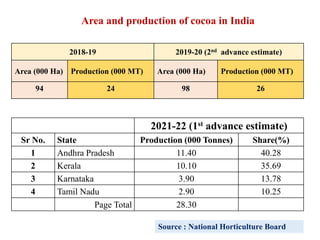

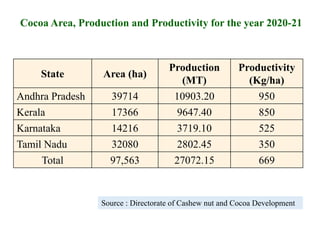

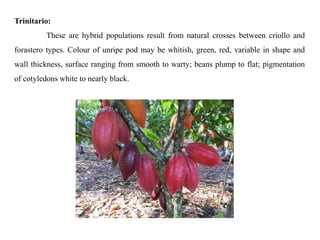

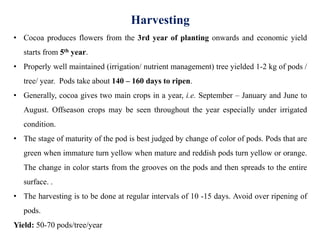

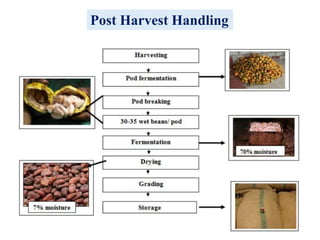

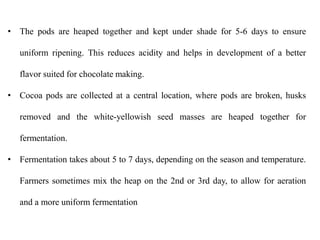

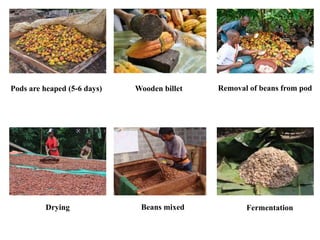

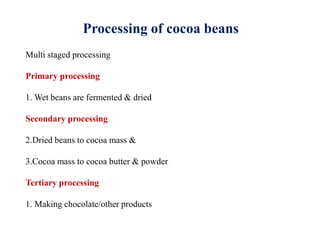

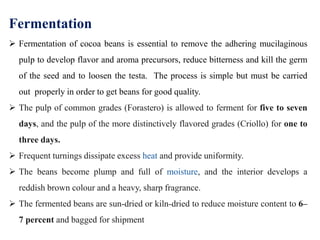

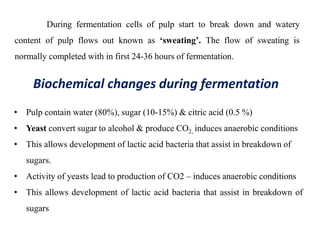

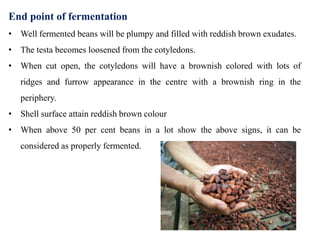

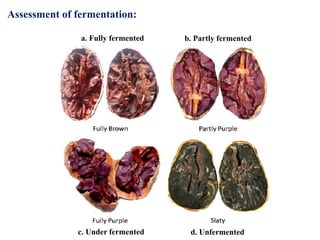

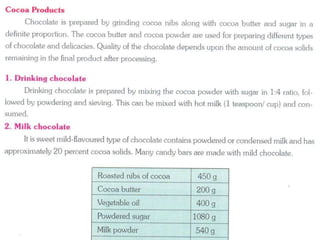

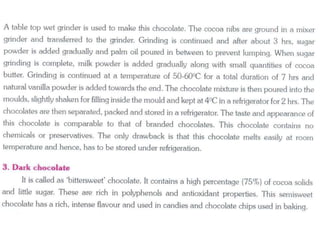

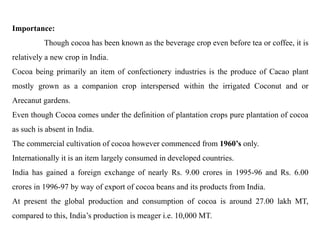

The document discusses cocoa processing and value addition. It begins with an introduction to cocoa and provides information on cocoa production in India. It then covers cocoa harvesting and post-harvest handling, focusing on fermentation. Fermentation is an essential process that develops flavor, reduces bitterness, and allows biochemical changes in the cocoa beans. Different fermentation methods like heap, box, basket and tray methods are described. The key steps and factors affecting fermentation are also summarized.