 38. Ferrous metals contain a relatively large amount of: · A. carbon (ANS} B. manganese C. phosphorous 0. sulfur 39. Which of the following is not a strength property of metals? A. tensile B. rocking strength (ANS) C. fatigue 0. torsional strength 40. A machine used in shaping metal by means of abrasive wheel or the removal of metals with an abrasive is called: A. planer machine B. power saw C. shaper machine O. grinding machine (ANS} 41. Which of the following is not a kind of mandrel? A. expansion mandrel B. taper mandrel C. contraction mandrel (ANS) 0. gang mandrel

- 21. ••• MACHINE DESIGN REVIEWER BY JAS TORDILLO 42. The kind of center which is being attached and meshed to the tailstock spindle which is also static while the work is rotating is: A. dead center (ANS) B. live center C. focal center D. work center 43. Which of the following is not a part of the headstock? A. spindle B. anvil (ANS) C. back gear D. motor 44. Which process does not belong to the group? A. resistance welding B. soldering C. hardening (ANS) D. brazing 45. The ratio of the average shear to maximum shear stress for a circular section equal to: A. 2 B. 2/3 (. 3/2 D. % (ANS) 46. When a solid cube is subjected to equal normal forces of the same type on all its faces. The ratio of volumetric strain/linear strain along any of the three axes will be equal to: A. 1 B. 2 c. J3 D. 3 (ANS) 47. The ratio of Bulk modulus to shear modulus for Poisson's ratio of 0.25 will be equal to: A. 3/2 B. 5/6 C. 1 (ANS) D. 6/3 48. The stress strain curve for a glass rod during tensile test is: A. a straight line B. a parabola C. a sudden break D. an irregular curve (ANS) 49. When shear force is zero along a section, the bending moment at that section will be: A. zero B. minimum (ANS) C. maximum D. minimum or maximum 50. Percentage reduction of area while performing tensile test on cast iron may be of the order of: A. 50% B. 25% C. 0% (ANS) D. 15% 51. The intensity of stress that causes unit strain is known as: A. Unit stress B. Bulk modulus C. Modulus of rigidity D. Modulus of elasticity (ANS) 52. For steel, the ultimate strength in shear as compared to in tension is nearly: A. same B. half (ANS) C. one-third D. two-third 53. Select the one that has no unit: A. Kinematic viscosity B. Surface tension C. Bulk modulus D. Strain (ANS) 54. When a part is constrained to move and heated, it develops: A. principal stress B. tensile stress C. compressive stress (ANS) D. shear stress MODULE 3 - ELEMENTS I 55. The tensile stress of a material is given by: A. Maximum load during test over Original cross-sectional area (ANS) B. Average load during test over Original cross-sectional area C. Maximum load during test over Area at the time of fracture D. Average load during the test over Area at the time of fracture 56. The size of hole that is drilled in plates for riveting is: A. equal to the diameter of rivet shank B. slightly smaller than the diameter of rivet shank C. 1.5 to 2 mm smaller than the diameter of rivet for rivets of 25 mm and above size. D. 1.S to 2 mm larger than the diameter of the rivet for rivets 2S mm and above size. (ANS) 57. The horsepower that can be transmitted by a shaft 60 mm diameter at 180 rpm with permissible shear stress of 850 kg/cm2 shall be approximately: A. 30-35 B. 35-50 C. 50 - 60 (ANS) D. 60-85 58. A column is called short column when: A. The length is more than 30 times the diameter B. Slenderness ratio is more than 120 C. The length is less than 8 times the diameter (ANS) D. The slenderness ratio is more than 32. 59. Which one is the correct statement about true stress-strain method? A. There Is no such phenomenon like true stress or true strain (ANS) B. True stress is load per unit area (actual) and similarly true strain is determined under actual conditions. C. This method can be used for compression test as well. D. It is more sensitive to changes in mechanical conditions.

- 22. MOCULE 3 - ELEMENTS IN MACHINE DESIGN ••• SS. The tensile stress of a material is given by: A. Maximum load during test over Original cross-sectional area (ANS) B. Average load during test over Original cross-sectional area C. Maximum load during test over Area at the time of fracture D. Average load during the test over Area at the time of fracture S6. The size of hole that is drilled in plates for riveting is: A. equal to the diameter of rivet shank B. slightly smaller than the diameter of rivet shank C. 1.S to 2 mm smaller than the diameter of rivet for rivets of 2S mm and above size. D. 1.5 to 2 mm larger than the diameter of the rivet for rivets 2S mm and above size. (ANS) S7. The horsepower that can be transmitted by a shaft 60 mm diameter at 180 rpm with permissible shear stress of 8SO kg/cm 2 shall be approximately: A. 30-3S B. 3S-SO C. S0-60 (ANS) D. 60-85 58. A column is called short column when: A. The length is more than 30 times the diameter B. Slenderness ratio is more than 120 C. The length is less than 8 times the diameter (ANS) D. The slenderness ratio is more than 32. S9. Which one is the correct statement about true stress-strain method? A. There is no such phenomenon like true stress or true strain (ANS) B. True stress is load per unit area (actual) and similarly true strain is determined under actual conditions. C. This method can be used for compression test as well. D. It is more sensitive to changes in mechanical conditions. 60. The total strain energy stored in a body is called: A. Resilience (ANS) B. Proof resilience C. Modulus of resilience D. Toughness 61. A material that is capable of absorbing a large quantity of energy before fracture is called: A. Ductility B. Toughness (ANS) C. Resilience D. Shock proof 62. Coaxing increases the: A. Strength by reversible cycling B. Corro~ion resistance by spraying C. Hardness by surface treatment D. Fatigue resistance by over-stressing the metal by successively increasing loadings (ANS) 63. Two shafts made up of mild steel one having circular cross section and the other being hollow circular with inner diameter half of the outer diameter. The ratio of the torque that can be transmitted in two cases give by: A. 2 B. 17/16 c. 1 D. lS/16 (ANS) 64. For a circular shaft subjected to torque the value of shear stress is equal to: A. Is uniform throughout B. Has maximum value at the axis C. Has maximum value at the surface D. Is zero at the axis and linearly increases to a maximum value at the surface of the shaft (ANS) 6S. In laminated spring the strips are provided in different lengths for: A. Economy B. Reduction in weight C. Improved appearance D. Equal distribution stress (ANS)

- 23. ••• MACHINE DESIGN REVIEWER BY JAS TORDILLO 66. Select the one for which diamond riveted joint can be adopted: A. Butt joint (ANS) B. Lap joint C. Double riveted lap joints 0. All types of joints 67. Hoop stress refers to: A. Circumferential tensile stress B. Compressive stress C. Radial stress D. Longitudinal stress (ANS) 68. Modulus of rigidity can be defined as the ratio of: A. linear stress to longitudinal strain B. Stress to volumetric strain C. Shear stress to shear strain (ANS) 0. Stress to strain 69. 1 Meganewton per square meter is equal to: A. 1000,000 N/mm 2 B. 10,000 N/mm 2 C. 100 N/mm 2 D. 1 N/mm 2 (ANS) 70. The value of shear stress changes is induced in the shaft because of the applied couple that: A. From maximum at the center to zero at the circumference B. From zero at the center to maximum at the circumference (ANS) C. From maximum at the center to minimum at the circumference D. From minimum at the center to maximum at the circumference 71. In the design of pulley, key and shaft: A. All three are designed for same strength B. Key is made weaker link (ANS) C. Pulley is made weaker 0. Shaft is made weaker 72. The radial pressure and hoop tension for a thick cylinder is: A. Maximum at inner surface and decreases towards outer surface (ANS) B. Minimum at inner surface and increased towards outer surface C. Minimum at inner and outer surfaces and maximum in middle D. Maximum at inner and outer surfaces and minimum in middle 73. Auto frottage is the method os: A. Calculating stresses in thick cylinders B. Relieving thick cylinders C. Prestressing thick cylinders (ANS) 0. Increasing life of thick cylinders 74. Ties are load carrying members that carry: A. Torsional loads B. Axial compressive loads C. Axial tension loads (ANS) 0. Transverse loads 75. If the areas of cross sections of square and circular beams are same and both are put to equal bending moment, then .the correct statement is: A. The circular beam is more economical B. The square beam is more economical (ANS) C. Both the beams are equally strong D. Both the beams are equally economical 76. In actual machines: A. Mechanical advantage is unity B. Mechanical advantage is less than unity C. Mechanical advantage is less than velocity ratio (ANS) D. Mechanical advantage is equal to velocity ratio 77. The essential condition of equilibrium of a body is: A. The algebraic sum of horizontal components of all forces must be zero B. The algebraic sum of vertical component of all forces must be zero C. The algebraic sum o f forces about a point must be zero. D. All of the above (ANS) MODULE 3 - ELEMENTS . 78. Coulomb friction is: A. Friction between two electrically charge bodies B. Friction between two bodies having relative motion C. Friction between a solid and a liquid (ANS) D. Friction between two dry surfaces 79. The coefficient of friction is equal to: A. The angle between the normal reaction and the resultant of normal reaction and the limiting friction B. The tangent of the angle between the normal reaction and the resultant of the normal reaction and the limiting friction C. The tangent of the angle of the net resultant force with the direction of motion. D. The tangent of the angle between the normal reaction and direction of limiting friction. (ANS) 80. The limiting force of friction is equal to: A. The value of friction force that stops the movement of the body. B. The value of friction force that cannot exceed under a given situation. C. The friction force when the body is just about to move. (ANS) D. The friction force acting on a body when it is in motion. 81. Ice is slippery when a man walks on it because: A. It has a smooth surface. B. It has no friction. C. It is very chilly. D. Increase of pressure causes it to melt. (ANS) 82. One joule is the same as: A. 10 8 ergs B. 107 ergs (ANS) C. 10 5 ergs D. 10 5 ergs 83. Static friction is: A. Always greater than the dynamic friction (ANSI B. Always less than the dynamic friction C. Always equal to the dynamic friction

- 24. MODULE 3 - ELEMENTS IN MACHINE DESIGN ... 78. Coulomb friction is: A. Friction between two electrically charge bodies B. Friction between two bodies having relative motion C. Friction between a solid and a liquid (ANS) 0. Friction between two dry surfaces 79. The coefficient of friction is equal to: A. The angle between the normal reaction and the resultant of normal reaction and the limiting friction B. The tangent of the angle between the normal reaction and the resultant of the normal reaction and the limiting friction C. The tangent of the angle of the net resultant force with the direction of motion. D. The tangent of the angle between the normal reaction and direction of limiting friction. (ANS) 80. The limiting force of friction is equal to: A. The value of friction force that stops the movement of the body. B. The value of friction force that cannot exceed under a given situation. C. The friction force when the body is just about to move. (ANS) 0. The friction force acting on a body when it is in motion. 81. Ice is slippery when a man walks on it because: A. It has a smooth surface. B. It has no friction. C. It is very chilly. D. Increase of pressure causes it to melt. (ANS) 82. One joule is the same as: A. 10 8 ergs B. 107 ergs (ANS) C. 10 6 ergs D. 10 5 ergs 83. Static friction is: A. Always greater than the dynamic friction (ANS) B. Always less than the dynamic friction C. Always equal to the dynamic friction 0. Either greater or more than the dynamic friction 84. When two forces that act at a point are such that if the direction of one is reversed, the direction of the resultant is turned through 90°, the forces must be: A. Equal in magnitude (ANS) B. Inclined at less than 90° C. Inclined at more than 90° D. Acting at 180° 85. The curve of a catenary by nature is. A. Ellipse B. Hyperbolic C. Circular D. Parabolic (ANS) 86. If the only force acting on two bodies is their mutual interactions and if both bodies start from rest, the distance traveled by each will be a: A. Proportional to the masses of the bodies B. Inversely proportional to the masses of the bodies (ANS) C. Inversely proportional to the square of the masses of the bodies D. Directly proportional to the square of the masses of the bodies 87. Which statement is correct? A. A body cannot have any energy without having momentum. B. A body can have kinetic energy without having momentum. C. A body in motion will always have kinetic energy more than the potential energy. (ANS) 0. None of the above 88. A man is standing near the edge of a uniformly rotating platform about an axis passing through its center. The speed of rotation of the platform will decrease if he: A. Moves towards the axis of rotation B. Accepts a heavy bag form one of its friends standing near by and hold it in his hand. (ANS) C. Extend his arms outwards. D. Jumps out from the platform.

- 25. ••=• MACHINE DESIGN REVIEWER BY JAS TORDILLO 89. A shaft revolving in a bearing forms a: A. lower pair (ANS) B. Sliding pair C. Higher pair D. Cylindrical pair 90. Select the one that is a higher pair: A. Thomson indicator mechanism B. Harts straight line mechanism C. Crossby indicator mechanism D. Tooth gearing mechanism (ANS) 91. The mechanism used to enlarge or reduce moments for reproducing drawings to different scales is called: A. Clinograph B. Trisquare C. Graphometer D. Pantograph (ANS) 92. When a ship is traveling in sea, which of the effect is more dangerous? A. Rolling B. Pitching (ANS) C. Steering D. All of the above 93. Slip in belt drive is: A. Loss of power B. Difference between the angular velocities of two pulleys C. Difference between the velocities of two pulleys D. Difference between the linear speed of the rim of pulley and the belt on it. (ANS) 94. In case of flat belt drive the length of belt in case of: A. Open belt depends on sum of the diameters of pulleys B. Open belts depends on difference of the diameters of the pulleys C. Cross belts depends on the sum of the diameters of pulleys (ANS) D. Cross belts depends on the difference of the diameters of the pulleys. 95. Kinematic pairs are those parts that have: A. Point or line contact between the two elements when in motion B. Surface contact between the two elements when in motion C. Elements of pairs not held together mechanically D. Two elements that allow relative motion (ANS) 96. A cam with a roller follower would constitute, which type of pair? A. Lower pair B. Higher pair (ANS) C. Open pair D. Close pair 97. The pitch point on a cam is: A. Any point on pitch curve B. The point of cam pitch that has the maximum pressure angle (ANS) C. A point at a distance equal to pitch circle radius from the center D. None of the above 98. The cam angle is: A. The angle of rotation of the cam for a definite displacement of the follower (ANS) B. Angle subtended by live portion of cam at the cam center C. The angle subtended at the cam center by the portion of cam during which the follower moves. D. The angle subtended by the cam at the cam center when the follower dwells. 99. Module can be expressed in: A. mm (ANS) B. mm/no. of teeth C. dimensionless D. none of the above 100. A reverted gear train is one in which: A. The direction of rotation of first and last gear is opposite B. The direction of rotation of first and the last gear is the same C. The first and last gear are on the same shaft (ANS) D. The first and the last gear are essentially on separate by parallel shafts. MODULE 4 - ELEMENT MODULE 4 1. In case of spur gears the flank of e tooth is: A. The part of the tooth surface lying below the pitch surface (ANS) B. The curve forming face and flank. C. The width of the gear tooth measureo axially along the pitch surface D. The surface of the top of the tooth. 2. In case of cross helical worm the axes o' two shafts are: A. Parallel B. Intersecting C. Non-parallel D. Non-parallel-non-intersecting (ANS) 3. In case of gears the addendum is give~ by: A. One module (ANS) B. 2.157 x module C. 1.57 x module D. 1.25/module 4. Gears for watches are genera. manufactured by: A. Die casting B. Machining on hobber C. Machining on a gear shape D. Stamping (ANS) 5. In case of helical gears the axial plane ·, given by: A. Diametral pitch over the sine of heli> angle B. Diametral pitch over the cosine of he1i> angle C. Diametral pitch over cotangent of helb angle D. Diametral pitch over the tangent o helix angle (ANS) 6. A cam wherein the follower reciprocate or oscillates in a plane parallel to the axis o the cam is called: A. Cylindrical cam (ANS) B. Reciprocating cam

- 26. 0 0 MODULE 4 - ELEMENTS IN MACHINE DESIGN •••• MODULE 4 1. In case of spur gears the flank of the tooth is: A. The part of the tooth surface lying below the pitch surface (ANS) B. The curve forming face and flank. C. The width of the gear tooth measured axially along the pitch surface D. The surface of the top of the tooth. 2. In case of cross helical worm the axes of two shafts are: A. Parallel B. Intersecting C. Non-parallel D. Non-parallel-non-intersecting (ANS) 3. In case of gears the addendum is given by: A. One module (ANS) B. 2.157 x module C. 1.57 x module D. 1.25/module 4. Gears for watches are generally manufactured by: A. Die casting B. Machining on hobber C. Machining on a gear shape D. Stamping (ANS) 5. In case of helical gears the axial plane is given by: A. Diametral pitch over the sine of helix angle B. Diametral pitch over the cosine of helix angle C. Diametral pitch over cotangent of helix angle D. Diametral pitch over the tangent of helix angle (ANS) 6. A cam wherein the follower reciprocates or oscillates in a plane parallel to the axis of the cam is called: A. Cylindrical cam (ANS) B. Reciprocating cam C. None of the above 0. Circular cam 7. Rope brake dynamometer uses: A. Oil is lubricant B. Water as lubricant C. Grease as lubricant D. No lubricant (ANS) 8. Which of the following dynamometer is widely used for absorption of wide range of powers at wide range of speeds? A. Hydraulic (ANS) B. Belt transmission C. Rope brake D. Electric generator 9. In a balancing machine the units for unbalance measurements are: A. cps B. gram C. gm-cm-cps D. gm-cm (ANS) 10. The supply of working fluid to the engine to suit the load conditions can be controlled by: A. Expansion valve B. Slide valve c. Flywheel D. Governor (ANS) 11. The function of a governor is to: A. Store energy and give up whenever needed B. Regulate the speed during one cycle of a prime mover C. Increase variation of speed O. Adjust variation of speed by varying the input to the engine (ANS) 12. According to law of gearing: A. Teeth should be of involute type B. Clearance between mating teeth should be provided c. Dedendum should be equal to 1.157 m D. None of these (ANS) 13. Bevel gears are used to transmit rotary motion between two shafts whose axes are:

- 27. ••• MACHINE DESIGN REVIEWER BY JAS TORDILLO A. Parallel B. Non-coplanar C. Non-intersecting D. None of the above (ANS) 14. If D and T be the pitch circle diameter and no. of teeth of a gear, then its circular pitch: A. OT B. T - D C. 0-T D. D/T (ANS) 15. If D1 and T1 be the diameter and no. of teeth of gear 1 and 0 2 and T2 the corresponding values of other gear in mesh, then speed ratio NJN2will be equal to: A. DJD2 B. DJD2 xTi/T1 C. TJT1 D. DJD1 (ANS) 16. Cold working: A. Increase the fatigue strength (ANS) B. Decrease the fatigue strength C. Has no influence on fatigue strength D. None of the above 17. Coaxing is the procedure of increasing: A. Metal strength by cycling B. Metal hardness by surface treatment C. Metal resistance to corrosion by coating D. Fatigue limit by overstressing the metal by successively increasing loadings. (ANS) 18. The notch angle of the lzod impact test specimen is" A. 20° B. 30° c. 10• D. 45° {ANS) 19. In Vickers hardness testing, the pyramid indenter apex is: A. 40° (ANS) B. 136° c. 161° D. 122° 20. In testing a material for endurance strength, it is subjected to: A. Static load B. Impact load C. Dynamic D. Completely reversed load (ANS) 21. Select the correct statement: A. A member made of steel will generally be more rigid than a member of equal load- carrying ability made of cast iron. B. A member made of cast iron will generally be more rigid than a member of equal load carrying ability made of steel. (ANS) C. Both will be equally rigid. D. Which one is rigid will depend on several other factors. 22. In majority of machine members, the damping capacity of the material should be: A. low B. zero C. high {ANS) D. could be anything 23. The crest diameter of a screw thread is same as: A. Major diameter (ANS) B. Pitch diameter C. Minor diameter D. None of the above 24. Muntz metal contains: A. copper-nickel B. copper-zinc (ANS) C. copper-tin D. copper-aluminum 25. A Babbitt is: A. a eutectoid of iron and iron phosphide B. a gadget for measuring C. a measure of magnetic induction produced in a material D. antimony bearing lead or tin alloy (ANS) 26. Steel balls for ball bearings are manufactured by: A. Turning B. Rolling MODULE 4 - aEMEl'I C. Casting D. Cold heading (ANS) 27. The blow of pressure of a safety va is: A. slightly more than atmospheric pressun B. half of the boiler working pressure C. equal to boiler working pressure D. 106% of boiler working pressure (ANS) 28. In case of a knuckle joint the pin is m likely to fail in: A. compression B. shear C. tension D. double shear (ANS) 29. Splines are used when: A. the power to be transmitted is low B. the power to be transmitted is high C. the torque is high 0. axial relative motion between the shi and hub ls necessary (ANS) 30. Splined shafts are generally used in: A. machine tools B. aircraft C. bicycles D. automobiles (ANS) 31. Which key normally used in watch? A. kennedy key B. tangent key C. sunk key D. none of the above (ANS) 32. Universal coupling is: A. used for non-collinear shafts (ANS) B. rigid coupling C. type of flange coupling D. used for collinear shafts 33. A flange coupling is: A. used for non-collinear shafts B. used for collinear shafts (ANS) C. flexible D. used only on small shafts rotating at speeds

- 28. nee era y d- e ti be -o lS MODULE 4 - ELEMENTS IN MACHINE DESIGN C. Casting D. Cold heading (ANS) 27. The blow of pressure of a safety valve is: A. slightly more than atmospheric pressure B. half of the boiler working pressure C. equal to boiler working pressure D. 106% of boiler working pressure (ANS) 28. In case of a knuckle joint the pin is most likely to fail in: A. compression B. shear C. tension D. double shear (ANS) 29. Splines are used when: A. the power to be transmitted is low B. the power to be transmitted is high C. the torque is high 0. axial relative motion between the shaft and hub is necessary (ANS) 30. Splined shafts are generally used in: A. machine tools B. aircraft C. bicycles D. automobiles (ANS) 31. Which key normally used in wrist watch? A. kennedy key B. tangent key C. sunk key D. none of the above (ANS) 32. Universal coupling is: A. used for non-collinear shafts (ANS) B. rigid coupling C. type of flange coupling D. used for collinear shafts 33. A flange coupling is: A. used for non-collinear shafts B. used for collinear shafts (ANS) C. flexible D. used only on small shafts rotating at low speeds 34. In flange coupling the weakest element should be: A. flange B. shaft C. bolt brush D. key (ANS) 35. Turn buckle has: A. Left hand threads on both ends B. Right hand thread on both ends C. Left hand threads on one end and right hand threads on the other end (ANS) D. No threads 36. Elastic nut is a locking device that has: A. One small nut is tightened over main nut B. A slot is cut partly in middle of nut C. Hard fibre or nylon cotter is received in the nut and becomes threaded as the nut is screwed on the bolt causing tight grip (ANS) D. Through slots are made at top and a cotter pin is passed through 37. Treating the welds as a line, the moment of inertia about center of gravity of a circular weld of diameter Q. would be: A. itd 2 /36 B. itd/6 c. rtd 3 /36 D. 7td3 /4 (ANS) 38. A single ply leather belt running at a velocity of 300 ft/min is likely to transmit per inch width: A. 2.5 HP B. 5.0 HP C. 4.0 HP (ANS) D. 3.0 HP 39. For but welding of two plates each of which is 25 mm thick, the best process would be: A. TIG welding B. MIG welding C. Gas welding D. Electro slag welding (ANS) 40. The compression members tend to buckle in the direction of:

- 29. ••• MACHINE DESIGN REVIEWER BY J AS TORDILLO A. Axis of load B. Perpendicular to the axis of load C. Minimum cross section D. Least radius of gyration (ANS) 41. The diameter of a washer is generally: A. Equal to the diameter of the bolt B. Slightly more than the diameter of bolt (ANS) C. Slightly less than the diameter of the bolt D. Of any size that suits the application 42. If the lead angle of a worm is 22 1/2° then the helix angle will be: A. 4S 0 B. 67 Y, 0 c. go• D. None of the above (ANS) 43. A reinforced concrete beam is considered to be made up of: A. Clad material B. Composite material C. Homogenous material D. Heterogeneous material (ANS) 44. Rankine formula is valid up to slenderness ratio of: A. 80 B. lSO c. 60 D. 120 (ANS) 4S. Slenderness ratio of a column is: A. Shaft diameter/shaft length B. Column height/Column cross section C. Column height/least dimension of column cross section D. Length of strut/least radius of gyration (ANS) 46. In hydrodynamic bearings: A. The oil film pressure is generated only by the rotation of the journal (ANS) B. The oil film is maintained by supplying oil under pressure C. Do not need external supply of lubricant D. Grease is used for lubrication. 47. The rated life of a bearing changes: A. Directly as load B. Inversely as fourth power of load C. Inversely as cube of load (ANS) D. Inversely as square of load 48. In oil less bearings: A. The oil film pressure is produced only by the rotation of the journal B. The oil film is maintained by supplying oil under pressure C. Do not need external supply of lubricant (ANS) D. Grease is needed to be applied after some intervals. 49. In cross or regular lay ropes: A. Direction of twist of in strands is opposite to the direction of twist of strands (ANS) B. Direction of twist of wires and strands are same C. Wires in two adjacent strands. are twisted in opposite direction D. Wires are not twisted. SO. Gears for wrist watches are generally manufactured by: A. lead angle B. pitch angle C. helix angle (ANS) D. pressure angle Sl. The type of cam used for low and moderate speed engines is generally: A. Harmonic (ANS) B. Tangent C. Involute D. Flat S2. The form coefficient of a spring is: A. The load/unit deflection B. Load/spring area C. Ratio of coil diameter to wire diameter D. Its capability of store energy. (ANS) S3. Coriolis component of acceleration is found in: A. Four bar mechanism B. Mechanism of steam engine MODULE 4 - ELEMENT; C. Lower pair D. Wit worth quick-return motion (ANS) S4. Cold working of materials: A. Increases the fatigue strength (ANS) B. Decreases the fatigue strength C. Does not change fatigue strength D. None of the above SS. A babbitt is: A. A eutectic of iron and iron phosphide B. A gadget for measuring volume C. Antimony bearing lead or tin alloy (ANS) D. A measure of magnetic induction produced in a material. S6. Addendum of a cycloidal gear tooth is· A. Cycloid B. Epicycloid (ANS) C. Straight rack D. Involute S7. Spiral gears are suitable for transmitting: A. small power (ANS) B. no power but motion only C. any power D. huge power S8. As pump speed increases, its (NPS ) net positive suction head requirement: A. Increases (ANS) B. Remains C. None of the above D. Decreases S9. In pump NPSH requirements are not satisfied: A. It will not develop head B. Efficiency will be low C. It will consume excessive power D. It will be cavitated (ANS) 60. Which type of chain is used in motorcycle? A. Bush roller (ANS) B. Pintle C. None of the above D. Silent

- 30. MODULE 4 - ELEMENTS IN MACHINE DESIGN •••• C. Lower pair D. Wit worth quick-return motion (ANS) 54. Cold working of materials: A. Increases the fatigue strength (ANS) s.. Decreases the fatigue strength C. Does not change fatigue strength D. None of the above S5. A babbitt is: A. A eutectic of iron and iron phosphide B. A gadget for measuring volume C. Antimony bearing lead or tin alloy (ANS) D. A measure of magnetic induction produced in a material. S6. Addendum of a cycloidal gear tooth is: A. Cycloid B. Epicycloid (ANS) C. Straight rack D. Involute S7. Spiral gears are suitable for transmitting: A. small power (ANS) B. no power but motion only C. any power D. huge power SS. As pump speed increases, its (NPSH) net positive suction head requirement: A. Increases (ANS) B. Remains C. None of the above D. Decreases 59. In pump NPSH requirements are not satisfied: A. It will not develop head B. Efficiency will be low C. It will consume excessive power D. It will be cavitated (ANS) 60. Which type of chain is used in motorcycle? A. Bush roller (ANS) B. Pintle C. None of the above D. Silent 61. Which of the following ropes will be most flexible? A. 6 by 9 B. 6 by 7 c. 8 by 19 D. 6 by 37 (ANS) 62. The working load (P) for a chain for crane application is expressed in terms of diameter of link "d" in cm as follows: A. P = l .Sd 2 s. P = sod' c. P = sood2 (ANS) D. P = 2Sd 2 63. If the square key and the shaft are to be of the same material and of equal strength, the length of key would be (d = shaft diameter) A. d B. 1.5 d c. 2d D. 1.23d (ANS) 64. In a standard coarse thread bolt the stress concentration is maxim um at: A. root (ANS) B. flank C. all over the surface D. top surface 6S. Fatigue strength of a surface may be increased by: A. Making surface rough B. Filling the surface C. Applying concentrated hydrochloric acid on the surface D. Polishing the surface (ANS) 66. The maximum deflection allowed in gantry griders is: A. L/200 B. L/SOO C. L/300 D. L/1000 (ANS) 67. The maximum size of the fillet weld that can be used at: A. 2 mm B. 3 mm (ANS)