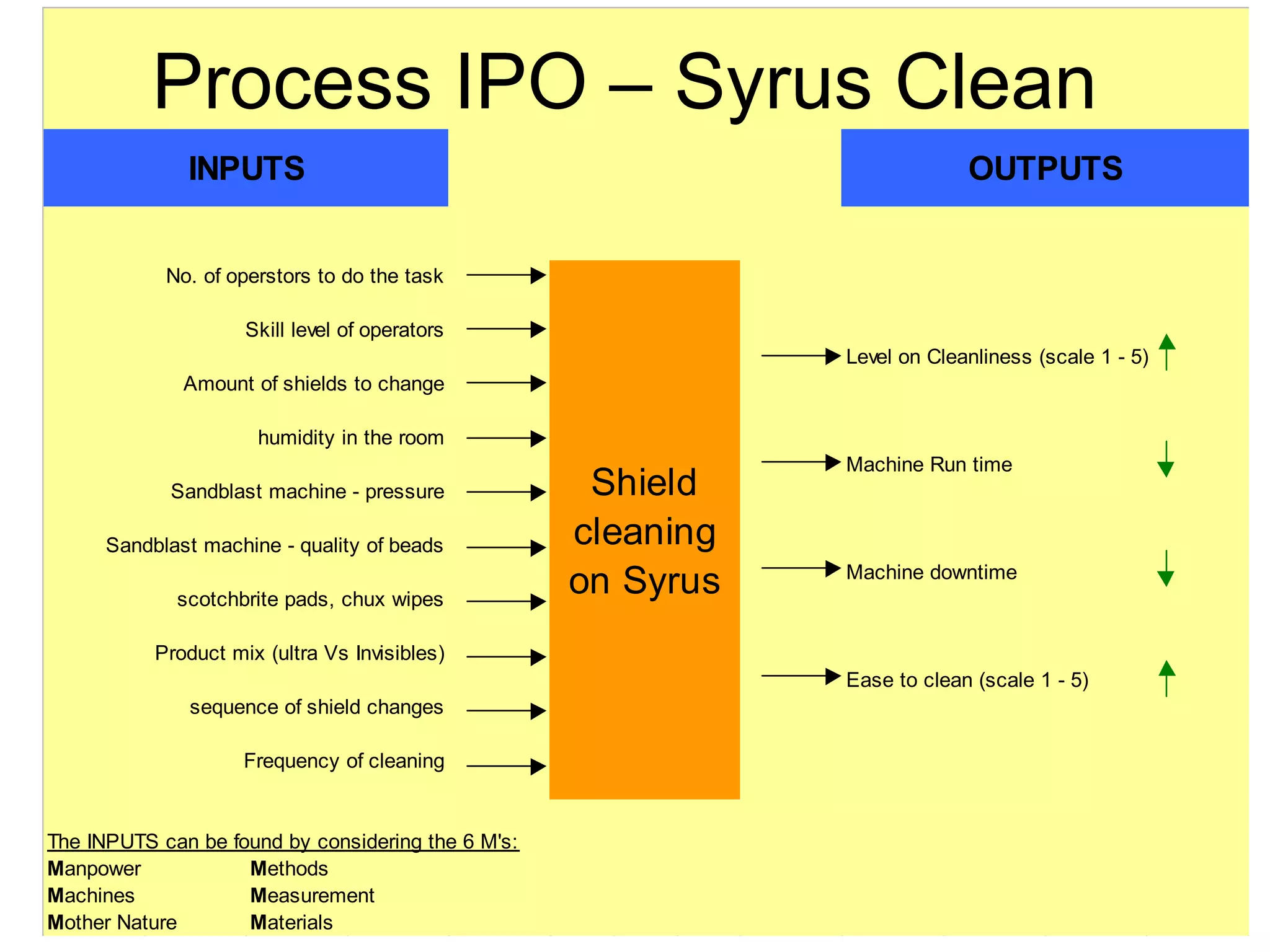

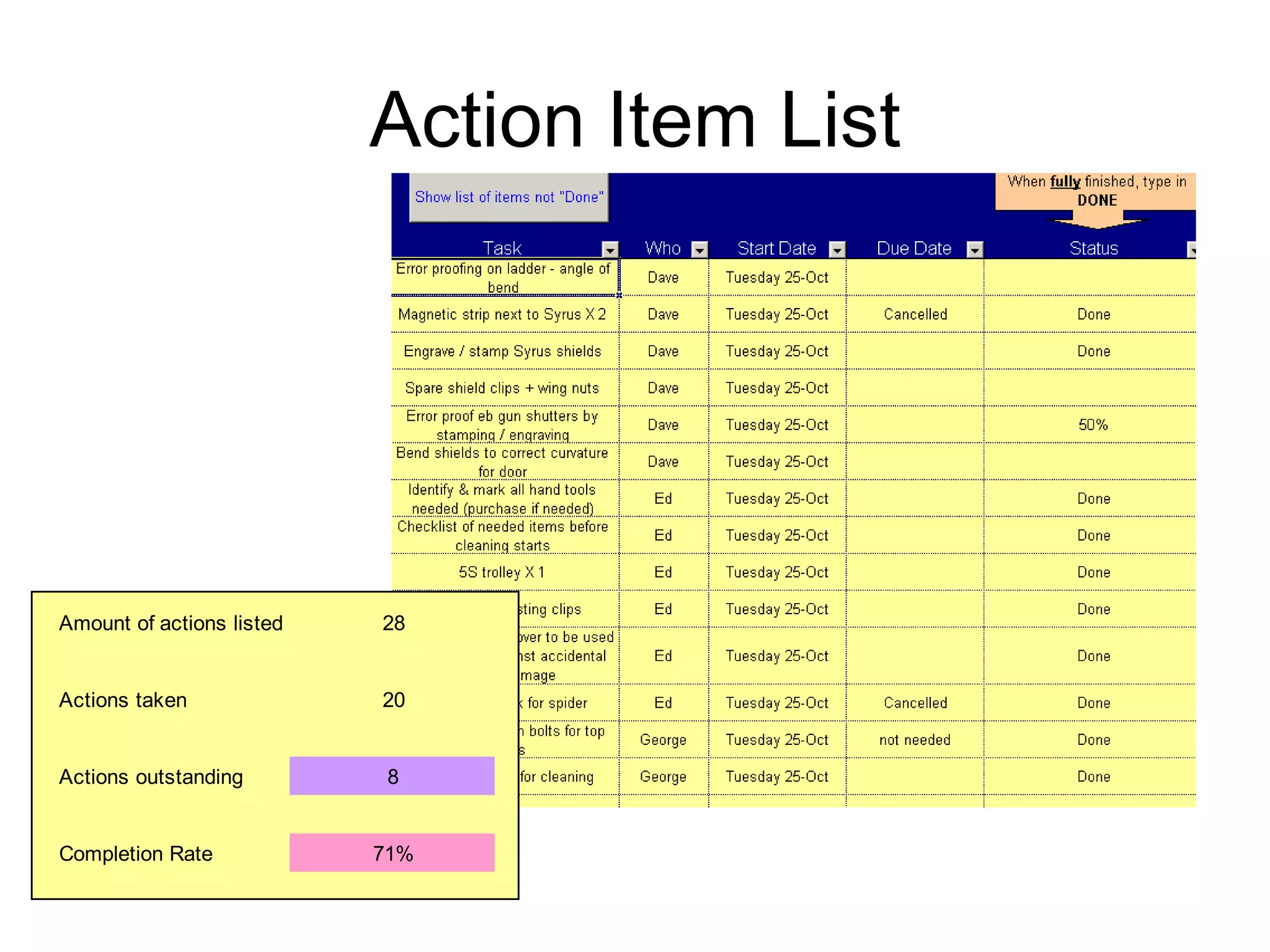

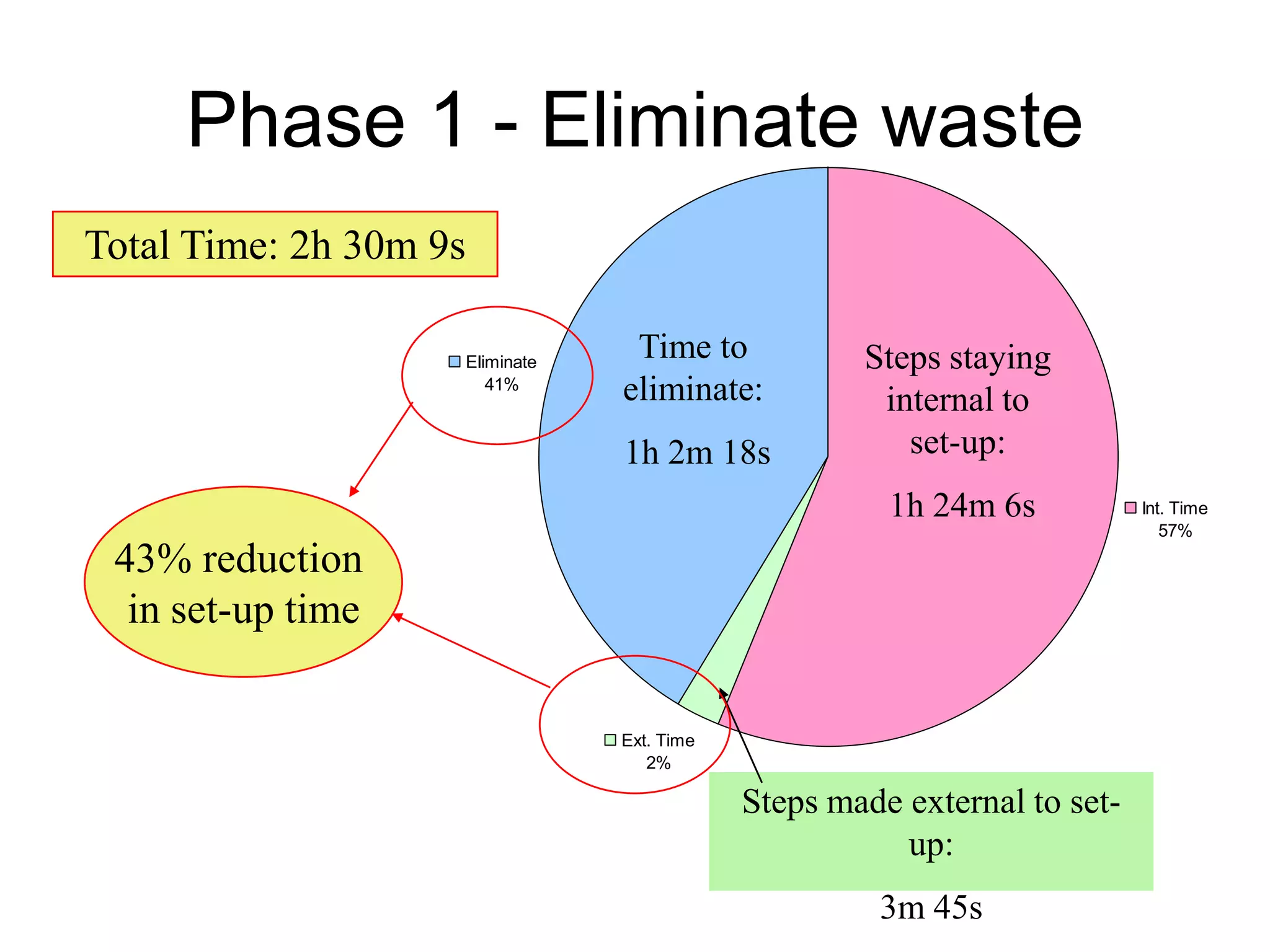

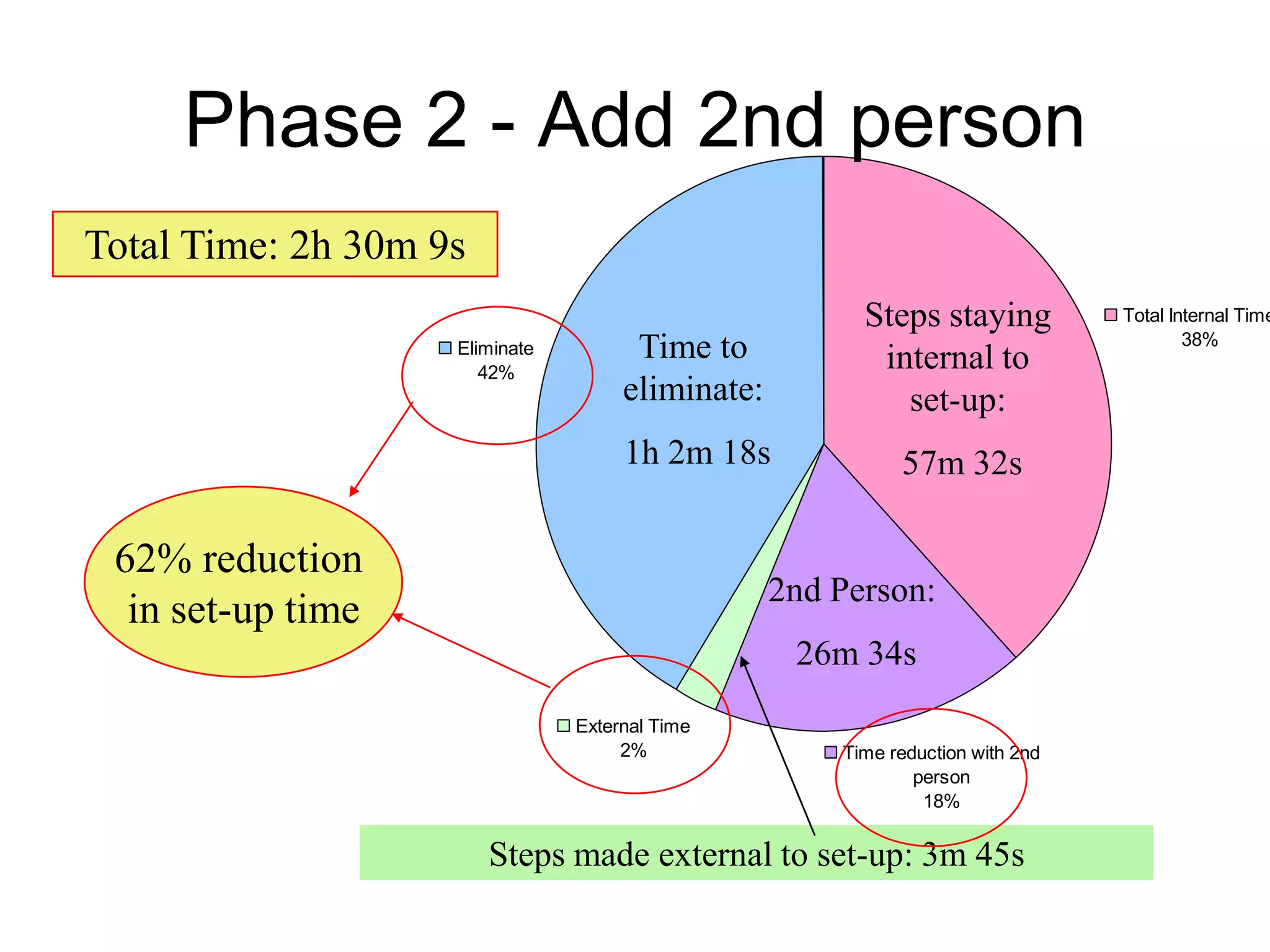

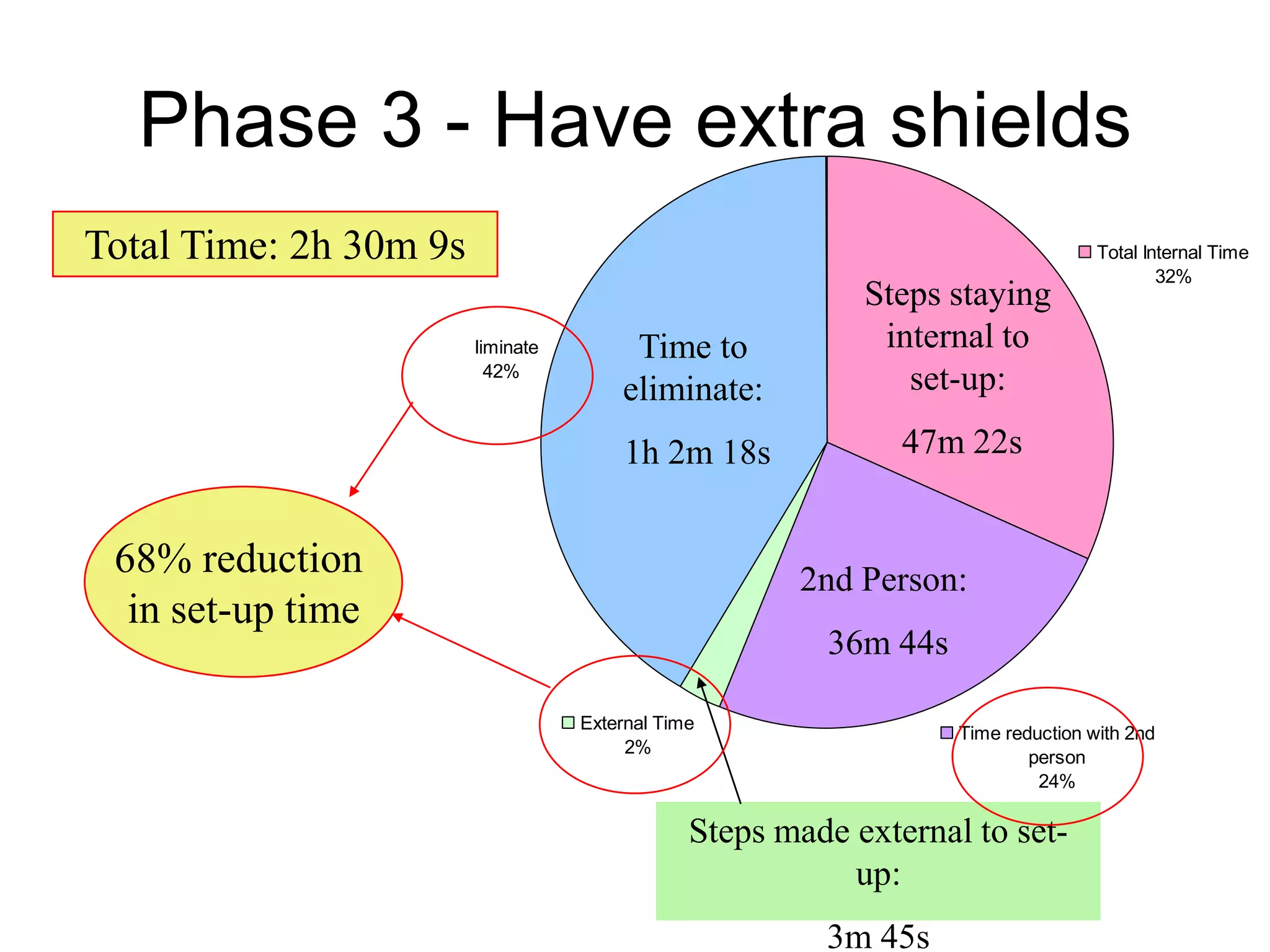

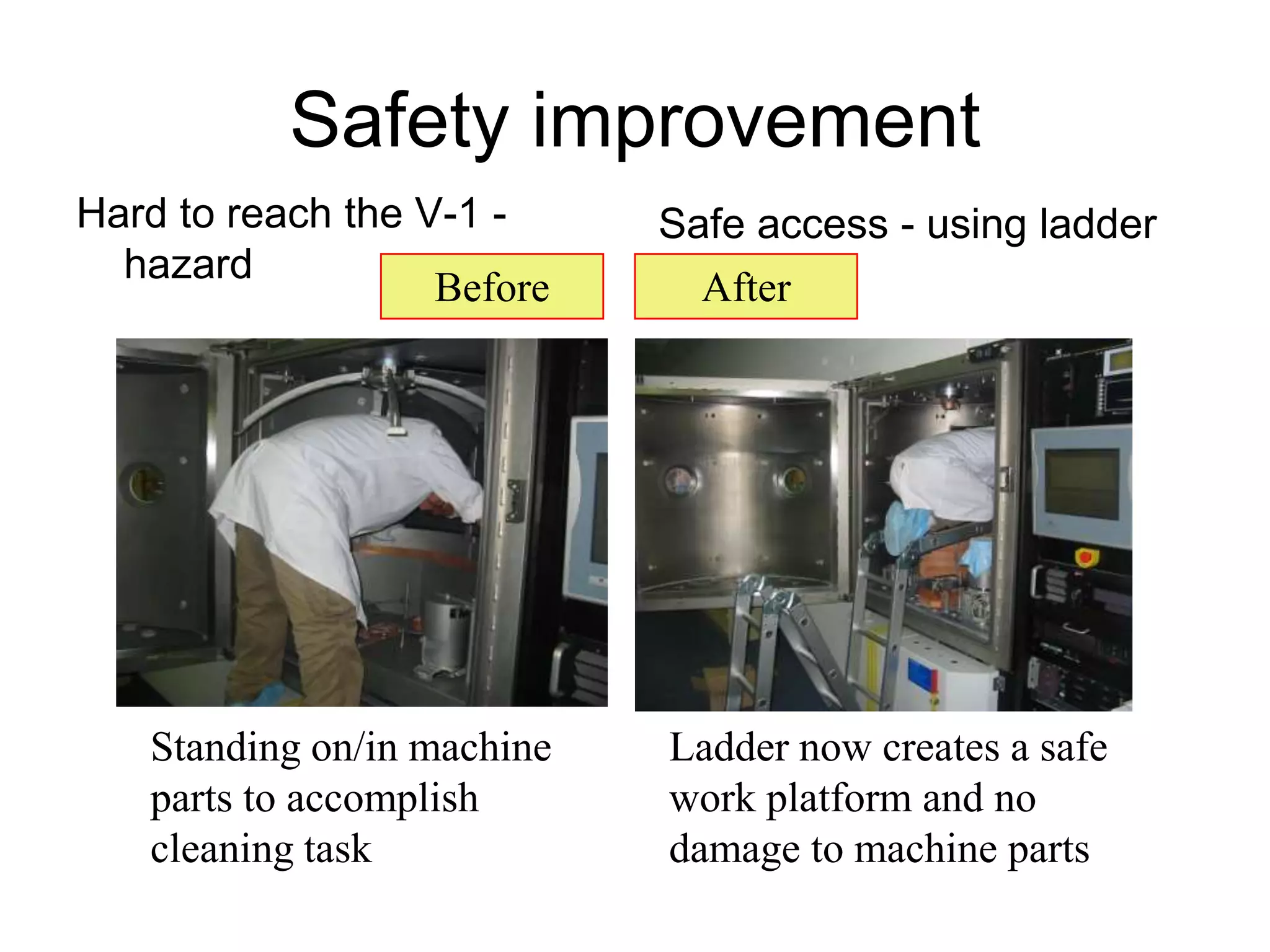

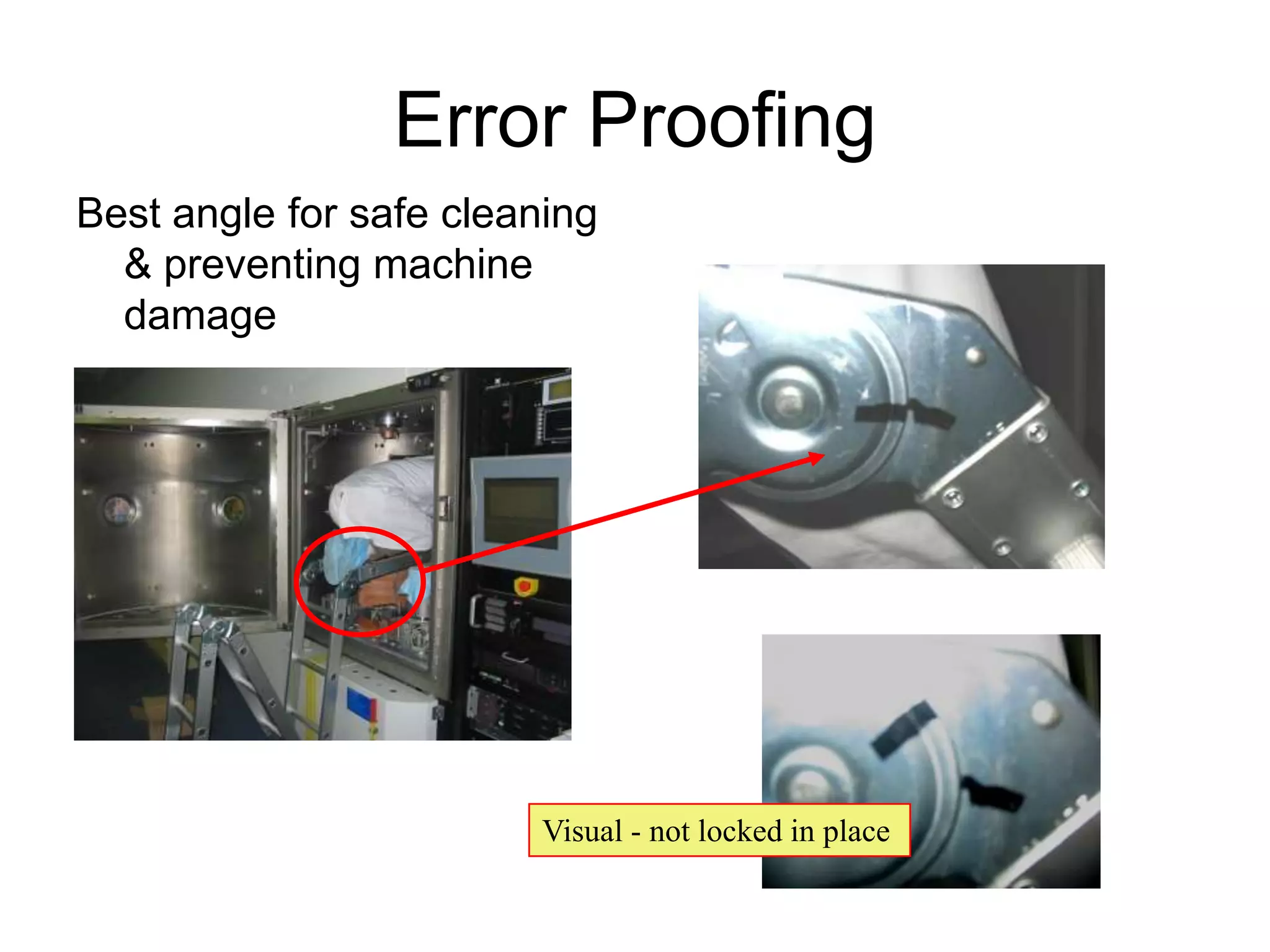

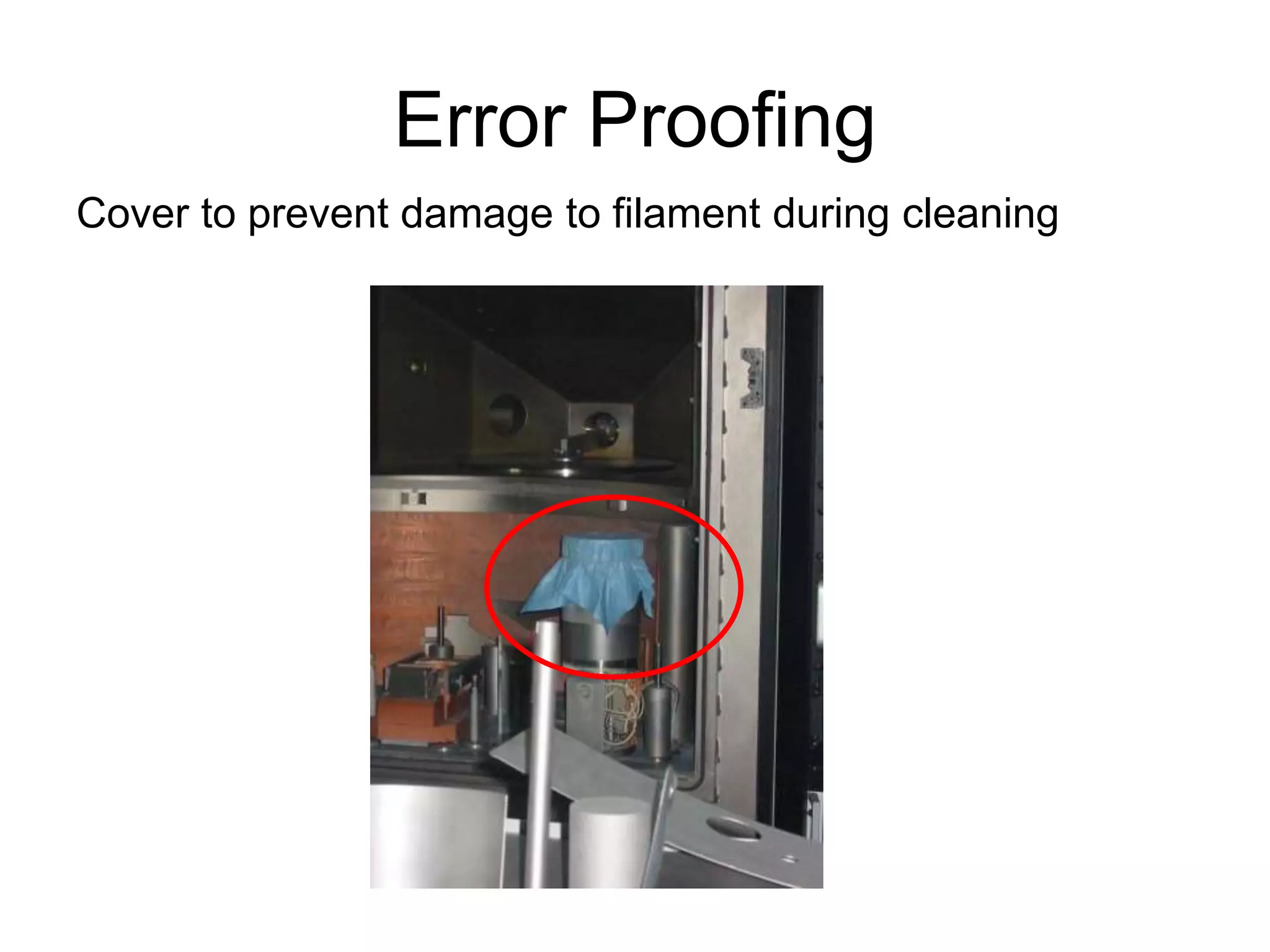

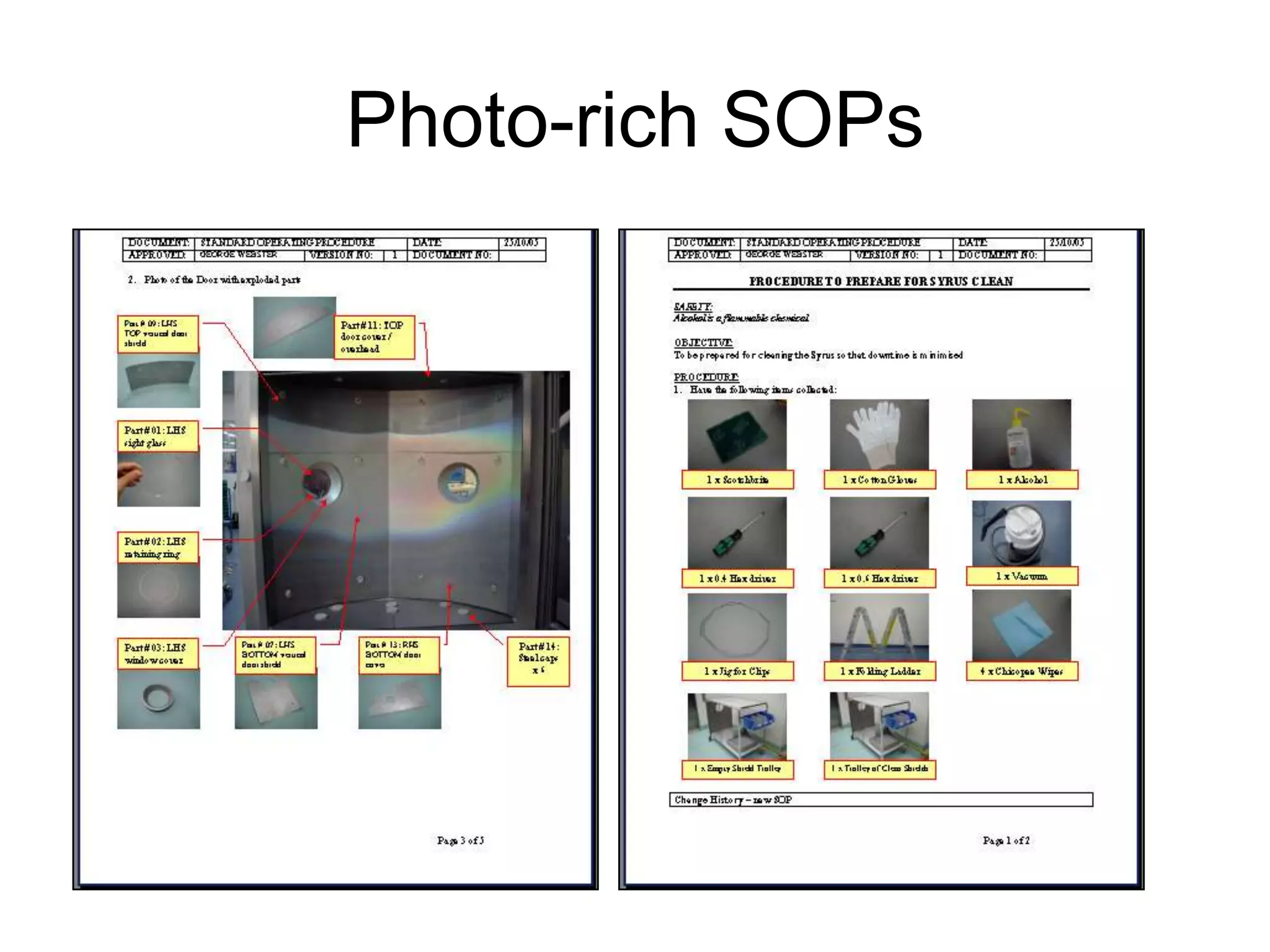

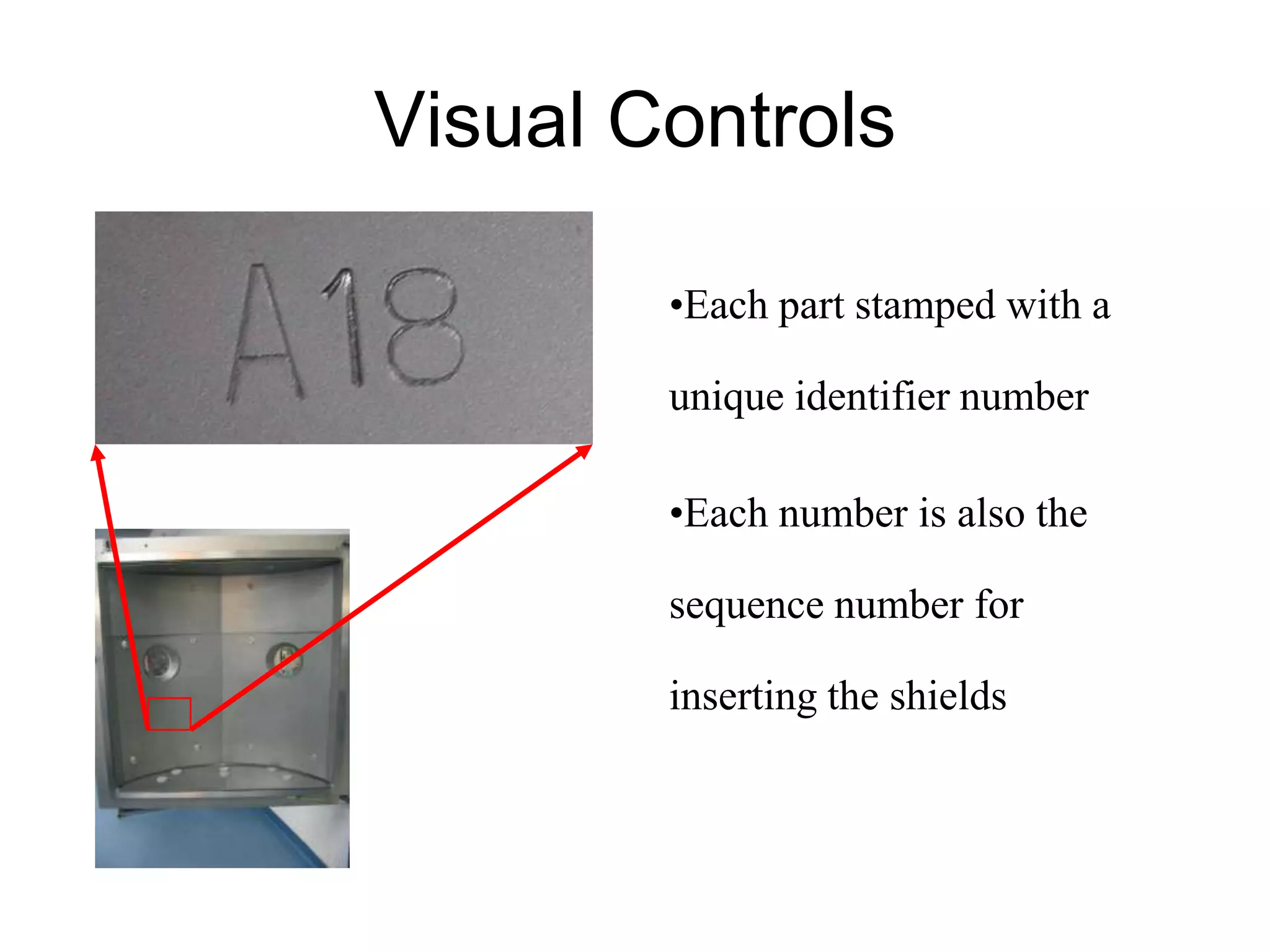

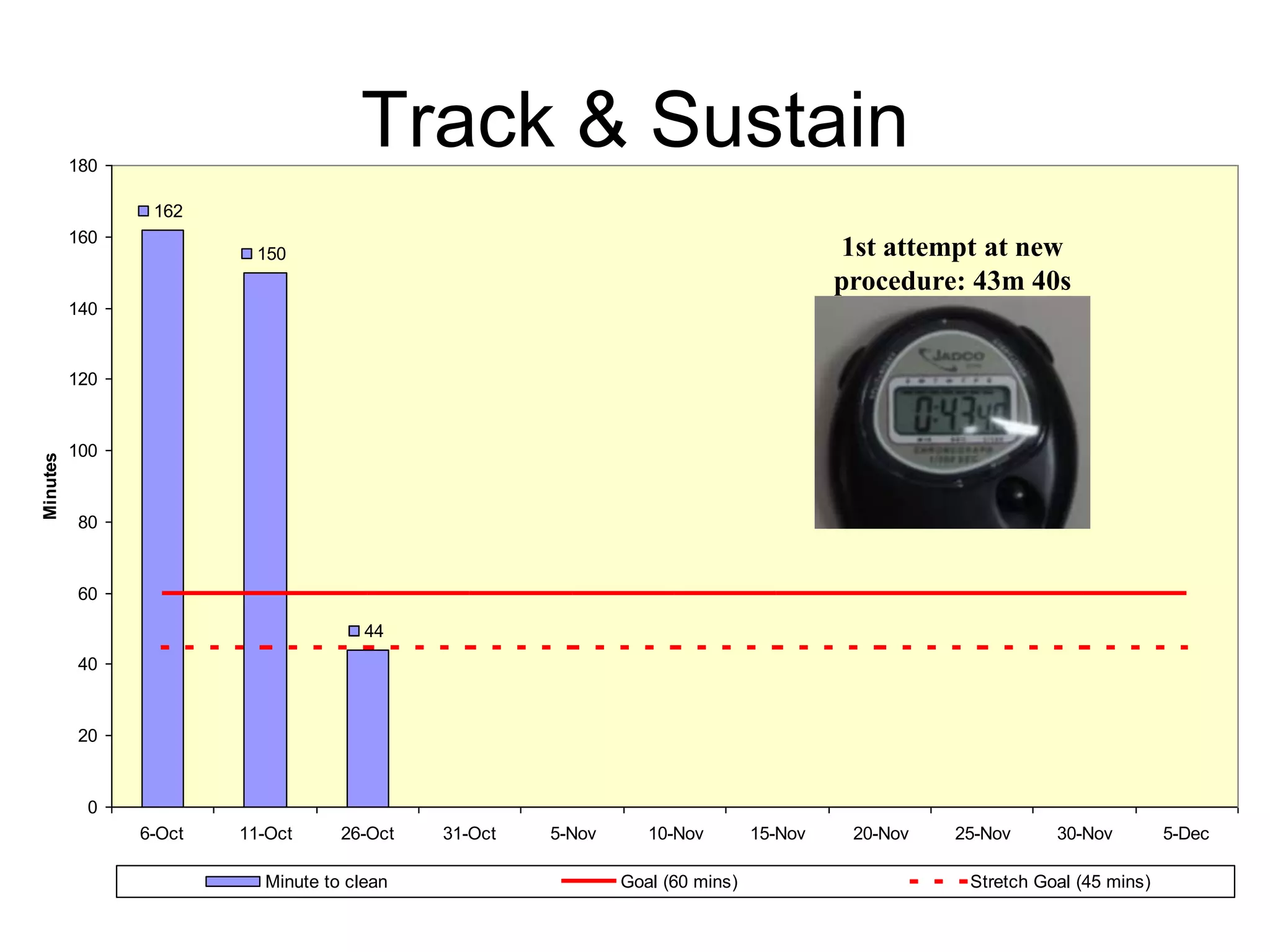

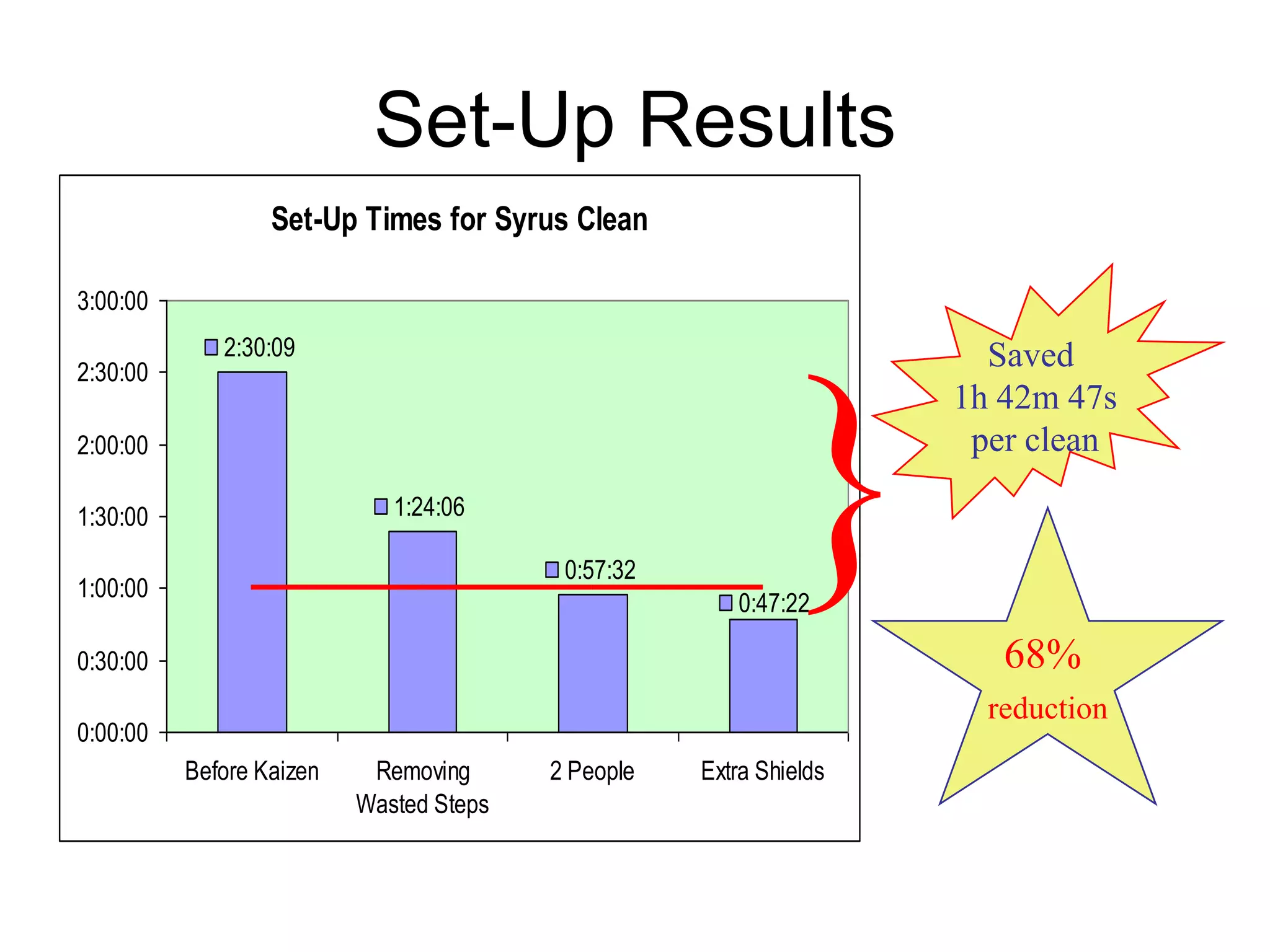

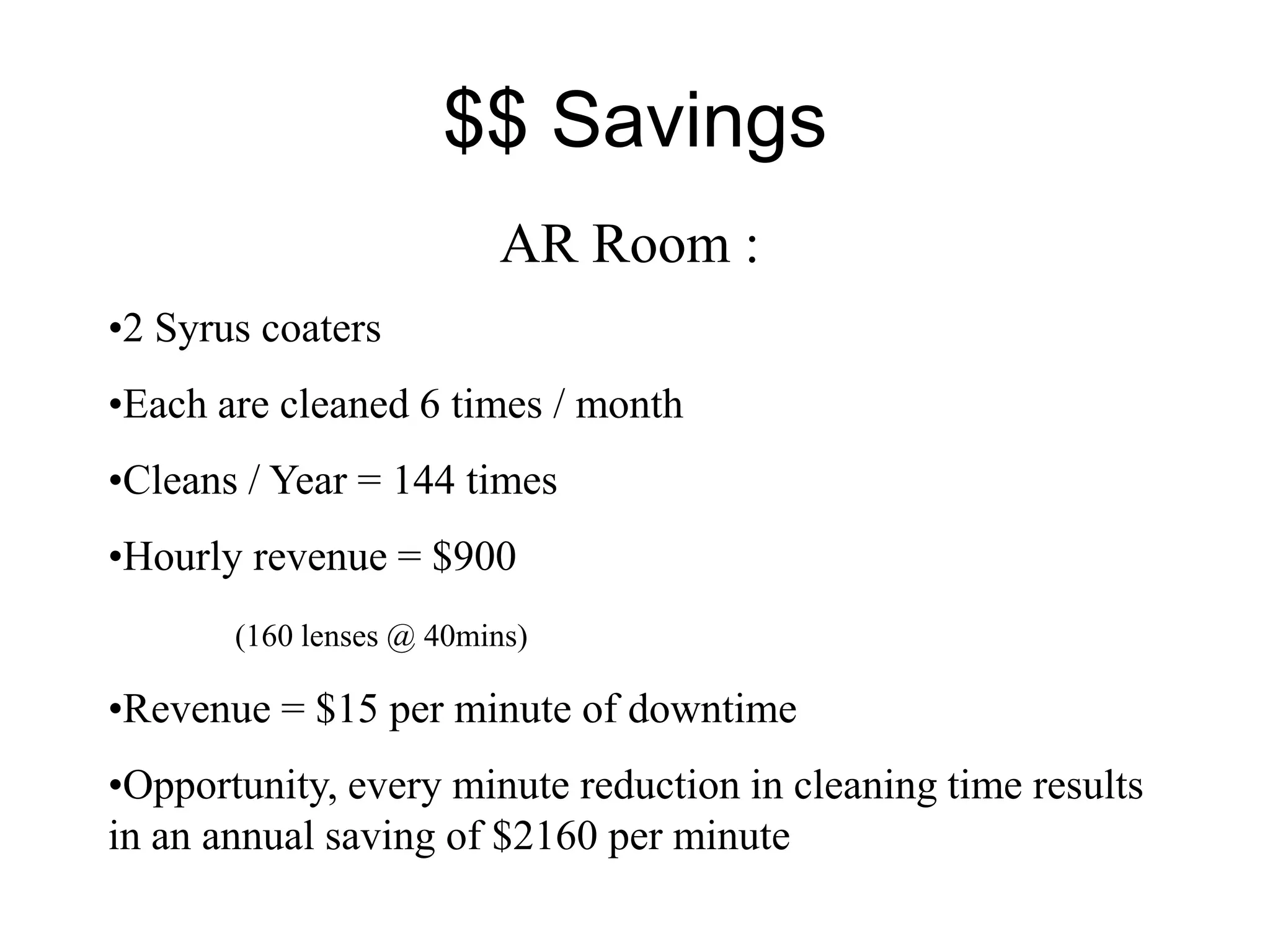

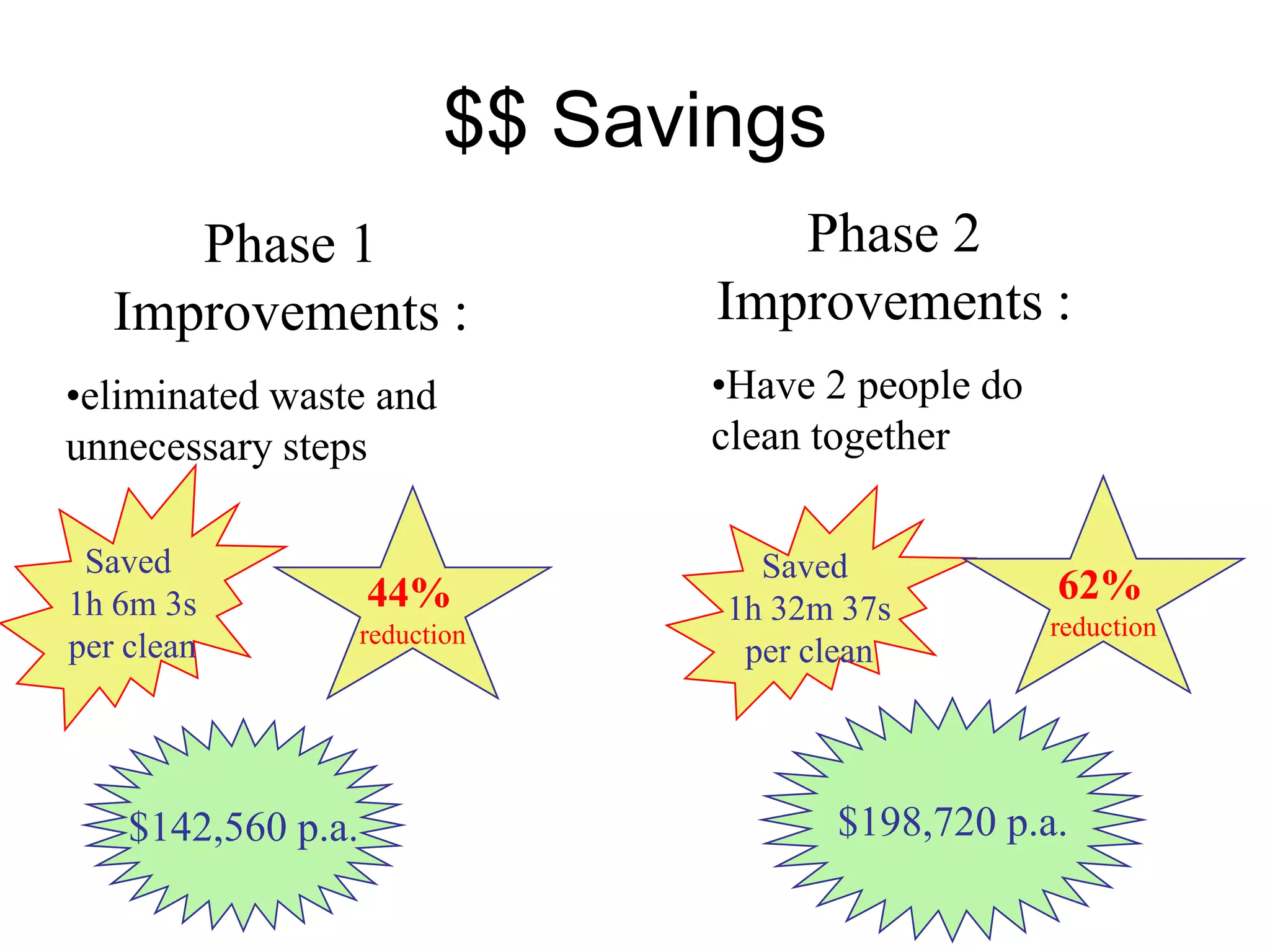

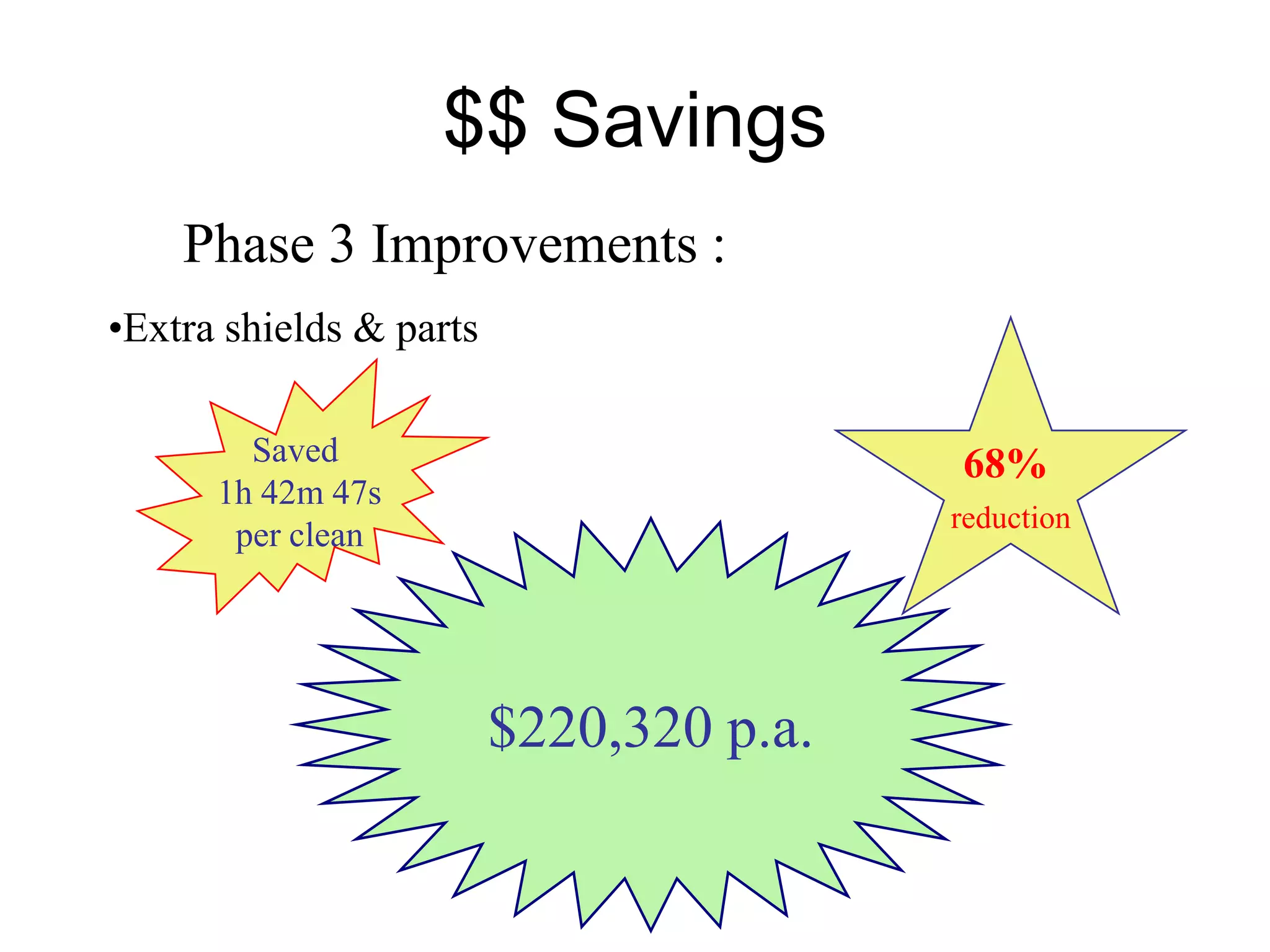

The document outlines a Kaizen Blitz event focused on improving the AR room changeover processes from October 24-26, 2015. Key objectives included reducing changeover time, increasing productivity, improving safety, and enhancing training materials, with specific actions leading to significant time and cost savings. The process involved detailed phases for eliminating waste, adding personnel, and optimizing resources, resulting in a 68% reduction in cleaning time and substantial annual savings.