Product Design Coursework

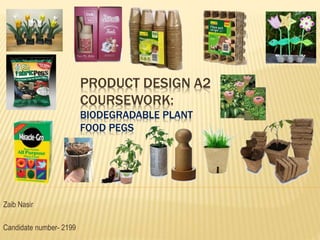

- 1. PRODUCT DESIGN A2 COURSEWORK: BIODEGRADABLE PLANT FOOD PEGS Zaib Nasir Candidate number- 2199

- 2. DESIGN BRIEF CHILDREN'S BIODEGRADABLE PLANT FOOD PEG PRODUCT DESCRIPTION/PURPOSE The need for more environmentally friendly products is becoming more prominent in today's market. It has also become more common to have various campaigns targeting young people to get involved with their own microcosm environment, to get involved in gardening and tending to nature in their own way. My product aims to get children interested in gardening using a aesthetic biodegradable plant food that children can plant in their own gardens, but will naturally decompose acting as a nutrient for the surrounding area. FUNCTIONS The product will be focusing on its environmentally beneficial aspect with its biodegradable feature. However, as this product is for children it also needs to be able to appealing as opposed to a standard gardeners practical plant food. So also a big aspect of the product will be its aesthetic feature. Some possible ways of this being developed would be designing the product in the shape of wacky flowers or plants, something that’s appealing to children but will also look good in the garden itself. CONSUMER NEEDS The target market is for children to use the product, however parents need to purchase so it needs to appeal to both markets. •As an item intended for children the product needs to be simple and easy to use, as well as not adding further complication for the parents. •As a product that is meant to naturally biodegrade it needs to be cheap, as its not built to last. •It needs to be aesthetically pleasing. MATERIAL One of the main focuses of this product would be the material, focusing on what would be the best material to mix the plant food with and also how it will biodegrade naturally and quickly. This page gives an overall introduction to my whole basic product and idea. In order to go about designing and developing my idea I first I must review the ‘skeleton’ of my starting point. These biodegradable plant pots already on the market use kinds materials that I would also be looking to use. Usually they are made of compressed developed compost or fibre, sometimes a paper alternative and they retail approximately at 20p each depending on size. The material wouldn't cost a lot to manufacture. These ‘plant food spikes’ are meant to stick into the soil beside the plant to give the plant some extra nutrients. I want to incorporate these ‘spikes’ with the aesthetic appeal and biodegradable aspect to appeal to young children. Currently, this product retails at approximately £1.27 for a pack. Another example of a biodegradable product is these garden pegs to temporarily secure materials to the ground and they can be buried into the soil when finished. Although no harm is done to the environment no benefits are actually had with this product in terms of soil and plant nutrition. My product aims to incorporate various elements of the products shown above LIST OF THINGS TO ADDRESS •Aesthetics: I need to know what kind of shape and colours appeal to children. I will draw up some possible designs then interview a child asking which one they like best. At the same time, the product mustn't look tacky and must have a professional feel about it, so it can also appeal to the parents of the child as they are the ones who are buying. •Anthropometrics: I need to do some research into how the product can be used by children easily and ergonomically fitting to their hands. The current plant food spikes on the market are too thin and small for children to adequately use them •Material: I need to do some research or perhaps obtain specialist help on what biodegradable materials can mix easily with a plant food solution. I need to also do some separate research on biodegradable materials itself, perhaps purchasing an existing product suing it and seeing how it already works. CONCLUSION As far as my current research has shown me, this product is unique in that it appeals to a younger audience and that it can naturally decompose. Further specialist research may be required for the material side of the product (combining the plant food with the biodegradable material) and I will need to do some research on developing the product anthropometrically fro children and aesthetically interesting in terms of shape and colour. PotatoPak is a material I could consider researching as a biodegradable material. The product is made of waste potato starch as the raw material and is vacuum moulded. There’s other biodegradable DESIGN BRIEF

- 3. MOOD BOARD This page explores possible designs and materials that could help into producing and designing my product. Part of my research and development. Part of the images I have included explore different biodegradable materials, aesthetic features of modern gardening products and the anthropometrics of kids gardening product on the market.

- 4. INSPIRATIONS GAINED FROM MOODBOARD Highlights some main inspirations I have from researching different products on the market. The innovative design used here in the children watering can appeals o both children and adults with its aesthetic appeal and toy like nature, I wish to incorporate this into my product as well Potato pak is a biodegradable material used in packaging like disposable cups and plates. Its an interesting concept which I wish to explore and consider to use in my product as well. I want my product to have an aesthetic appeal to adults as well as children Like this compostable crisp bag I want my product to have a biodegradabi lity function and to be compostable. These tools have been specially designed with children in mind. I want to make sure that my product is ergonomic so that children can easily grip and use it with ease. I’d like to also keep in mind the minimal. During my research of other products on the market I have established the best products for children are kept reasonably simple for them to understand how to use it and the product itself doesn’t look to cluttered. The compactness of products is a useful element for product to have. The consumer would prefer and purchase a product that they can easily store like these ones. The colour coalitions of the product all have combinations of the natural and gardening, I want my product to have the same. This innovation and creativeness is unique and stands out on the market, this is a good feature to have.

- 5. Start producing models using a variety of techniques and materials. Develop a range of ideas, displaying in the coursework the progression of ideas and solutions Start to focus upon developing products specifically for the final product Using safety standards information, test materials in destructive and non- destructive testing Develop more ideas through CAD using Google Sketchup Througho ut ensure child safety and hygiene is considere d Is the produ ct safe? Produce a 3D isometric and 2D orthograp hic projection s of Final Design Assemble Final design Any areas need specif ic impro veme nt? Contin ue to Finish Final Design Take product back to clients across the market – record voices and write reports Develop a Marketing Strategy including advertisin g, marketabil ity, advert, logo design, product name Begin to Evaluate design, comparing back to specification and 3rd party feedback comments, including future developments Write up and carry- out small improvemen ts for future developmen ts using CAD or sketches Evaluate entire process – compare back to this project plan ENDSTART Identify the key areas to research to help developme nt of my product. Link in with current manufacture s relating to my product. Keep in mind safety as the product is for children. Gain inspiratio n and ideas via current products of the market. SEP Have I got enough informatio n to write an adequate specificati on? Get outsiders to asses and provide opinion of situation Focus on anthropometrical data , ensuring it is relevant to the target market which would be children. Write a justified and detailed product specification Outline some basic ideas using rough sketching to mind map thoughts. YE S OCT NO Begin sketchin g using inspirati on and researc h to aid in the process Fine line, highlight and analyse successful ideas with scope for development against specification Need for close- up mechan ism drawing s? Using peer assessment and client analyse narrow the ideas down and develop further. NOV YE S NO DEC Do some material testing for the biodegradable aspect of my product. JAN FEB MAR APR NO YE S NO YE S PRODUCTION PLAN Before starting my project I believe the most important factor in the success of my product is my project plan. Here I have produced a time-scaled flow-diagram to illustrate my entire design process. Using a specific project plan allows me to time manage this project and maximise possible outcomes. This may not be entirely accurate but gives a general guideline.

- 6. DESIGN RESEARCH MANUFACTURER RESEARCH This page gives an in depth research into three manufactures I contacted requesting an answer to the questions I asked in the email below. They provided information regarding their materials and the science behind them, this way I can make an informed decision into which material I can use for my product. I contacted three manufactures of biodegradable products via email (Vegware, Bio-D and Biopla) and asked them questions regarding how their specific material works. I can use all this information to help me make an informed decision on which biodegradable material is best to use for the product I’m intending to make. Getting an insight into how the material on the market work can help me develop, improve or perhaps tweak my idea appropriately to suit the needs of my target market. Vegeware, manufacture of compostable products . They wrote back saying it is important to note the difference between the term 'biodegradable' and 'compostable'. Biodegradable can be a misleading term as it doesn't specify a time for breakdown. A wooden house for Vegware are a manufacture of eco friendly catering disposables and food packaging. compostable products spans cutlery through to tableware, napkins hot and cold drink cups, and takeaway packaging. Bio-D promotes the use of hypoallergenic, environmentally responsible detergents they also do compostable bin liners. Biopla is a manufacturer of biodegradable compostable material and bio plastic products including vacuum moulding , blowing film, injection , foam and PLA staple fibre example is biodegradable but can stand for generations. Compostable items break down quickly within a composting environment (heat, microbes, moisture etc) and as such only compostable items can be recycled with food waste. Everything that is compostable is biodegradable but not everything that is biodegradable is compostable. All of Vegeware’s products are certified compostable. This means that they can be recycled along with food waste and under son trolled composting conditions they will break down in under 12 weeks. MATERIALS PLA: Made from corn starch, tapioca roots, chips or sugarcane. PLA can be used as a compostable packaging material, either cast, injection moulded, or spun. Cups and bags have been made of this material. In the form of a film, it shrinks upon heating, allowing it to be used in shrink tunnels (a heated tunnel mounted over or around a conveyor systems so items such as packaging, have shrink film loosely applied with heat, the film shrinks to fit snugly around the wrapped object). It is useful for producing loose-fill packaging, compost bags, food packaging, and disposable tableware. In the form of fibres and non-woven textiles. CPLA: A combination of PLA, chalk and other biodegradable additives. Although CPLA has a high molecular weight and high melting-point, it begins breaking down into a low-molecular weight polymer, in natural environments, after 5-6 months. Complete decomposition after 12 months. When composted with food garbage, it begins breaking down into a low-molecular weight after 2 weeks. (this is an ideal decomposition time for my product). CPLA is made by made by fermenting cornstarch, cheese whey, etc. with aliphatic polyester (e.g dicarboxylic acid or glycol made from fermentation of glycerol). All are renewable resources. Bagasse: This is the dry fibrous residue left after sugar cane fibre has been pressed. It is ideal for producing tableware due to its strength, and can be considered a tree-free paper. It is currently used as a bio fuel and in the manufacture of pulp and building materials. Agave bagasse is a similar material that consists of the tissue of the blue agave after extraction of the sap. At the moment this is used as an alternative to Plywood and is used to make furniture. It isn’t built to decompose so probably wouldn’t be the best choice to be a material for my product. Natureflex: Compostable cellophane made from sustainably-sourced wood pulp. The manufacturing for NatureFlex is based on the process used for both Cellophane films and viscose fibres. To achieve the required composting standards, the chemistry of the process is altered during the development of the NatureFlexfilm range. Mulch film made from a PLA-blend called bio-flex. MANUFACTURE R FEEDBACK

- 7. CLIENT RESEARCH Using a survey I conduct research of what my client requires. I also establish the needs of consumers, manufacturers, distributors, and retailers. I also investigating the work of other designers in gardening innovation This Grobal Self-Watering Planter retails at $25 or £15.28 and is a contemporary plant pot designed by Karim Rashid, and comes in variety colours. It's selling point is the fact that it’ self watering. The Grobal product draws water and nutrients from the reservoir into the soil in the top chamber. Each Grobal egg- shaped vessel is made from a high- gloss plastic and available in a range of Bottle Top Watering Spikes are ‘fill it and leave it’ waterers. The water can last up to 2 – 3 weeks. The Bottle Top Watering Spike is one of the first, fully automatic, weather or room temperature controlled watering system. They utilise discarded plastic drinks bottles, or decorative green’ flasks as a reservoir. Watering Spikes can be used indoors or outdoors, for use in hanging baskets, pot plants, patio pots etc. Watering Spikes are an ideal ‘Holiday Watering Solution’’. They retail at £4.00 each. I would try to implement the practicality and versatility of this product to mine. …The only plant maintenance needed is to periodically check the water level through the in built indicator and refill when needed through the front 'Nutriport'. This products low maintenance yet aesthetic appeal I what I need for my plant nutrient spike. Perhaps I could also could consider adding more features to the product. As it stands it simply biodegrades providing nutrients for the soil, but it also could somehow provide a different use as well. The plant nanny is for a forgetful plant owner or a frequent traveller. The Plant Nanny Stakes are here to water the plants and use your empty wine bottles. You fill an empty wine bottle with water, attach the threaded Plant Nanny Stake and stick it into a pot. These plant caretakers are designed to release just the right amount of water into the soil by gravity feed, keeping the roots of the plant at the correct moisture level. Ideal for any type of potted plant, with one wine bottle allowing for up to 7 days of water for a 1-gallon pot. A set of four can be bought for £10.36. SAFETY ISSUES Safety is fundamental to the design of products, especially as the product is for children. |Firstly there’s the hazards during the manufacturing to the workers and such, use, maintenance, cleaning I did a sample of 10 sample parents going to and coming out of a garden centre. Generally , they placed health and safety as well as practicality in the top priority position for what they thought would be the most important element to the product. When talking to a few children they preferred the idea of something more aesthetically pleasing , something associated with a character and colourful, they didn’t really care about the function aspect. Most of the response received in regard to weather the children get involved with gardening was no, when asked to elaborate they said there’s nothing really to get involved to. The market for children gardening products is slim. Some said they would buy the product if it was reasonably priced, however, there needs to be some other practical aspect to the product to be completely sold. To MANUFACTURER NEEDS The needs of a manufacture who produces this product on a mass scale is really material dependent. If the material is made of some sort of liquid which dried (for example art mache, a paper liquid which can be moulded or a simple biodegradable mix of water heat and corn flour which would be cheaper to sell and manufacture) then the best machinery which could mass produce the product efficiently would be injection moulding . The specification in terms of size would be something which doesn’t exceed a height of 60 mm and a width of 30mm and colour would be added in the mixture as required. (the same shape but with different colours) Hand made on a small scale the mixture can be poured into previous made moulds which would be a standard component, though this would not be efficient time or money wise. RETAILER NEEDS The retailer would need to market the product correctly as it would not be all clear what it would be. It would need to be packaged and labelled clearly on a stand which makes it clear it’s a children's product, the environmental benefits and the biodegradability. The retailer would probably need to test the product first to make sure it sells, therefore only buying a small sample. This is a reason NEED OF CONSUMERS By conducting an interview with both the potential user of the product (a child) and the buyer of the product (the parent/ guardian). I was able to draft the following criteria necessary to take into account when designing my product…. For example the size of my product, small pieces could cause a choking hazards. During all phases of design, production, storage, marketing, distribution and use of products, the hazards should be identified, risks assessments should be recorded and action should be taken to reduce or eliminate the risks to people’s health and safety.

- 8. CLIENT RESEARCH (CONT.) Obtaining details such as sizes, environment, cost, Anthropometrics and ergonomics. I also address legislations such as British standards regarding this field. I’ll include exploration of current market trends and consider relevant social, moral, environmental, cultural and sustainability issues. SIZES Seeing as the product is intended for children, the sizes have to be universally specific to be in able to be used for all children. The product has to be reasonably small. I specified that a maximum width shouldn’t exceed 100mm and the width 50mm. Specific specifications are subjective to the design of the product, but general limits can be specified. The product can’t be too small otherwise children would find it hard to use. Compared with other children's products, it has to be reasonably bulky and easy to grip but not too big. Although this is specific to adults, the anthropometrics could still be useful to create a universal product used by children and adults. ENVRONMENT The environmental aspect is one of the major components of this product. With all the campaigning towards encouraging children to be more environmentally friendly, this product needs to contain information on the products benefits to the environment. The naturally biodegradable aspect is of course environmental but there’s also the packaging and manufacturing, even the transportation all needs to fit with the products image of being ‘environmentally beneficial’. For example, it needs to be made sure transportation is cut down as it possibly can be, materials are all sourced sustainably and used efficiently with minimum wastage. Chemical waste should be cut down as there isn’t any harmful materials being processed. The packaging of the product needs to have environmental associations. The only issue is the delicate product needs to be protected, COST Making sure all materials used in the product are sustainable etc. may prove to be costly as well as the machinery. The manufacturing of the product will prove economically beneficial in the long run as products can be mass produced time effectively and efficiently. Perhaps a biodegradable yet cheap product will prove more cost effective for my product. Taking the example of the manufacturing production expenses with relation to the product I am planning to manufacture, we can see what can be reduced or expanded according to our needs. For example, the most costly would be circulation cost and manufacturing and distribution. This can be perhaps produced by locating factories close to retailers to reduce distribution costs. Advertising expenses wouldn’t be necessary it’s a small product. However, free advertising can still be implemented, for example free online social media can spread the message equally fast and free as TV advertising and print can. ANTHROPROMETRICS This should be a compact product however ERGONOMICS What will assure that the product is ergonomic will be based on the anthropometrics most of all, but what will also make the difference would be the gripping action. The shape will make the product easily fit into the soil, depending how the child can hold it without slipping. Some sort of curvature needs to be associated to allow for this to happen. SOCIAL ISSUES Social issues take advantage of the current social status. For example the government is paying more attention to environmental campaigns, especially groups who advertise to get involved with nature, and get children to reform their own gardening space. Being more environmentally aware is a big social issue right now, so my product benefits from this factor. MORAL ISSUES Moral issues cover the way that design and manufacture of things affect the safety, comfort and well being of people who come into contact with our designs. This could include the designer CULTURAL ISSUES When designing the product it must be considered that particular shapes, colours, words and images can have different meanings to different groups of people for example there’s religious beliefs that need to be considered, so the product must not have any offensive surface pattern or not be in a offensive shape and this has to also be a consideration when thinking about political views , sexuality, personal choices and beliefs ( for example vegetarianism) and traditions. Universal factors need to be thought out for example something that means something in one part of the world may not mean the same in another. SUSTAINABLITY ISSUES A sustainable product is one that is manufactured with little of no negative impact on the environment and on the health and well being of the workers employed to make the product. Some examples of sustainability incorporated into a product would be one which has organic, biodegradable, reclaimed and recycled materials. My product focuses on biodegradability, so the most likely material chosen will be organic and toxic chemicals won’t be used. To reduce carbon emissions the solution as mentioned before would be to keep A diagram detailing the life cycle of making a product.

- 9. CRITERIA PURPOSE 1.1- The purpose of this product is to biodegrade into the soil leaving behind nutrients for the soil and plants. It needs to be an environmentally aware product. 1.2- To have bright and bold colours to appeal to the target market of young children, so children get interested in maintaining their own natural microcosm gardens. If not this it needs to be an interesting shape to still appeal to the younger audience. FUNCTION 2.1- To act as plant food and nutrients for the garden. 2.2- To be aesthetically pleasing to a young audience. 2.3- It also has to be anthropometric according to the child's grip. PERFORMANCE 3.1- It needs to successfully biodegrade. 3.2- Needs to provide the nutrients for the soil, all in a reasonable time space. 3.3- It needs to be easy to use and simple for children, so it needs to be durable to an extent ,at the same time. (built to decompose but not just break easily). SIZE/WEIGHT 4.1- This should be a compact product however not too small that children cannot use it. The maximum height of the product should not exceed 100mm and the width 50mm. In terms of the depth of the product it should be approximately 30mm. The weight should be sturdy enough to pierce the soil but not too heavy for children, depending weather it would be hollow or solid, the weight still varies. ERGONOMICS 5.1- This product should be designed according to the needs of children. 5.2- The product should fit with the finger and thumb well according to children's hands. 5.3- It has to be easy to pierce into the soil. PRODUCTION MEATHODS 7.1- The basic shape would have been moulded using a die cast method, so that each shape would be the same and consistent. This would be produced using machinery. 7.2- Any external pattern added on the product surface l would be done using something like pad printing or maybe even double shot injection moulding if any other surfaces would be raised. ASSEMBLY 8.1- In terms of assembly there isn't much to put together apart from maybe if the product was in two half's and they are moulded and pressed together with heat . 8.2- If there’s any other external pieces to mould to the product such as a design or maybe an extra piece it would probably be done at this stage, but it isn't essential. FINISH 9.1- Adding patterns and stickers ect. There isn’t much of a further finish to be added. Either way whatever colour or decoration externally needs to be compostable so there’s not many avenues to explore. 9.2- Then the edges can be smoothed off t the end to give a professional finish. HEALTH AND SAFETY 10.1- Its actually quite important that the edge are smoothly cut and not too sharp, otherwise the user can possible cut themselves whilst using the product. Also especially if they’re a child. 10.2- The manufacture would of have to make sure the piece of plastic would be a solid piece ,without separate small pieces falling off it. 10.3- The material used, must be safe for the user as well. QUALITY/ STANDARDS/TESTING 11.1-To test the quality of the product the In this page I’m addressing everything the manufacture would have when producing this product. I’m stating things that the product should have, what the product would have and what the product could have when I am improving the product myself. 11.3- Whether the product biodegrades in the small time frame it needs to. MAINTENANCE 12.1- As there’s nothing electronic involved in this model, the manufacture wouldn’t have to worry about maintenance, there’s not components that need to be replaced. 12.2-The product isn’t built to last, its built in obsolescence. TARGET MARKET REQUIRMENTS 13.1- The simplicity of this product mean that it’s a very universal. Plus this doesn’t have to be purely for children, it can be expanded as a range of gardening products 13.2- As a child is using the product extra surface area and gripping surface is needed. 13.3- It needs to be ergonomic in terms of putting it easily in the soil but not too sharp that it will be unusable for young children . AESTHETICS 14.1- The product needs to be aesthetically interesting with different colours or and shapes to especially appeal to children. 14.2- To keep a smooth professional finish I would like to avoid any ridged surfaces or shapes. VALUE ISSUES 15.1- If the manufacture decided to do some sort of picture printed on the surface, it can’t offence to any culture or within society. This is the same with shape. 15.2- In terms of environmental aspects, it’s already strongly attached to the idea of being compostable and environmentally friendly. 15.3- Has the product been made in a moral way? (The more likely way this COST OF PRODUCTION 16.3- In order to produce this product to make a substantial profit, the material used needs to be cheap, but also be able to work. Because of the paper mulch type material |I’ll inevitably use, its likely to be cheap, however if I use more of a specialist material it could cost a bit more. 16.4- Due to very few steps of production, apart from machinery, this product can be cheap to produce in it’s simplest form. Currently on the market they approximately retail about 3p for each small fertiliser spike, my product will be slightly bigger and will cost more. RETAIL 17.1- The manufacture needs to take into account where his product will sell and for what price. 17.2- If the product has a particular design on the surface it can be sold in perhaps more fashionable and quirky shops. If it were to be sold in its simplest form it could remain to be solely sold in garden centre type shops. 17.3- Home wear shops sell more specialist items, if the manufacture has made the product, it can be sold at a higher price, packaged and presented professionally opposed to just the raw product on its own. VIDEO 1: A child talk about his current standing with the gardening market .

- 10. INITIAL IDEAS In this page I’m exploring unique ways in which I can develop my idea, focusing on innovation and aesthetics . I want my product to appeal to children, so colour and shape is a key element, however, the ergonomics and practical aspect also has to be present.These three ideas are mainly based upon aesthetic value. This is because the product is specificall y aimed at children. Although it has to be taken into account how these complex shapes will be manufactu red on a large scale . As a one off it will be easy but on mass production heavy machinery will have to carry out processes such as die cast and injection moulding would be most likely This ‘palm tree’ like design fro the product adds to its use, whilst being compostable plant food it also catches the rain by extending its limbs out of the flower bed/plant pot, the only issue here is weather the material used can be durable for The leaf design allows the product to blend in with its surroundings, this is an environmental benefit because it will not look like anything unnatural to garden wildlife. The ‘dragonesque’ type product on the right can be aesthetically beneficial fro children as well as cover a larger surface are to provide nutrients for the soil The hollow funnel like shape allows for further precipitati on to be concentrat ed on where the product was placed. It’s long tem also allows it to be secure where its pieced, adding an element of ergonomic . The tiny pellets in the shape of little creatures for the child's benefit, can be spread across a larger surface are and will biodegrad e quickly.

- 11. INITIAL IDEAS (CONTINUED) CONT. In this page I’m exploring unique ways in which I can develop my idea, focusing on innovation and aesthetics . I want my product to appeal to children, so colour and shape is a key element, however, the ergonomics and practical aspect also has to be present. The first idea focuses on the aesthetic appeal whilst the one below that focuses more on the ergonomic s and anthropom etrics needed for the child to be able to use the product easily. The one directly below that may not be aesthetical ly appealing for the child, however, it ‘s practical and provides that extra feature of wrapping and adjusting around the plant pot. This also covers the most This fan idea at the top works in both ways. Obviously it is built in obsolesce nce and therefore biodegrad es over a certain time, but also it expands out to catch extra precipitati on, it can also fold in so can be stored easily ask well without damage done to its ‘wings’. The pincers allows room for innovation , for example, each limb could have a different nutrient treated in t, and because of its The starfish design can spread through a large surface are, as well as there’s room for aesthetic improvement as surface decoration and pattern can be added to appeal to children, room for marketing movement. The small spikes with a model on the top can compost quickly and would be cheap to produce because of its size. Below that and the honeycomb shape as well as the branch again all focus on that aesthetic element, but specifically fitting in with the natural environment

- 12. CONSUMER FEEDBACK This page will help me develop my product further as I gain feedback from potential consumers (including children and their parents). This will help me decide what initial ideas I should develop further and improvements I should initiate. INITIAL IDEAS 1: This page focuses more on the childish aesthetic side of the product, focussing on shape rather than practicality. These designs are more likely to appeal to children rather than adults. However, this could be an advantage as the product is for children itself, and it’s supposed to encourage children to garden. INITIAL IDEAS 2: This second page focuses on a more practical side, for example the idea shown at the bottom right serves a practical purpose, it covers more surface area and it’s simple to use (making the product appeal to adults) however it’s not very aesthetically pleasing to INTERVEIW WITH CONSUMER (CHILD) I did two interview, one with a parent and another with a child. Both gave very different opinions that contrasted. In terms of which initial ideas the child liked. FEEDBACK •The child liked all of the products which were aesthetically pleasing, he didn’t pay much notice to the ones which had more of a practical appeal, he wanted the ‘toy appeal’ to b in the product. IMPROVEMENTS •As my product is for children, it clearly needs to appeal to them, the product is practical but more about encouraging environmental awareness and gardening to children, it needs to have the appeal of a toy- but at the same time be a product that will appeal to adults as a practical gardening fertilizer and garden accessory. I need to make sure the initial idea I develop has that appeal to young children as almost a toy does. INTERVEIW WITH CONSUMER (PARENT) As I did a interview with a parent, I found there was a stark contrast in what both parties desire in the product… FEEDBACK •The adult asked a lot more questions regarding the practical uses for the product, and aesthetically gravitated to more of a contemporary look rather than childish. They understood it was children but the practical aspect needs to be clearer. The look of the fan shaped product appealed the most to the adult. IMPROVEMENTS •As mentioned before the practical uses need to be made clear. This is something I’ll have to address on the packaging of INTERVEIW WITH RETAILER I also did an interview with a potential retailer of my product, a local garden centre. I asked one of the higher members of the workforce on their opinions towards my potential marketable design ideas. FEEDBACK •One of the significant things they said was that the ideas needs to look unique, amongst the shelves competing with other potential products, it needs to stand out the consumer. In this aspect they liked the fact it was marketed towards children because there was design potential to make it colourful and aesthetically pleasing. •They were most gravitated by the interesting shapes, like the beehive pentagon shapes, things that would look most appealing to the customer, however in terms of a more practical and ergonomic use they liked the idea of the product which ringed round the interior of the pot. IMPROVEMENTS •The consensus amongst all parties I interviewed would be the fact that they all want a more refined practical use. As well as the aesthetic value. VIDEO 2: This is a short video interview with a child on what they desire from the product and what's on their agenda Adults want something modern, contemporary and aesthetically appealing in their gardens, but this product is for children it must appeal to them at the same time using interesting colour and shape.

- 13. MATRIX This page will help me assess the ideas I have as well as choosing a final product.. It will help me establish what further developments I need to make to my initial ideas against my specification. A red and green colour used illustrates negative and positive points about each product. Weight This would be a strip that lines the pot- reasonably weightless Depending whether it’s hollow or solid and what material , weight of this product could be hefty. As these are small they won’t weigh a lot Like the person figure this product could potentially be hefty in weight. The thin fan like structure at the top of this initial idea allows this product to be lightweight . The thin branch structure will allow minimal weight to be spread across the products. Ergonomics For children this product could prove difficult to use Easily used by children, simple. Again, simple mechanism allow children to use this product This could involve burying into the soil which could require adult assistance. Easily pierced into soil. Easily pierces into soil. Anthropometr ics This thin structure could be difficult for young children to work with. The chunkiness on this product allow children to grip it like children's toys. This may be too small for children to use, their hands won’t be accustomed to it. The toy like hardiness of this product will allow children to easily hold and grip this product to use. Core of product can be edited chunkier to make the product more graspable by young children. May be too thin for children to hold with ease. Aesthetics Not very aesthetically exciting. Interesting to children, different shape. Colourful and interesting ,known shapes are used. A unique design to appeal to young children, animal concept was liked This is still interesting with shape but not colour for children. Interesting aesthetically but possibly not for children. Biodegradabil ity Will quickly biodegrade and evenly around the pot. May not biodegrade quick enough due to size, material dependant. Small and will biodegrade easily and quickly making it a reasonably disposable product. Like the person shape also may take time to adequately biodegrade. Thin top will biodegrade easily Thin branches will biodegrade easily, Function This will biodegrade in the adequate time space providing nutrients to the soil and fulfilling its function. May not easily biodegrade quickly and therefore not fulfilling its function. Small, will biodegrade, but perhaps too quickly? Will evenly biodegrade throughout the soil. Provides additional function of water catcher as well as biodegrading nutrients Material subjective like the rest, thin shapes will biodegrade easily Cost May be the least costly to manufacture due to the simple strip shape. The cost of machinery :die cast/ injection moulding my be substantial but pay off in mass manufacturing. Low cost, small. The cost of machinery :injection moulding my be substantial but pay off in mass manufacturing. Complex structure may cost more to produce The cost of machinery :die cast/ injection moulding my be substantial but pay off in mass manufacturing. Manufacturin g Processes The material would be in sheets and then sheared, this may be a complex process involve For putty like masses, compression moulding can be used, one of the lowest cost moulding New manufacturing processes like 3D printing can be utilised for these small A process such as shell moulding may be used to create a non-metal cast. Low labour requirements. This would involve two parts, a flat cut sheet attached to a blow moulded core. Complex? Rotation moulding could possibly used however this is a slow process.

- 14. MODELLING DEVELOPMENT Photos and videos showing my physical models as well CAD with areas to develop for final idea. This page clarifies any mechanisms/movement that the product may have and mentions what materials and tools were used ,relevance to specification/research is mentioned, and scales of ideas as well as function. To make these physical models foam and scalpel was used to create the desired shape. Foam is lightweight and easy to sculpt creating an easy method to portray my design ideas as a physical model including accurate scale and dimensions. I can use these lightweight physical models to help create a more anthropometric as well as ergonomic product for children. BENEFITS OF USING PHYSICAL MODELLING You have a three dimensional easily and easily adjustable physical model of your idea. They can be therefore tested against specification in terms of ergonomics and anthropometrics of a hand, by getting a child to hold it. DISADVANTAGES OF USING PHYSICAL MODELLING The disadvantages of using a physical model would be the cost and waste of resources as well as human error not being able to repair any mistakes made. (A computer software can easily re-do mistakes whereas a physical model cannot. PHYSICAL MODEL 1 Aesthetically interesting appealing to both children and adults, the bulky shape on the ‘stem’ makes it easy for children to hold and use. However the size of the product may prove to be too long to biodegrade, as well as cost of manufacturing. PHISICAL MODEL 2 The function and practicality aspect of this product is prominent, it pierces into the soil proving efficient nutrients. However, the appeal to children and ergonomics and anthropometric consideration isn’t there. The child can easily hold this product or use, let alone be aesthetically interested in it. PHYSICAL MODEL 3 This focuses on the ergonomic side of the product as children can easily hold on to it as it’s shape is bulky enabling small hand to grip onto it. However, the large complex shapes that are hexagonal may be costly to manufacture on a large scale. Also, although it has an aesthetic appeal to on audience, being a more mature one, it doesn’t aesthetically appeal to mine, that being children. PHYSICAL MODEL 4 This is the product that aesthetically appeals the most to children PHYSICAL MODEL 1 PHYSICAL MODEL 2 PHYSICAL MODEL 3 PHYSICAL MODEL 4

- 15. MODELLING DEVELOPMENT (CONT.) Photos and videos showing my physical models as well CAD with areas to develop for final idea. This page clarifies any mechanisms/movement that the product may have and mentions what materials and tools were used ,relevance to specification/research is mentioned, and scales of ideas as well as function. CAD MODEL 1 CAD MODEL 2 CAD MODEL 3 Using a CAD software like Google Sketchup enables my design ideas to be visually represented in a 3D format without resources being wasted. It’s a more cost efficient way to present my ideas further developed from a two dimensional drawing using still accurate dimensions and visualisation next to a plant pot. BENEFITS OF USING CAD •Higher productivity rate, less time consumed making physical products. •Higher accuracy. Human error when physically modelling can lead to mistakes, however when using computer software mistakes an be reversed and models can be copied and repeated. DISADVANTAGES OF USING CAD •The need to learn a new software. •Not as flexible as physically modelling with your own hands. •Can be (not always) an expensive software which requires expertise. CAD MODEL 1 Simplistic shape. May prove ergonomically difficult for child to use as the product would be hard to pierce into the soil and child may hurt themselves trying. Too boring to actually develop any further. CAD MODEL 2 The interesting an d natural shape would appeal to adults as it fits in with the garden theme. However the complex shape would probably be complex and costly to manufacture on a mass scale making this a poor economic choice for developing the idea. CAD MODEL 3 This idea produces a secondary function which appeals to both adults and can be aesthetically altered to appeal to children as well. The hollow stem and the fan shape is also a concentrated water catcher which concentrates the flow to the roots, and of course the biodegradable aspect would be incorporated also. This product can be developed further to make it appeal to children in a better way.QUICK PEER ASSESSMENT AUDIO 1: This is a quick sound recording of one of my peers underlining some feedback on both my physical and CAD modelling. They talk about possible ones I should develop further as well as any additional improvements I could also incorporate. Double click play button to hear the audio.

- 16. MATERIAL TESTING This page will document the process of creating a low cost naturally biodegradable material and testing it against my specification to help me create a mock up of my product The materials I used to test the homemade biodegradable material is a mixture using water, corn flour and oil. Corn flour being a natural nutrient material to the soil. Firstly I mix the mixture of water and flour well, producing a thin even consistency to prevent their being lumps in the final mock up of the product. After it’s become an even liquidly texture it means all bubbles have been eradicated, creating a smoother medium. I add oil to the mixture which will act as the binder to the solution. This prevents cracking when the mixture dries and strengthens the model. 1. 2. 3. 4. Mix vigorously . Heat up 30 seconds in the microwave to turn liquid into solid. The mixture has hardened, as it’s hot it needs to be left to rest Cool water can be added to soften the mixture if too hard. 5. 6. 7. 8. Mixture has been kneaded so that its smooth throughout. Add more oil to the mixture to act as that binding agent otherwise the model will dry Mould into shape using mixture. Now wait about three days for the product to dry throughout and come back to test material against specifications. 9. 10. 11. 12. VIDEO 3; This video shows how two weeks have affected the model. For mass manufacture and a more professional outcome I may consider using a material like polymorph which is made from styrofoam melted in acetone or gas mixed with milk and vinegar. It is a plastic which melts at around 60 degrees C, so you can melt it in hot water and mould. It sets again when it cools and is probably as tough as nylon or some other domestic plastic. It’s fully biodegradable and non-toxic 13. After 2 weeks the material is beginning to show signs of decomposition, with a weak crumbly texture rather than a hardened one. It’s lifespan can be prolonged by adding more oil. But this

- 17. FINAL PRODUCT DEVELOPMENT This page will indicate all the improvements and development of my final idea. This page should also underline specific details such as dimensions in mm. PROPOSAL My final product proposal would be to incorporate a Japanese folding fan mechanisms for the top ‘water catcher part of the product. That can easily be folded and stored attached to the hollow tube. The papery material which would be a naturally decomposing and biodegradable material will disintegrate quickly, leaving the biodegradable tube left to decompose. MATERIALS FOR FINAL PRODUCT Top of the product, the fan part will be represented by a paper folding fan material. The paper would be strong enough to concentrate rain water yet be weak enough to decompose. Wooden stick will help support this structure . The bottom will be a hollow plastic tube. Similar to the biodegradable material I made out of oil corn-flour and water mixture as it accurately biodegraded. AESTHETIC Not forgetting that the purpose of the product is to engage children in looking after their own gardens and getting involved with the environment, the product still needs to be developed to become aesthetically pleasing. IMPORTANT THINGS TO REMEMBER WHILST DEVELOPING FINAL PRODUCT •Needs to still be aesthetically pleasing to children •Children anthropometrics need to be taken into account •Needs to be lightweight •Should fold effectively so it can be stored. DIMENTIONS This anthropometric detail can be useful in developing accurate dimensions for my biodegradable fan. All the data applies to the hand which is the primary part that will be used in working the My This sculptural stainless steel and teak water catcher will gather rain— saving water and repeated trips to the kitchen sink. Just rock it forward and its spout will fill your watering cans Petal Drop rain catchers. fit onto the top of empty plastic bottles. When they’re full, use the water on the plants. WATER CATCHER ELEMENT My final product has a water catcher element that’s now playing an important role as a purpose of my product. I did some brief research into water catchers currently on the market so I can brainstorm developments for mine. A rain barrel that makes saving water easy by providing a watering can that is automatically filled when it rains. So the user doesn't have to fill the can with our precious tap water, but uses 'free' rainwater instead. The proposal for my final developed product is for the fan part to have surface decoration that will appeal to children (or colour). The stalk, or tube that pierces into the soil will be biodegradable however the fan piece will not. This means in the space of to weeks the tube will have biodegraded ;leaving the fan for children to keep as novelty item. The holes on each layer insured the water fed through gets distributed evenly and the shape is bulky and

- 18. FINAL PRODUCT DEVELOPMENT CONT. This page will illustrate the final idea for my product thought working drawings and cad modelling. TOP VIEW LEFT VIEW ISOMETRICVIEW BOTTOM VIEW BACK VIEW CAD FINAL DRAFT OF PRODUCT These drawings and final models help with the development of my final product, especially the dimensions that are underlined in the isometric drawings. The mechanism used to attach the fan part to the stalk are wooden stick with ball shapes on the end. This allows the fan to be adjusted back and forward left and right and can easily be clicked off at the same time. The wooden sticks will run all the way through the plastic fan part under each fold so the whole structure remains stable. These CAD models help illustrate the 3 dimensional feel of my final proposed idea. Upon reading about developing the materials I could use the most practical solution could possibly be polymorph- as polymorph is completely biodegradable in soil conditions and is 100% non-toxic. Using a material like polymorph - -could mean the product is more durable and doesn’t have to be made in obsolescence, it would be easier to work with in terms of mass production and can be fortified with plant food to still benefit the soil. The polymorph is also

- 19. ORTHOGRAPHIC DRAWING Large orthographic drawing of my final idea. Measurements are in millimetres. 90 10 60 16 20 10 80

- 20. DEVELOPMENT AND MANUFACTURE This page will underline the major developments that have took place in my proposed final idea so far in the project and also he beginning of my manufacturing and making process of my final product. This was my first initial proposed idea for the product. The whole product was meant to be built in obsolescence all dissolving eventually into the soil, this was a spin of my initial proposed idea with primarily one function of naturally biodegrading providing plant food to the soil but this also acted as a water catcher. This was my CAD development side of the product where I modelled proposed ideas as this point appeals to both adults . The hollow stem and the fan shape is also a concentrated water catcher which concentrates the flow to the roots, and of course the biodegradable aspect would be incorporated also. But aesthetically it wouldn’t interest children. The proposal for my final developed product is for the fan part to have surface decoration that will appeal to children. The stalk, or tube that pierces into the soil will be biodegradable however the fan piece will not. This means in the space of to weeks the tube will have biodegraded ;leaving the fan for children to keep as novelty item.The proposal for my final developed product is for the fan part to have surface decoration that will appeal to children. The stalk, or tube that pierces into the soil will be biodegradable however the fan piece will not. This means in the space of to weeks the tube will have biodegraded ;leaving the fan for children to keep as novelty item. The development on the CAD model was how the fan part can be adjusted back and forward left and right and can easily be clicked off at the same time. Also I propose a material change to polymorph as it’s non-toxic to children, biodegradable in soil and easier to manufacture. Through injection moulding. MANUFACTURING AND MAKING PROCESS I have decided to manufacture this product (the stalk part) through aluminium moulding, to create this mould I make the shape out of foam to cast around. In order for the model to be easily worked with and for the process of documenting dimensions are all 2x 1. If any human error occurs whilst creating the cast for the model, I have made two of the same just in case. These foam models will melt away whilst creating the cavity for the mould, in which the polymorph can be pressed into. 2. I used a scroll saw to cut the curved shapes out easily. Using a hand saw would be too labour intensive and wouldn’t accurately cut the curved shape. Also the fine blade gave an extra added accuracy to the cutting. 3. In order to get the rounded shape that I require for my product I use both files and sandpaper to achieve this intended shape. Some of the ends of the product could be lightly sanded with a band saw to get that rounded shape, however the inner 4. -with the flat sander, therefore manual techniques needed to be used for the part. Using different sized grains of sandpaper helped ix the rougher surface created via filing 5. Now the shape is ready to b used for making the cast. A cast generally would be more of a efficient way of mass manufacturing this product, to get a consistent product without excessive human labour. Most likely an injection moulding machine would press the plastic into the mould. 6. 10. 11.7. I first tested the polymorph and foam together to see I can make a mould. The foam stuck to the surface of the polymorph so this wasn’t a viable option. I would have to make a separate mould to the polymorph to go in later. 8. Next I thought a more permanent cast would be aluminium, and as I had two models, I tested aluminium casting with my product. First I moulded oil based sand around the foam model tightly . I used a sieve with the sand to make sure the grain was fine and moulded 9. Once I had filled the casting square around my foam model is was time to pour in the metal. The foam, would melt away when the metal is poured on top, leaving the metal to fill the gap of where my model was creating the cast. Once the metal is adequately melted I use the handle to slowly and carefully pour the material into the sand mould I’ve poured the metal, now I must leave it to cool for at least two hours, Some of the aluminium has leaked out the bottom of the mould but hopefully hasn't affected my initial cast. EVALUATION: Though the metal cast shows an ease in the manufacturing process, it is a one of- once the foam has been melted off the cast cannot be used again. Also aluminium is durable but doesn’t fit in my product specifications, it’s heavy and doesn’t 12. This test can be used to assist me in packaging my final product without

- 21. DEVELOPMENT AND MANUFACTURE CONT. (continuation) This page will underline the major developments that have took place in my proposed ideas manufacturing and making process of my final product. I’ve documented the whole process so it’s easy to evaluate which stages went well or where I encountered issues of manufacturing. I set out to create a more permanent mould so I can test different materials in it, firstly, the mould needed to be able to accommodate a lot of materials, to the surface had to be a non-stick surface for the moulded object to slip out with ease. This is similar to non- stick silicon cake trays where it’s easy to pop the baked product out the mould- -In order to do this I lined the foam model with latex liquid. The latex formula consisted of liquid latex and thickener so it can be easily painted on. Whilst holding the product I couldn’t cover the surface with the mixture as my fingers were getting in the way I then poked a stick through the top so I had a- -temporary hold on the model, and I could cover the whole surface with latex. It was painted on in several layer, before more layers could be added on, each layer was hand dried with a hair dryer by myself in order to speed up the process and use time effectively. After I had painted and dried several layers onto the model I waited for a day for it 14. 15. 16. 17. 18. 19 20. 21. 22.13. I added several pieces around the latex mould so it would be easier to work with, the light art roc will cover the latex mould holding everything in place, creating a more permanent fixture. After wrapping several layers of art roc around the latex mould I used a band saw to carefully cut the mould in half so I would have two half's I could work with, before sticking them both together. The completely dry latex was thick enough to be stretched and bent without losing it shape. Therefore the latex mould could be taken out of the art roc base and the temporary foam template could be easily popped out of the mould to be filled with my material. STRENGTHS OF MY MOULD: Some positives would be that my mould can now be reused again and again by filling it with different materials other than my proposed polymorph, which can be useful if I want to test other materials. The latex is waterproof and flexible 24. 25. 23. 26. 27. 28 29. 30. After heating the granules of polymorph I worked with it packing it tightly into the mould, it didn’t take long for it to set and after I had my two pieces of the product I set out to file and sand any imperfections that had been made originally with my mould. Using machinery in mass production this wouldn’t be a stage reducing labour and time to manufacture the final product. The plastic pieces were easy to stick together using a band facer, which melted the halves together using friction. This saved me using a non biodegradable adhesive that could be potentially harmful to the environment. Polymorph is biodegradable, and can be mixed with any material such as plant nutrient pellets to help the plants etc. In my prototype I have decided not to mix any external pant feeder into my polymorph because I wish to separately layer this on when naturally colouring the product. I now needed a core I will later drill holes around my product like in my design so rain/ precipitation can be drained equally into the soil when the product in pierced into the ground. I mixed plant food spikes which I ground down to create a fine powder, safe food colouring and corn flour (also good for the plants) to create a colour mix I could paint on top of my product. I did this so I could provide a natural looking product with earthy colours, that look aesthetically batter than a plain one, and also to add some extra plant nutrient on top of the biodegradable polymorph. Now I move on to constructing the fan part of my product. I use light bamboo and thin sheet polymer. I carefully sliced slits into the bamboo so I can slide in the sheets of cut plastic. I also sand now the ends of the bamboo so I have a good angle to stick the fan extension onto the base of my product. I also cut bamboo pieces to be stuck onto the top on the fan where the thin plastic is bare. I did this as a safety precaution to provide a round edge so children do now cut

- 22. FINAL PRODUCT AND MARKETING I talk through the final stages of my product and marketing . I will talk about the unique selling points my product has, the weaknesses and how to market it correctly taking it all into consideration. UNIQUE SELLING POINTS/ MARKETING STRENGTHS •Not any other product on the market. •Aimed at children, products which tend to gardens do not usually target children. •Aesthetically individual, stands out, looks intriguing. •Focuses on environmental protection, popular topic amongst public. MARKETING WEAKNESESS •If not marketed correctly, there is hardly a market for the product at all. Consumers would probably dismiss the product as they will argue that they do not need it or that these's no market for it. The problem I aimed to solve whilst in the development for this product is that there's a missing market for gardening products for children, the environmental aspect is an extra selling point- but if this isn’t marketed correctly the product would never be successful on sale. PROMOTING AND ADVERSTISING Advertising is a good way to get the product across to the public and raise awareness. However televised advertising can be costly. A much more up and coming method to advertise are short ads uploaded on YouTube, which can often turn into widely successful campaigns if done correctly . This is a non-cost way to promote a new product. YouTube ads can also be placed before successful videos. Other means of advertising via technology could be relevant website banner advertisements, an example relevant for my product would be http://www.homebase.co.uk or somewhere like http://www.thegardencentregroup.co.uk/ which is in charge of national local garden centres. LOGOS Some important things that I needed to consider whilst making the logo was that it needed to incorporate an attractive element that would appeal to children. At the PRICE The price of production is subjective to how much machinery is used in mass manufacture. For making a one off product like mine I used approximately £15.00 work of materials excluding labour and time costs. However, if my product was mass manufactured, then this would be significantly less as there would be a pre-made mould, possibly using injection moulding and little human intervention beside quality control, making my product more affordable on market- approximately £5.00 to make it both affordable and profitable. MARKET COMPETITORS I researched top retailers products and there’s no product on the market which combines both a plant feeder and watering system in one, especially not aimed towards children, here’s some main competitors: 31. 32. 33. I used a glue gun to secure the fan extension onto the base. I made sure that the angle was such that if you pierced the product into the ground straight, the rain would easily slide down from the branches into the hollow base, watering the soil. To make sure any rain water is distributed evenly throughout the soil I used a handheld drill to drill into the core of the base several times creating a sort of watering can drainage system. Waterproof plastic means the product wouldn’t dissolve. After adding finishing touches, my final product prototype is complete. Name: Plant dripper Function: Waters plant whilst owners are away. Price: £16.94 Weaknesses: Aesthetically dull ,cost, only one function. Strength: Practical, stores more water . Name: Plant feed Function: Gives plants nutrients. Price: £6.99 Weaknesses: Not actually a product, dull, expensive for what it is. Strength: Practical. My logo (On the next page) here incorporates everything I want the consumer to know about my company: The colours are natural yet bright denoting that its for children and my company creates products that help the environment. The simplistic shape is memorable and the name shows that the product is for kids and environmentally

- 23. MARKETING (2) I This page focuses on the promotional marketing side the product. I will include a proposed leaflet design, and packaging design and process. This proposed leaflet design can be handed to customers outside garden centre stores to raise awareness of the product. The strong fun colours appeal to children and inform adults the type of product it is (via the strong earthy colour scheme showing the products association with nature). I included contact details on the back of the leaflet as well. This design is versatile and can be used not only in leaflet but packaging, website ad banners and other means of promotion. FRONT LEAFLET DESIGN INSIDE BACK For the packaging I used the vacuum former. First I used my previous aluminium model to mark out a shape on a block of wood, I will use this cut piece of wood for the plastic to vacuum form around as shown in the picture above to he right. I cut the formed plastic to shape making sure my product before sticking on the card backing I have made.

- 24. MARKETING (3) Continues my packaging process and design as well includes a short advertisement mock up for my product. Here’s the front and back of my packaging.. The front includes the name of the product, the logo and the recyclable logo. I've kept it simplistic at the front as when the production shelf the consumer wouldn’t wanted to be bombarded with unnecessary information, and this places more emphasis onto the product. The front also includes a Polythene terephthalate (PET) logo, which indicates the material used for packaging, is 90% recyclable and the symbol reminds the consumer of this fact. Hopefully the consumer will place the used packaging in the recycle bin, if they can find one. On the back I’ve bent the plastic to secure the packaging and some rudimentary information about the product as well as basics like a barcode and the rice. I have also included the lion mark which is displayed on a product when the manufacturer/retailer has agreed to the ‘British Toy and Hobby Associations’ Code of practice. It is a consumer symbol that represents the manufacturers promise to conform to all relevant safety information. And considering my product is aimed at children and can be considered a toy this is important. The symbol next to the FRONT PACKAGINGDESIGN BACK VIDEO 4: This is a short proposed advertiseme nt I made for my product. The ad wouldn’t be televised but most likely be in an ad before a You Tube video given its unfinished relaxed childlike feel. It’s 42 seconds long. I drew it out on a whiteboard, took pictures and edited it together

- 25. MANUFACTURING IN MASS PRODUCTION I will talk about the manufacturing processes and examples that would most likely be used if the product was mass produced as opposed to one off. MOULD (Stages 1-26) A large proportion of my making is taken up through making a mould for my product. Potential manufacture processes can maker manufacturing more efficient and, in time, economically more productive. BLOW MOULDING This is manufacturing process by which hollow plastic parts are formed. The blow moulding process begins with melting down the plastic and forming it into a parison (a tube-like piece of plastic with a hole in one end through which compressed air can pass). The parison is then clamped into a mould and air is blown into it. The air pressure then pushes the plastic out to match the mould. Once the plastic has cooled and hardened the mould opens up and the part is ejected. This is an adequate method that would take out a lot of labour and time in producing a mould and the moulded material is already pre- compressed into the mould . It will also save me drilling a hole to make to product hollow. This will help my mass manufactured product biodegrade quicker and use less material, reducing the cost of manufacture and retail price. FAN EXTENSION (28-30) Rather than crafting the fan part by hand it would be much simpler if I could use a machine to create the shape reducing labour time and material. Thermoforming does this using one sheet of plastic. THERMOFORMING This manufacturing process is where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mould, and trimmed to create a usable product. For the thin fan extension part this is perfect as one piece of materials can be cut and bent, not wasting any material. its simplest form, a small tabletop machine can be used to heat small cut sections of plastic sheet and stretch it over a mould using vacuum. This method is often used for sample and prototype parts. In complex and high-volume applications, very large production machines are utilized to heat and form the plastic sheet and trim the formed parts from the sheet in a continuous high-speed process, and can produce many Blow moulding diagram showing how this shape can be produced using the mould halves. This thermoforming diagram shows how the plastic sheets can be heated to shape, if the mould was changed in this diagram it would adhere to my product. FINISHES (THROUGHOUT ,DETAIL COLOUR ETC.) This will have to be done by hand. In various manufacturing there will have to bet the following things that would be taken into account such as , working conditions and equal pay. This will create jobs too. Attaching the two components and painting will add more of a handmade authentic look as well. ALTERNATIVE METHODS 3D PRINTING Even though it’s in the early stages of development and costly, 3D printing would be a perfect way to manufacture The hollow plastic and complex shape parts of my product. This also allows me to manufacture using PLA (polylactide ) a thermoplastic aliphatic polyester derived from renewable resources, such as corn starch , tapioca roots, chips or starch, or sugarcane. This bio plastic would be perfect for my biodegradable product. 3D printable models may be created with a computer aided design package or via 3D This bio plastic would be perfect for my biodegradable product. 3D printable models may be created with a computer aided design package or via 3D scanner. The manual modelling process of preparing geometric data for 3D computer graphics is similar to plastic arts such as sculpting., the machine reads the design from 3D printable file and lays down successive layers of liquid, powder, paper or sheet material In this case PLA) to build the model from a series of cross sections.

- 26. TESTING This page contains a SWOT Analysis, an effective way that I can analyse my product. The four sections of SWOT analysis are strengths, weaknesses, opportunities, threats. Consumer feedback and professional feedback are also included. VIDEO 6: Shows how rain would slide on the waterproof surface I created. The product seems to cope under water pressure, the grooves carry the water well and non of the aesthetic work is rubbed off in the process Audio 2: Audio with a interview with the potential consumer pictured above. I ask the consumer questions regarding the product against the specifications, so I can use the feedback to improve my product. CONSUMER FEEDBACK Pictured to the left is the product in use. I will assess how it coped in the natural environment, The product remained durable and SWOT ANALYSIS STRENGTHS: •The product is ergonomic: the child I interviewed in the consumer feedback said it was easy to put in the soil and didn’t find any major difficulties in this respect. My professional said it was Universally accessible •Aesthetics: the products appearance fits the criteria of looking like a product for the outdoors. Because it blends in this could be a benefit as it prevents any birds from ruining it . •Function wise both feedback parties said it was fine. •Fairly reasonably price •Robust and interesting looking for consumers WEAKNESSES: • Biodegradability: the product doesn’t biodegrade as quickly as I thought it would. Although the outer layer did (the plant food corn flour mixture) the polymorph took longer. The ruined the collectable aspect of my product and the fact it was meant to be built in obsolesce. •Weight: Top heavy but light base. May be difficult for children. Audio 3: A interview with Ian, a manager of a local gardening shop. He provides me with useful and comprehensive feedback PROFESSIONAL FEEDBACK •The surface needs to be smoother (corn flour plant feed mixture) uncomfortable for children to hold. •Curve may need to be deeper more for small hand to grip. •Anthropometrics: “big and cumbersome” •Drop retail price slightly as not well know brand. OPPORTUNITIES: There is scope to market this product efficiently especially in the recent light of child based environmental awareness campaigns: this product could do well. THREATS There may be well known companies that override the function of my product. As I am not a well know brand consumers PRODUCT IN USE BEFORE AFTER I left the product planted in the soil for three days outside to see what the effects would be. There was no precipitation that would help decompose, the product, which after three days was showing signs of decomposition by losing some of its outer layer. This shows me that the external layer infused with the plant nutrient will easily decompose.

- 27. EVALUATION I compare my product to my specification, evaluating both good and bad features an further improvements that can be made as well as its strengths. VIDEO 5: Shows a weakness/ flaw of my product I would need to repair and improve on. PURPOSE 1.1- The biodegradable aspect of my product isn’t built in obsolescence as Intended the important top layer biodegrades leaving the nutrients in the soil. But the polymorph has made the product more permanent than intended. 1.2- The look of the product blends in well with the environment. 1.3- I’ve added the additional purpose of water being concentrated through the soil via the fan extension. The testing shows this to be successful with no erosion of the surface due to waterproof paint. FUNCTION 2.1- Plant food layer erodes off, but polymorph does not. 2.2- My feedback was largely positive towards the aesthetic appeal. Perhaps add brighter colour to appeal to a younger audience. 2.3- It seems to be largely anthropometrically accurate, however to be sure it would be best to make the curves deeper to accommodate for small hands. PERFORMANCE 3.1- Biodegrades a layer but takes too long to fully decompose. Perhaps make polymorph skin instead of hollow block to speed SIZE/WEIGHT 4.1- The size of my product increased slightly during the manufacturing process to make it easier for me to make. As my consumer feedback mentioned, he would prefer the product to be small. This was my original intention and in mass manufacturing this size increase wouldn’t be an issue. However as a handmade product, to make things simpler I made the prototype slightly bigger acting as disadvantage to get accurate feedback on size and weight. My professional feedback pointed out my product was top heavy but light at the bottom: this may have to evened out. ERGONOMICS 5.1- The whole shape is specially built to accommodate a child's hand, this has been successful. 5.2- The child found it easy to hold, a recommendation would be to deepen the curves 5.3- Easily pieced into the soil. MATERIALS AND COMPONENTS 6.1- Though the materials for my fan extension worked out fine, the biodegradable material isn’t the result I intended. Either I make the polymorph layer thinner to speed up the biodegrading process of use another material in my mould that’s quicker in decomposition. PRODUCTION MEATHODS 7.1- I was able to produce a mould for my product, a useful tool as I can recreate the product in different materials with ease. 7.2- My external decoration is a natural mixture infused with plant nutrient. There is no damage to the environment whatsoever. ASSEMBLY 8.1- Instead of drilling holes to avoid glue I had to stick the fan on. More precise manufacturing methods would have prevented this but due to human error, I had to reconsider my original design intention. FINISH 9.2- Though the finish was professional at first, the fan extension erodes slightly from weathering. Perhaps a stronger acrylic paint with turpentine would strengthen the surface preventing erosion. MAINTENANCE 12.1- Solid product, apart from repair needed towards the end. This is why I intended to drill the fan into the base to secure it as a more permanent fixture. 12.2- I didn’t intend for the product to last, but as it does a repair would be to make the surface thicker and more permanent. If I were to re do the product I would use a different base material. TARGET MARKET REQUIRMENTS 13.1- The product would be appealing to both children and adults alike, making my product universally marketable: it has succeeded in this aspect. AESTHETICS 14.1- The aesthetic look of the product fits my criteria of being colourful enough to attract children, and appeal to adults by blending into their gardens. 14.2- The unusual shape of the product looks interesting, and visually appealing VALUE ISSUES 15.1- There’s no social issues with this product or its packaging, making it universally retail- able. 15.2- The product stands for environmental awareness and protection, a important moral and marketing tool. 15.3- There isn’t excessive human labour in my proposed mass manufacturing process keeping the process free of any potential ethical issues. COST OF PRODUCTION 16.3- The use of specialist materials like latex made the product costly. However the surface mixture I made out of cheap materials at home which acts as a benefit. Of course human labour isn’t included because most mass manufacture would be on machine. 16.4- The p0roduct costs more than an average fertiliser spike, however if marketed correctly and if the consumer knows about the additional functions, the product is less expensive then contemporary products on the market now. RETAIL 17.1- The manufacture needs to take into account where the product will sell and for what price. My professional feedback indicated that the price was fine but to make the consumer more comfortable with purchase to lower the price to the £4 region to make it more appealing. 17.2-The product isn’t a raw plant fertiliser practical product. It’s unique aesthetical appeal allows the product to be sold in quirky gift