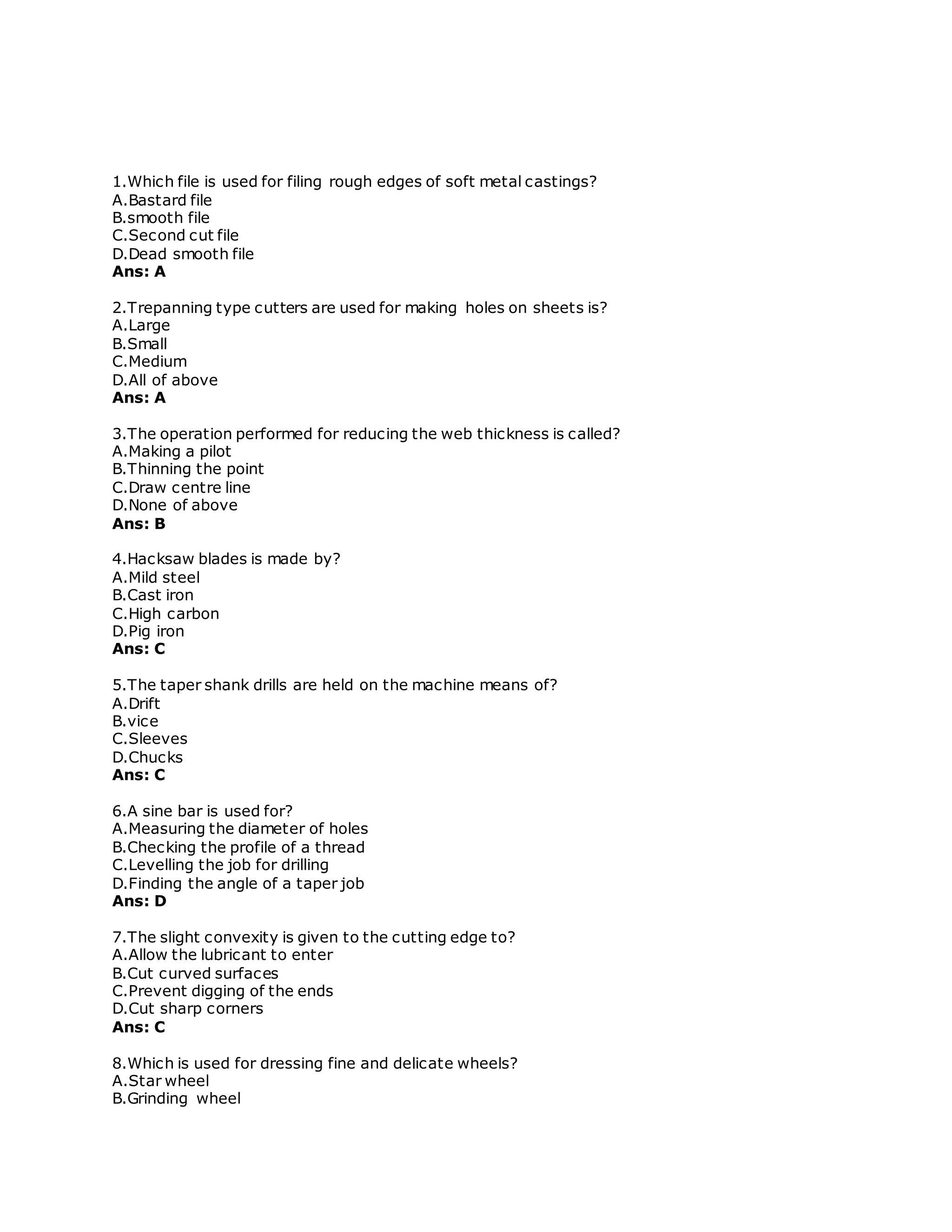

This document contains 70 multiple choice questions related to tools and manufacturing processes. The questions cover topics like files, drills, reamers, sine bars, micrometers, and more. They assess knowledge of what different tools are used for, standard sizes and specifications, common manufacturing terms, and other fundamental concepts in machining and metrology.