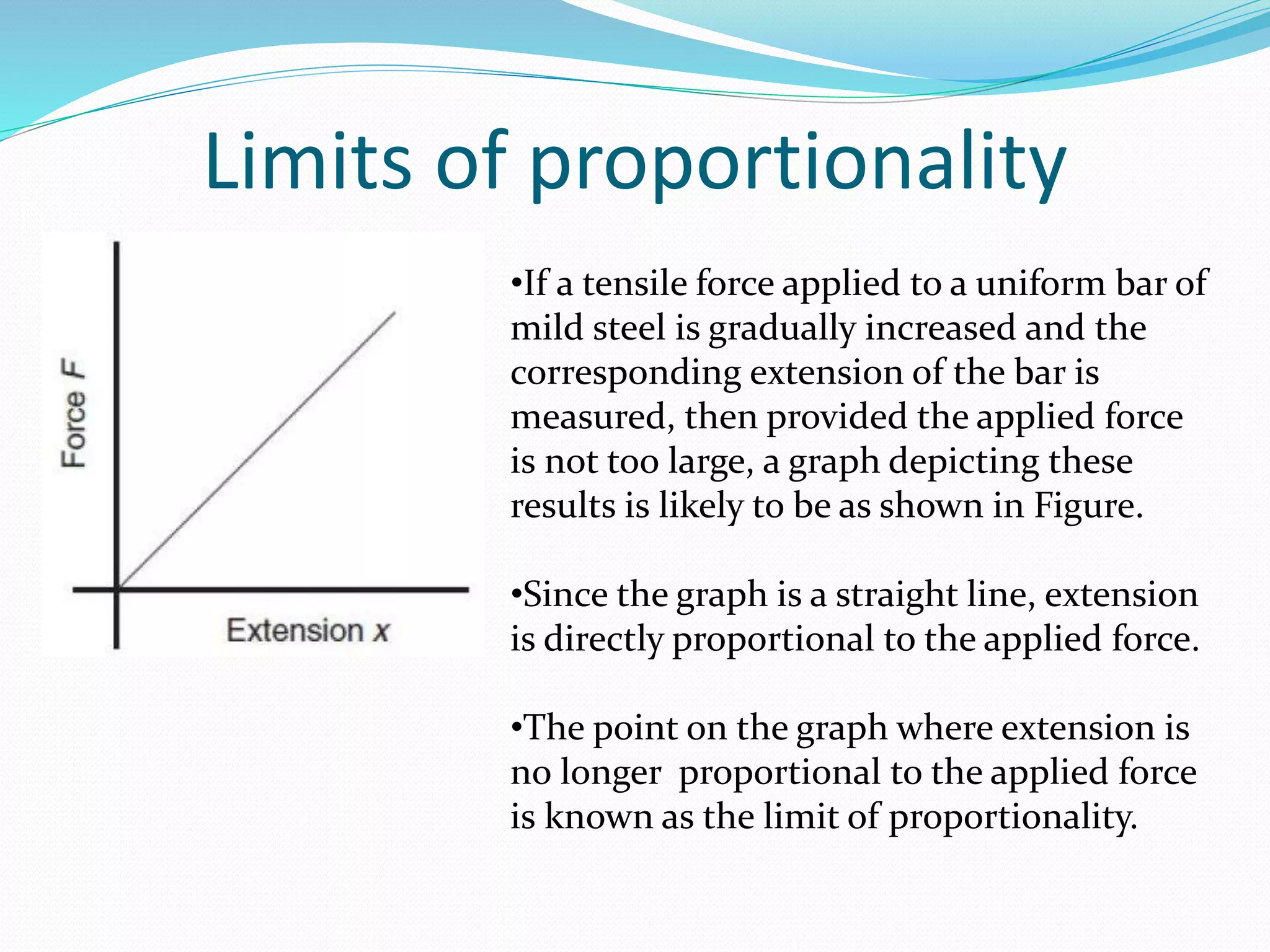

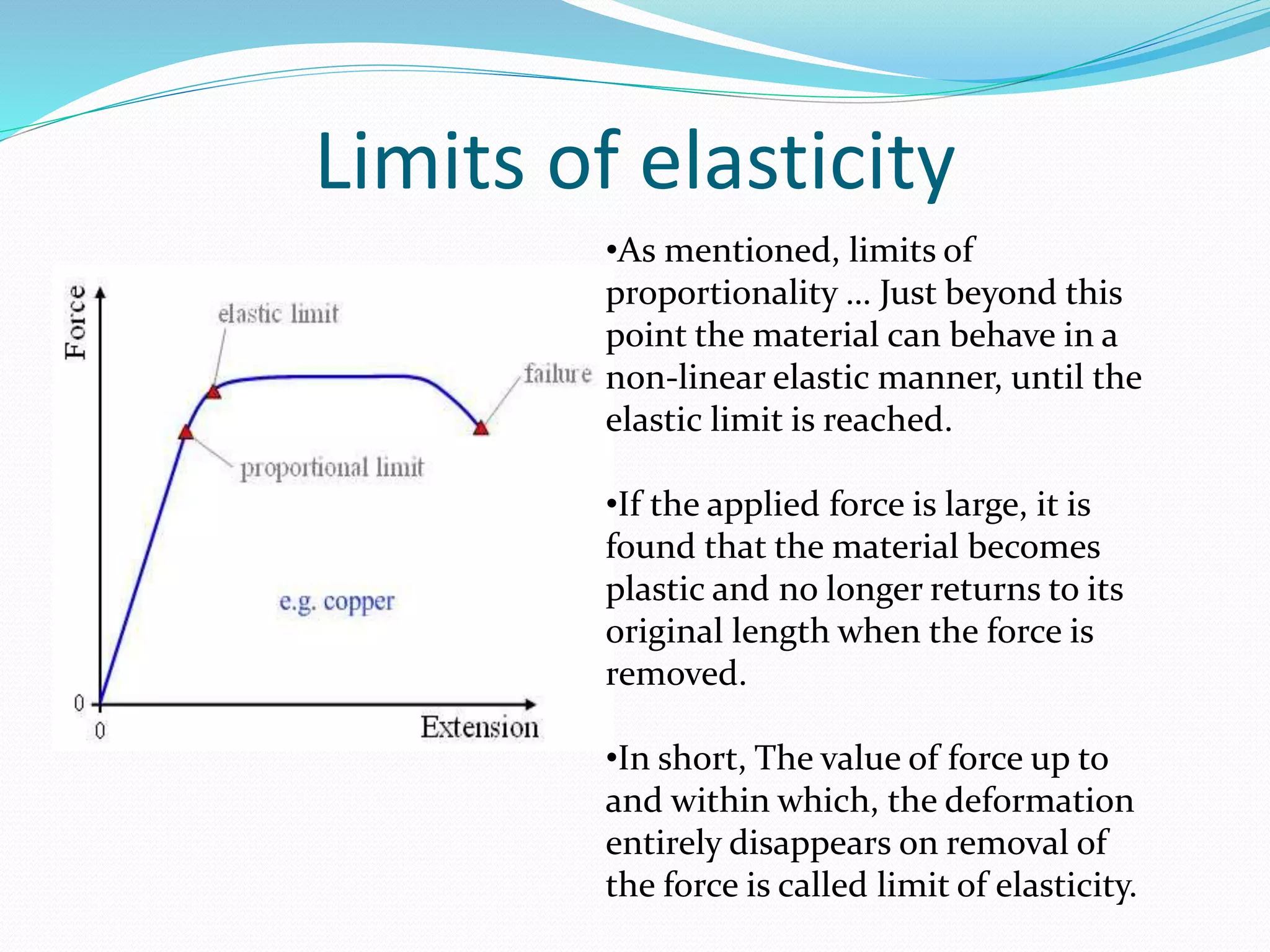

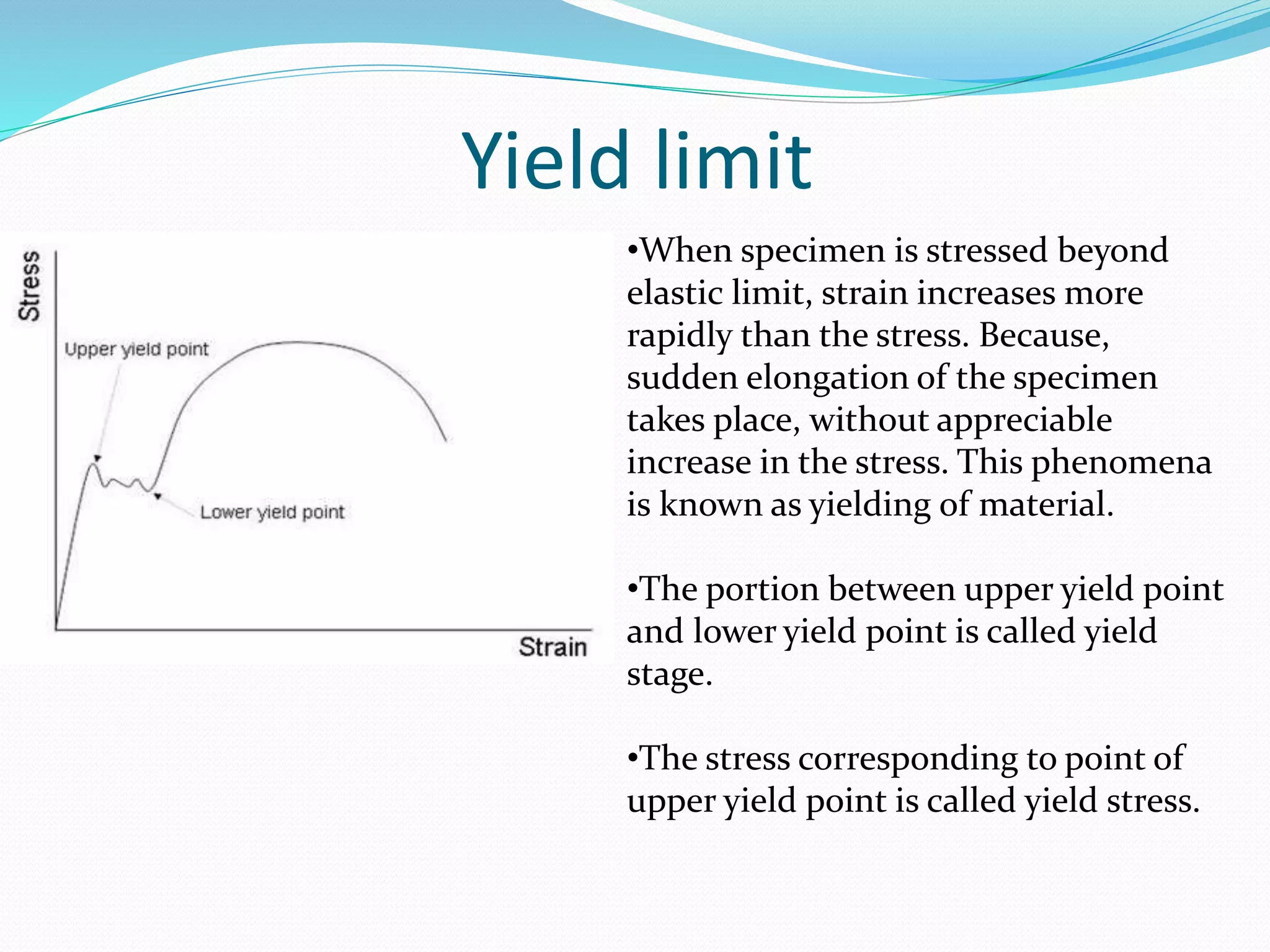

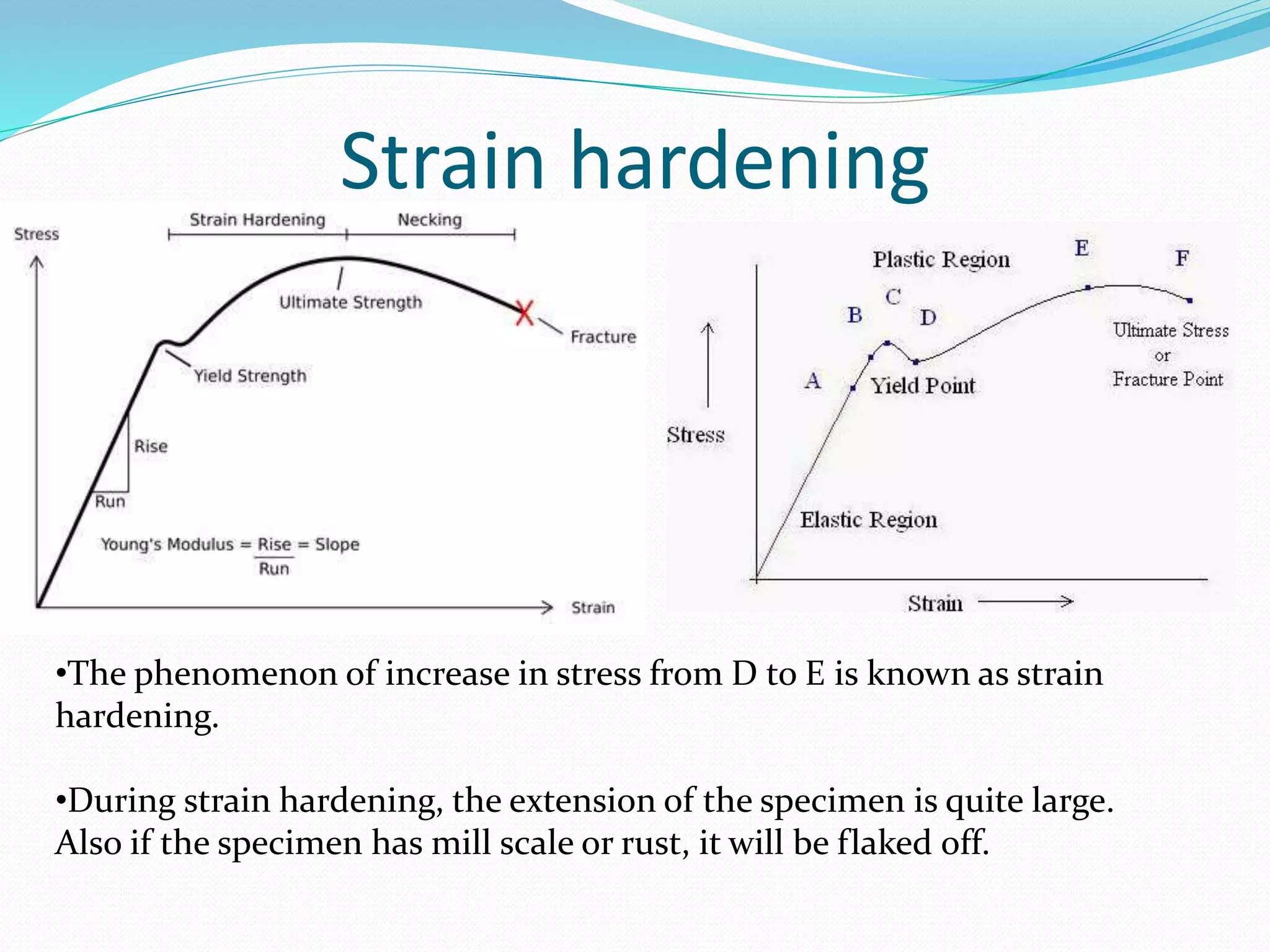

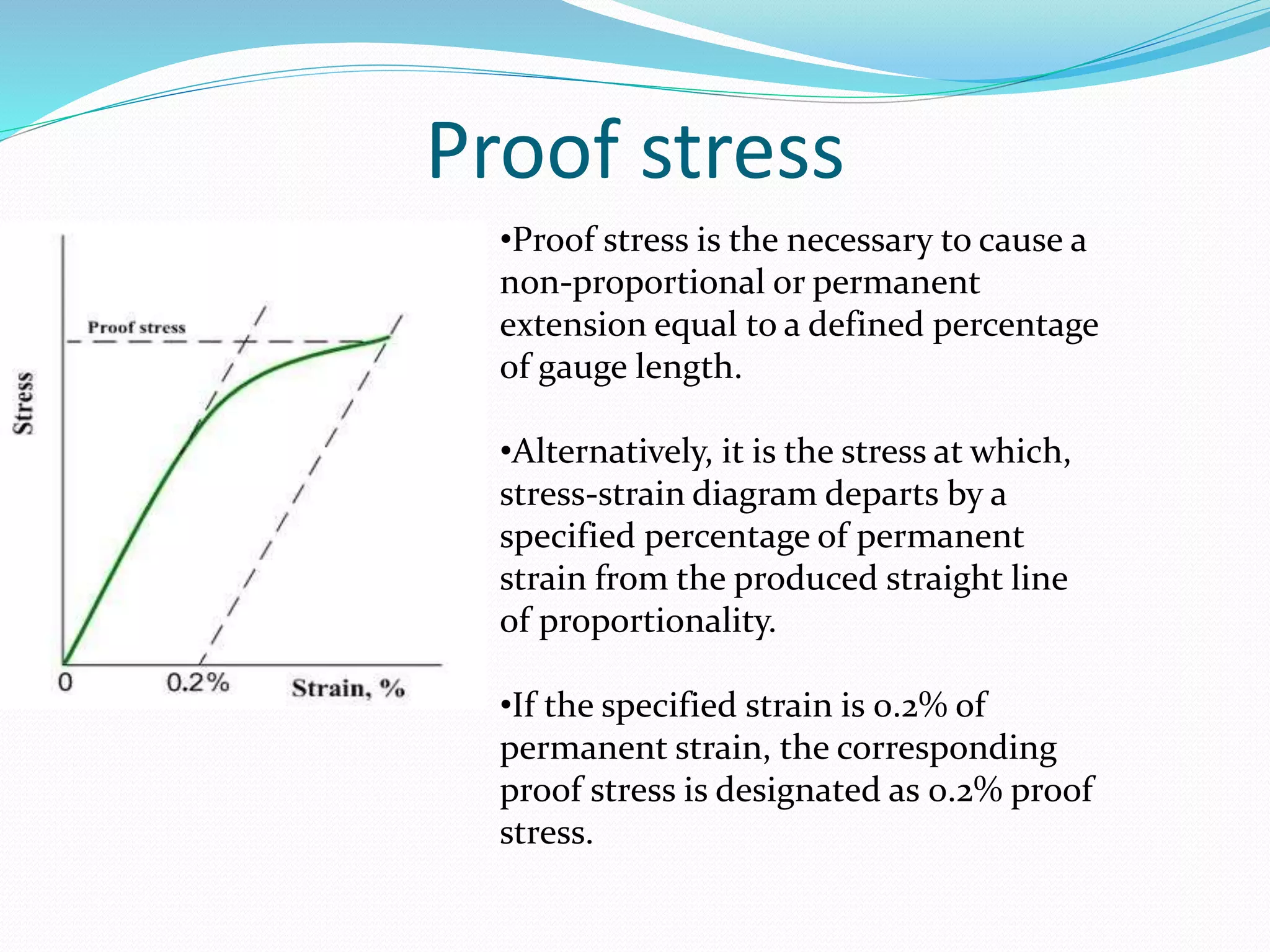

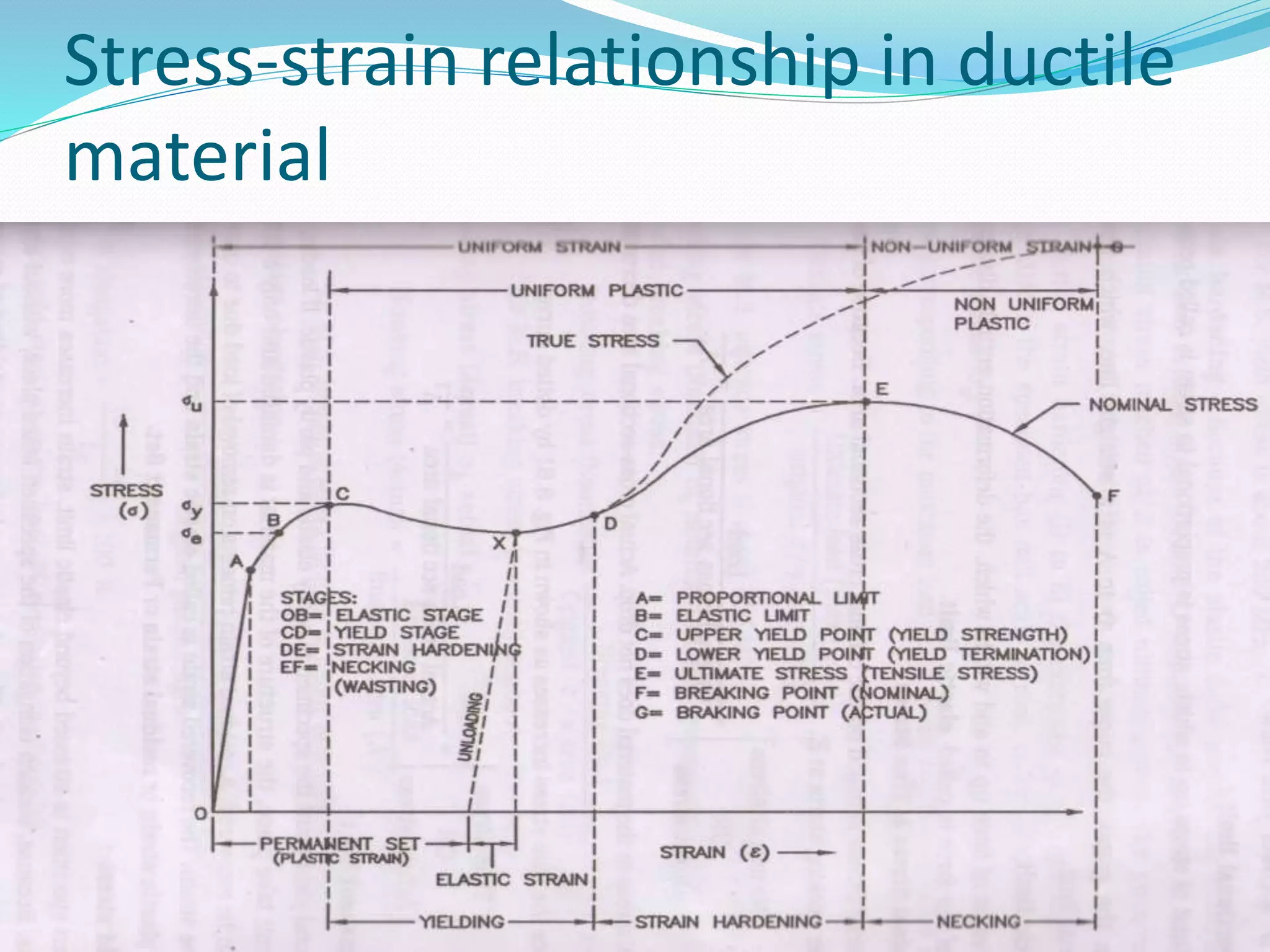

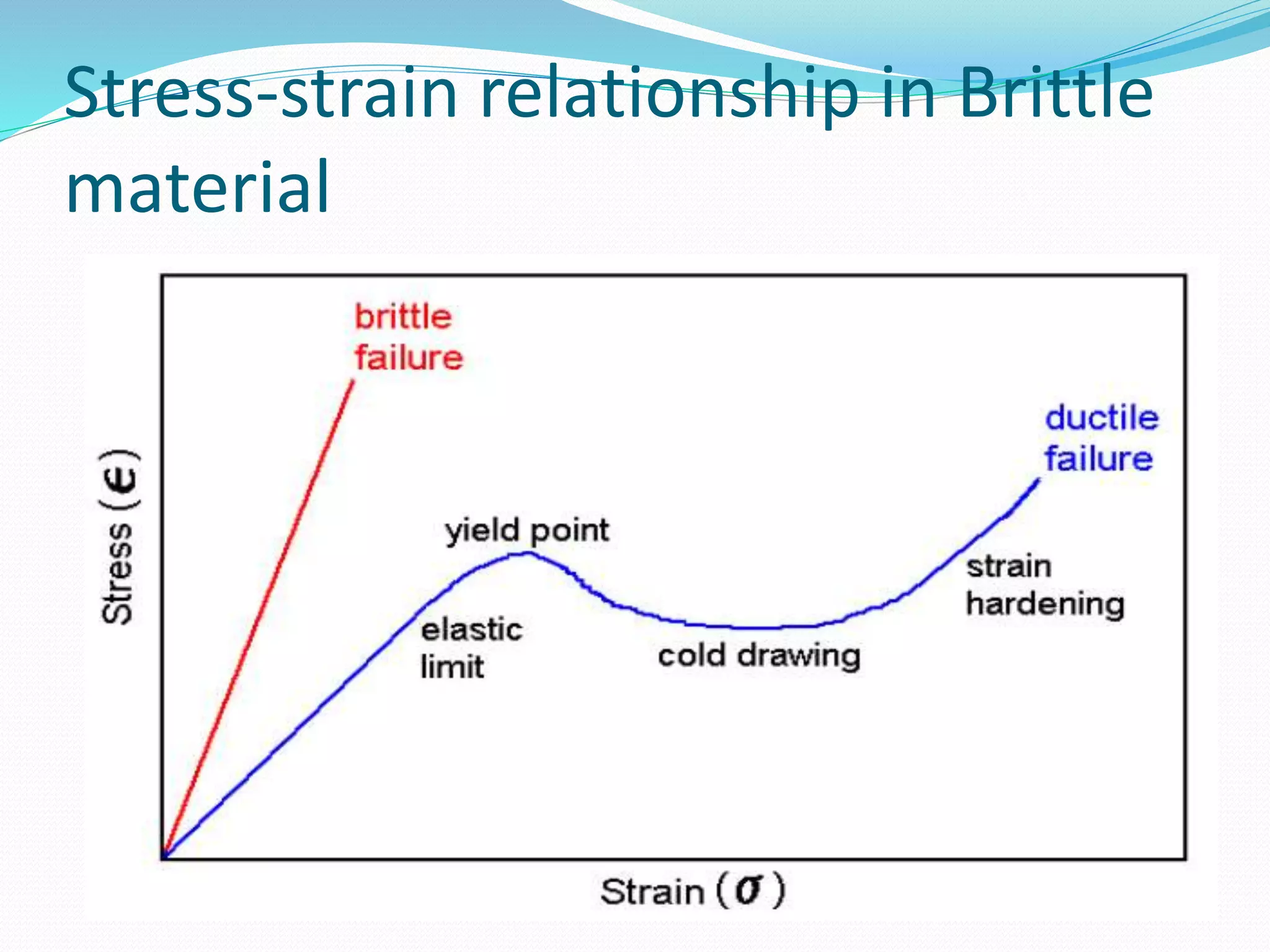

The document discusses key concepts related to elastic, homogeneous, and isotropic materials including: limits of proportionality and elasticity, yield limit, ultimate strength, strain hardening, proof stress, and the stress-strain relationships of ductile and brittle materials. It provides definitions and examples for each term and describes the stress-strain graphs for ductile materials like mild steel and brittle materials.