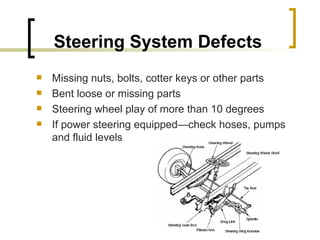

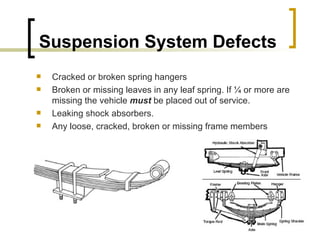

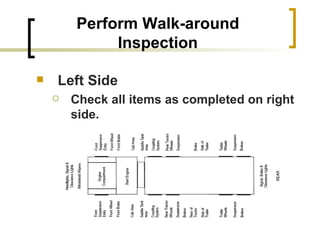

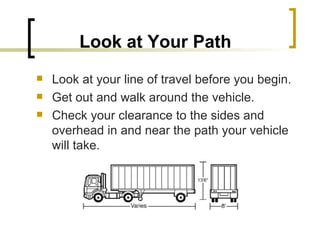

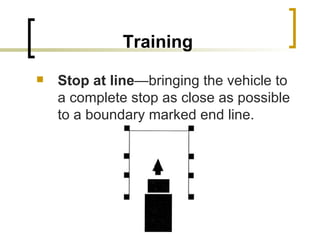

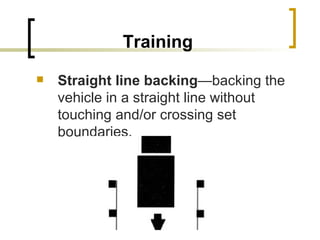

This document outlines procedures for spotter truck operators to safely inspect and operate their vehicles. It describes conducting a daily vehicle inspection to check for issues with tires, wheels, brakes, steering, suspension and other components. The inspection process includes approaching the vehicle, reviewing past reports, checking fluids and controls, lights, signals and performing a walk around check. Operators are instructed on how to properly accelerate, steer, back up and use basic vehicle controls. Backing safety is emphasized, including using helpers and mirrors and turning the steering wheel in the appropriate direction depending on the vehicle.