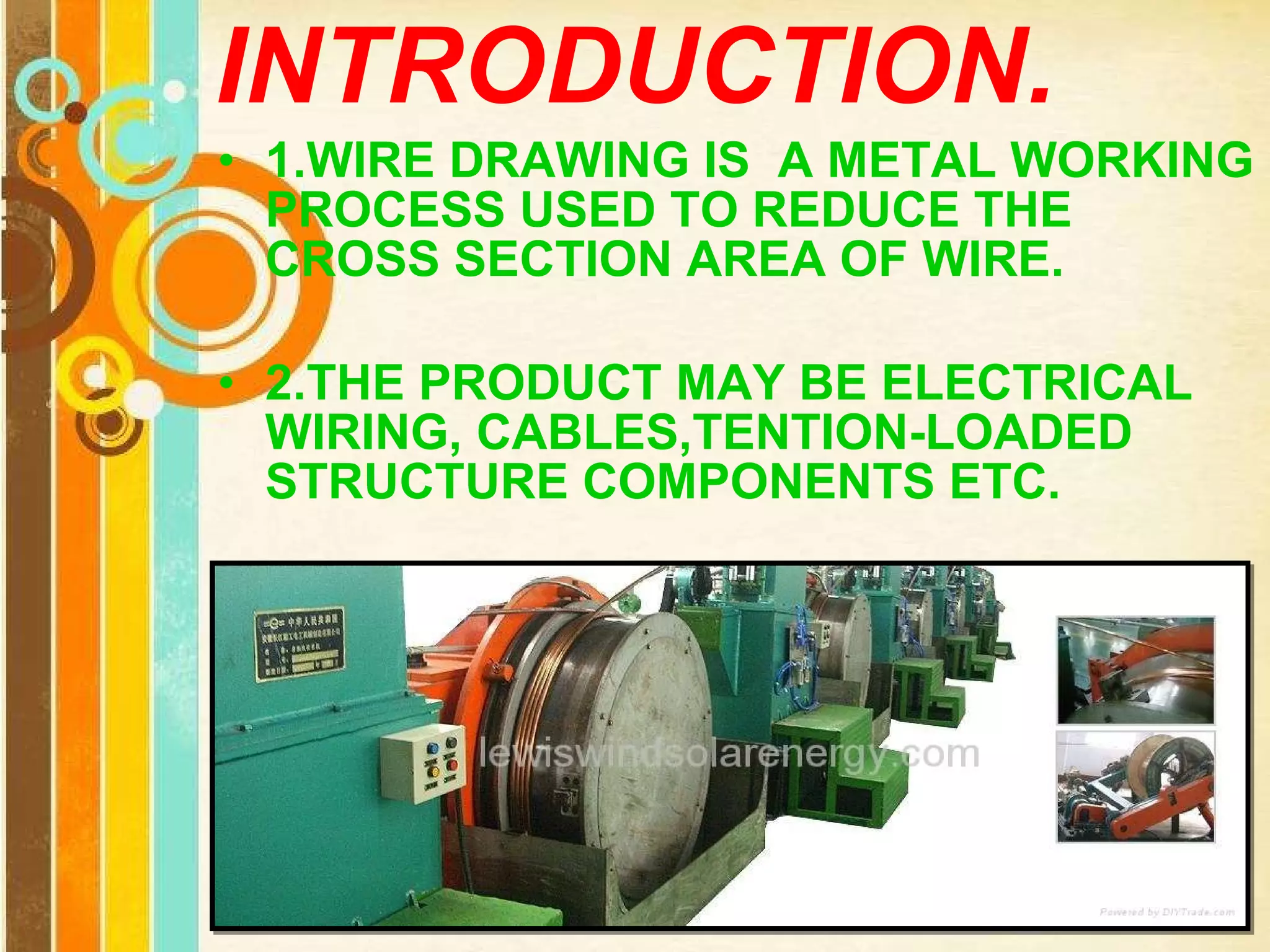

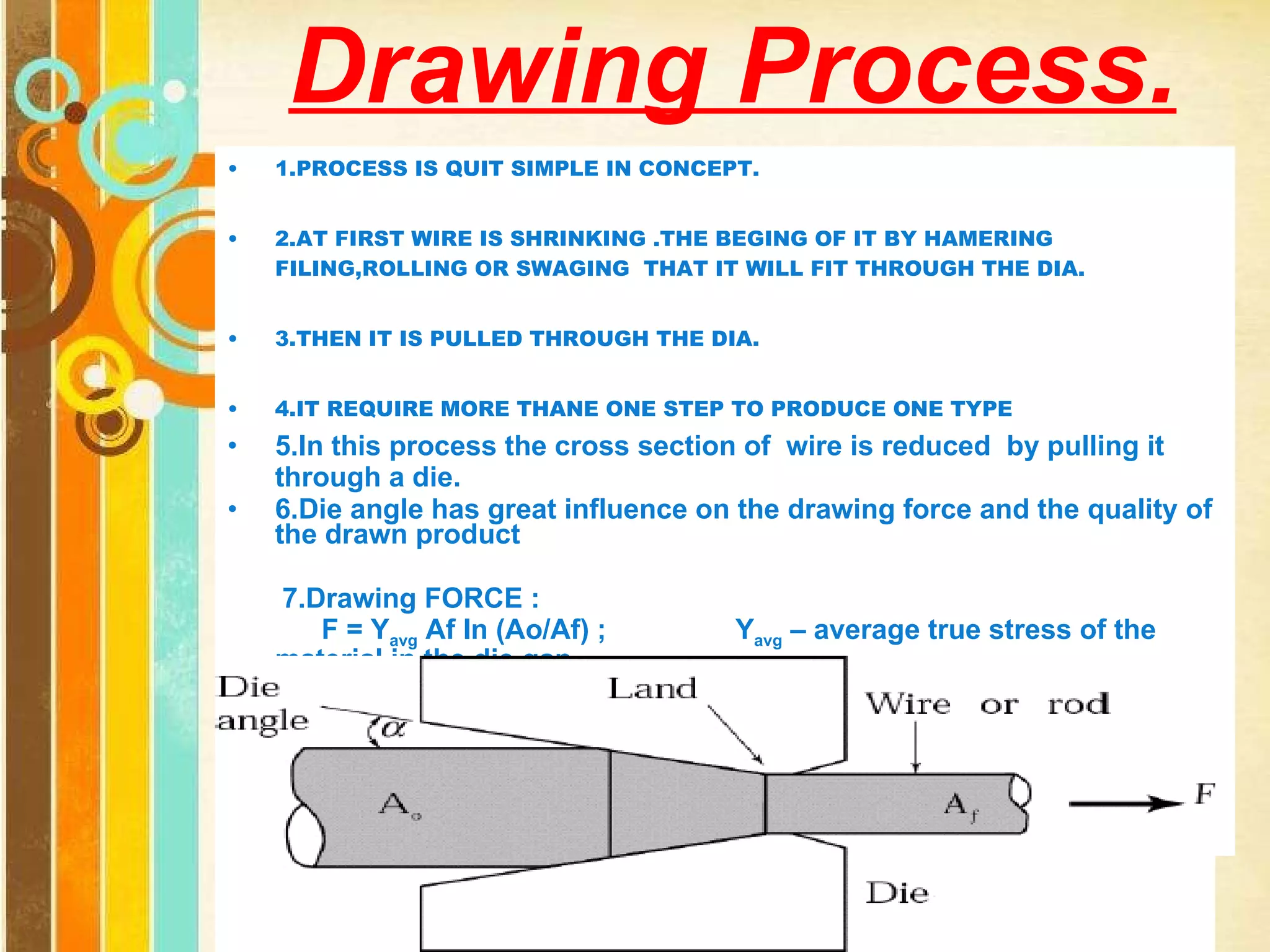

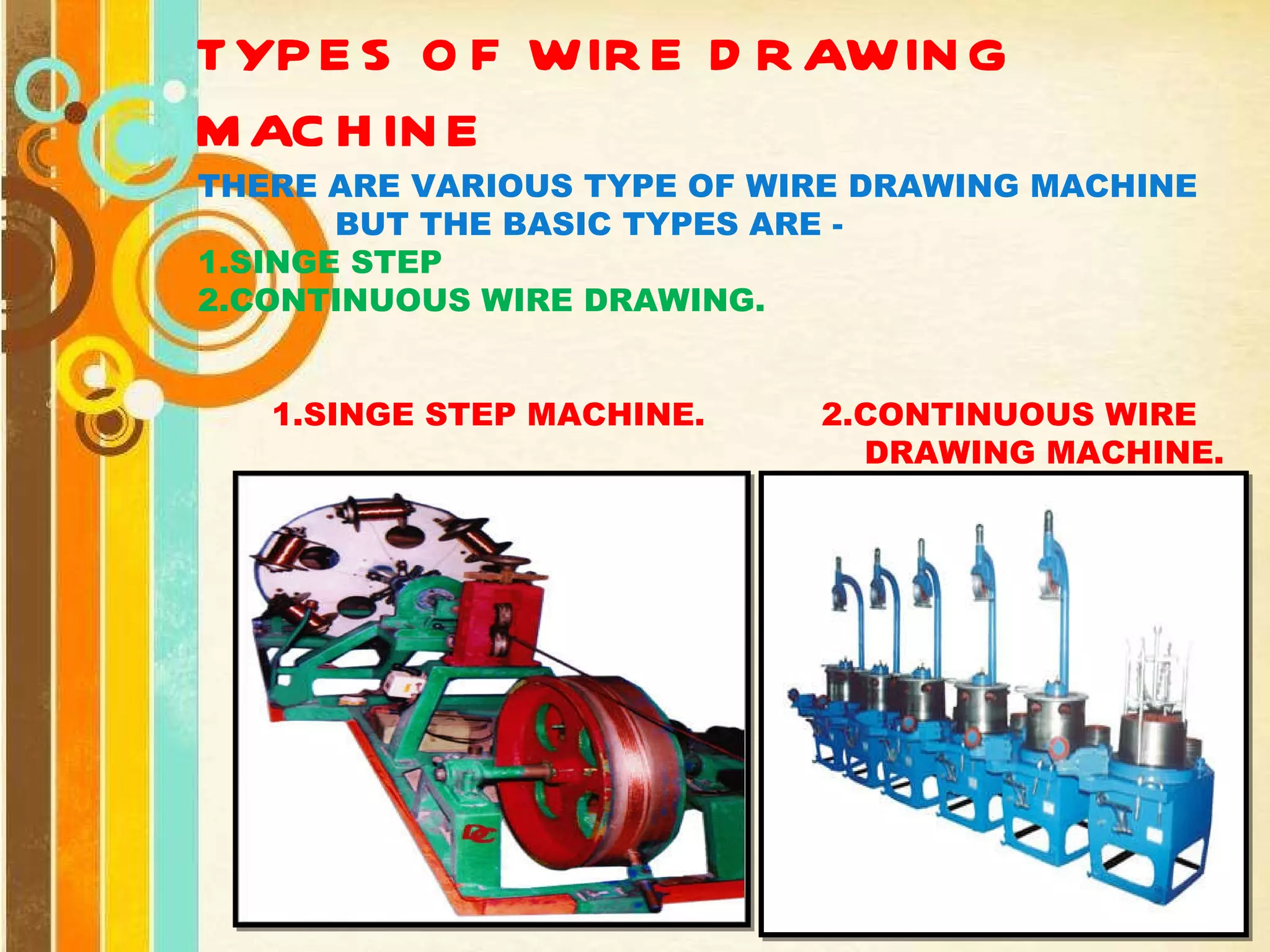

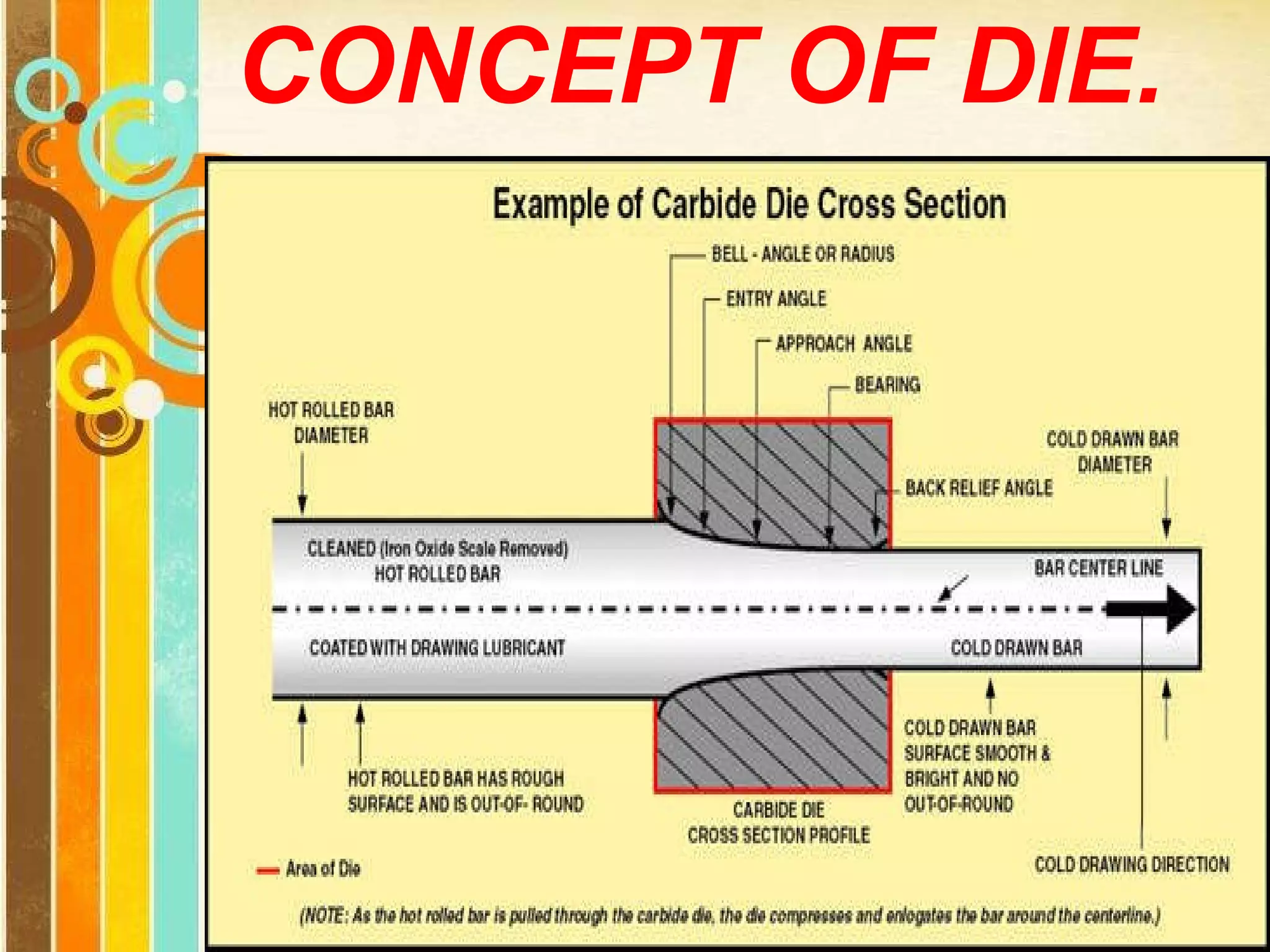

The document summarizes the wire drawing process. Wire drawing is used to reduce the cross-sectional area of wire by pulling it through progressively smaller dies. There are single step and continuous wire drawing machines. Proper lubrication is important for smooth finishes and long die life. Different types of dies and materials are used depending on the type of wire. Automation using programmable logic controllers allows maintaining constant speed and drawing force for high accuracy and reduced labor costs.