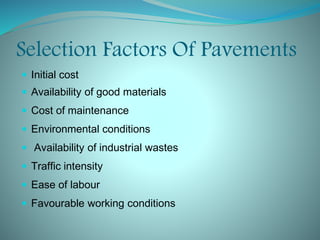

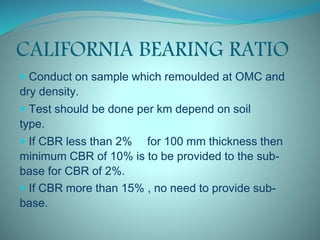

This document discusses different types of pavements, including flexible, rigid, and semi-rigid pavements. It describes key design factors for both flexible and rigid pavements such as traffic load, pavement materials, subgrade strength assessed by CBR value, and design life. The document emphasizes the importance of pavement design, noting it accounts for nearly half the road construction cost. Good pavements are important as they can easily bear and transmit loads.