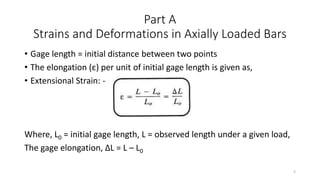

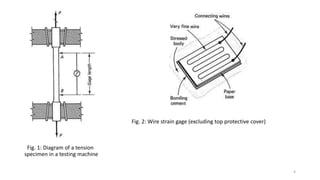

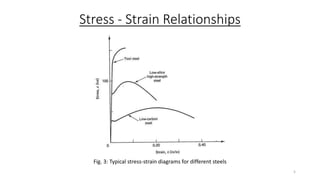

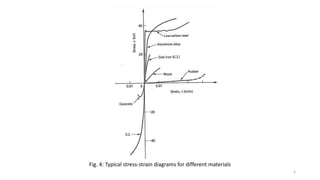

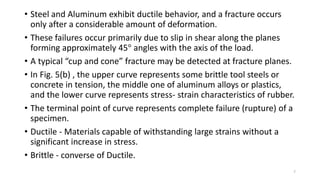

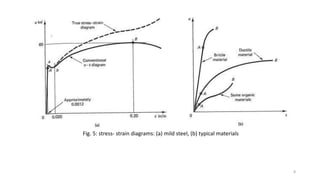

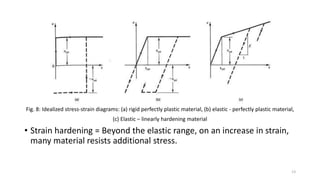

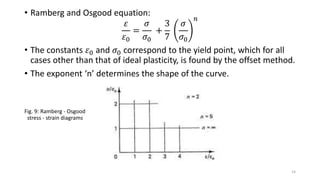

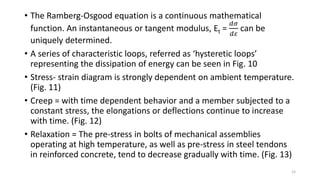

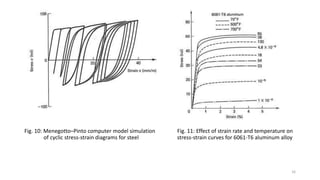

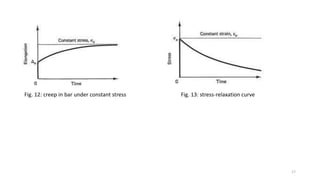

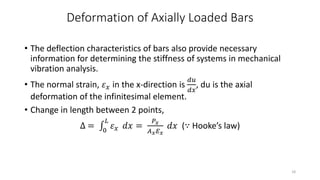

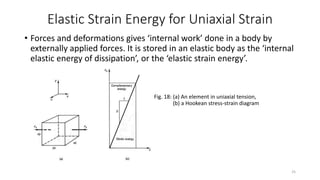

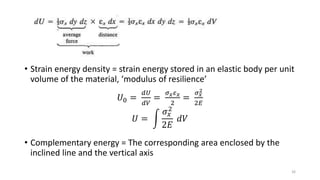

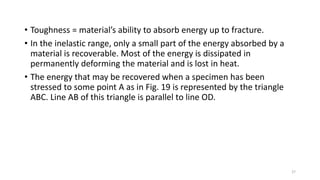

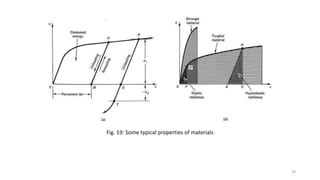

This document discusses stress-strain relationships in materials subjected to axial loads. It covers key concepts such as elastic and plastic deformation, ductile and brittle behavior, stress-strain diagrams, and the effects of temperature, strain rate, and time-dependent behavior like creep and stress relaxation. Measurement techniques for strain like strain gages and extensometers are also described. Various stress-strain models are presented, including Hooke's law, the Ramberg-Osgood equation, and idealized perfectly plastic, elastic-plastic, and strain hardening models. The relationships between stress, strain, elastic modulus, yield strength, and other mechanical properties are examined through diagrams and equations.