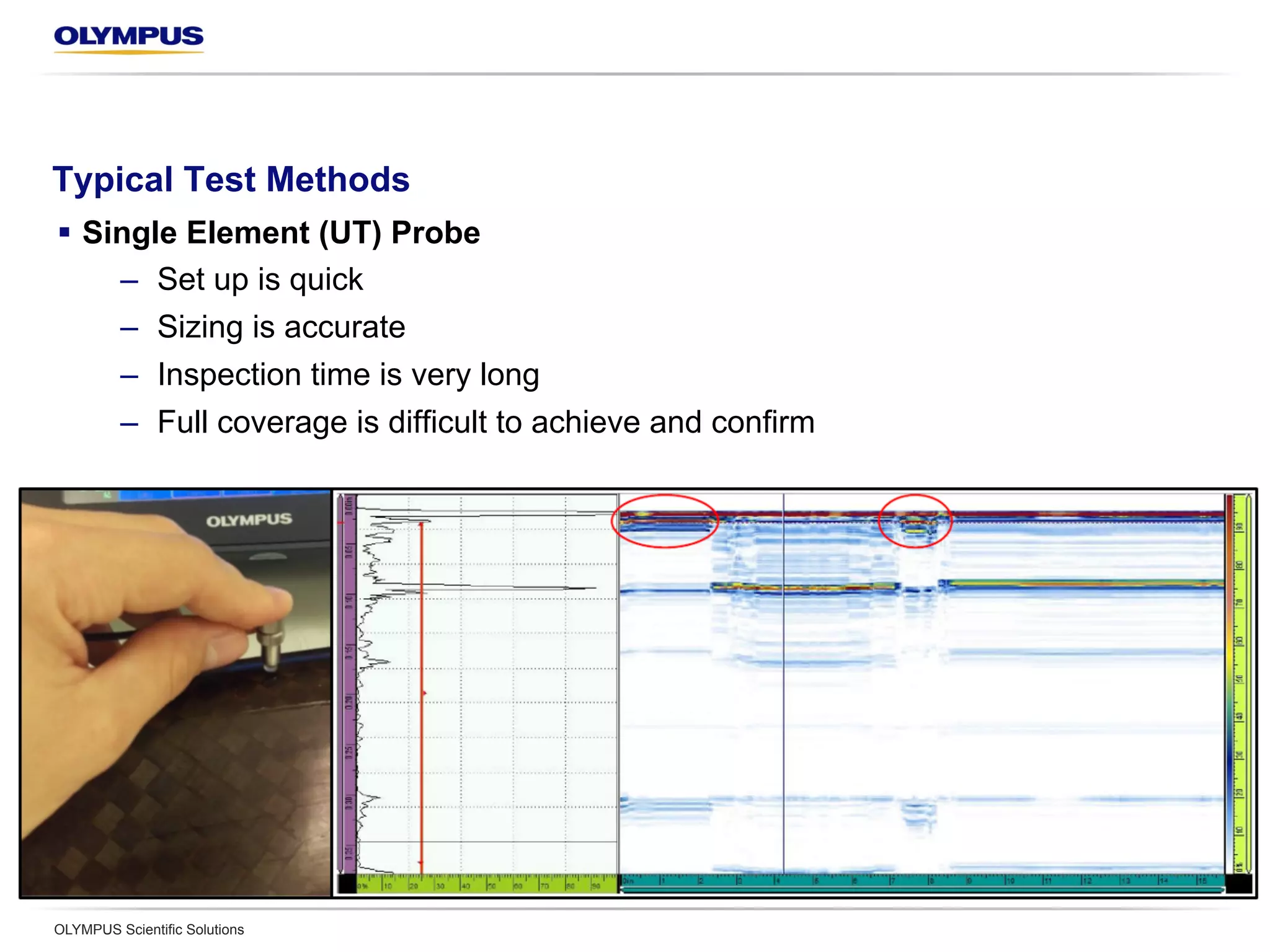

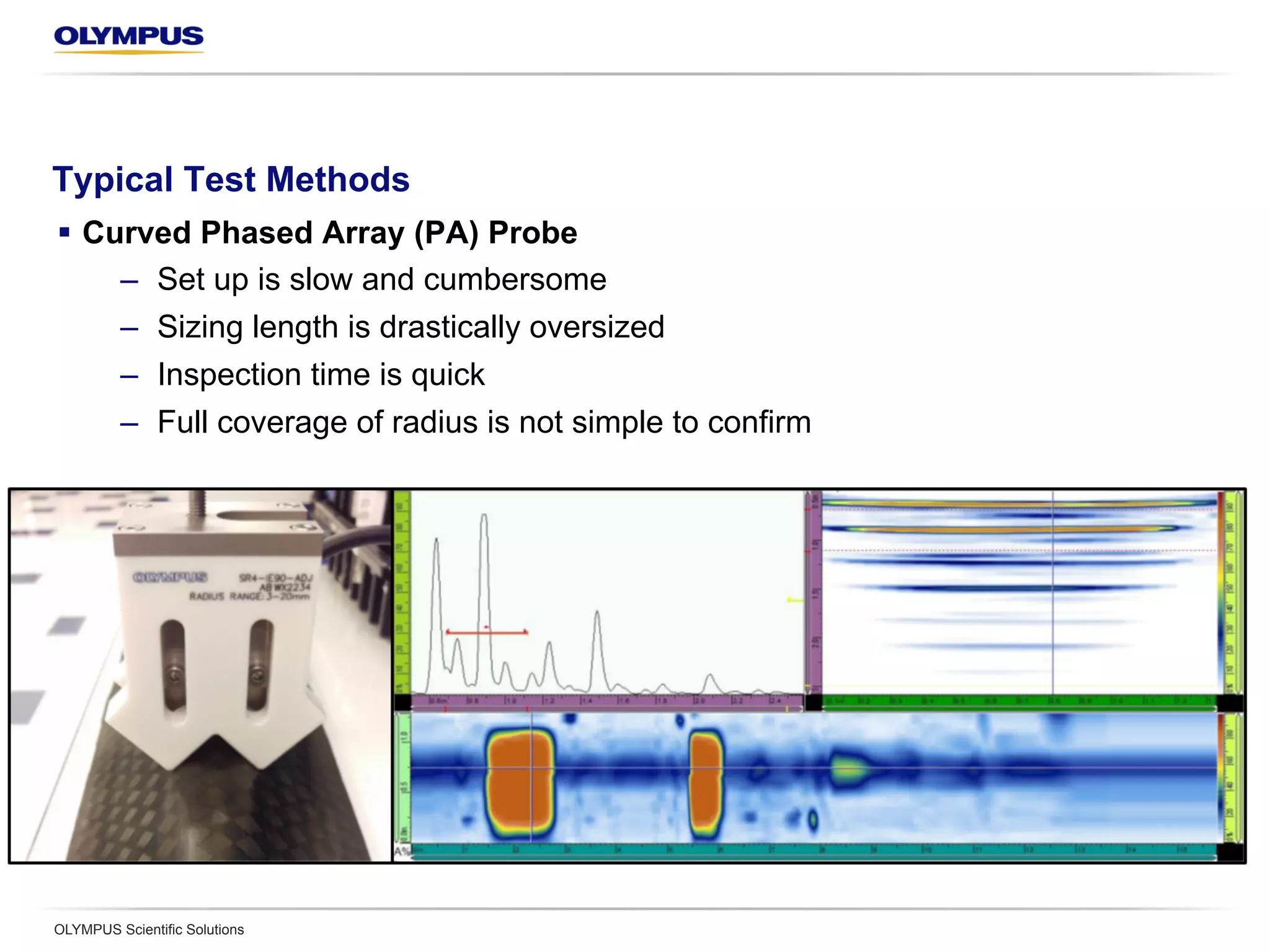

Flexible ultrasonic phased array probes can inspect complex composite part geometries. The document discusses:

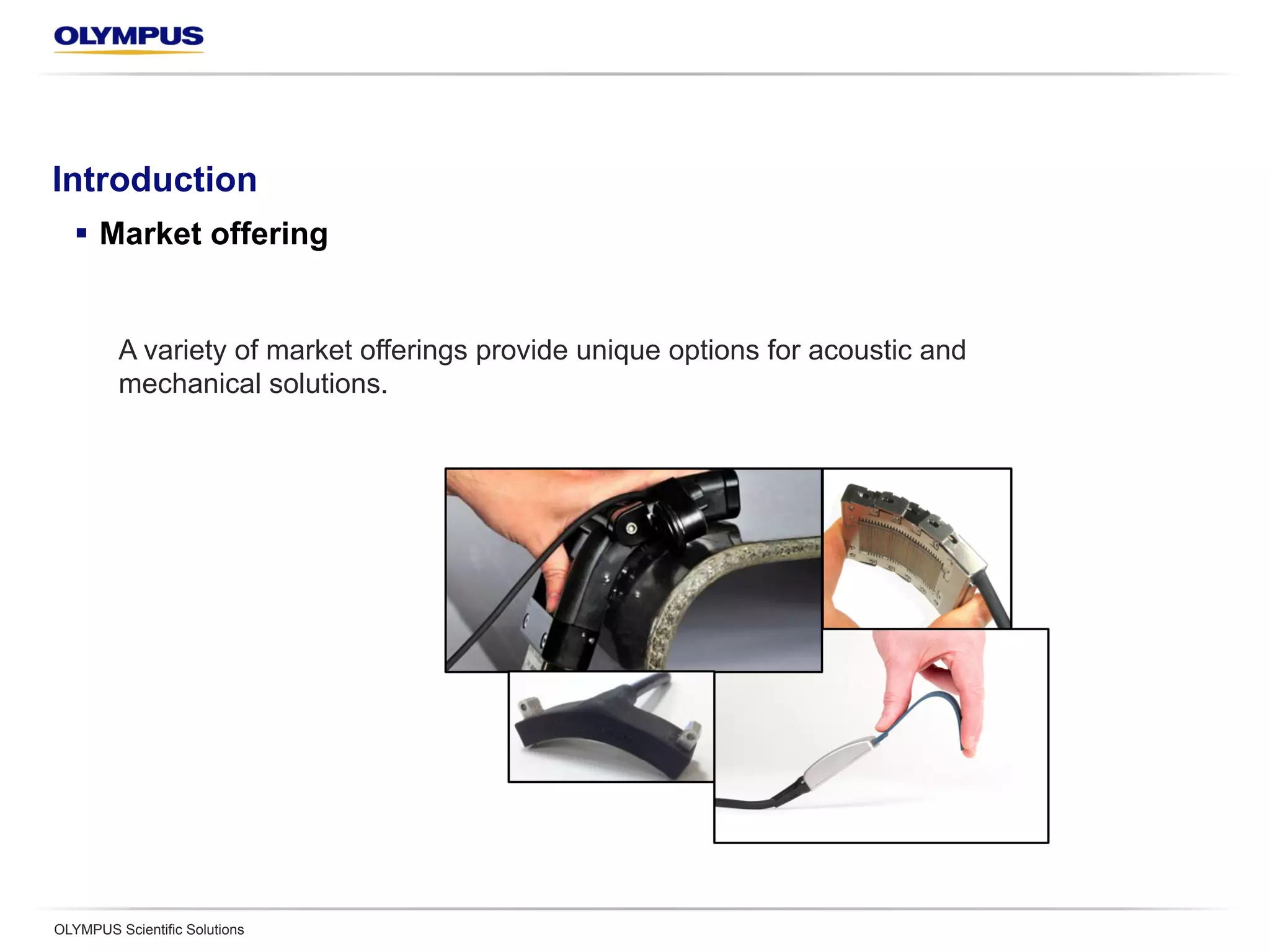

1. Flexible array technology that allows probes to flex and keep elements perpendicular to surfaces.

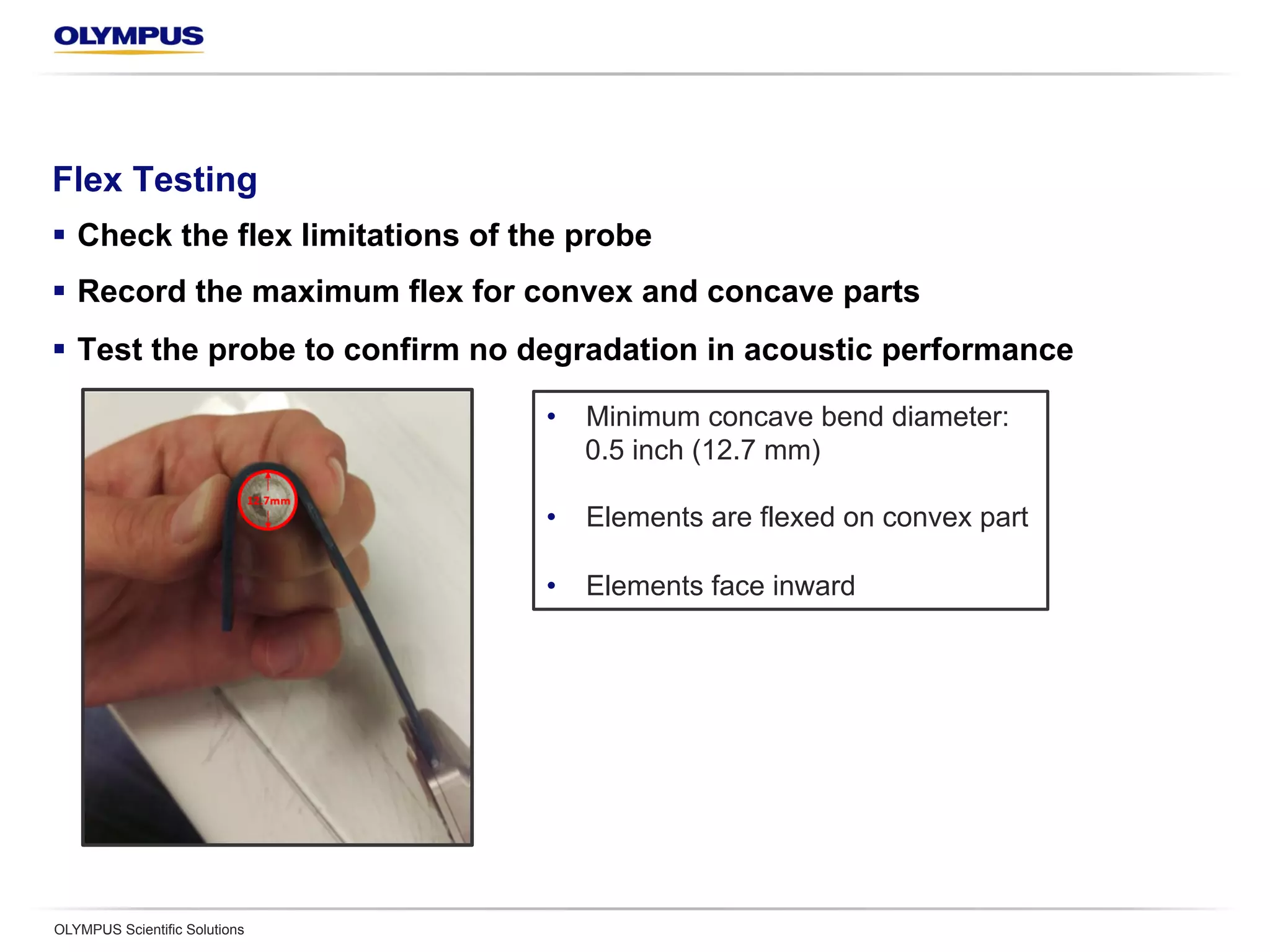

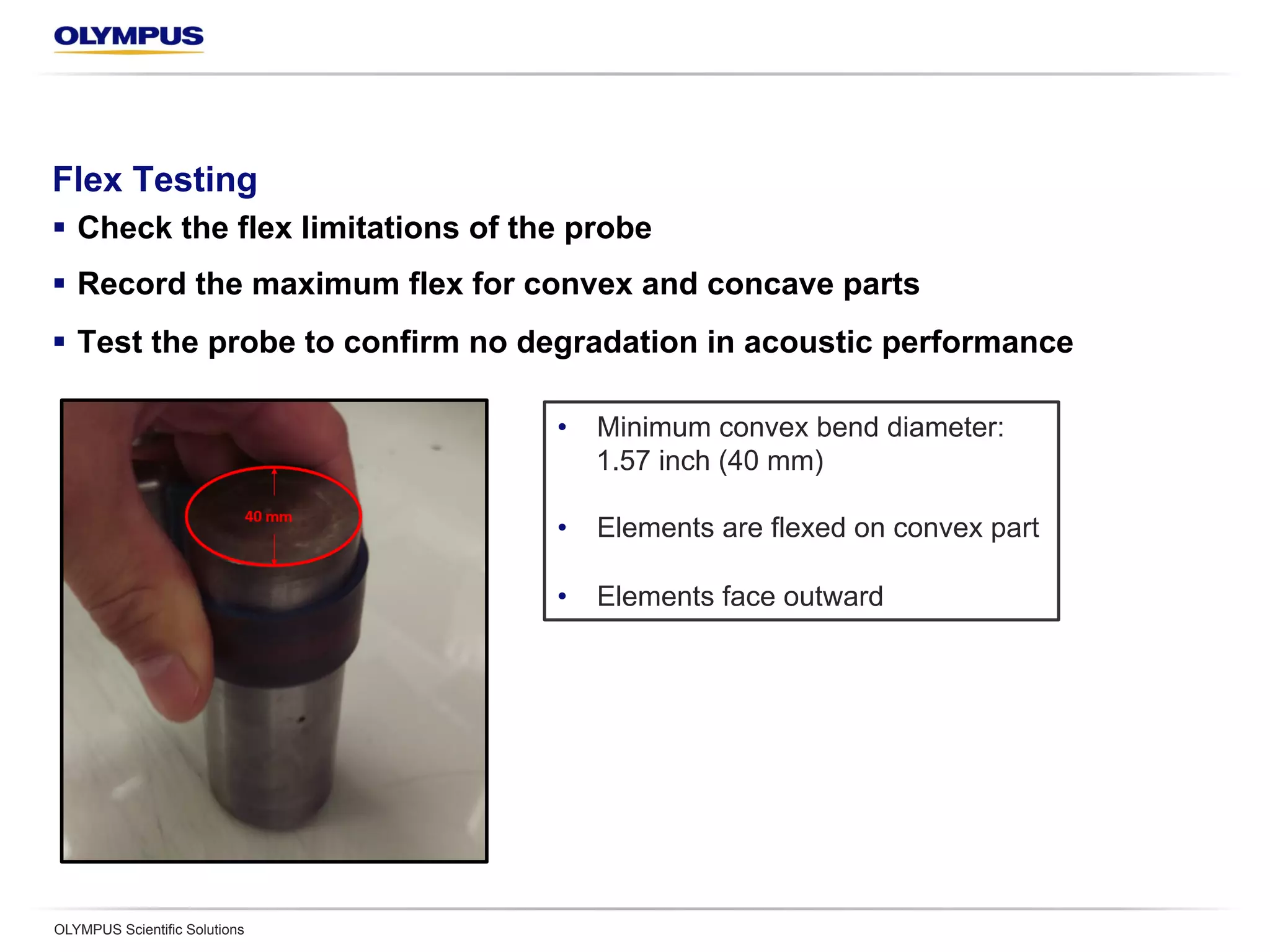

2. Testing that showed a probe could flex to a minimum diameter of 12.7mm concave and 40mm convex without degrading performance.

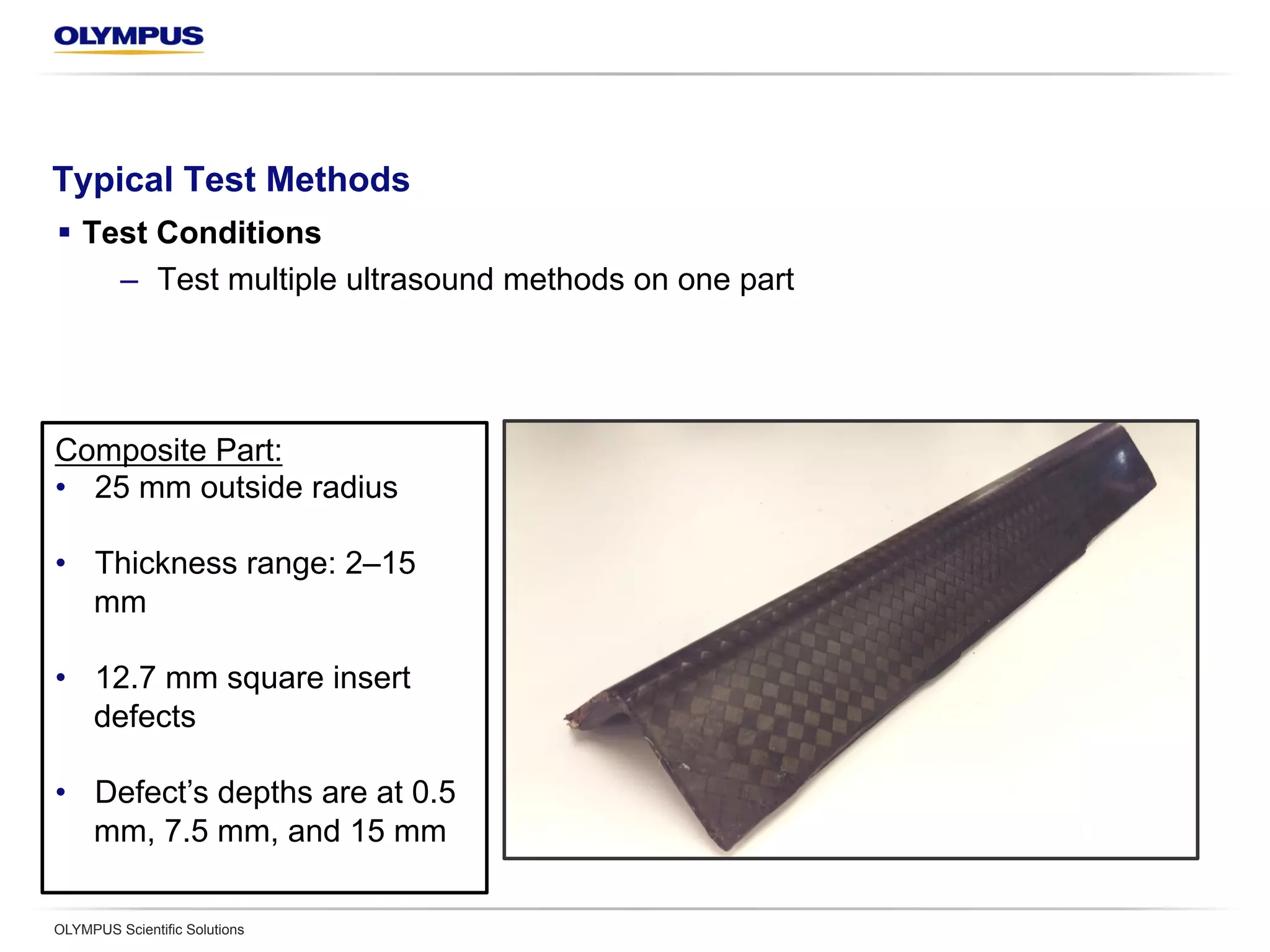

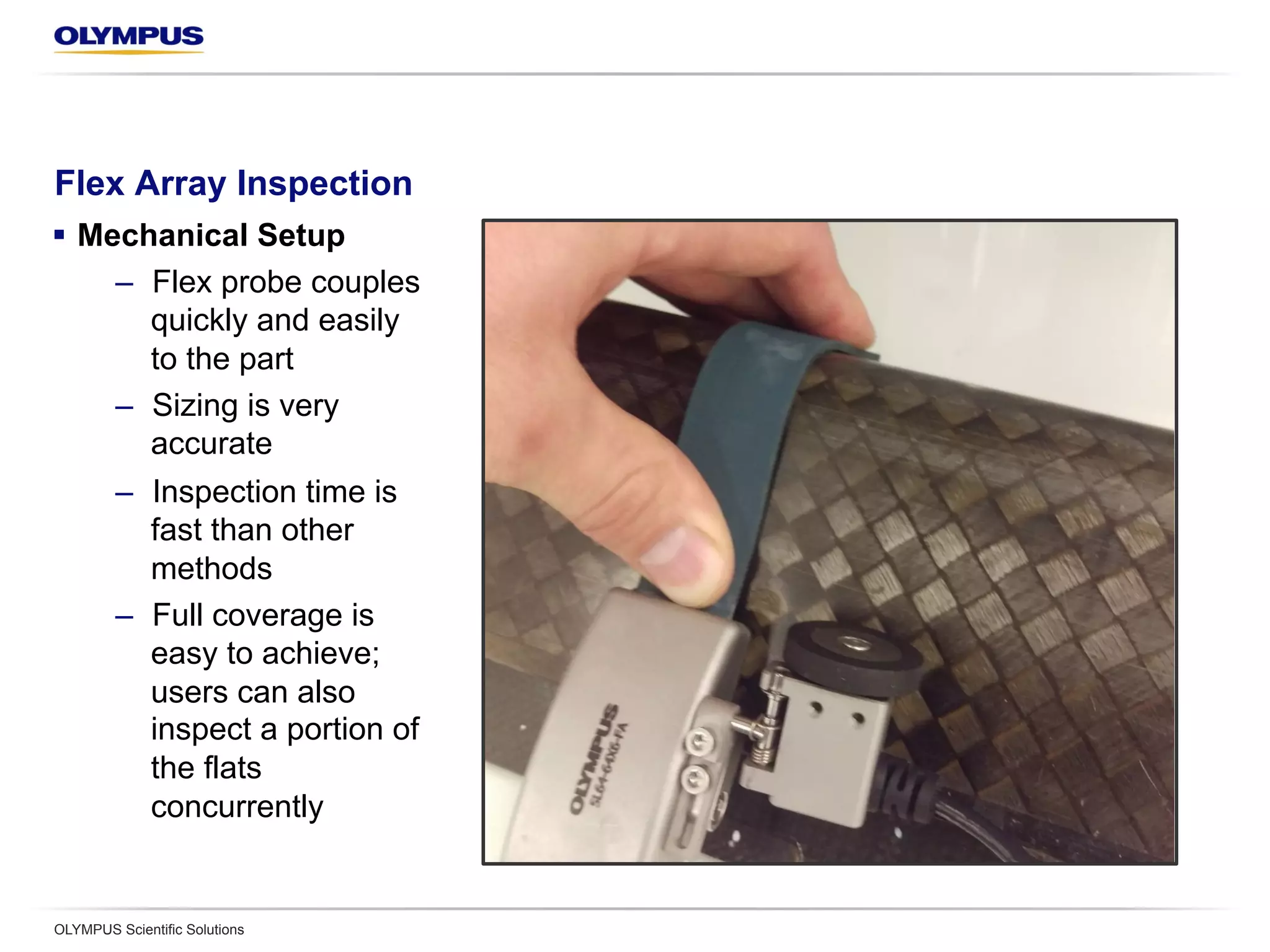

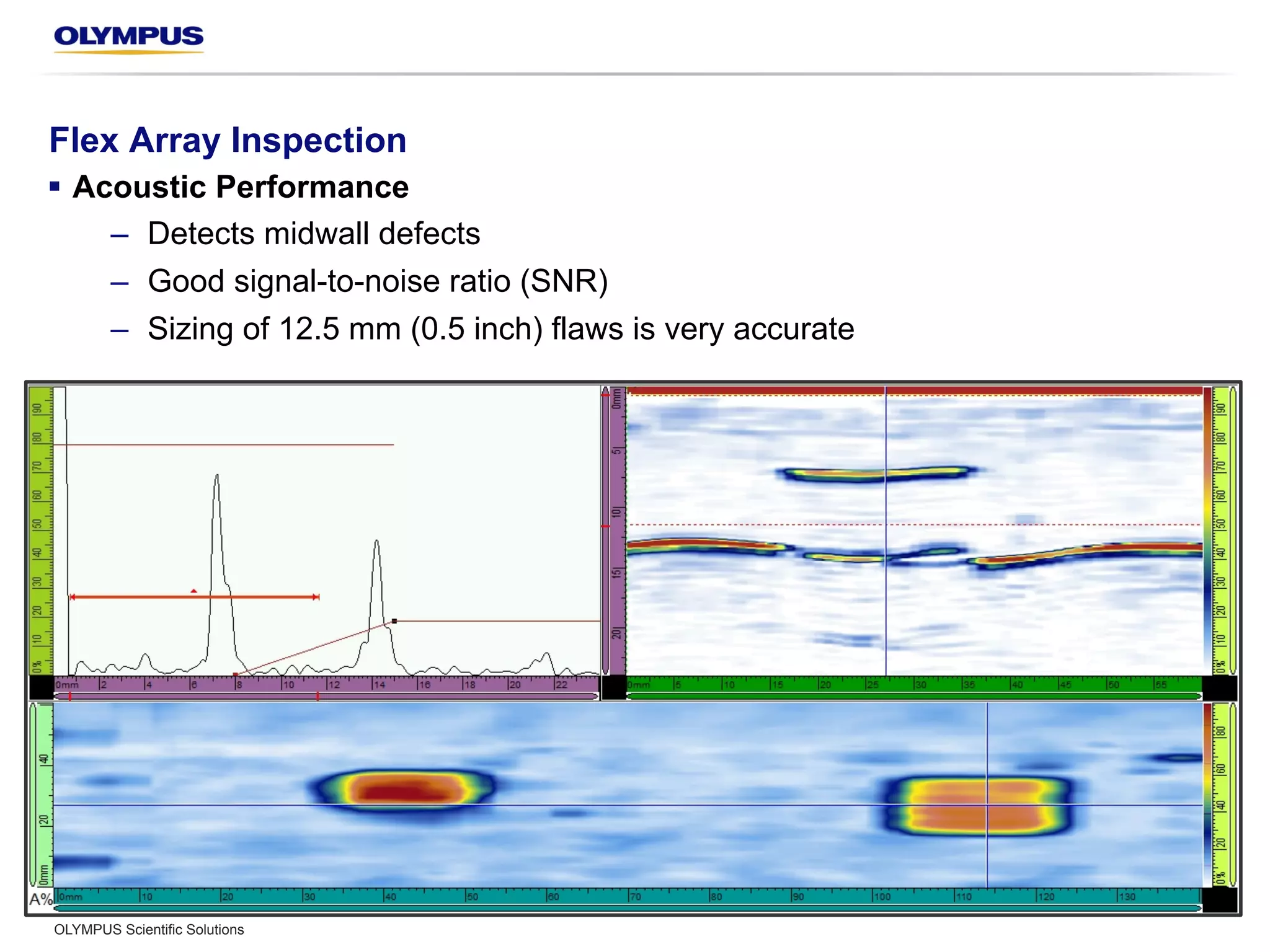

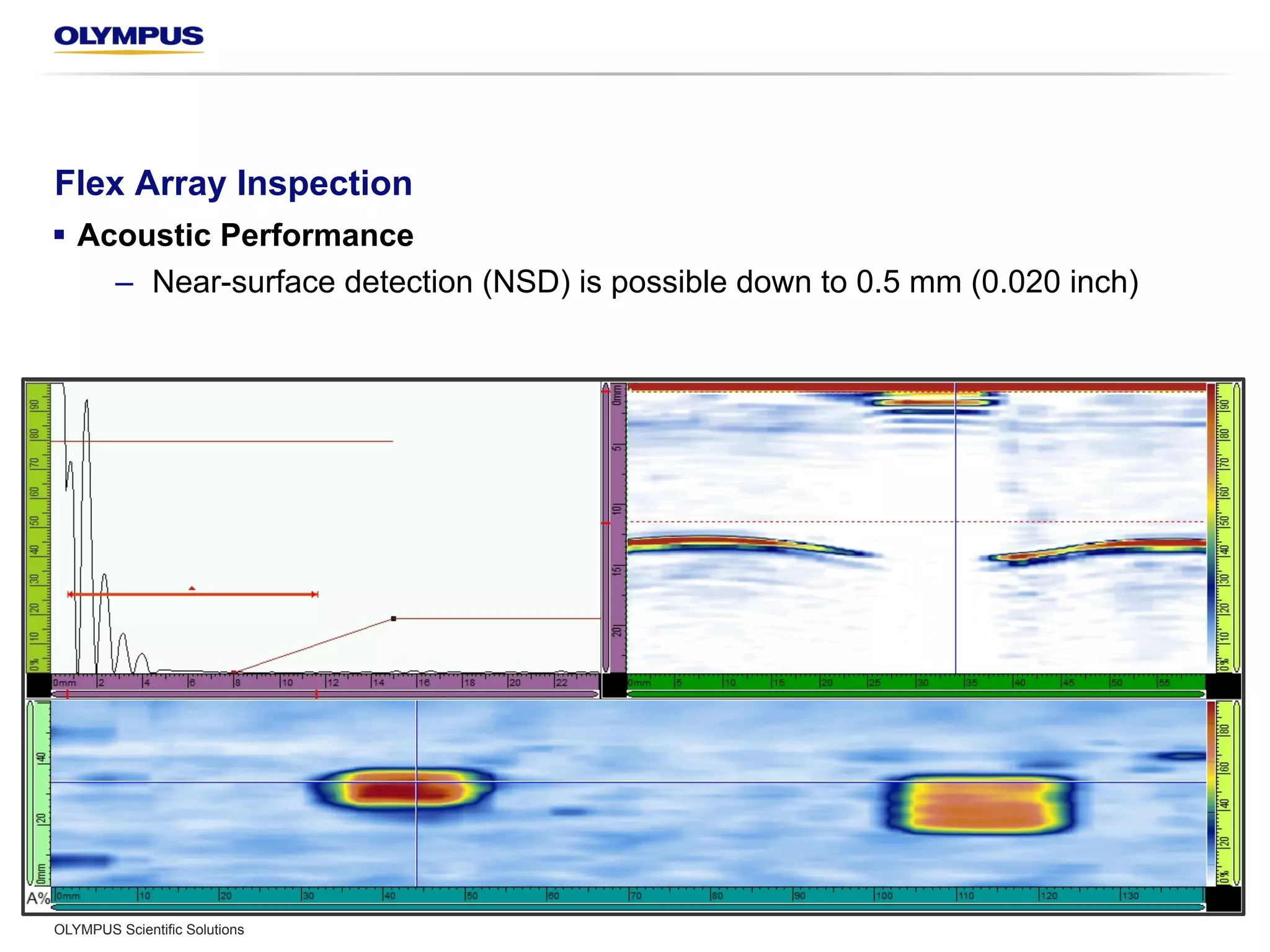

3. Inspection of a composite part with a flexible probe that allowed fast, accurate inspections and detection of defects as small as 0.5mm.