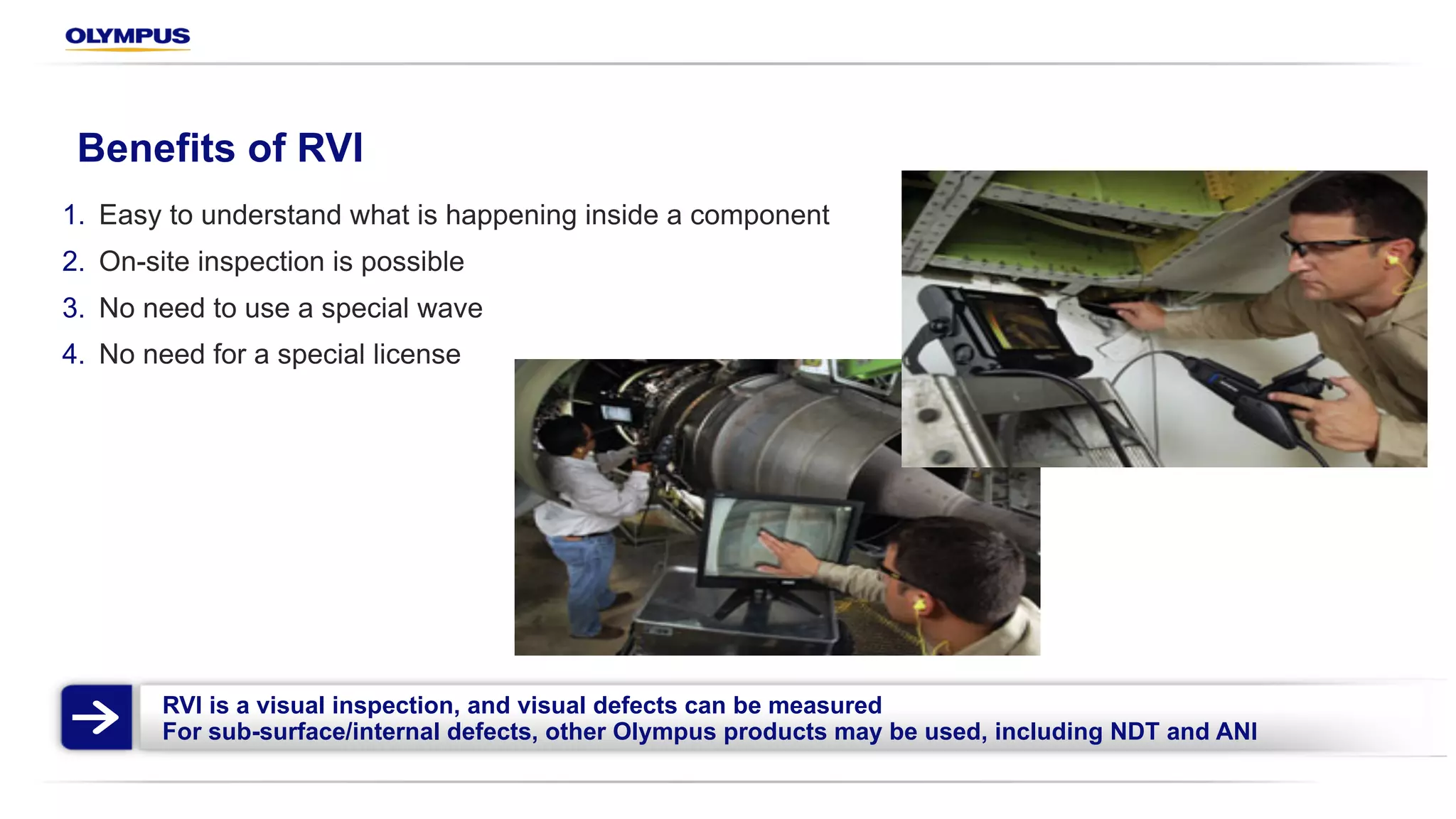

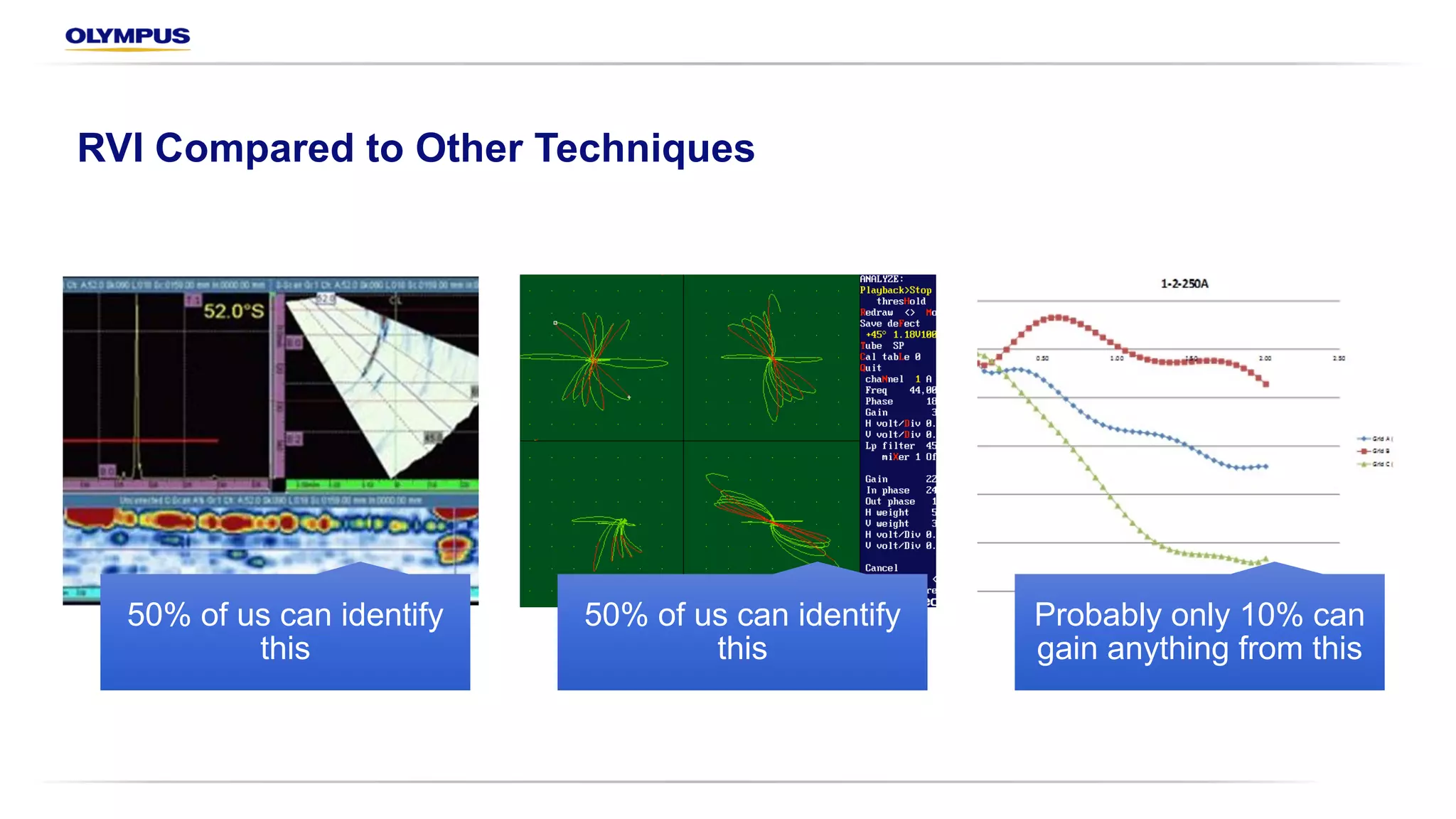

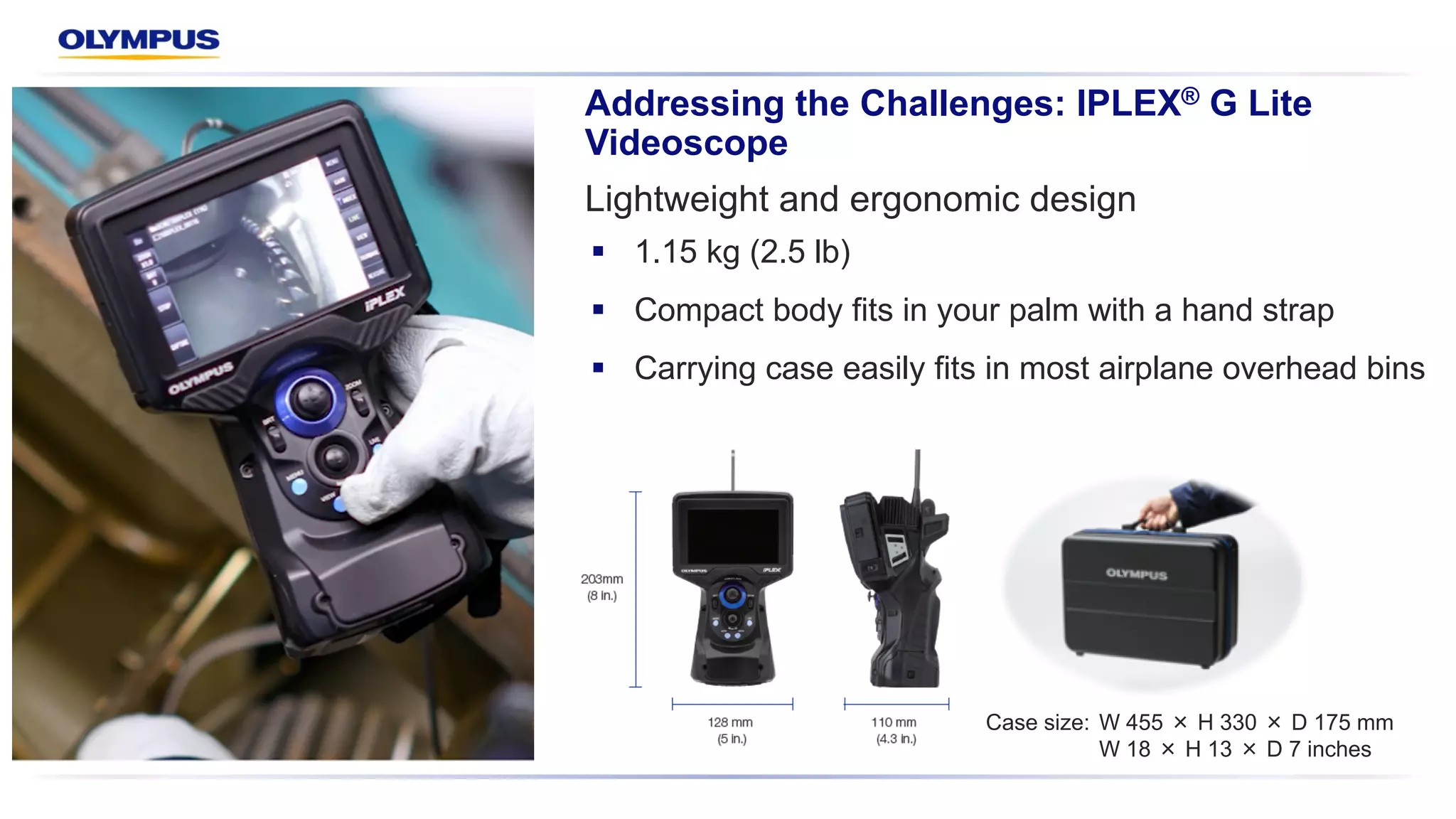

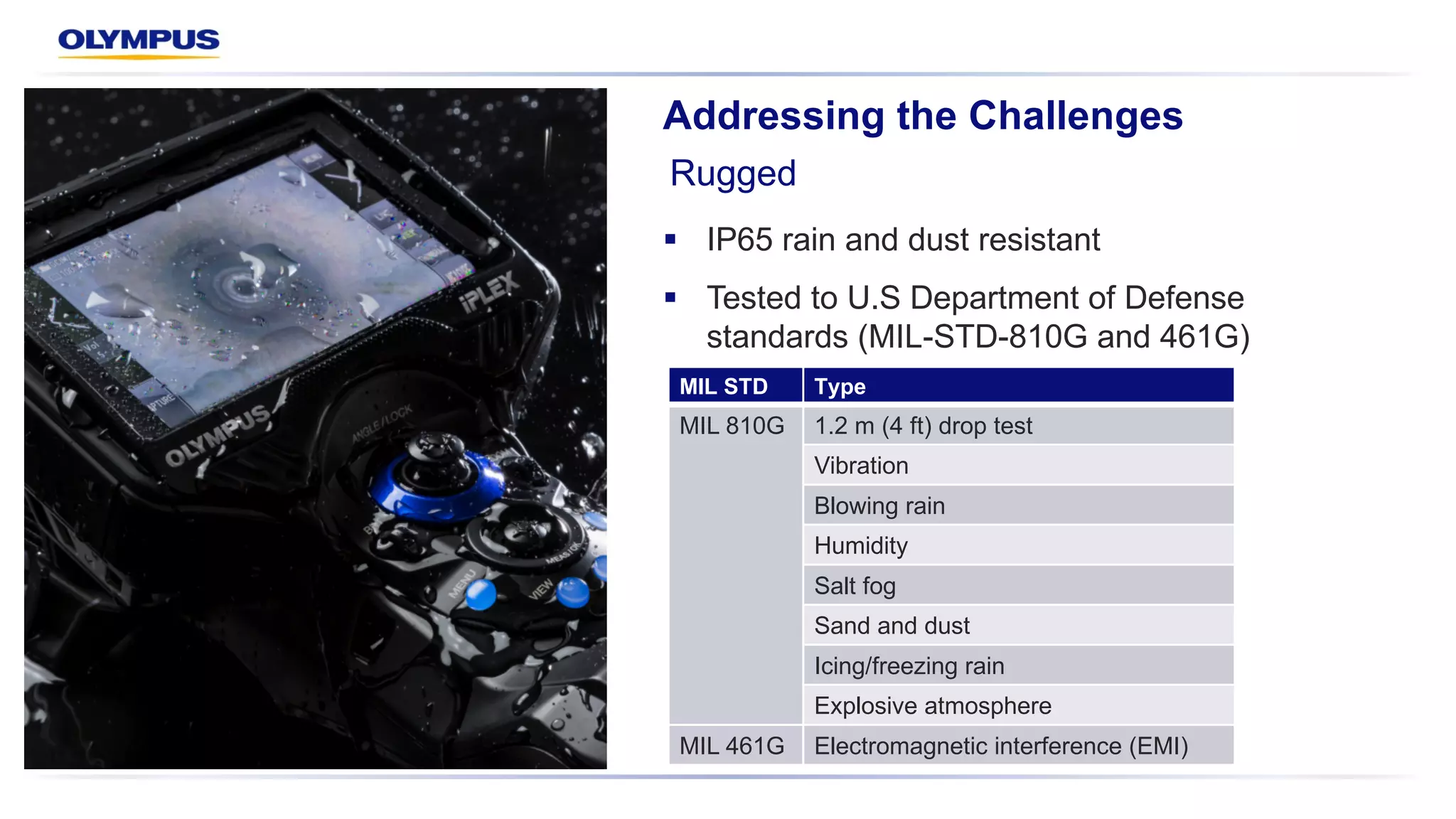

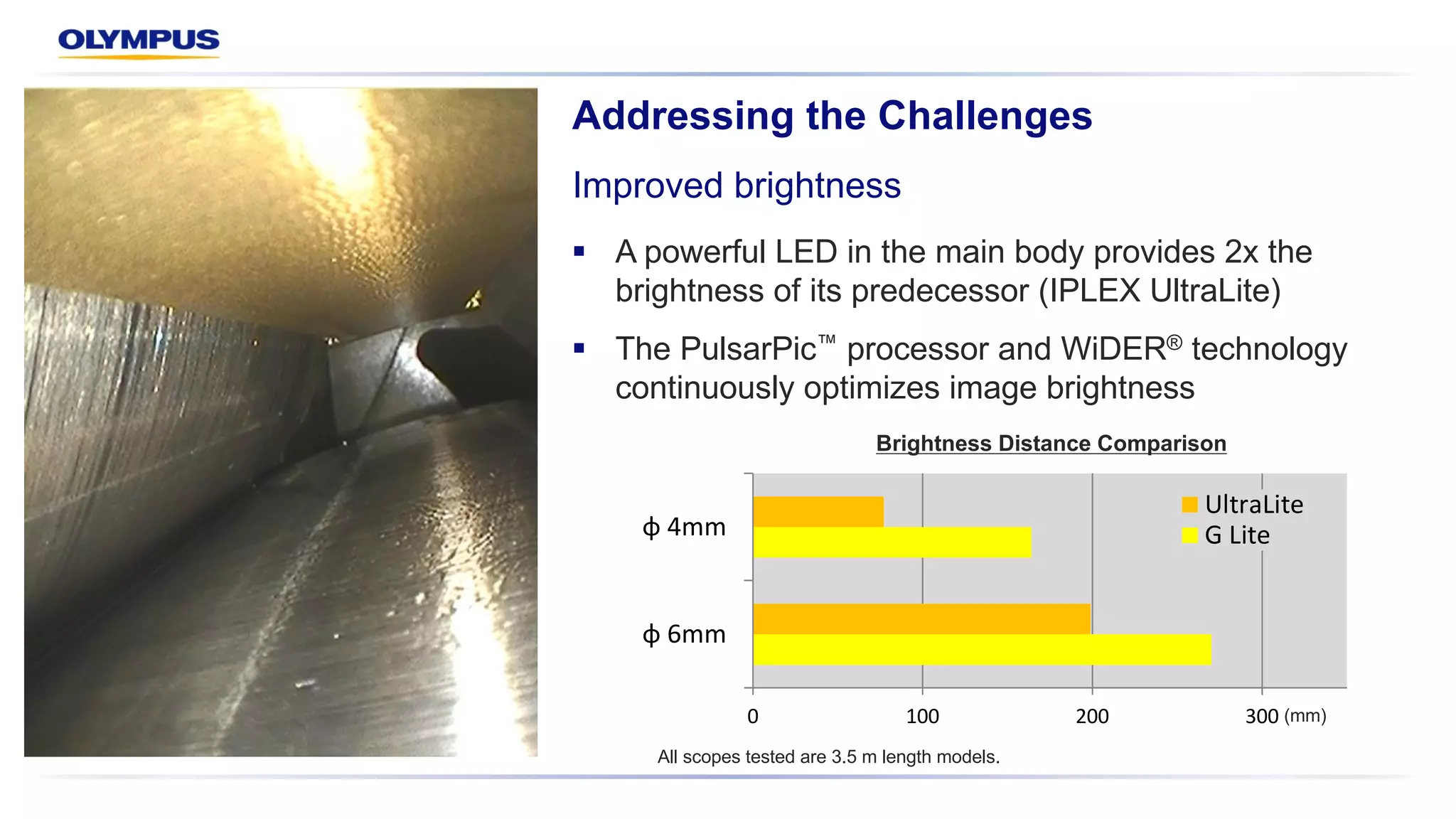

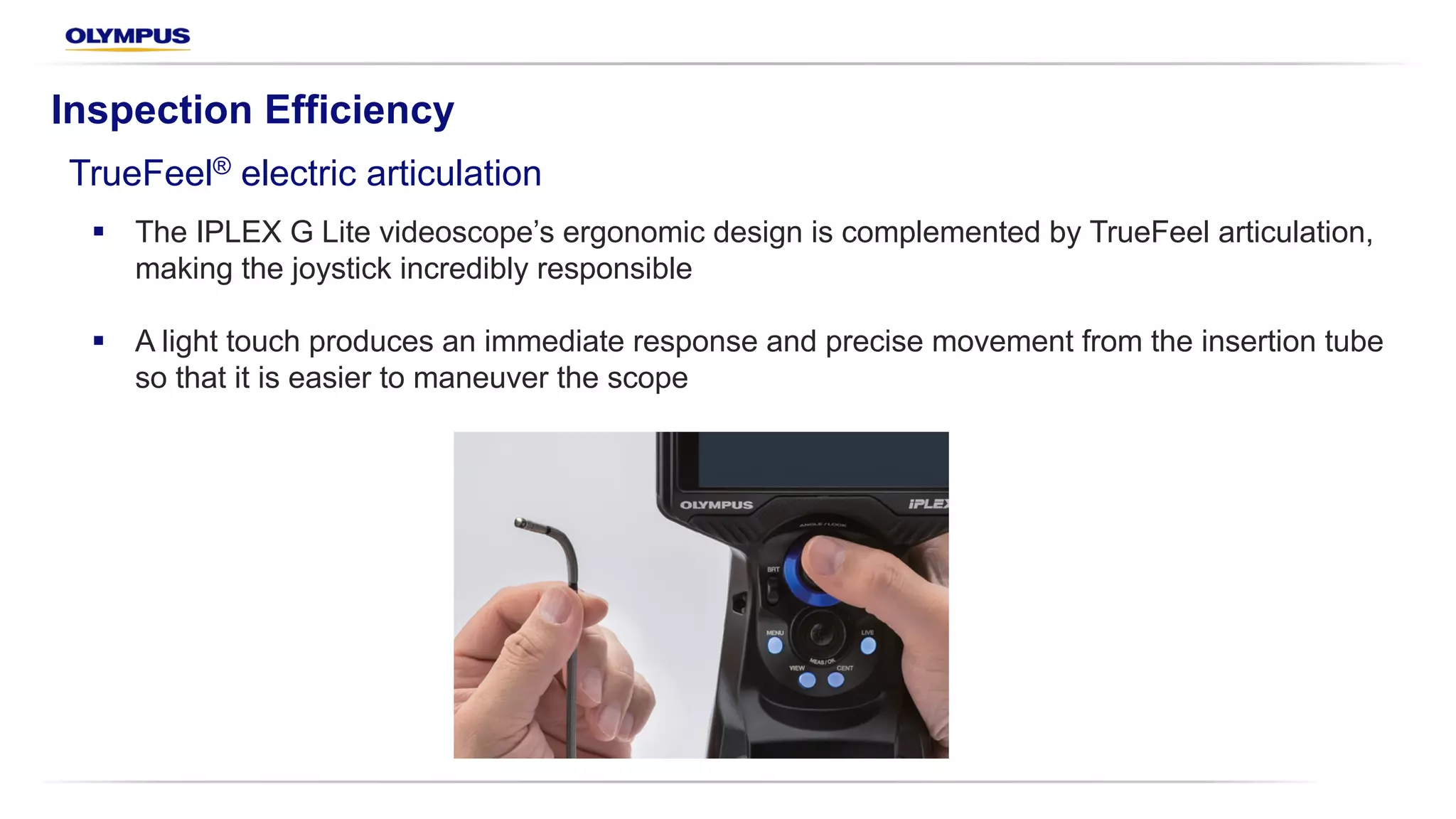

The document discusses the efficiency and challenges of wind turbine gearbox inspections, emphasizing the importance of regular inspections to prolong turbine lifespan. It outlines the benefits of Remote Visual Inspection (RVI), such as ease of understanding and on-site capabilities, and addresses the challenges faced during inspections, including maneuverability and light conditions. The document introduces the Iplex G Lite videoscope, highlighting its advanced features that enhance inspection efficiency, including improved image clarity, ergonomic design, and live image streaming.