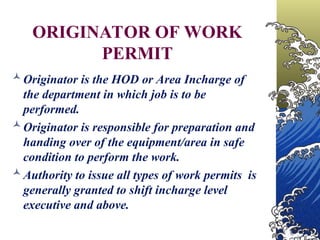

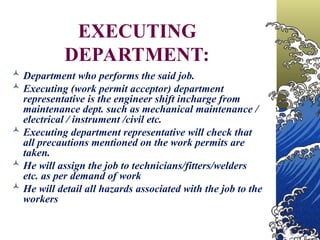

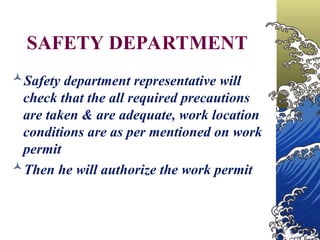

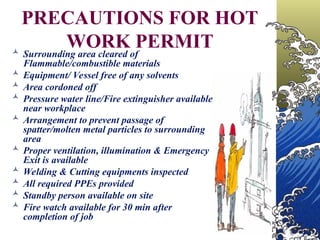

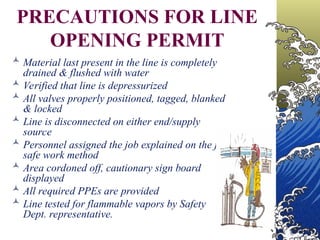

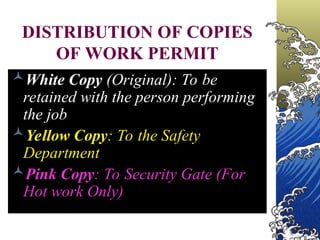

The document outlines the work permit system, which provides authorization for specific tasks while ensuring safety protocols are followed to prevent injuries and property damage. It specifies types of jobs requiring permits, such as maintenance, construction, and confined space entry, along with detailed precautions for various types of work. It also delineates the roles of personnel involved in the permit process and the requirements for its validity and surrender upon job completion.