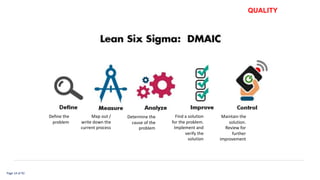

This document provides an overview of an organization's integrated management system covering quality, health and safety, and environmental policies and procedures. It discusses the organization's quality management system which follows the Six Sigma DMAIC methodology. It also outlines the organization's health and safety policies covering OHSAS 18001 requirements, duties of employees and management, and safety committees. The document aims to train employees on the organization's integrated management system.