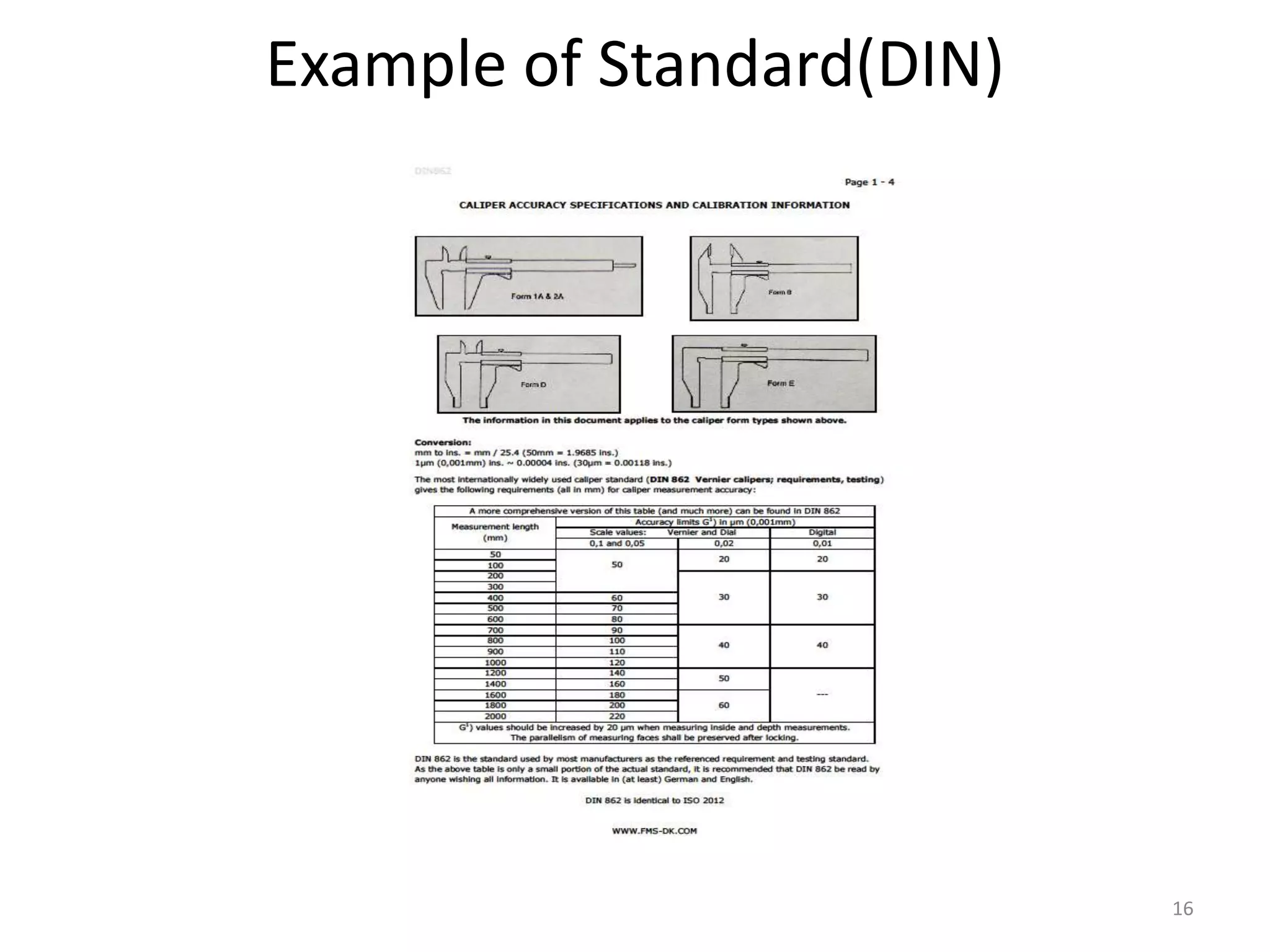

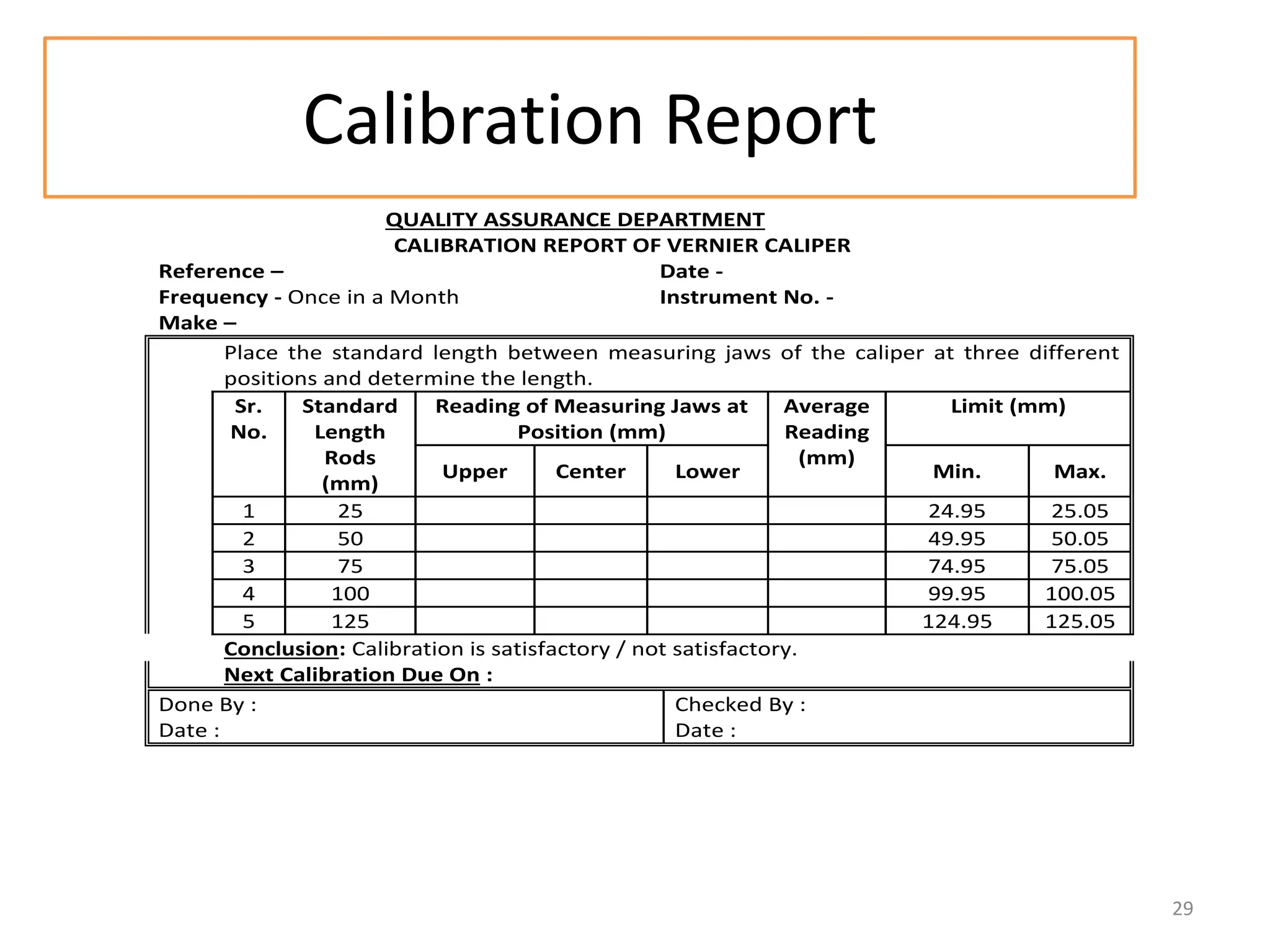

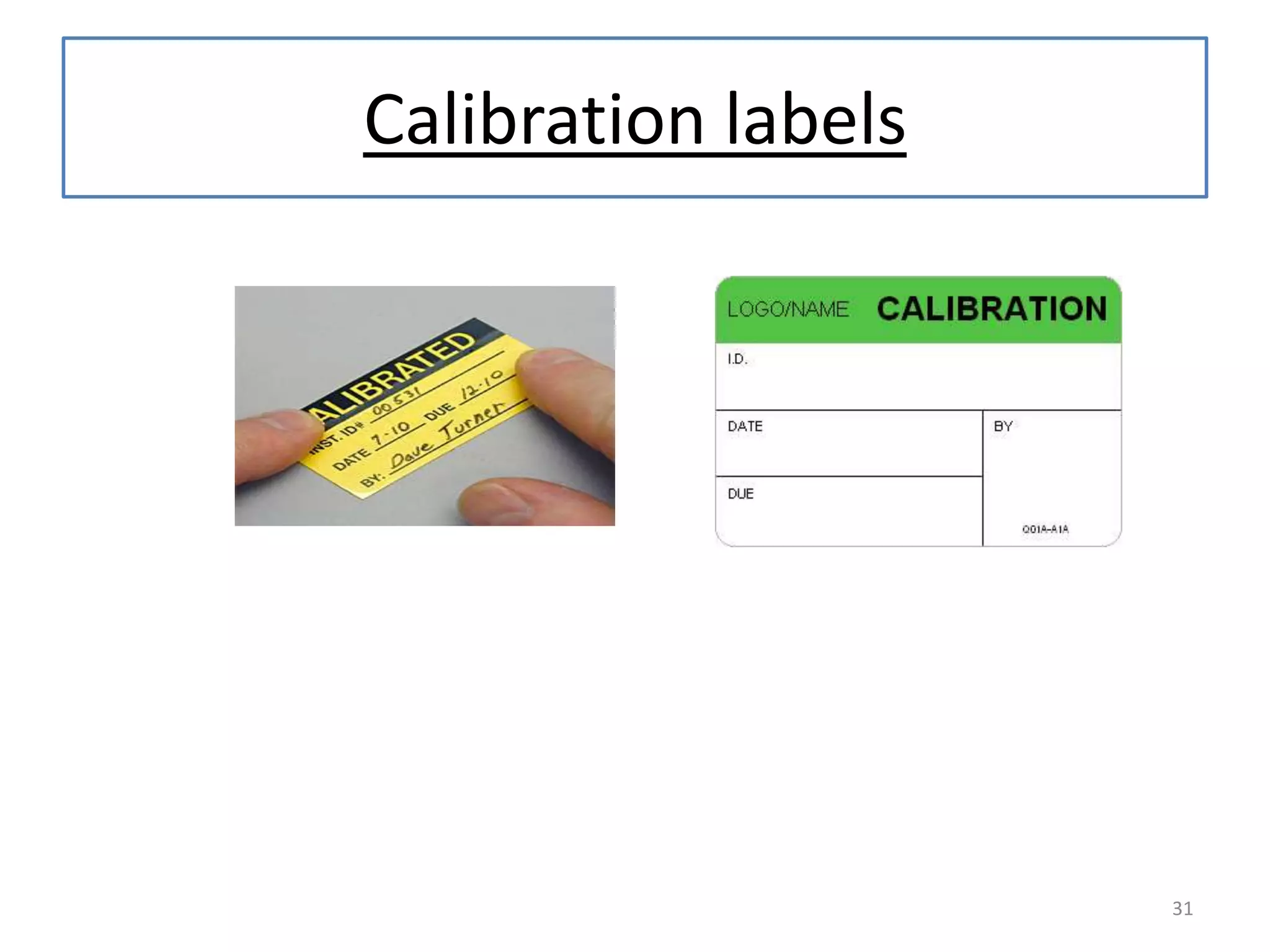

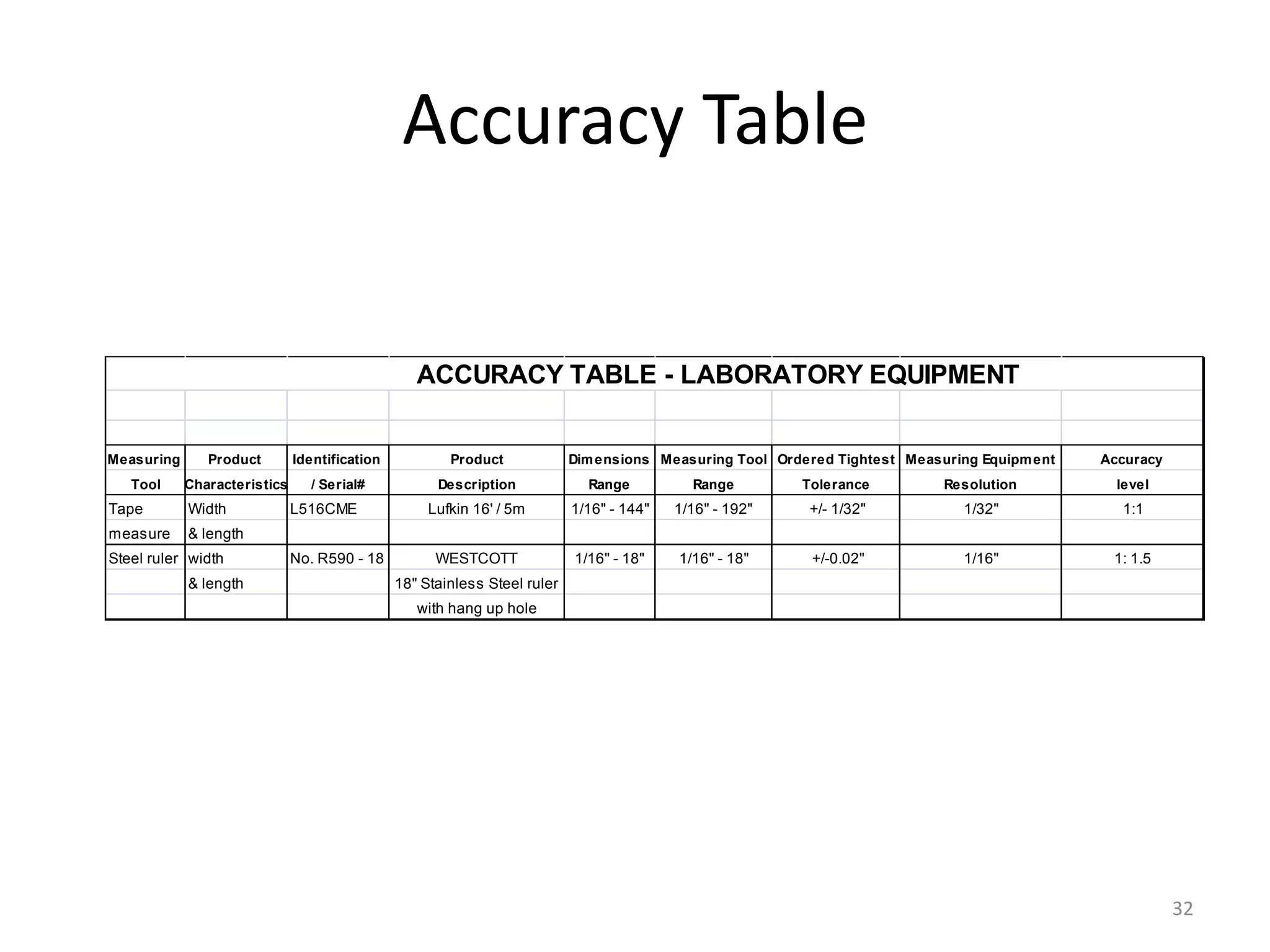

The document provides instructions for calibrating calipers. It describes the purpose, scope, procedures, environmental conditions, and types of standards used. The detailed calibration procedure involves cleaning the caliper, checking for defects, measuring standard lengths at multiple points with the caliper jaws, recording observations, and labeling the caliper with calibration details. Calibration intervals depend on usage frequency and environment, with more frequent calibration needed if past results were outside specifications.