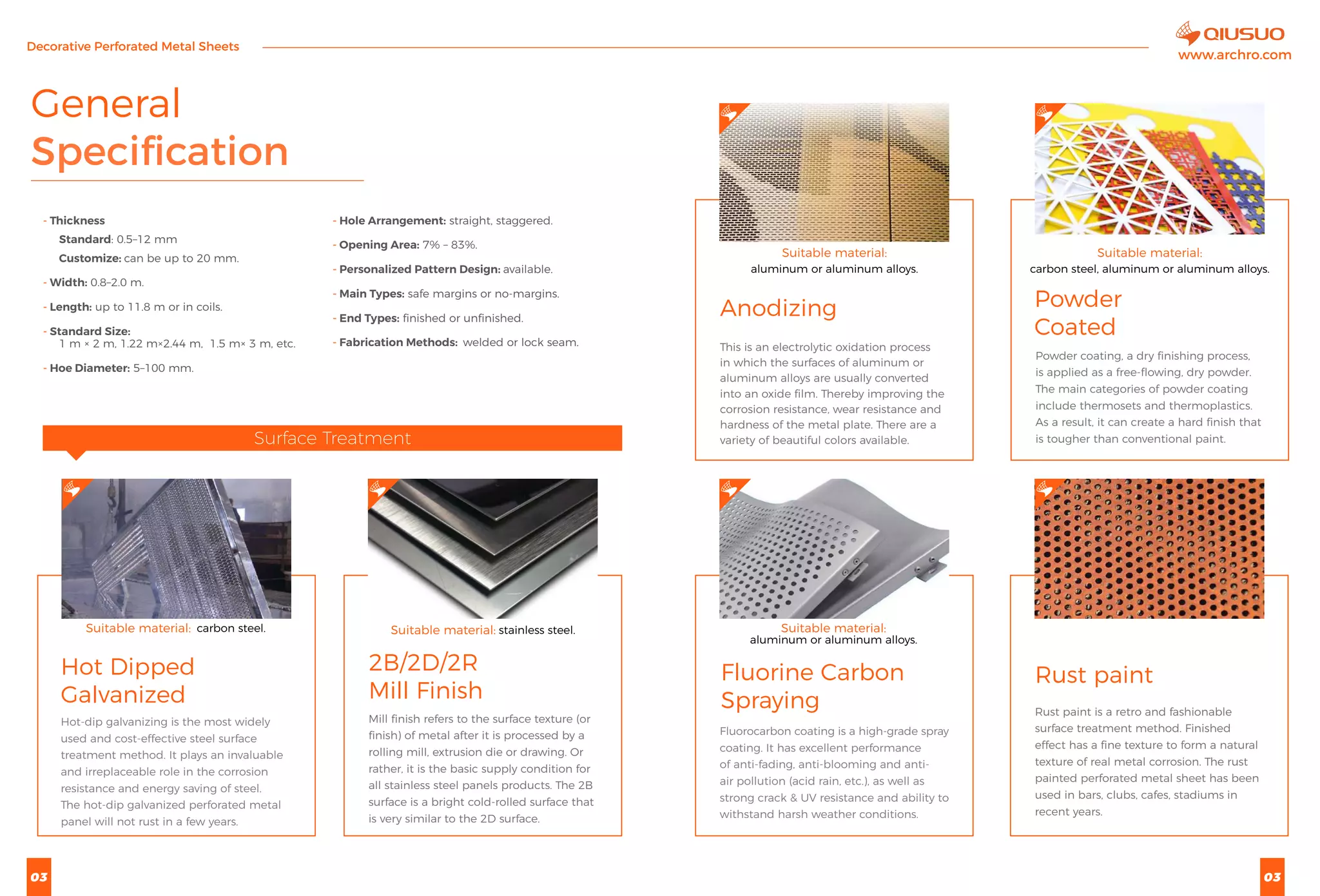

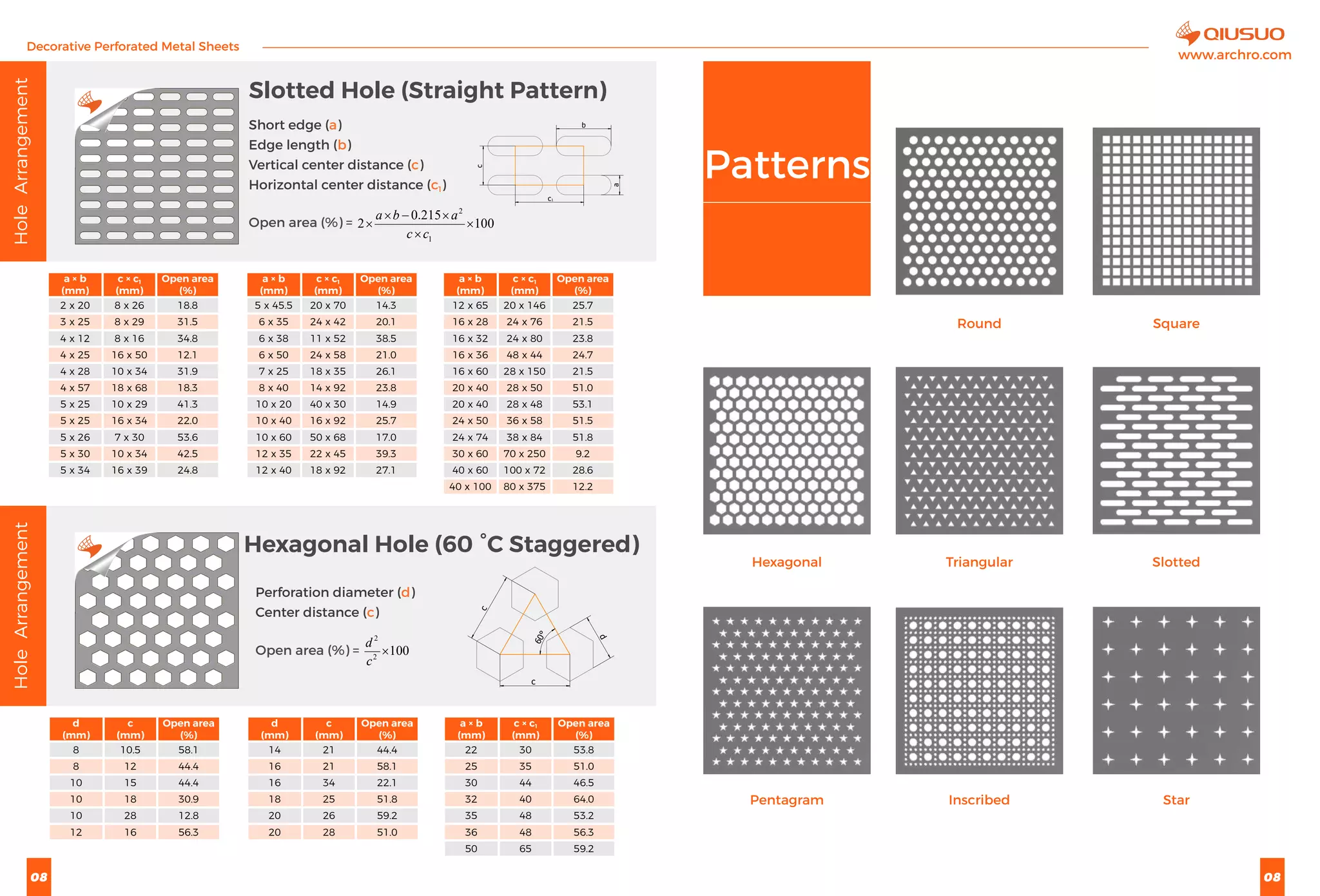

Hebei Qiusuo Wire Mesh Products Co., Ltd., established in 1998, specializes in manufacturing decorative perforated metal sheets and various other metal products for construction and automotive industries. The company offers custom solutions with a wide range of materials including aluminum, galvanized steel, stainless steel, and copper, featuring various hole shapes and surface treatments. Their global sales network reaches the USA, Middle East, Europe, and Africa, providing high-quality products tailored to customer needs.