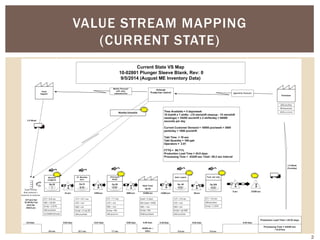

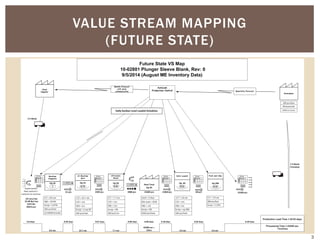

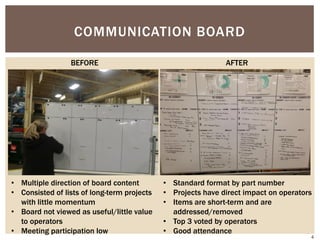

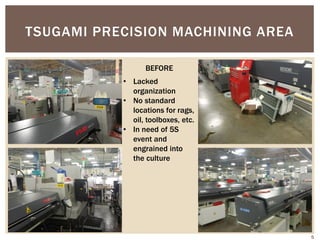

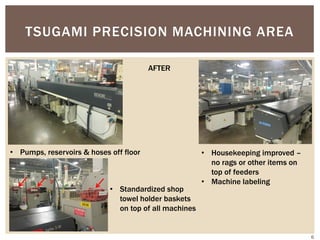

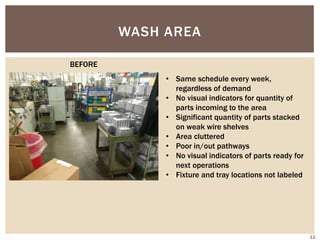

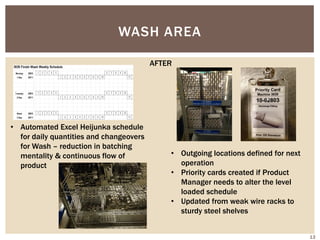

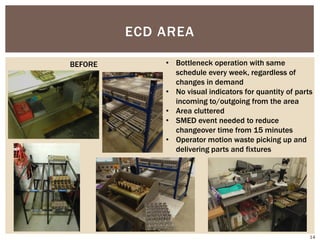

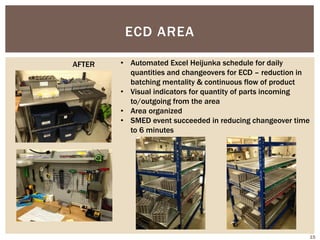

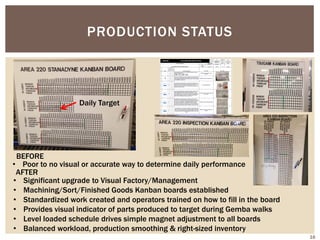

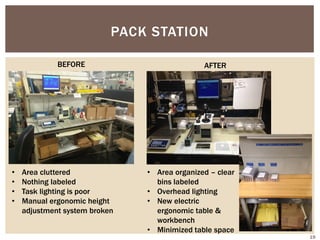

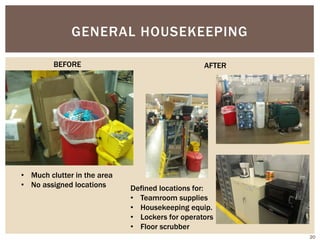

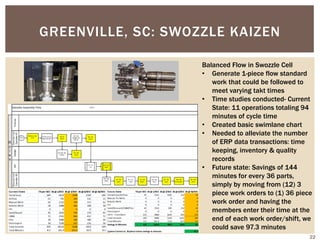

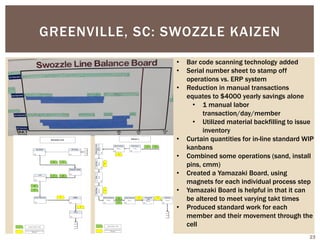

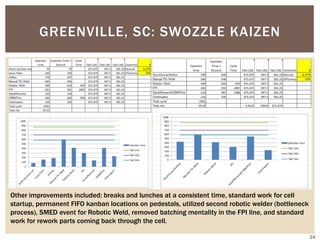

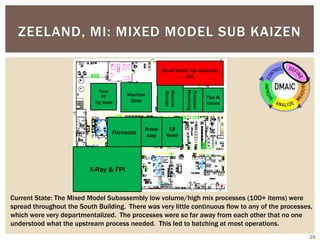

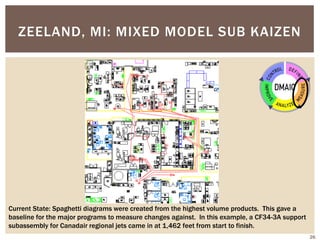

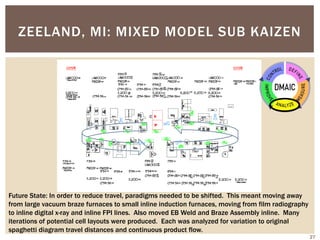

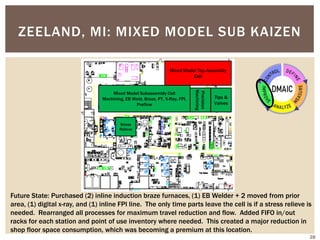

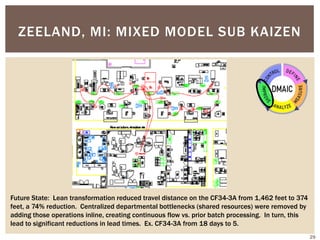

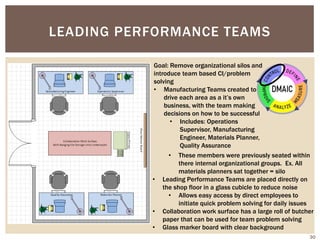

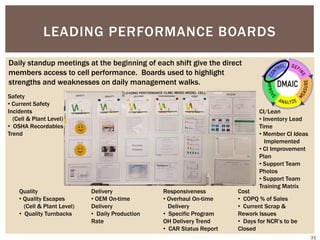

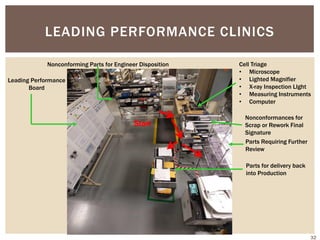

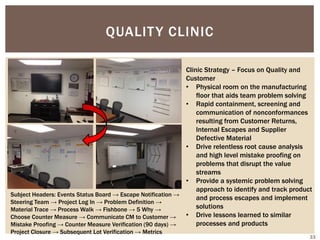

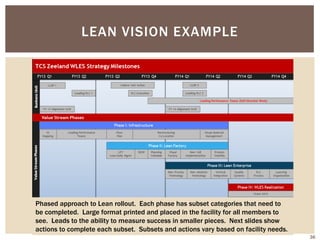

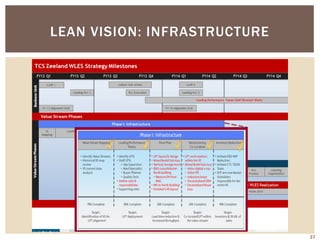

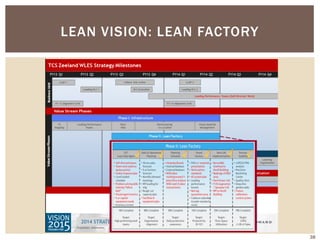

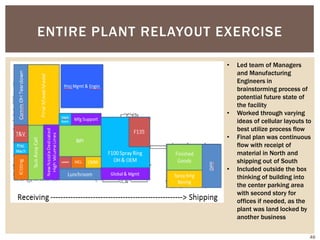

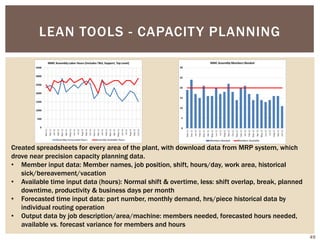

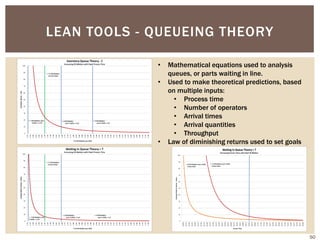

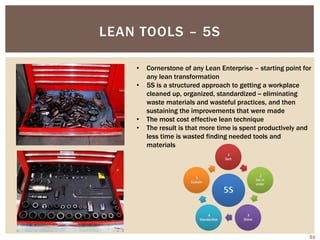

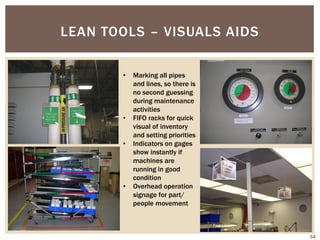

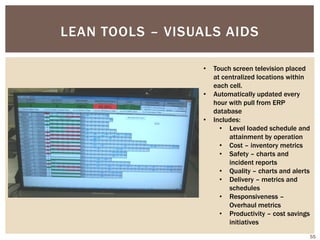

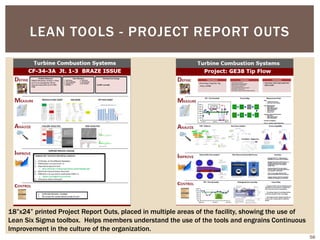

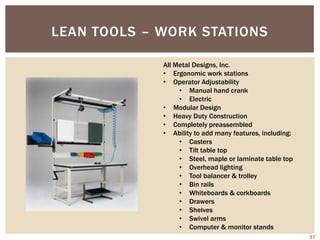

The document describes various lean improvements made at Stanadyne and Woodward facilities. It discusses implementing value stream mapping, standardizing boards and visual management tools, conducting 5S events, improving organization and flow, reducing set up times, implementing kanban systems, and level loading production schedules. Metrics like travel distance, lead times, and changes overtime were used to measure improvements. Training on lean principles and culture change was also provided.