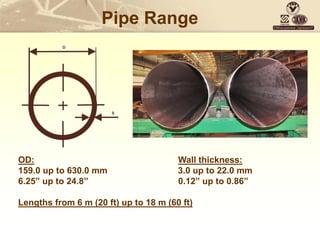

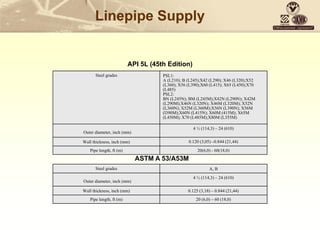

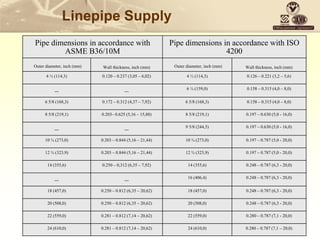

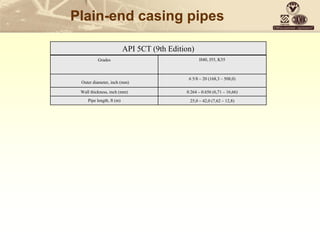

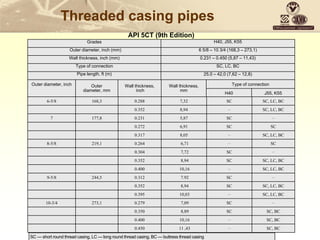

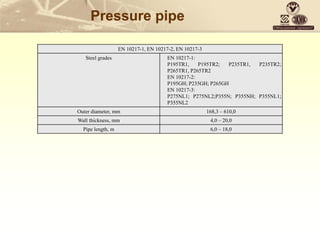

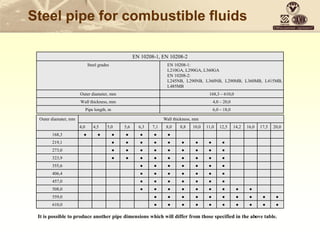

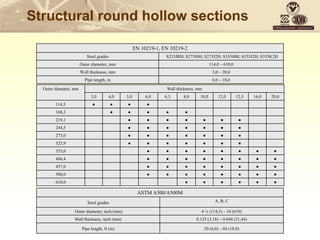

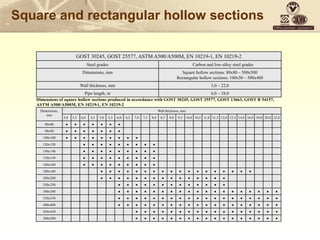

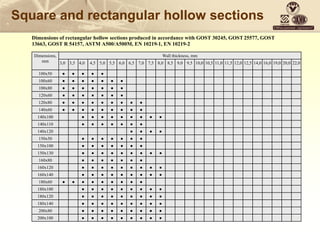

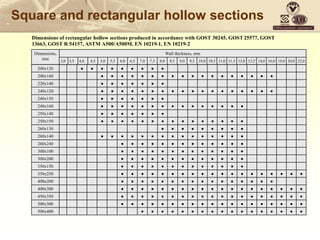

URALS PIPE WORKS produces various types of steel pipes including line pipes, casing pipes, pressure pipes, and structural hollow sections. The document provides detailed specifications on the dimensions, steel grades, standards, and product ranges for each type of pipe. Pipes can be produced in outer diameters ranging from 114-630mm, wall thicknesses from 3-22mm, and lengths from 6-18m.