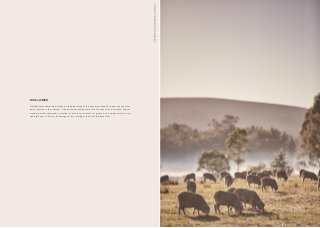

Wool, primarily produced from sheep, is a renewable and biodegradable fiber, notable for its unique properties and diverse applications in textiles. Australia leads in both the production of fine merino wool and non-mulesed wool, emphasizing responsible practices and animal welfare. While wool comprises only 1.2% of the global apparel market by volume, it holds 8% of its value, reinforcing its status as a luxury material with notable sustainability benefits over synthetic fibers.