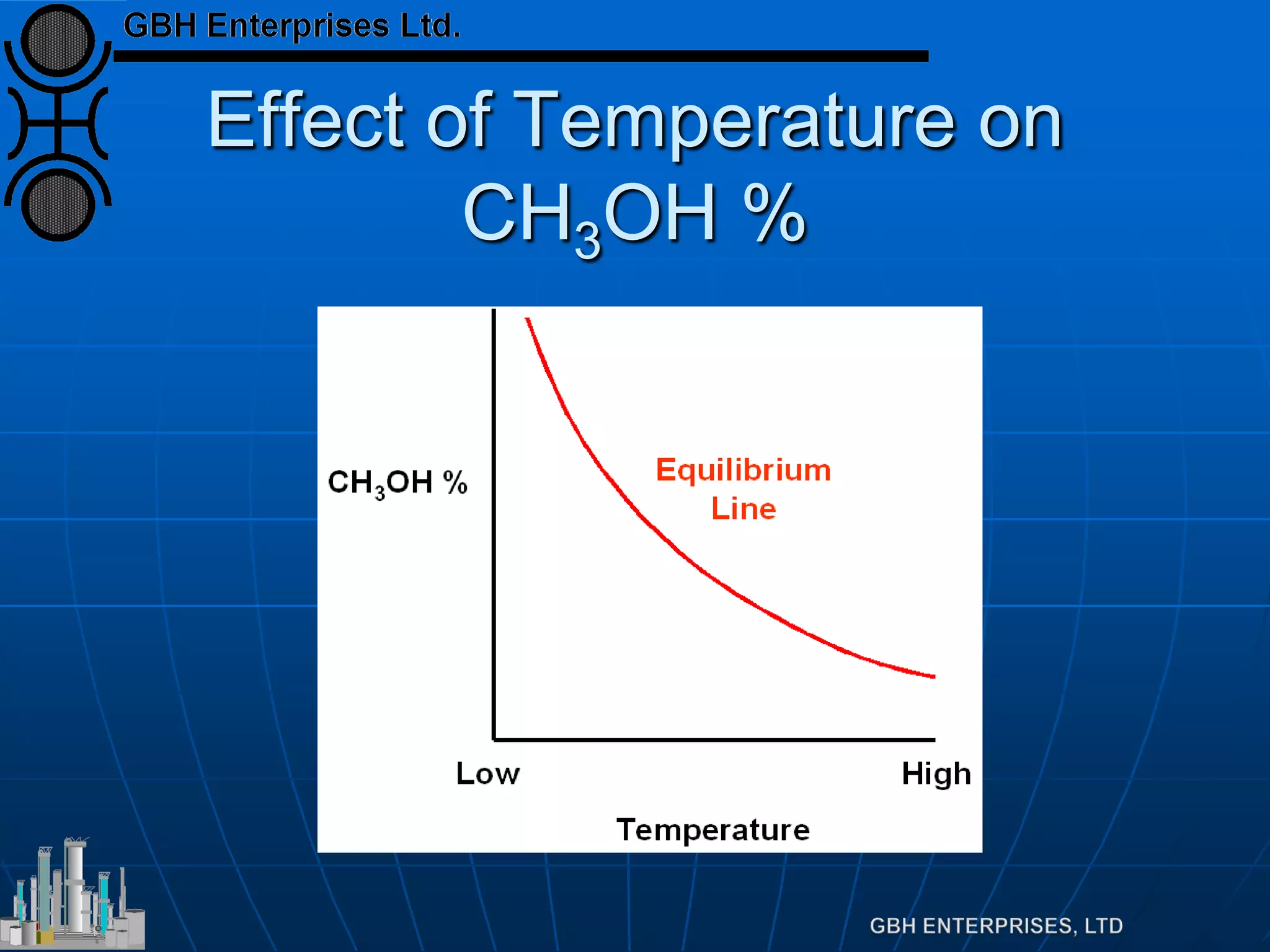

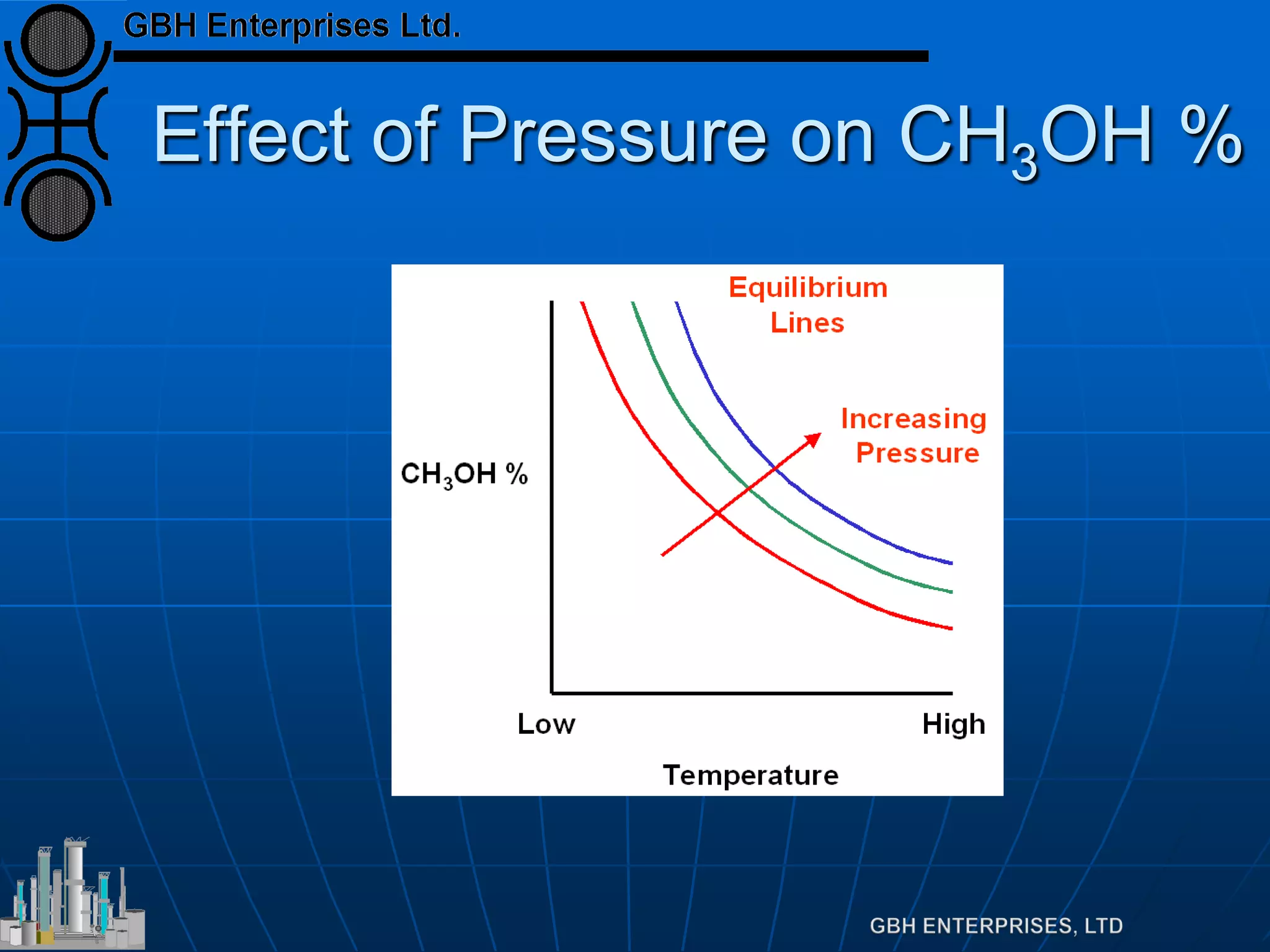

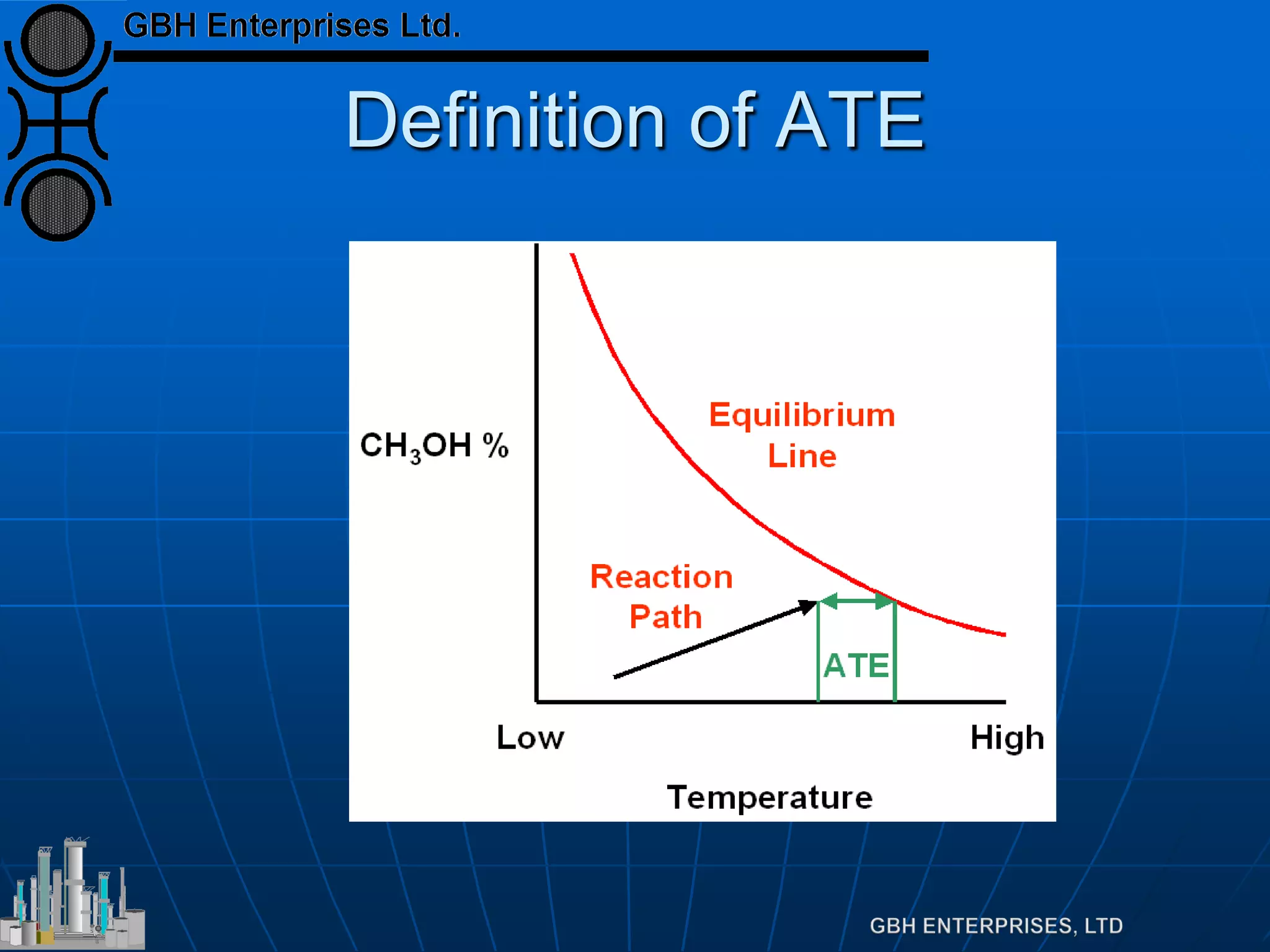

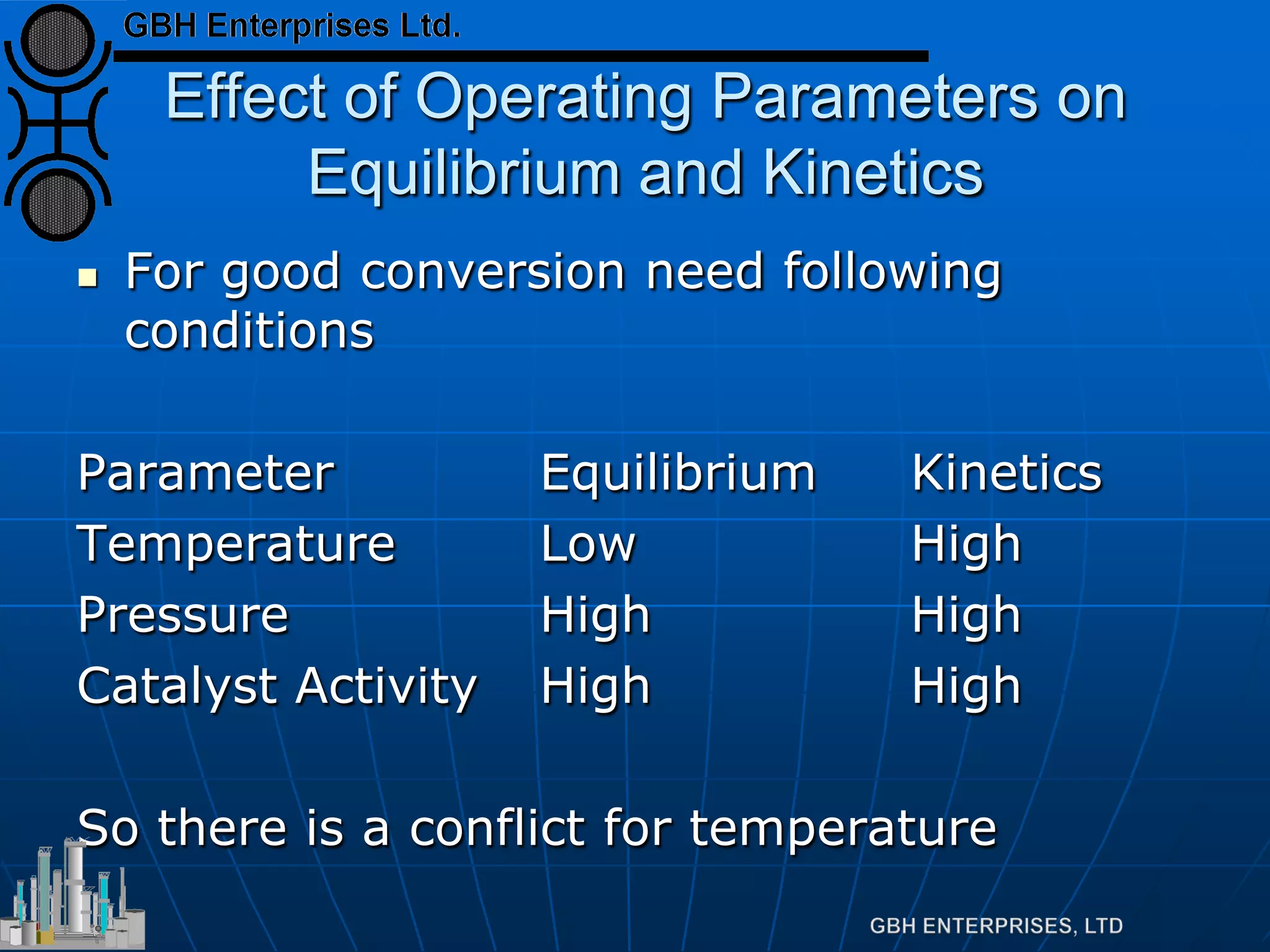

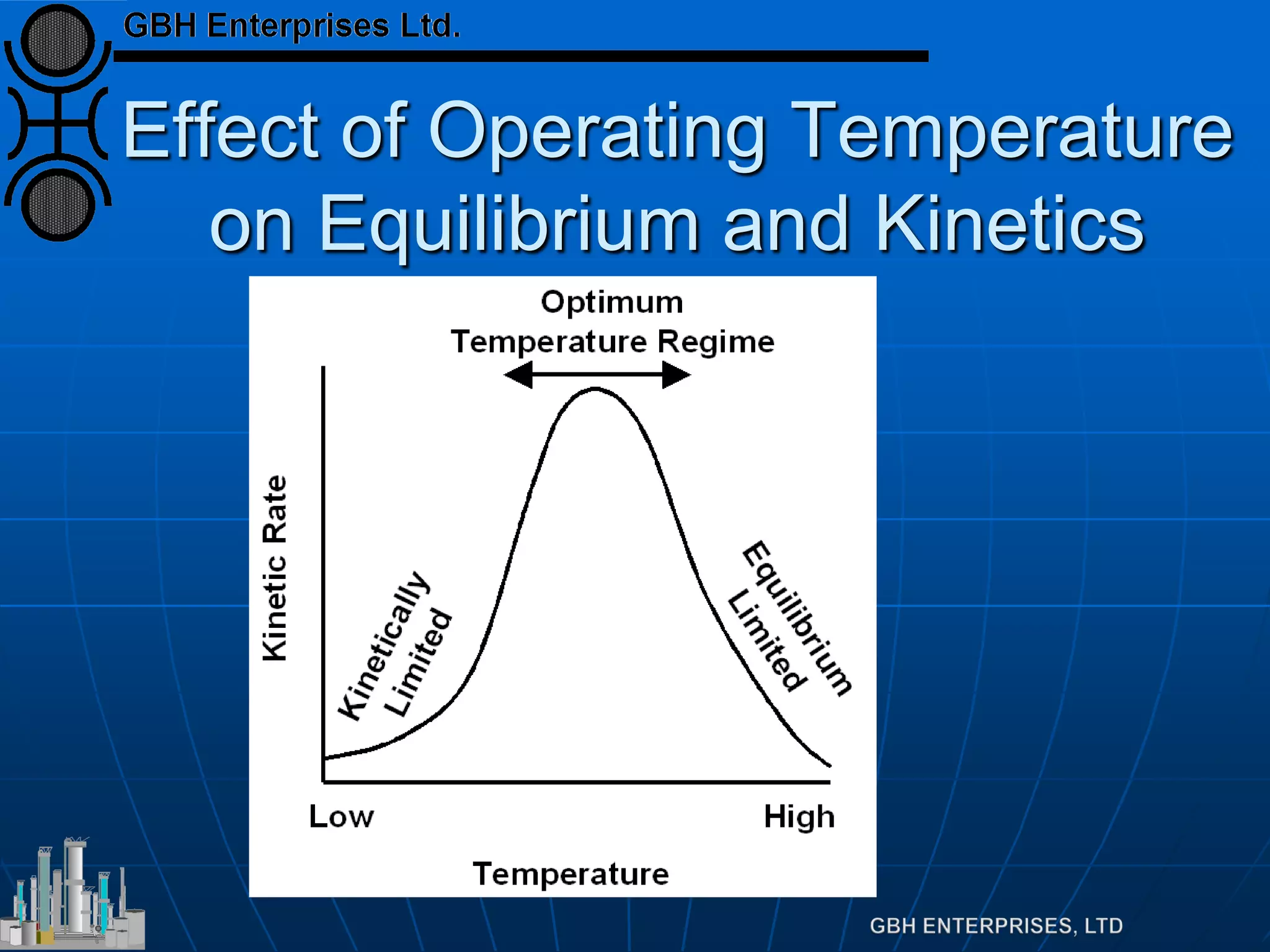

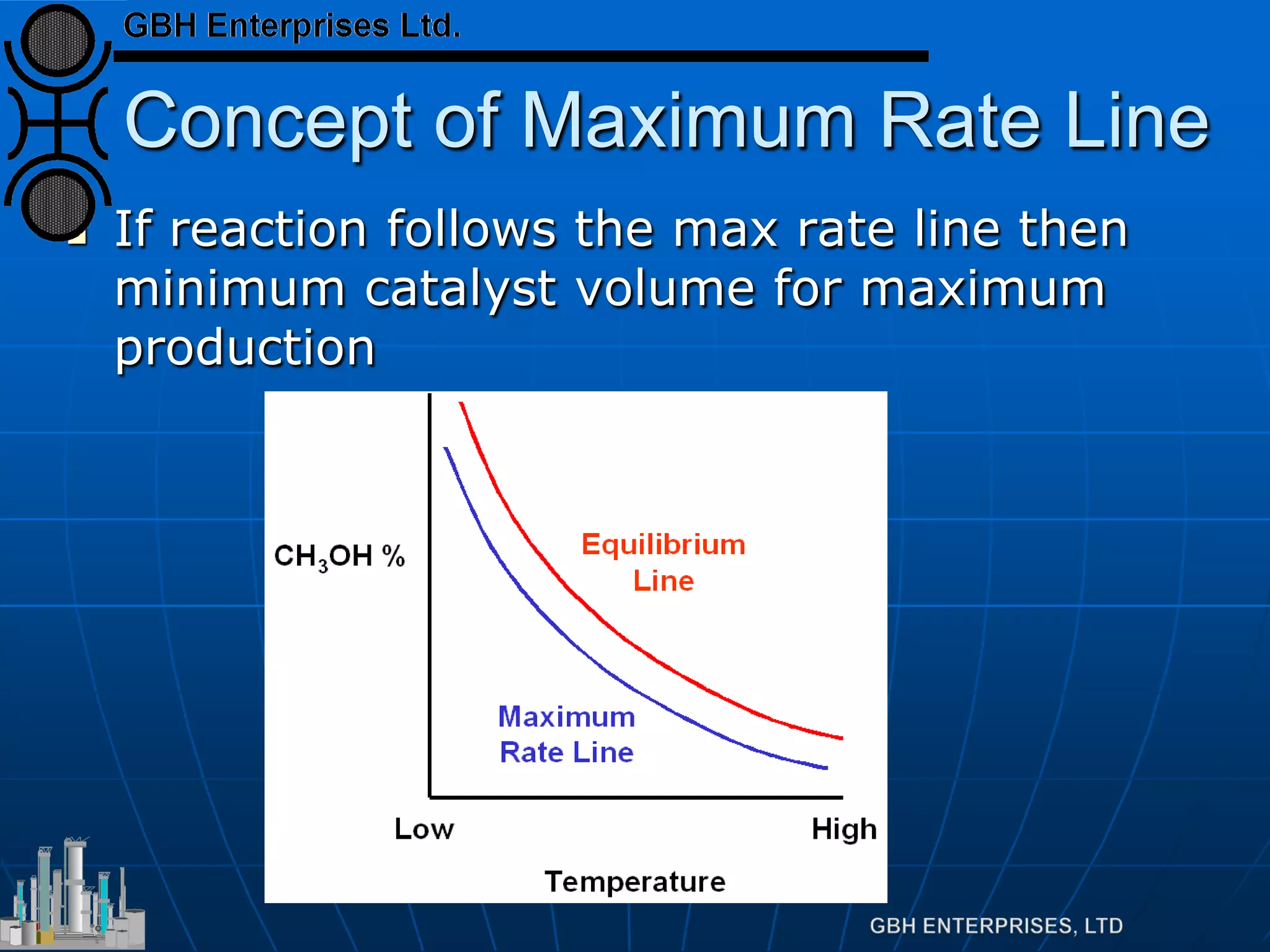

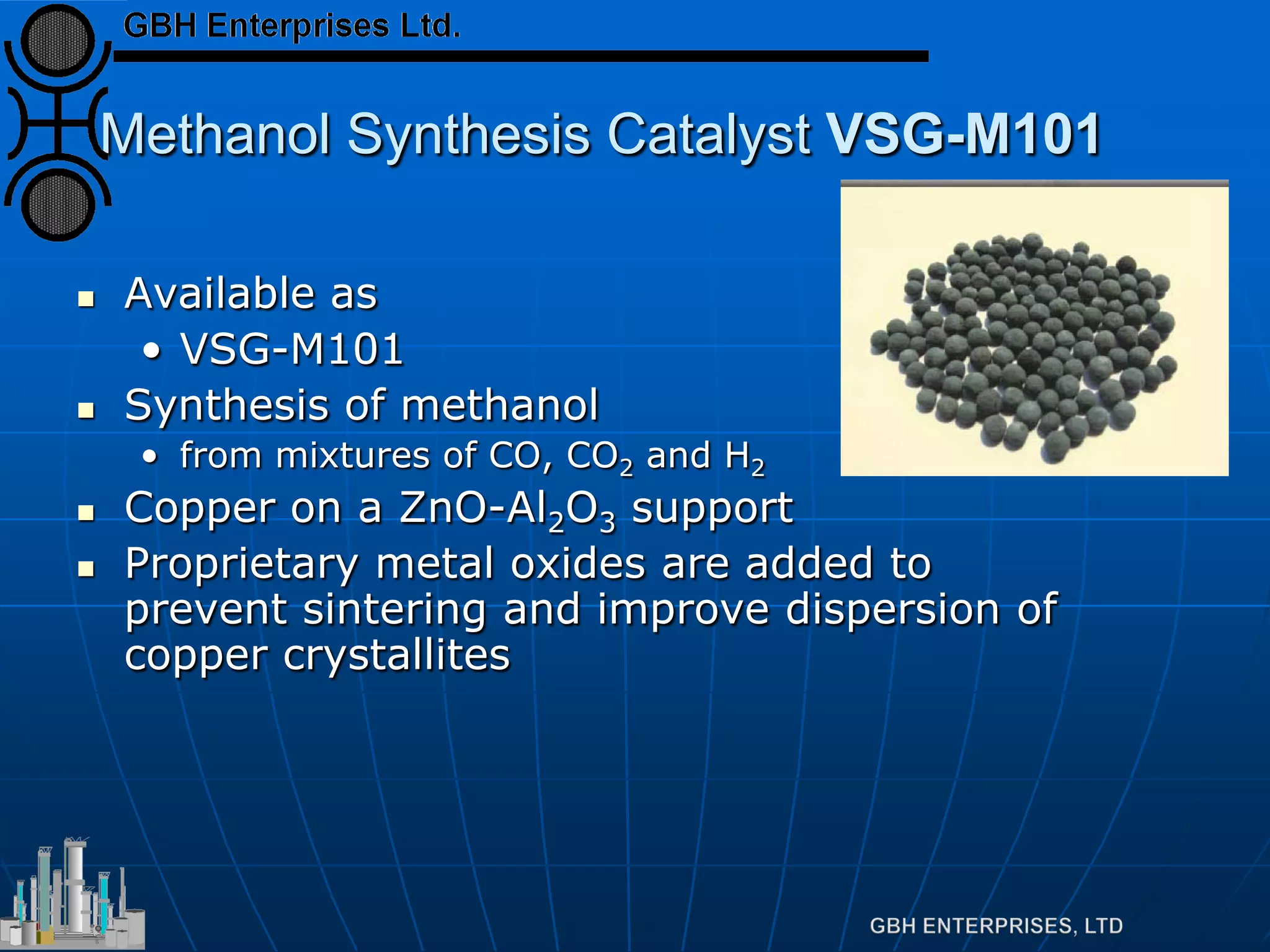

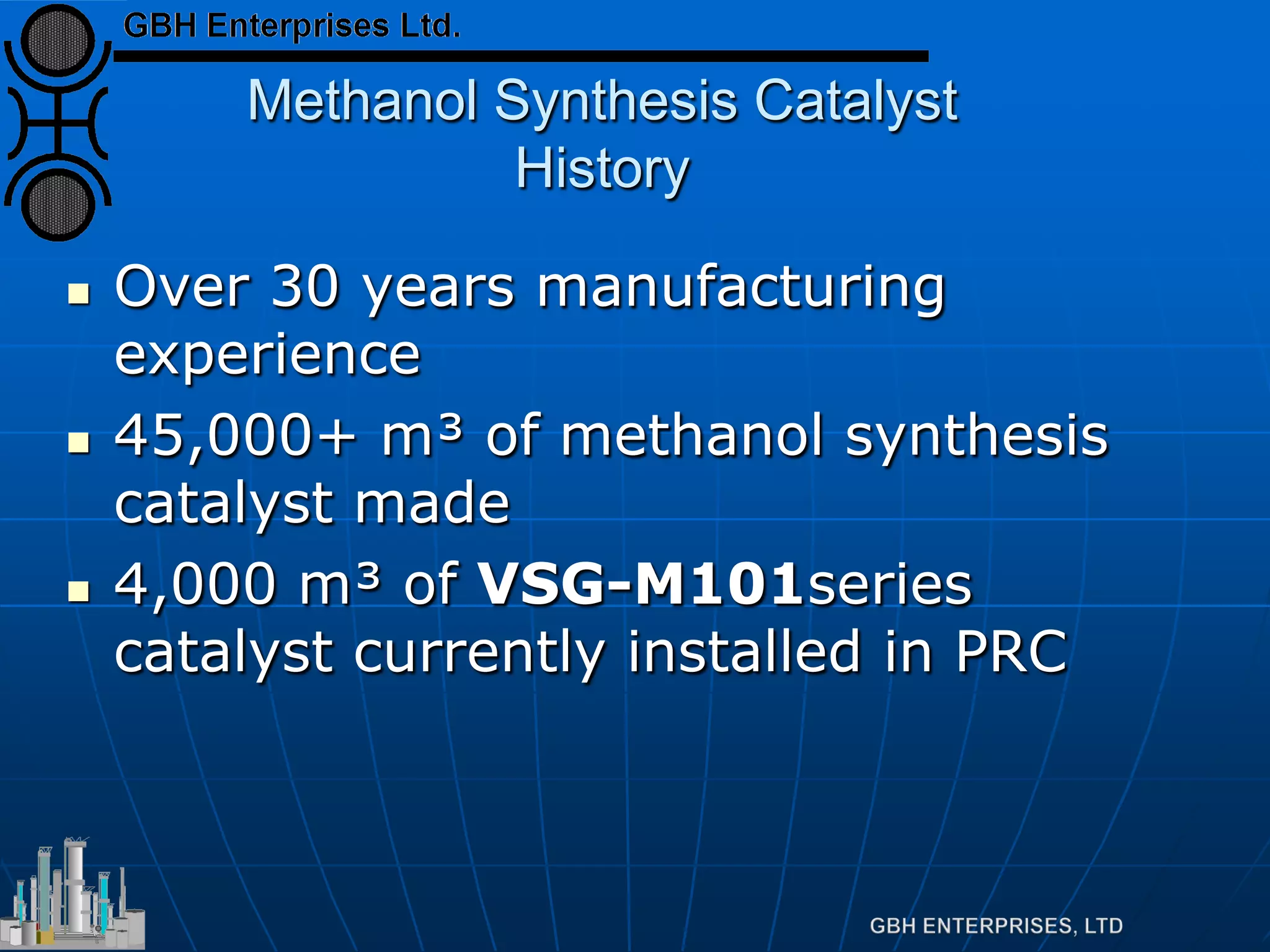

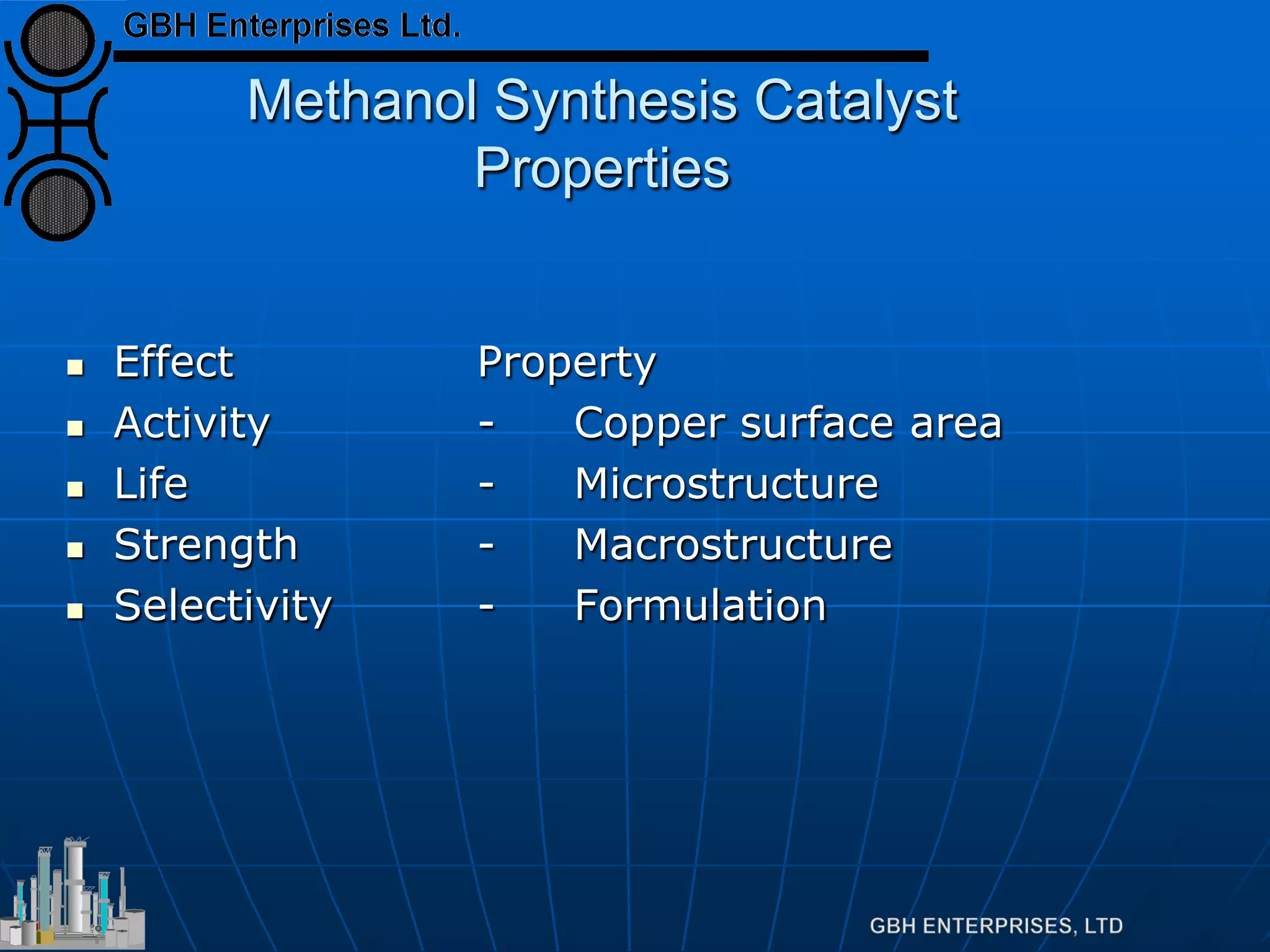

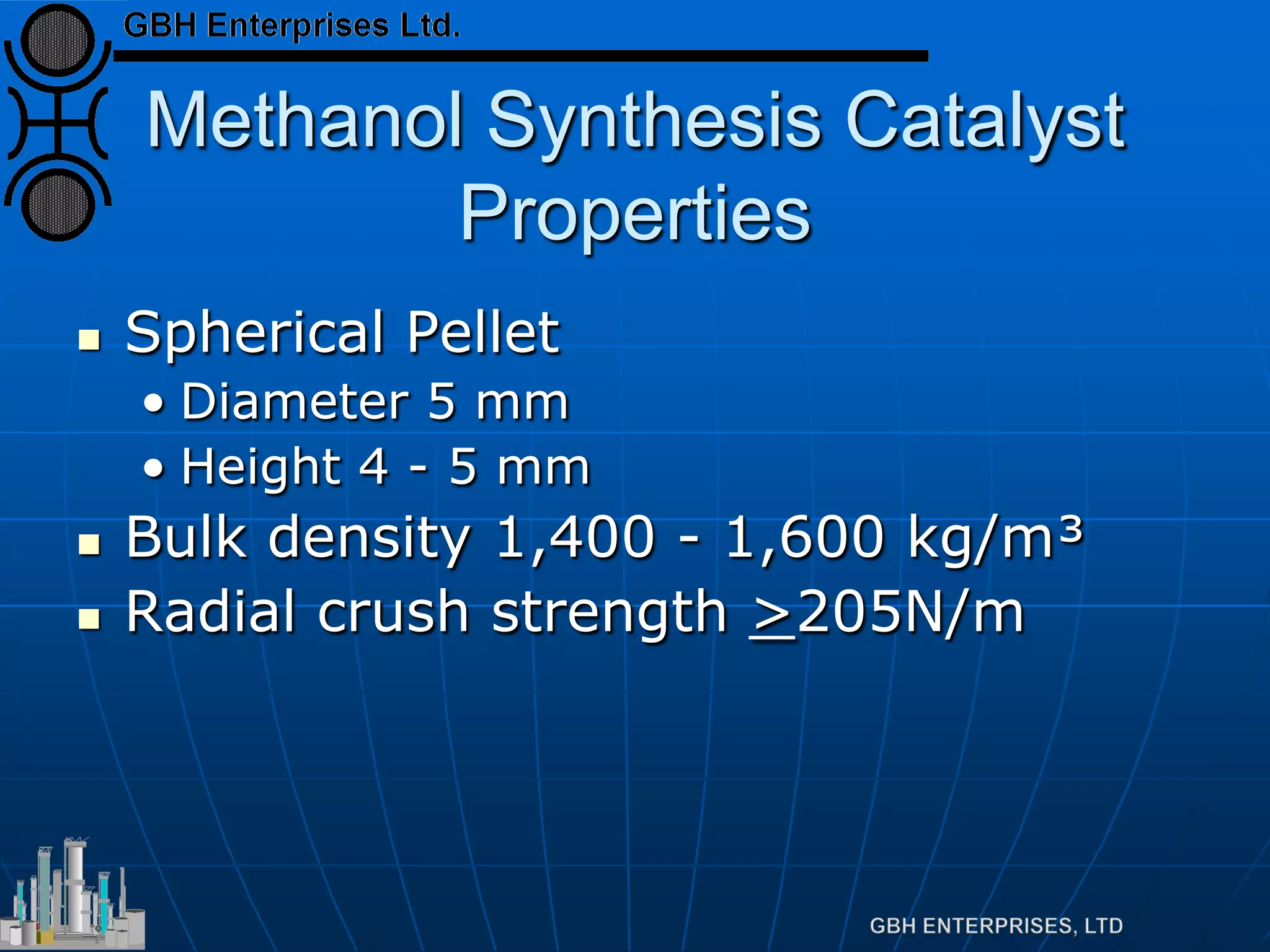

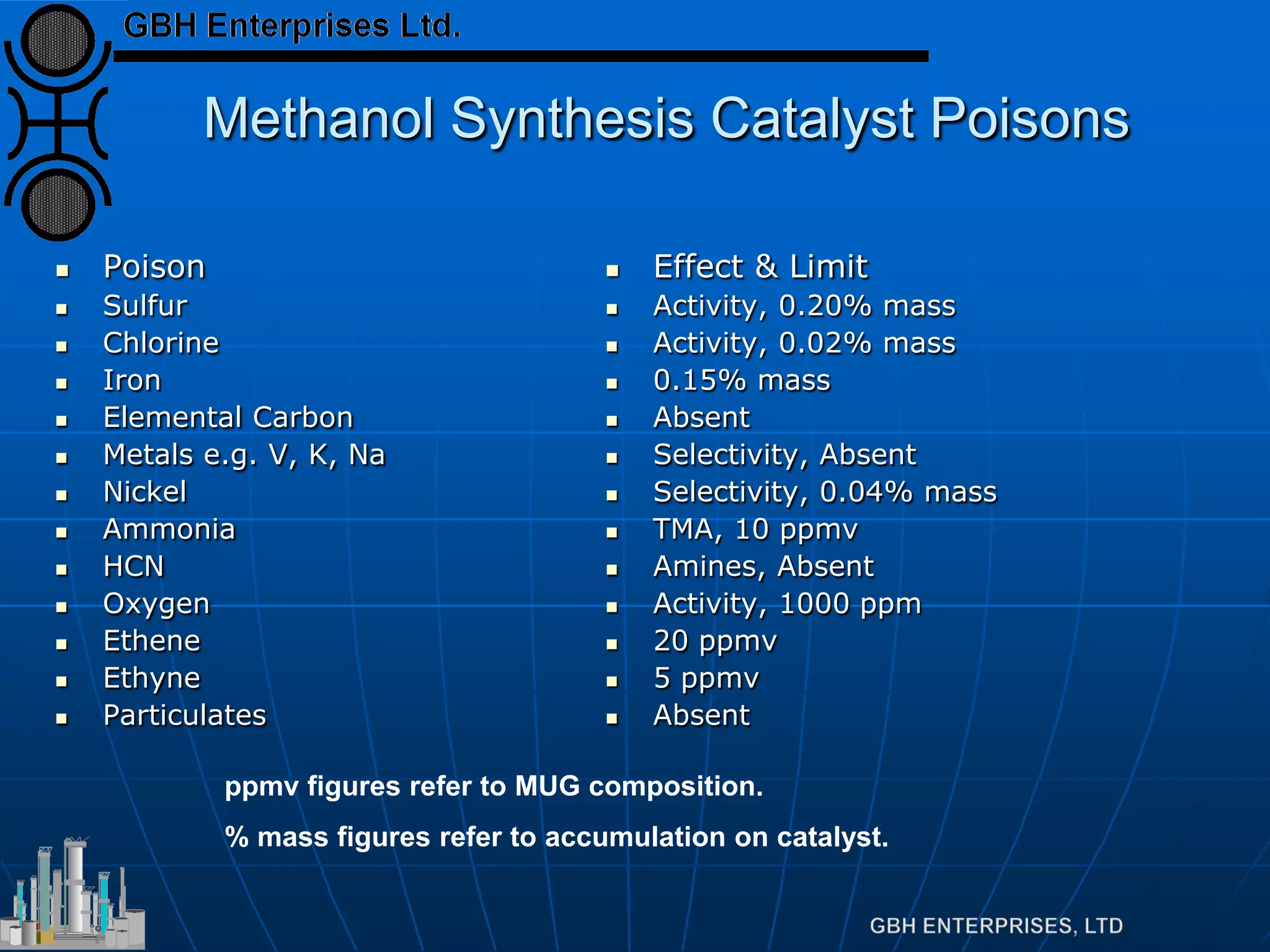

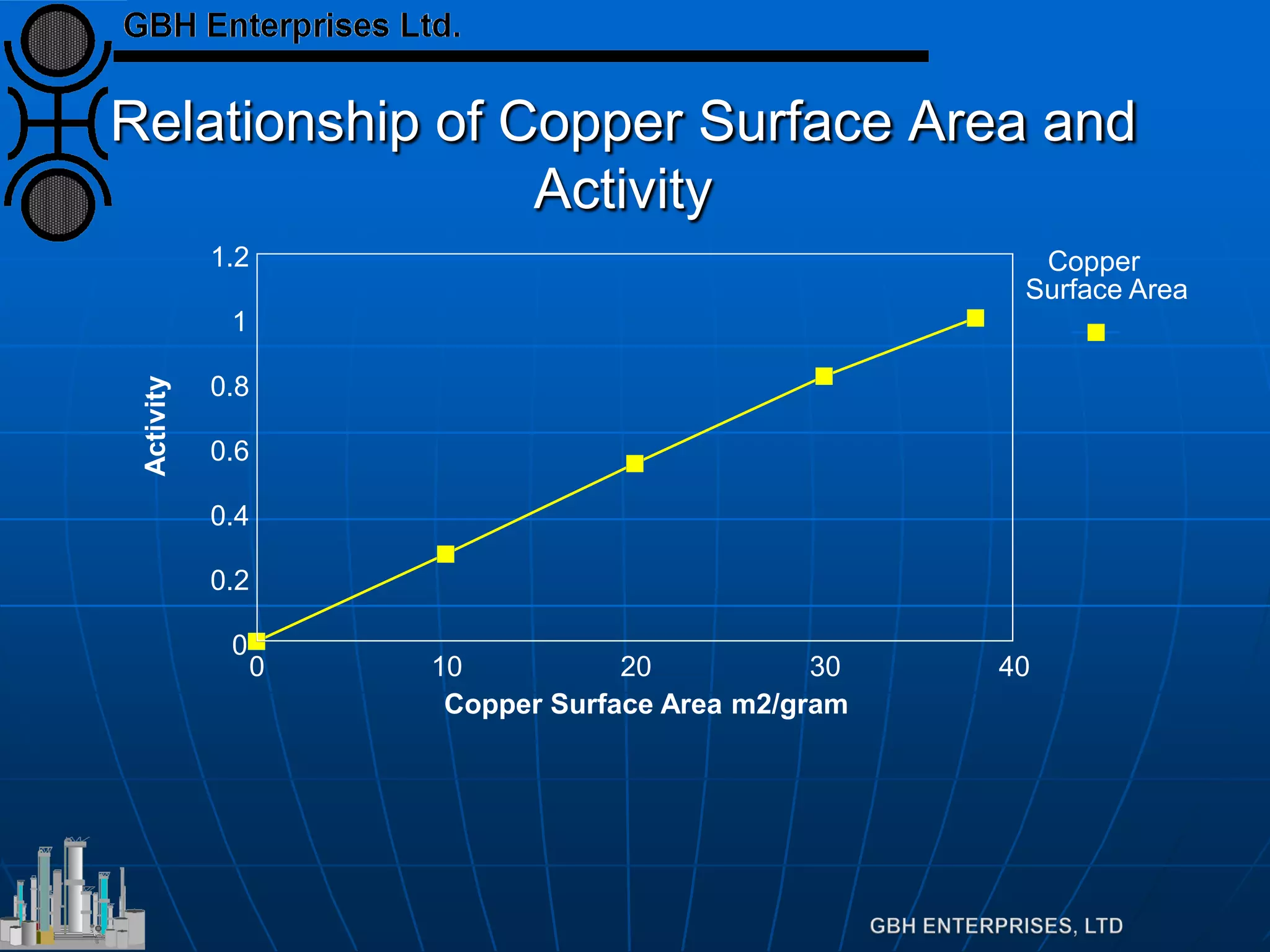

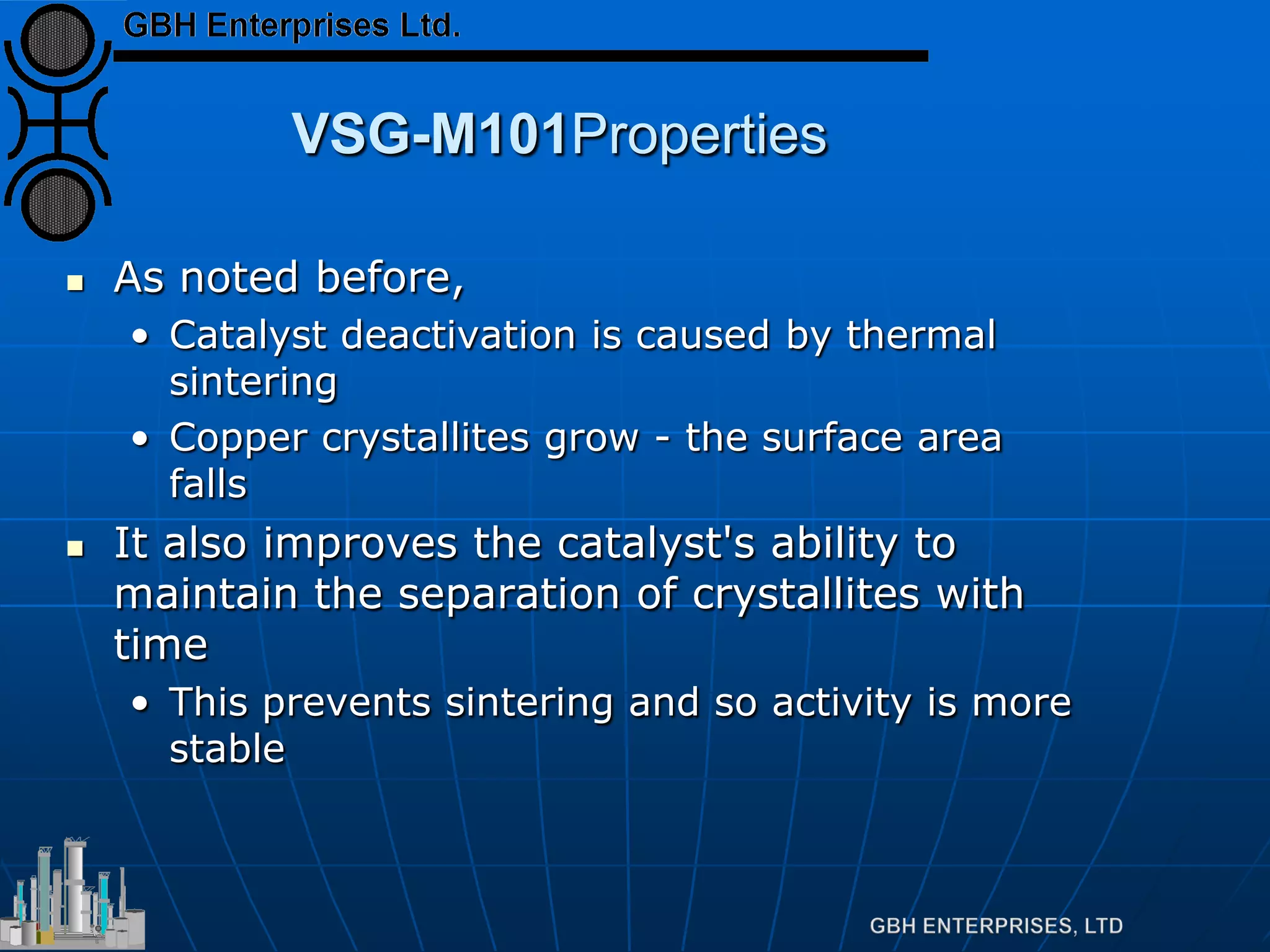

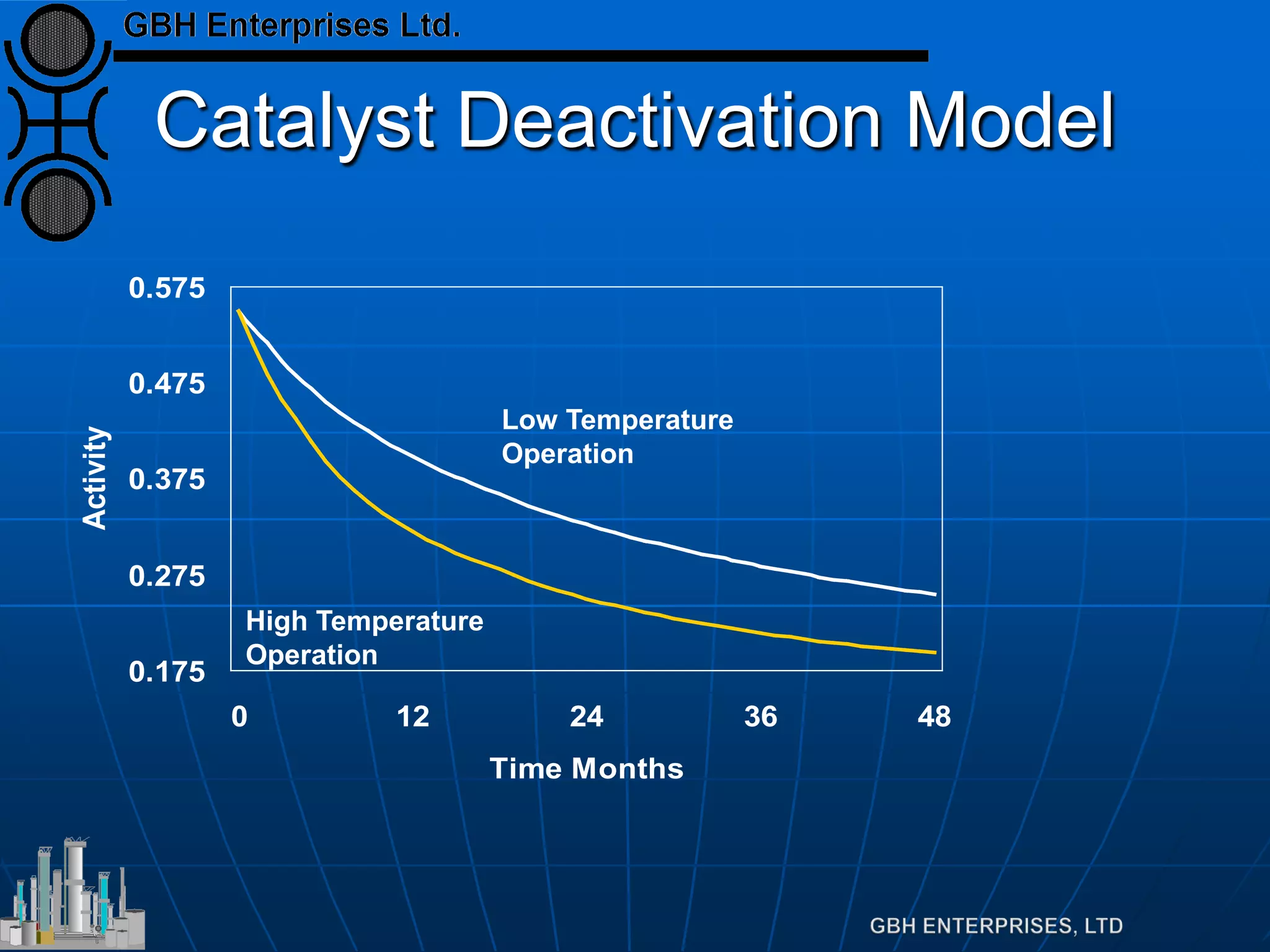

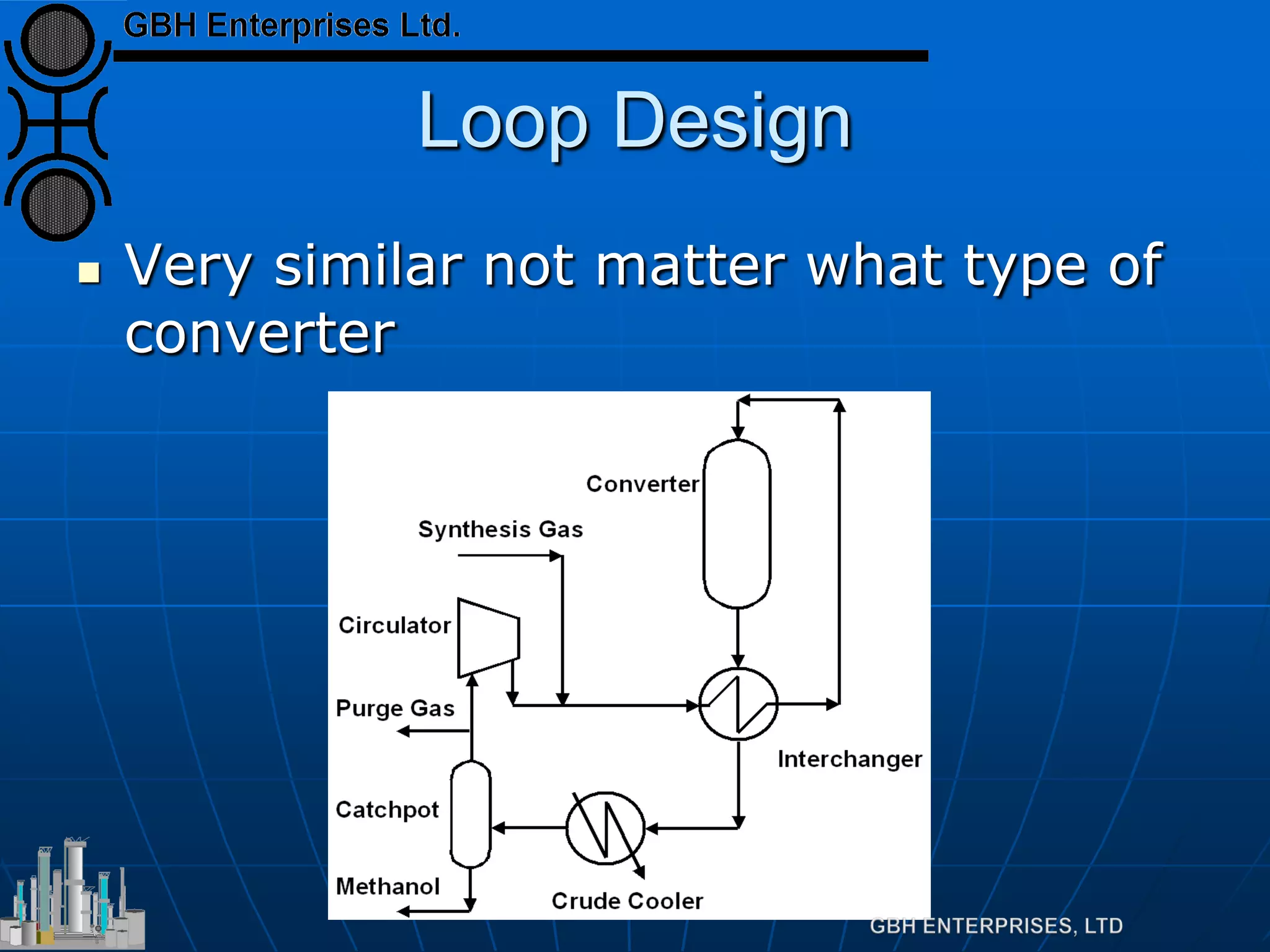

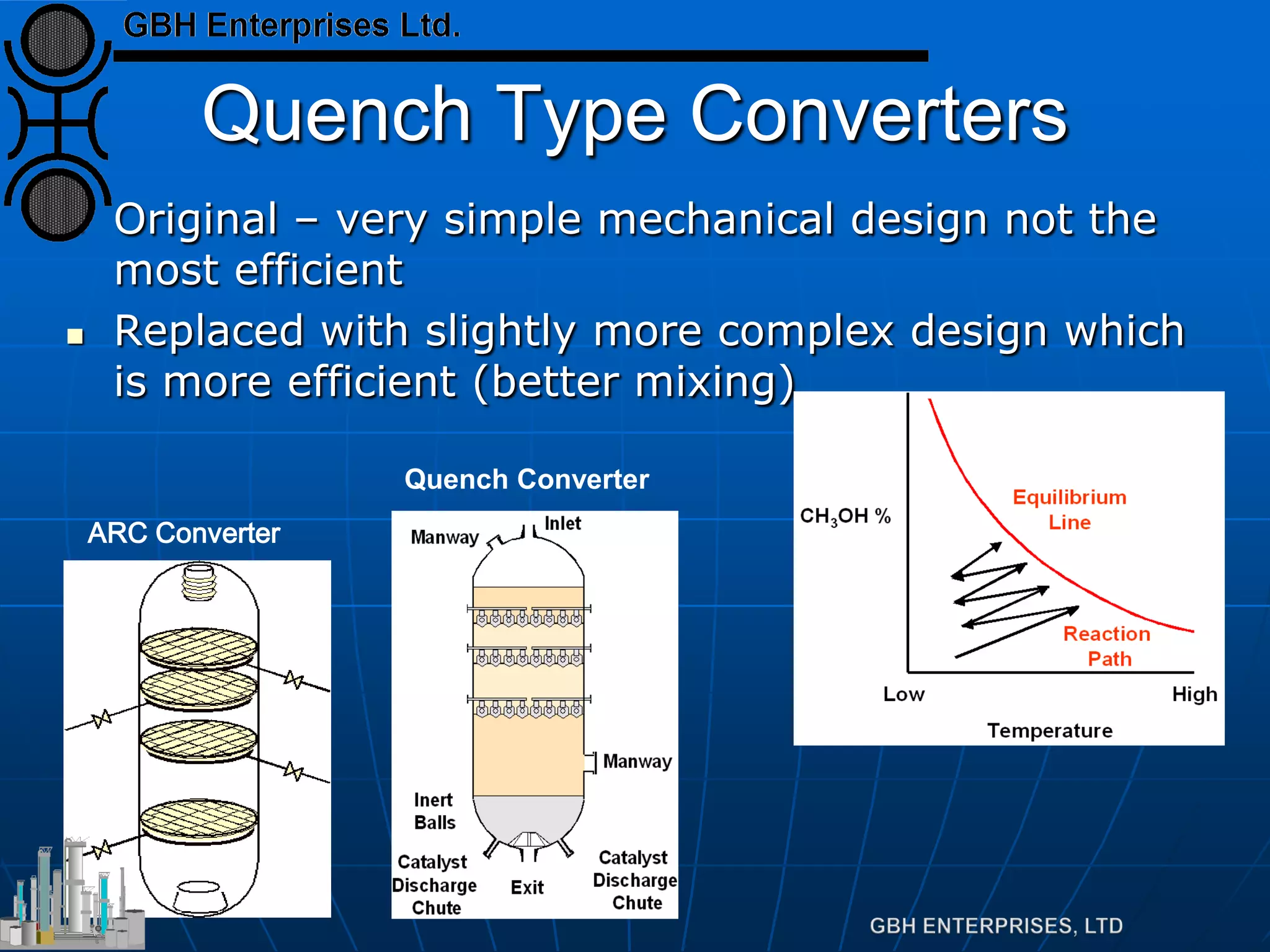

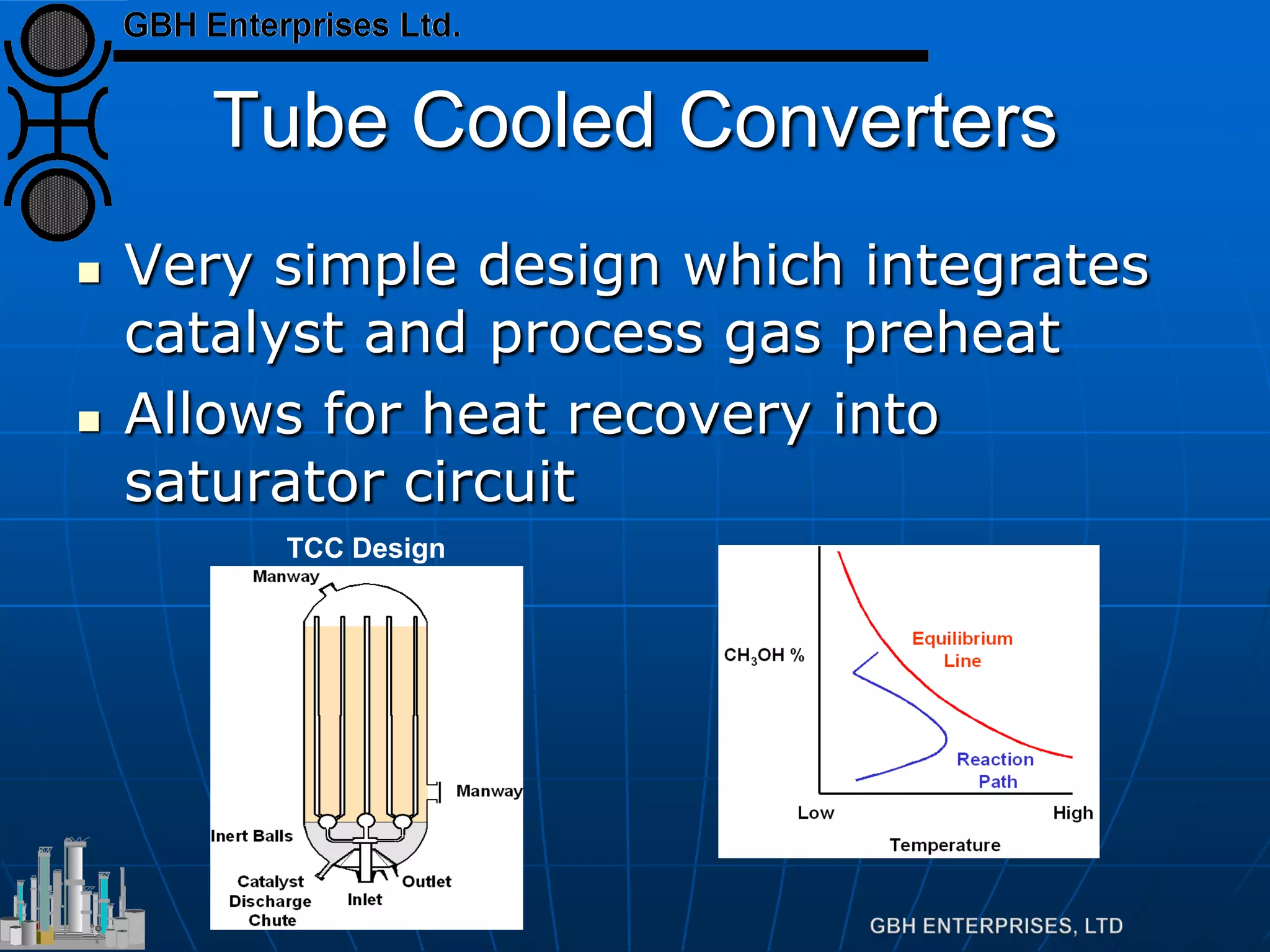

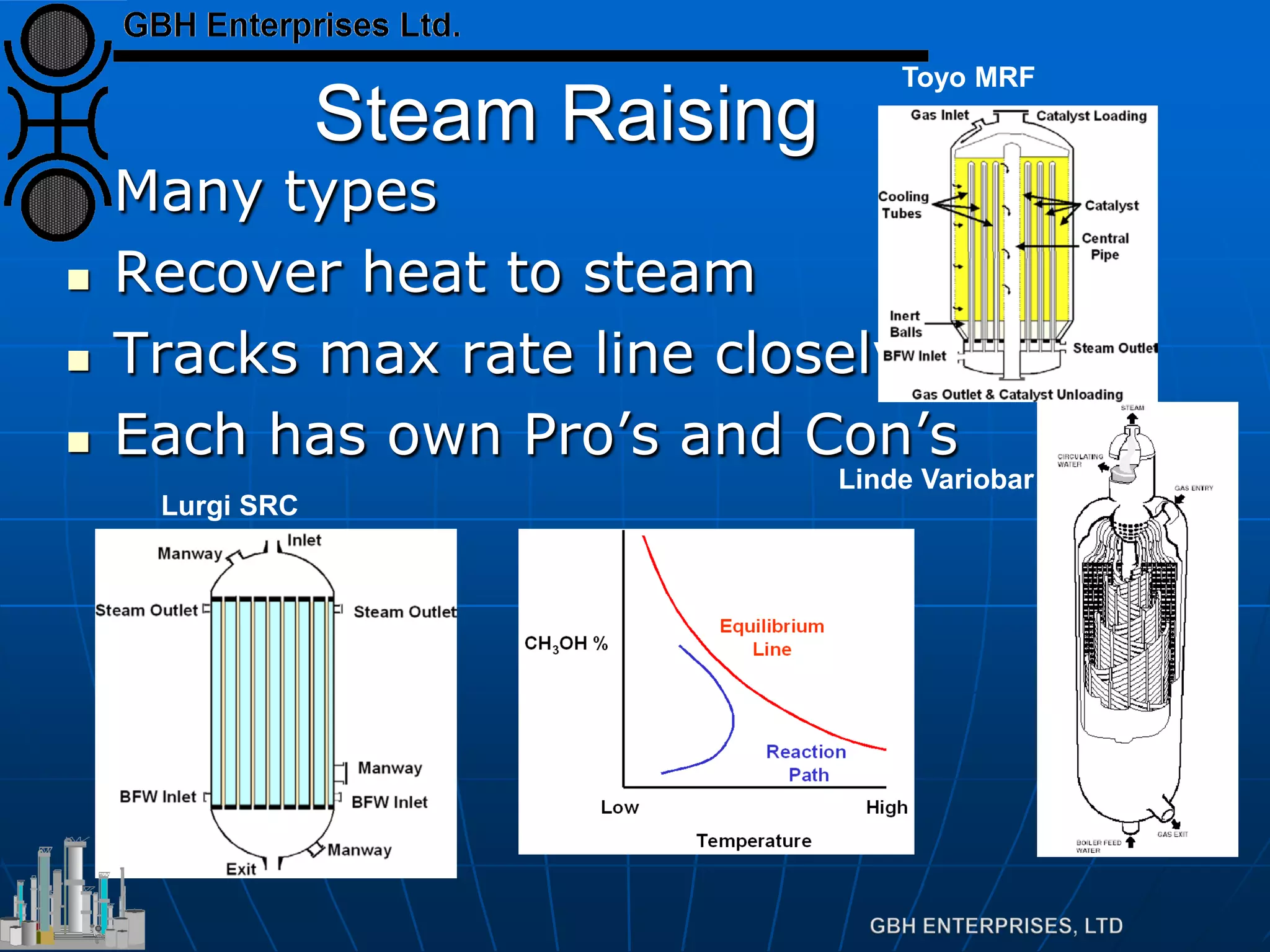

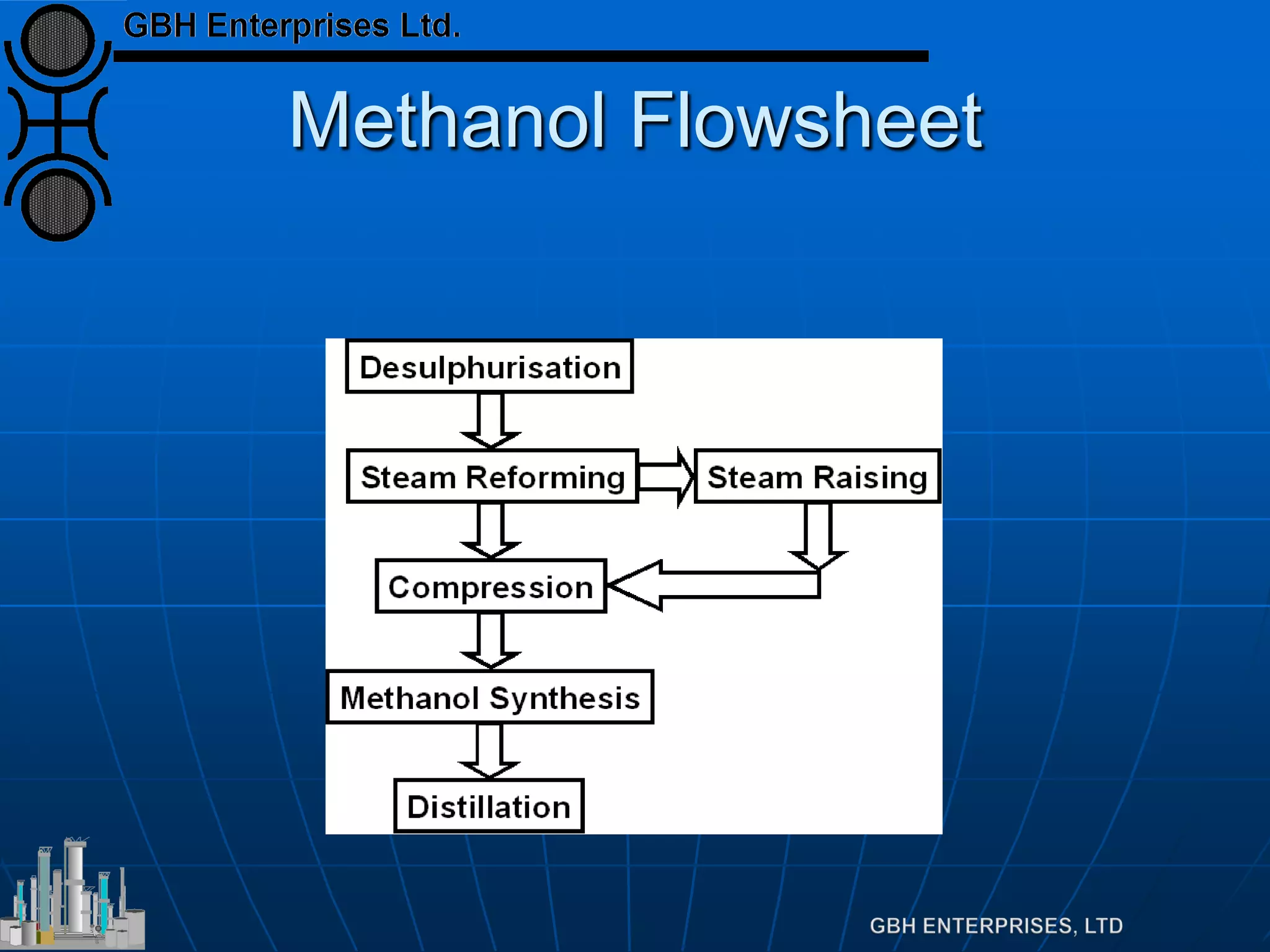

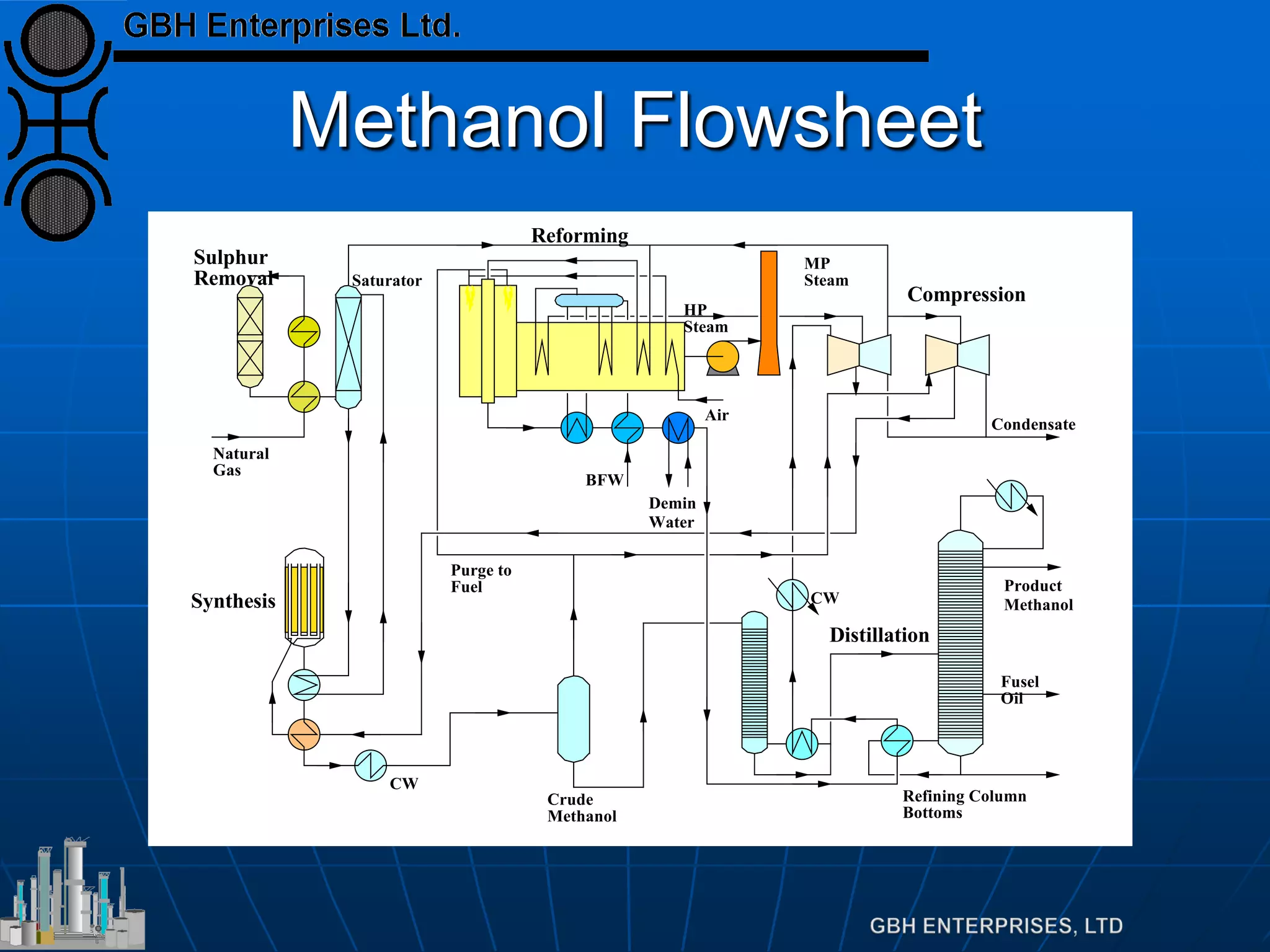

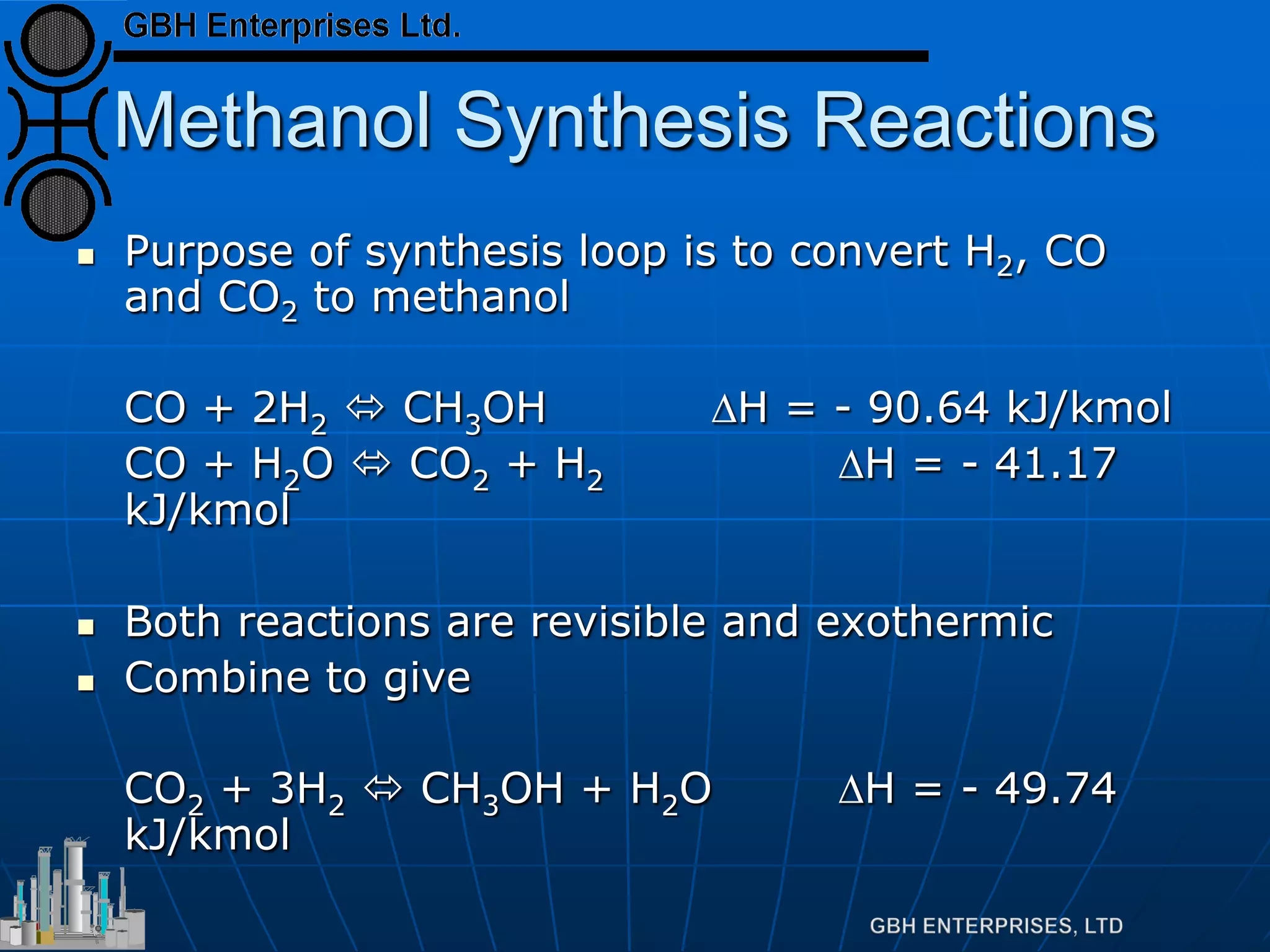

This document summarizes the theory and operation of methanol synthesis. It describes the typical methanol synthesis flowsheet that involves natural gas processing, reforming, and methanol production and purification steps. It also discusses the methanol synthesis reactions, catalysts used including their properties and deactivation mechanisms. Key factors that affect the equilibrium and kinetics of the synthesis reactions like temperature, pressure and catalyst activity are described. Methods to maximize the reaction rate within operational constraints are covered.

![Methanol Synthesis Reactions

Methanol is produced from CO2

Proven by use of radioactive C14

CO is shifted to CO2 and then to

methanol

Rate of reaction is given by

5.0

2

2]./[3

][

][

.exp.

OHP

COP

Activity

dt

OHdCH TRE∆−

∝](https://image.slidesharecdn.com/methanolsynthesis-theoryandoperation-130730212230-phpapp02/75/Methanol-Synthesis-Theory-and-Operation-6-2048.jpg)

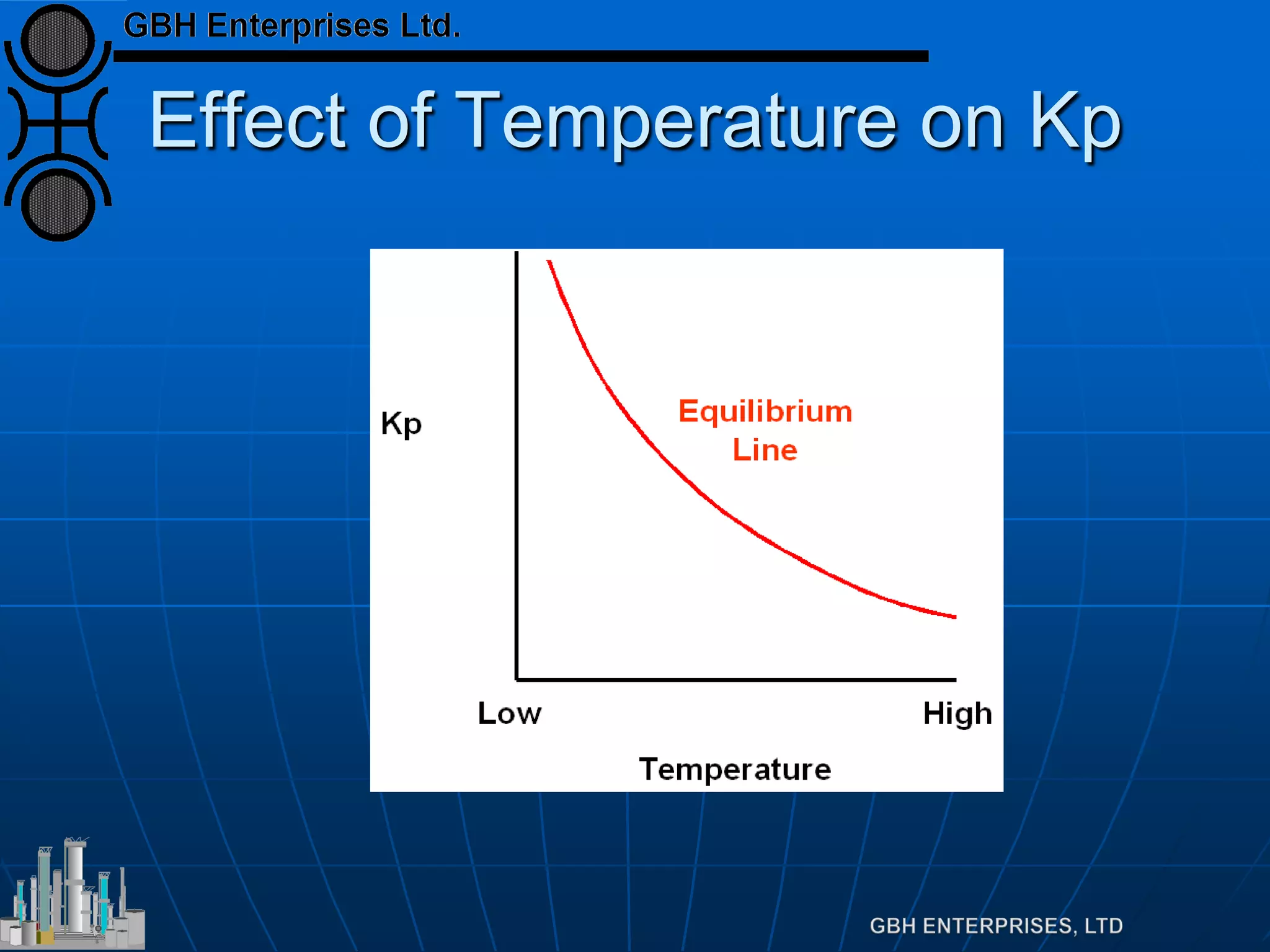

![Equilibrium

Equilibrium defined by

Which can be rearranged to

Which is far more useful

[ ] [ ]

[ ] [ ]3

22

23

.

.

HPCOP

OHPOHCHP

Kp =

[ ]

[ ] [ ]3

22

2

3

.

][.

HPCOP

OHPKp

OHCHP =](https://image.slidesharecdn.com/methanolsynthesis-theoryandoperation-130730212230-phpapp02/75/Methanol-Synthesis-Theory-and-Operation-7-2048.jpg)