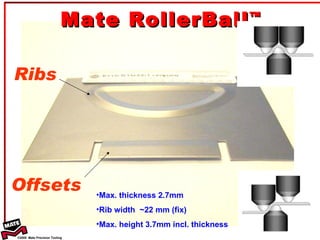

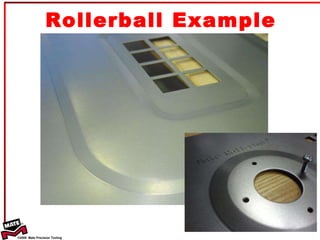

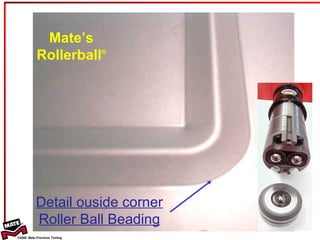

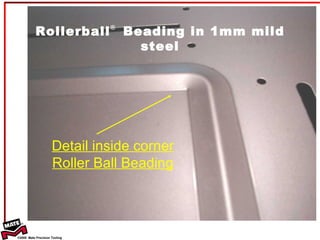

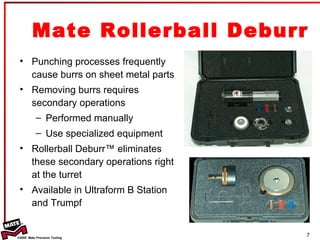

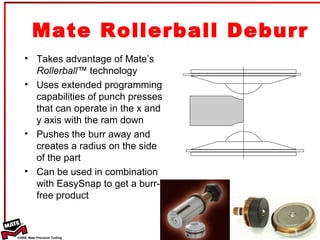

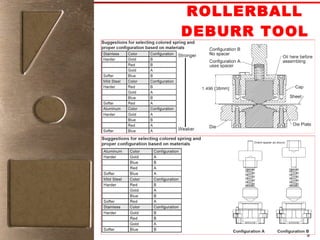

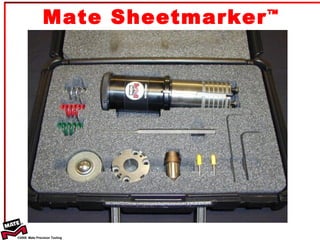

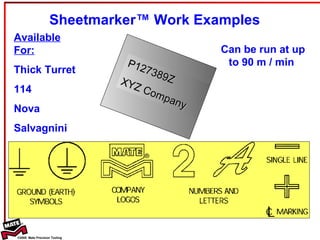

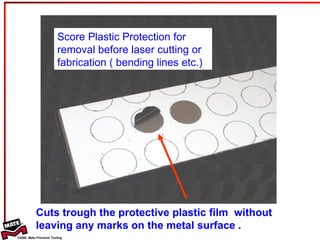

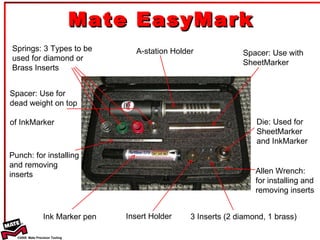

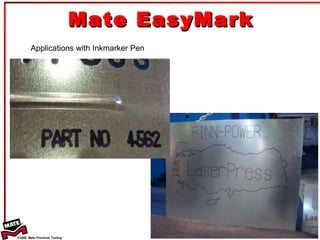

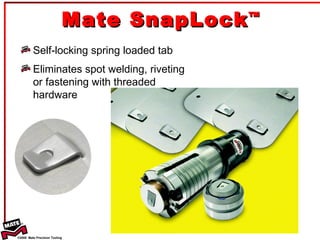

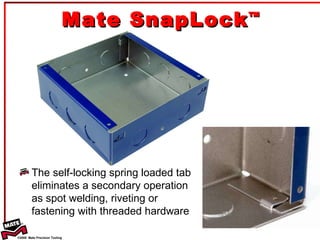

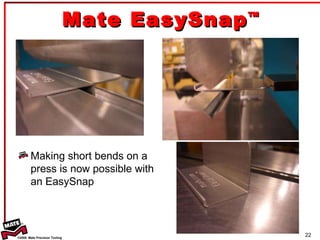

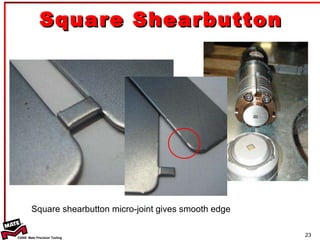

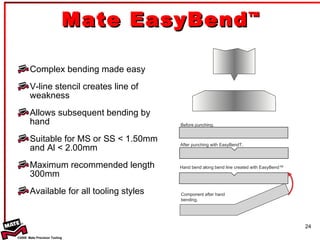

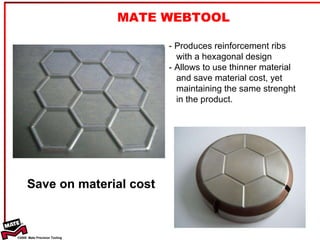

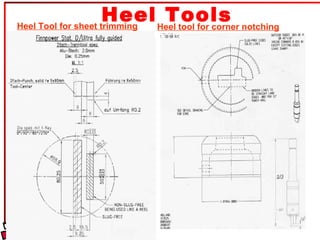

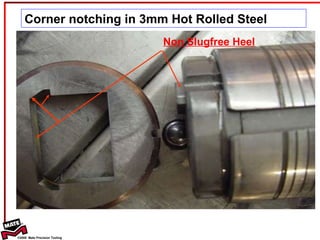

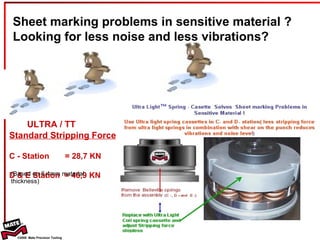

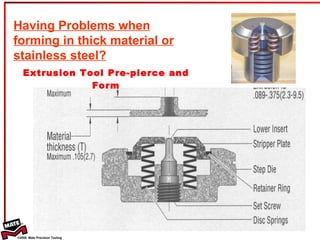

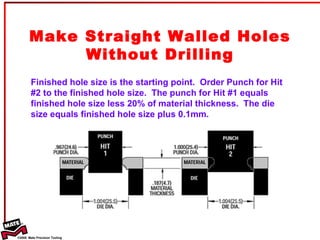

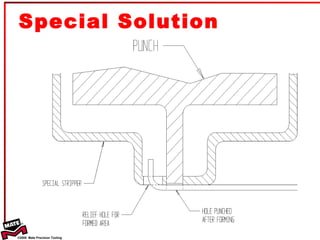

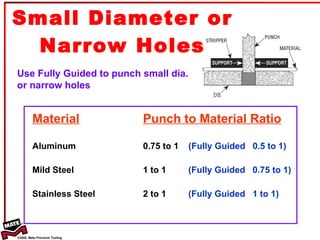

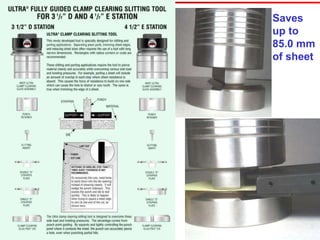

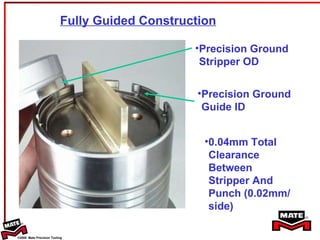

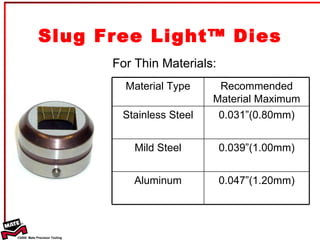

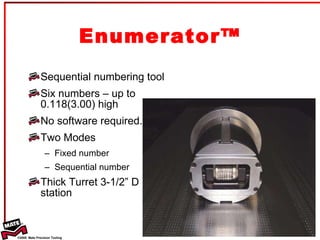

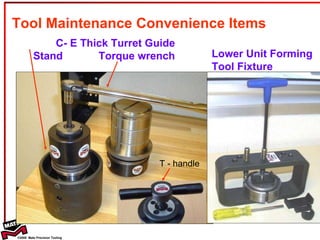

The document discusses various specialized tools from Mate Precision Tooling for punching and forming sheet metal parts. It describes tools that eliminate burrs during punching, create bend lines for easy bending, provide fastening methods to replace welding, and reduce sheet marking on delicate materials. It also provides information on tools for precision hole punching, sequential numbering, and tool maintenance.