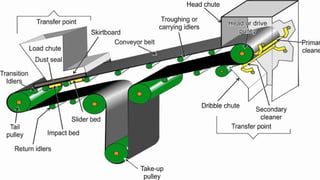

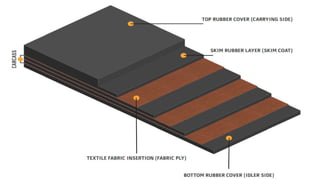

A conveyor belt is an endless belt operating between two or more pulleys that is used to transport materials. It consists of a carcass (usually made of woven fabrics), skims to provide adhesion between plies, and covers to protect the carcass. Conveyor belts transport bulk materials and objects over long distances at high speeds. They are useful in industries for moving heavy or bulky materials. Fabric materials like woven Kevlar provide advantages over steel reinforcement in conveyor belts, including flexibility, strength, and corrosion resistance.