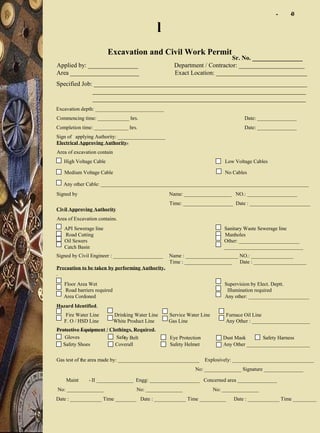

This document is an excavation and civil work permit that specifies the details of an excavation job, including:

- The applicant department and contractor

- The exact location of the excavation

- The specified job and excavation depth

- Commencing and completion times

- Signatures from electrical and civil approving authorities confirming the area is safe to excavate

- Precautions that must be taken, such as barriers and illumination

- Potential hazards identified in the area like gas lines

- Required protective equipment

It provides important instructions that the permit must be displayed, is only valid for the specified area and time, and must be reissued if work extends beyond the expiry time. Additions or alterations invalidate