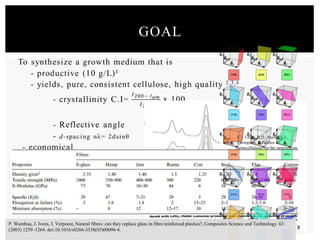

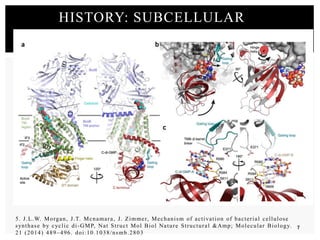

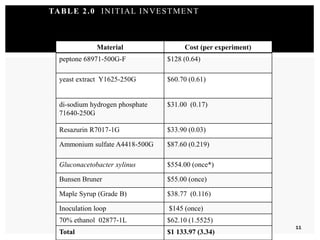

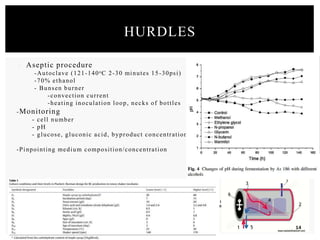

This document outlines Baraka Gitari's Masters thesis proposal on bacterial cellulose. The goal is to synthesize, process, and characterize bacterial cellulose. Bacterial cellulose is produced intracellularly by bacteria like Gluconacetobacter xylinus using glucose as a substrate. It has properties like being biodegradable, sustainable, and able to be used for applications like capacitors or reinforced plastics. The plan is to grow the bacteria using a modified Hestrin-Schramm medium, extract the cellulose, electrospin it, and characterize it using various techniques. Challenges include maintaining aseptic conditions during growth and synthesis.