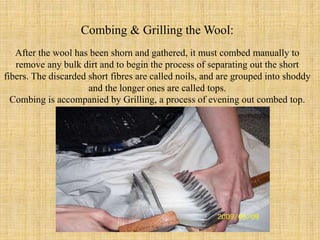

Wool is a natural fiber obtained from sheep and other animals like goats, alpacas, and camels. It provides warmth because wool fibers trap air. Australia is the largest producer of wool. The document discusses the production process of wool including shearing, cleaning, carding and spinning into yarn. It describes the properties of wool like absorbency, elasticity and wrinkle resistance. Various uses of wool are mentioned such as clothing, carpets, insulation and medical purposes. The future of wool is promising due to its sustainability and technical developments.