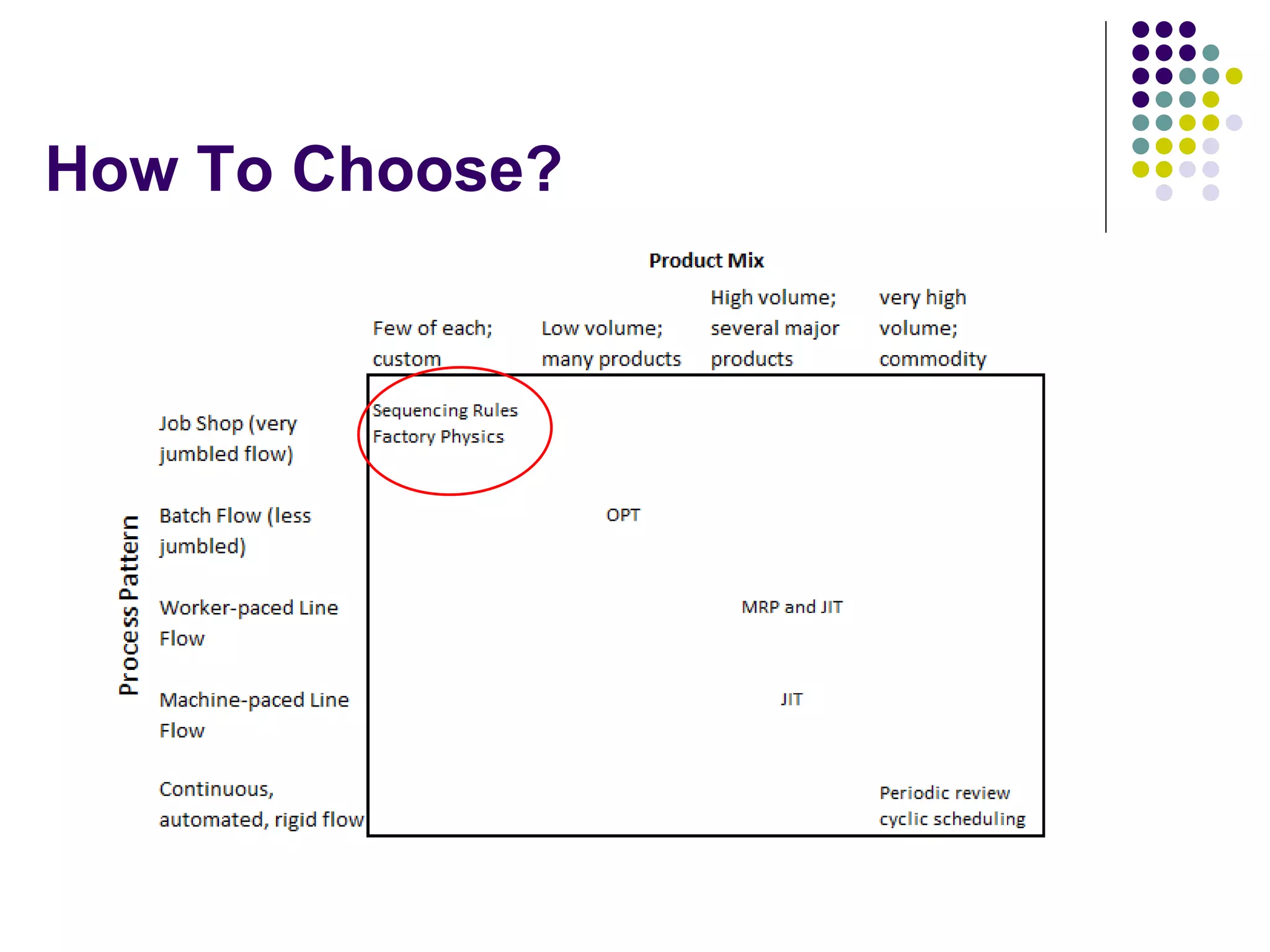

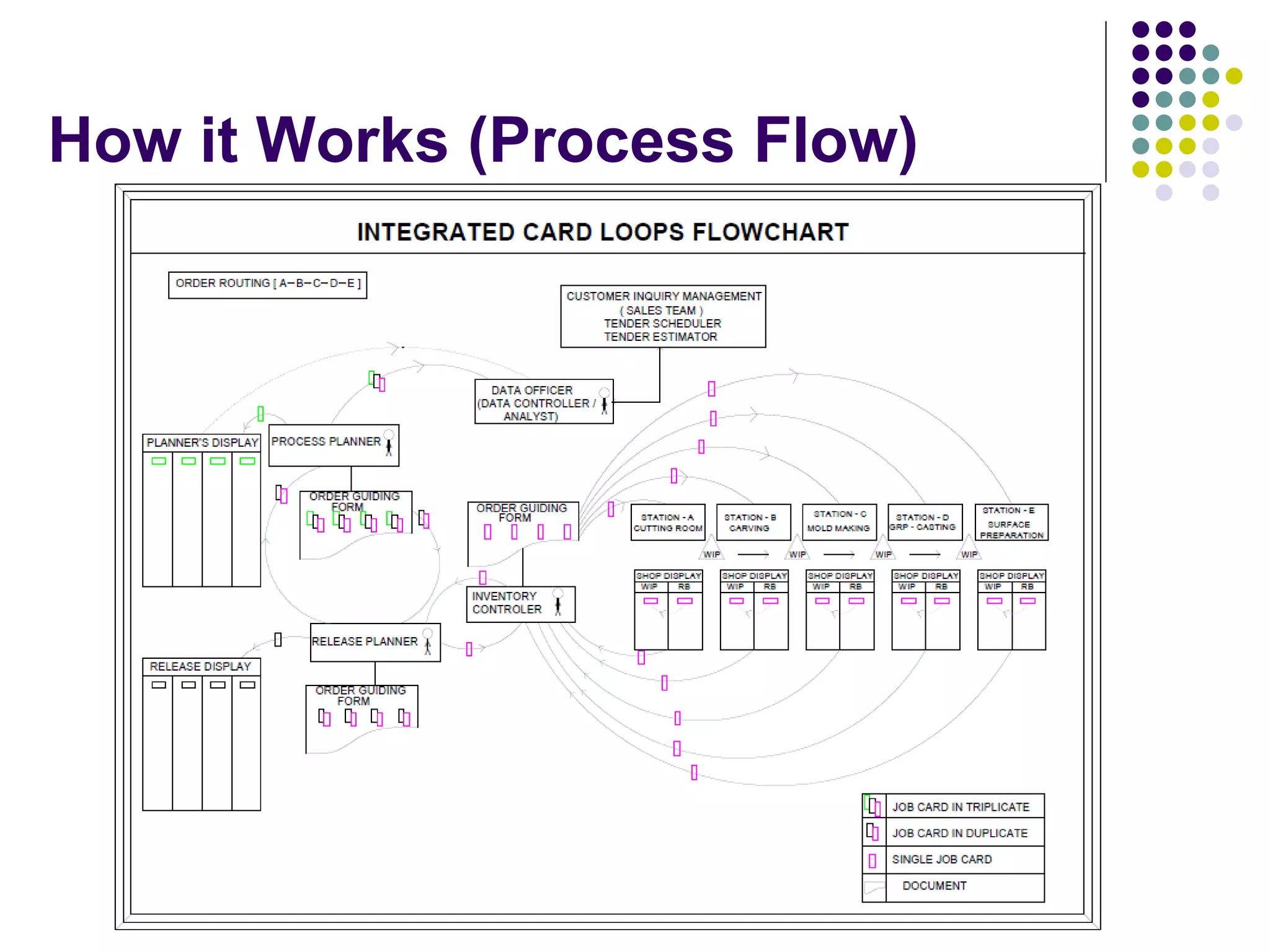

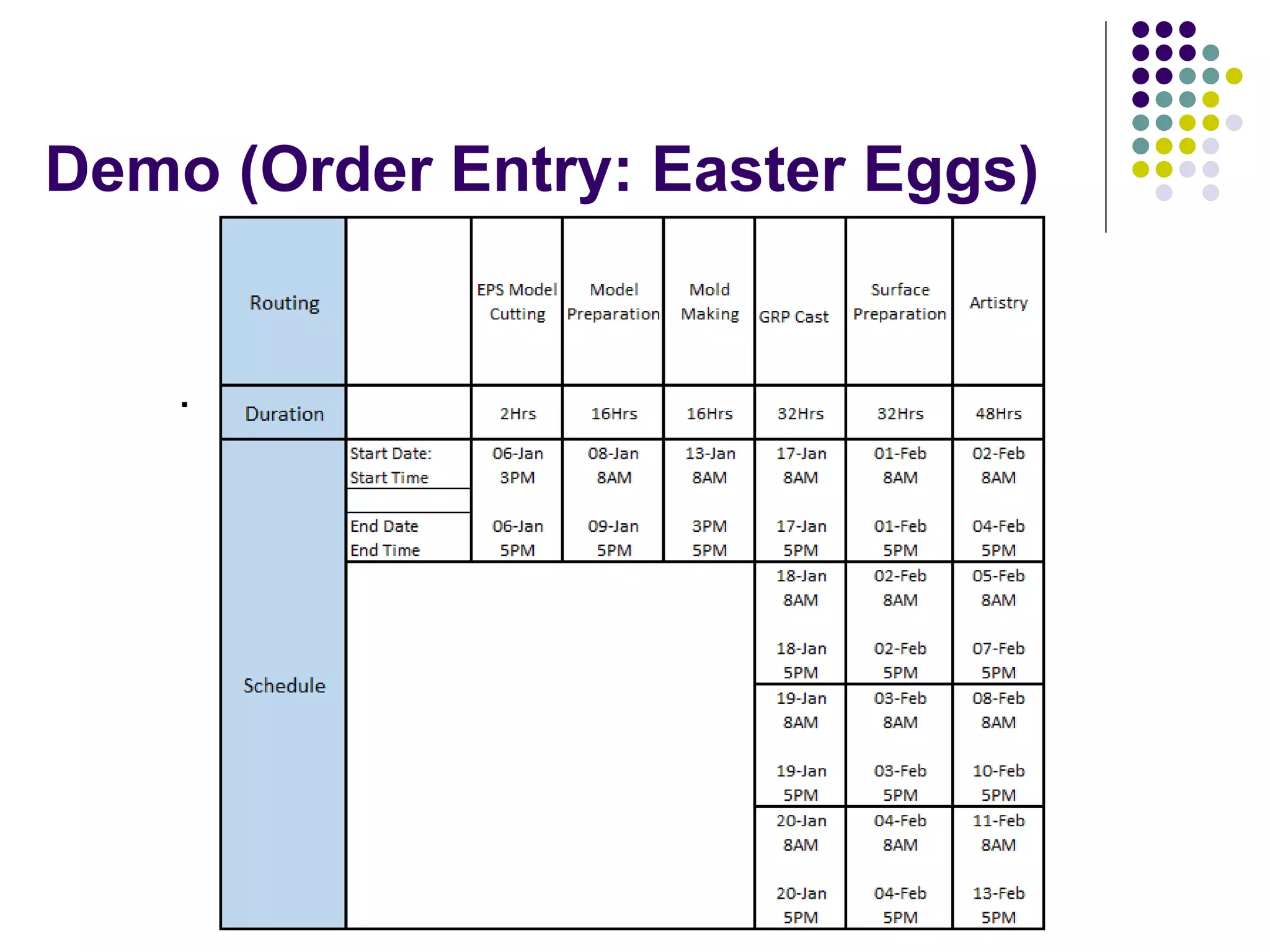

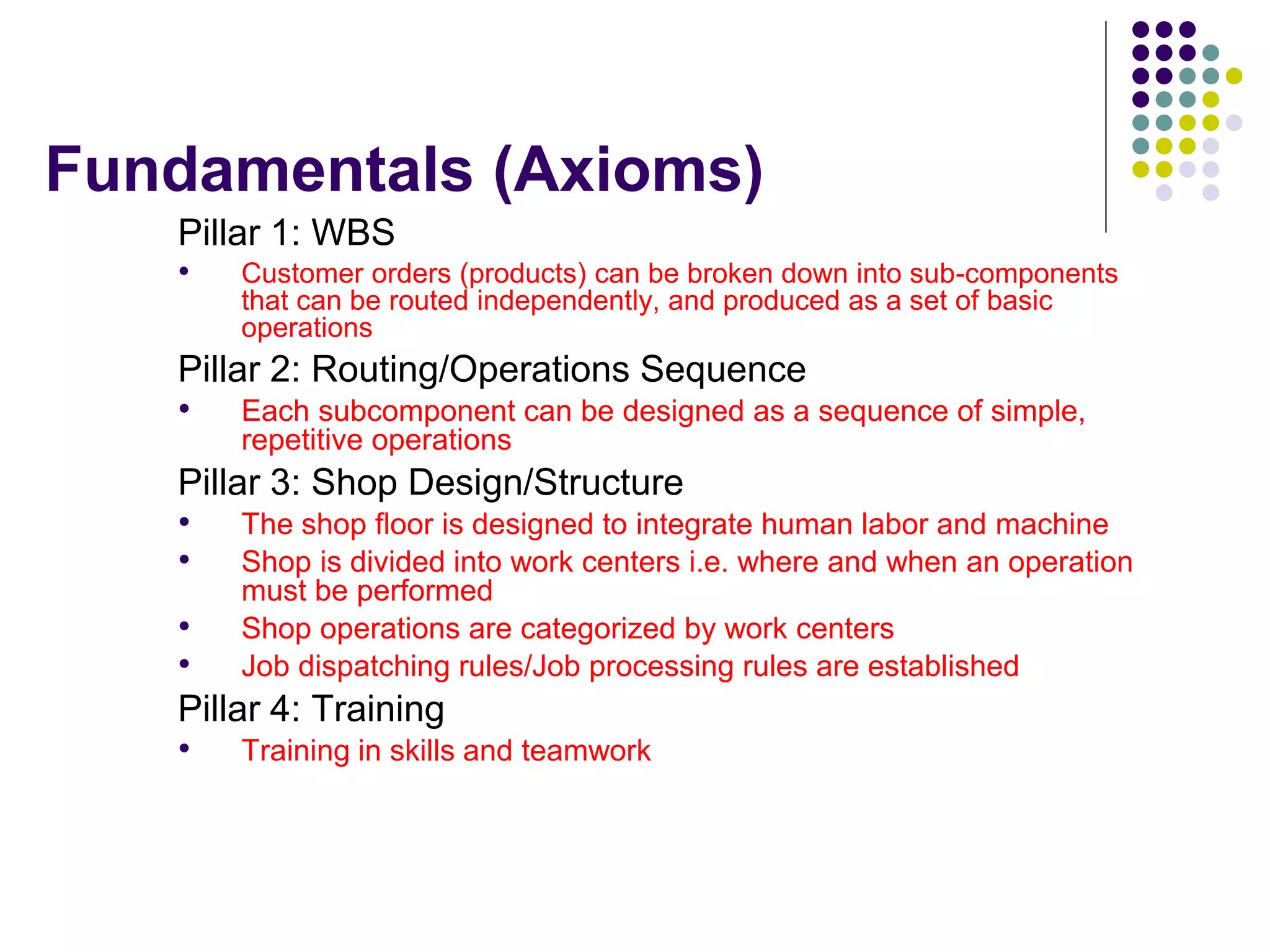

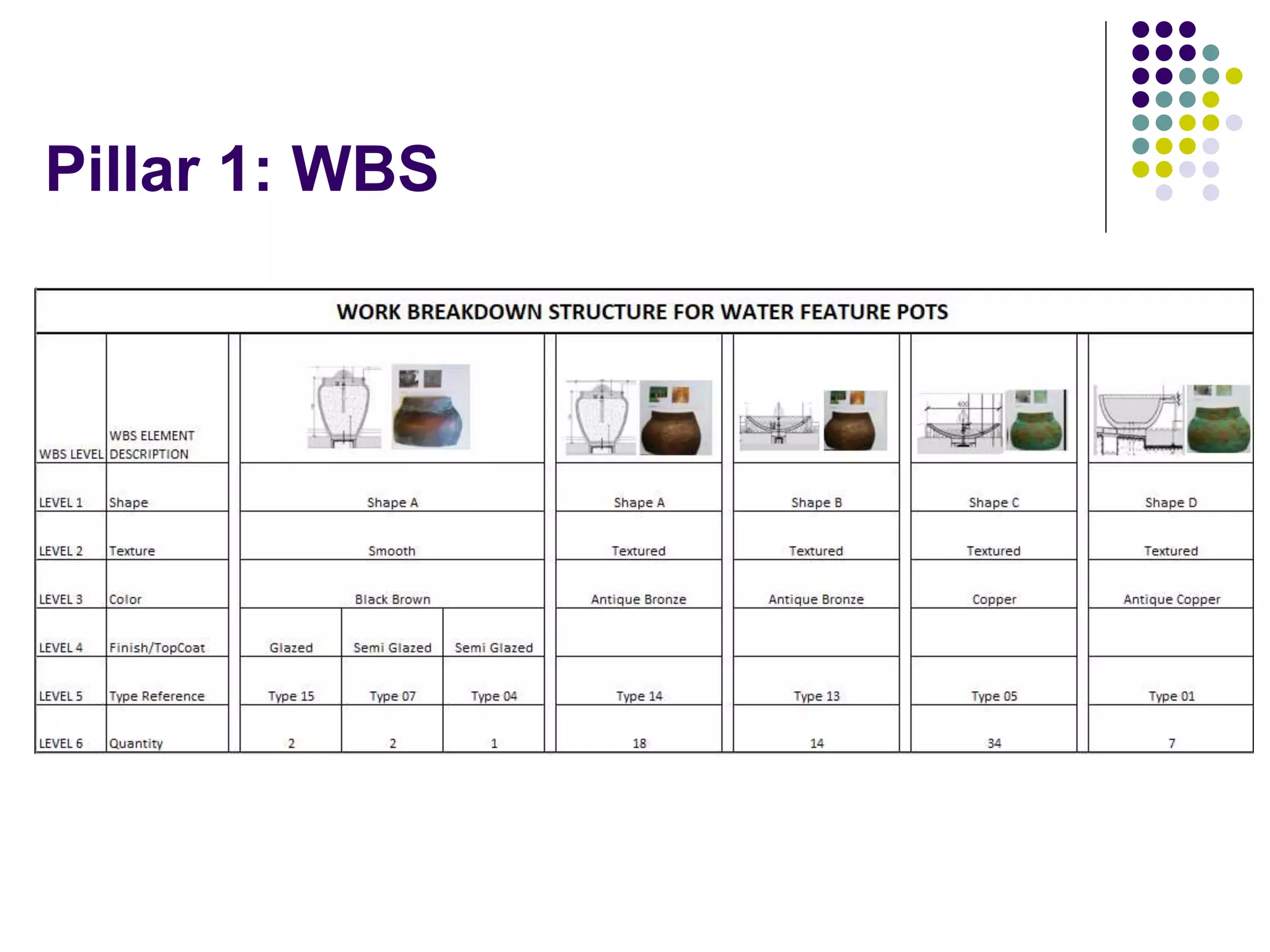

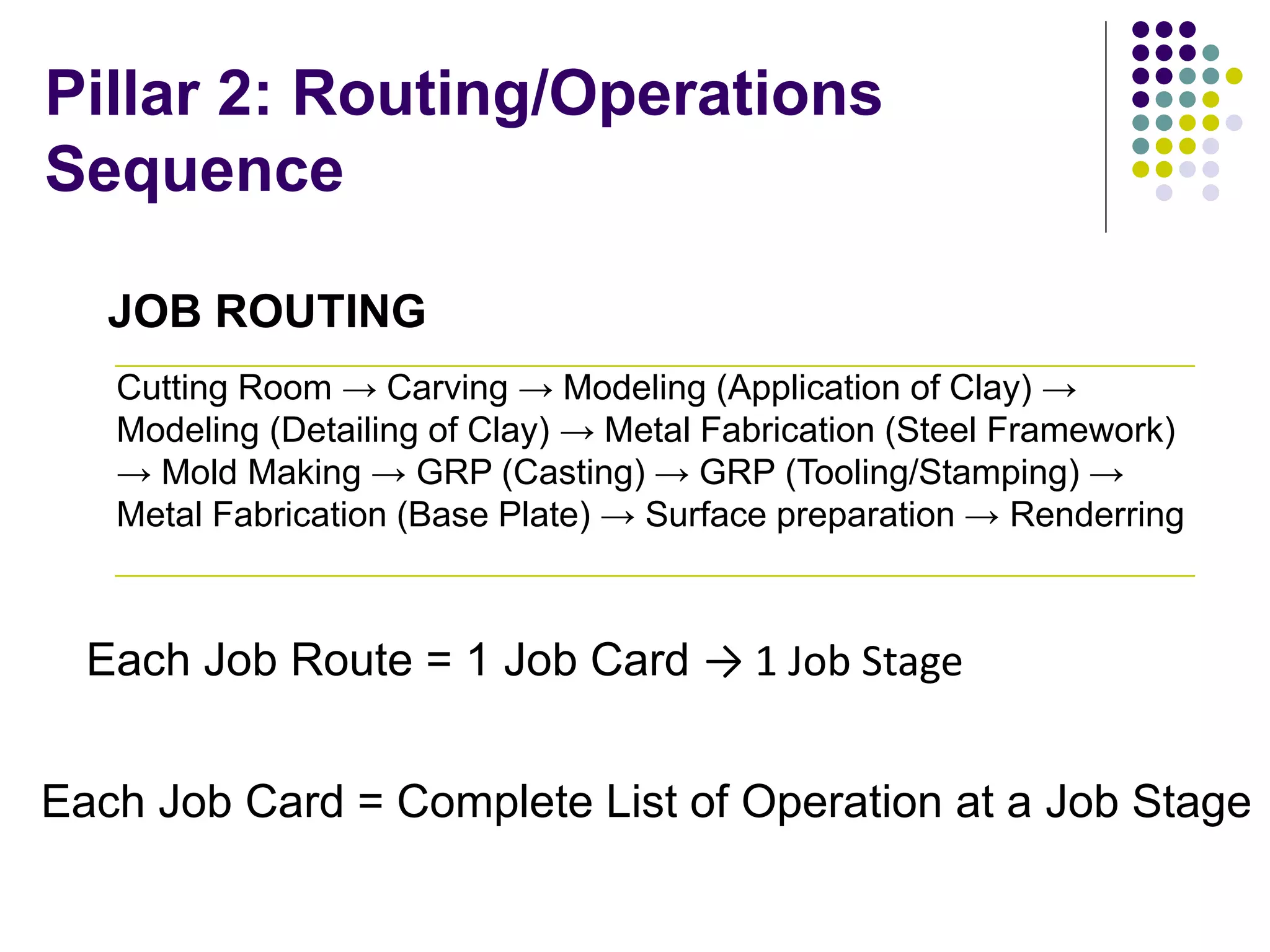

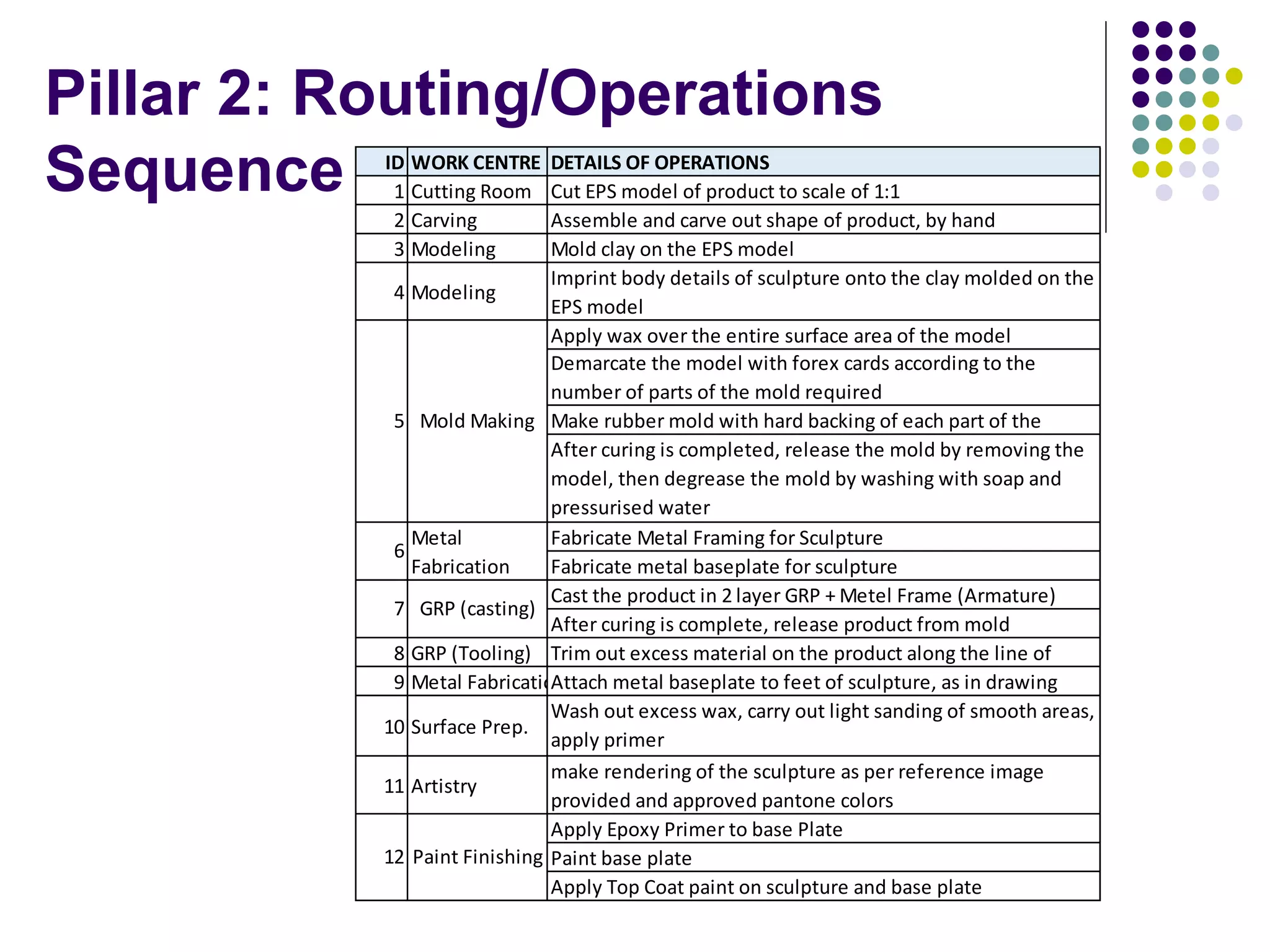

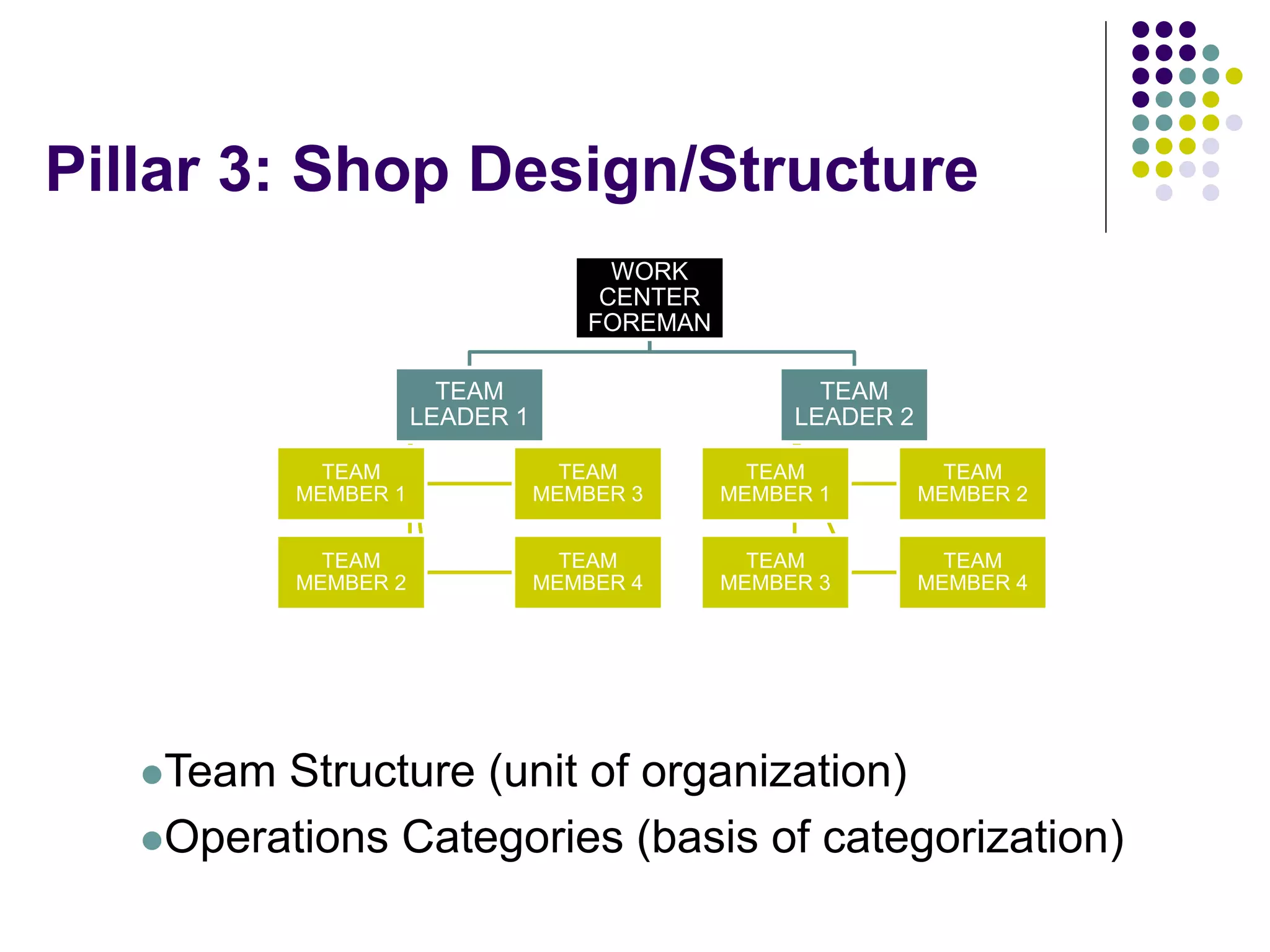

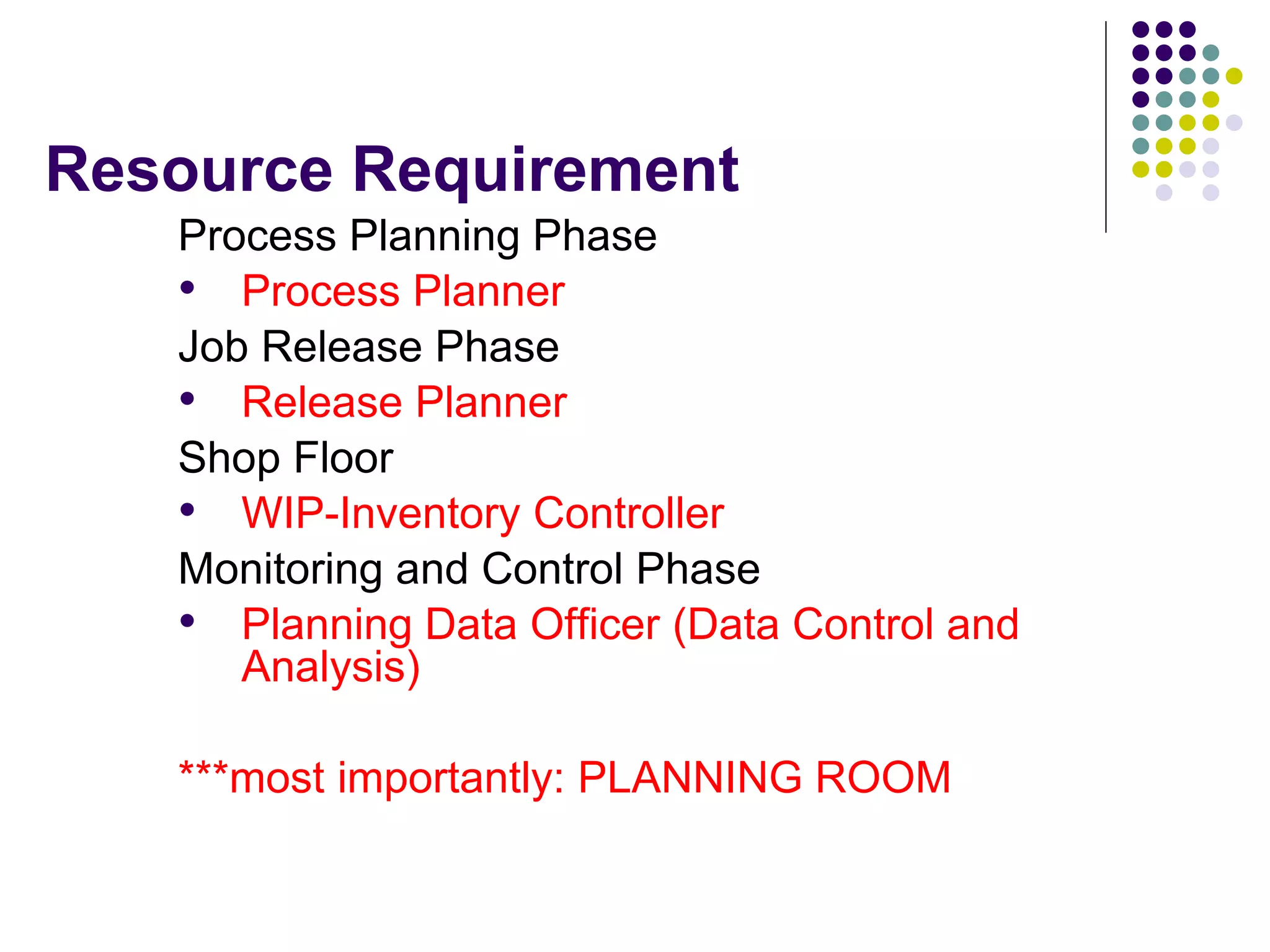

The document summarizes Card Based Production Planning & Control (PPC) System. It describes the system's components including a loop of cards between the shop floor and planning office and card display boards. It explains how the system works through phases like order entry, process planning, job release and execution. The system aims to provide realistic delivery times for customers by monitoring current workload and throughput. It also demonstrates the system with a sample of jobs and order entry. The document outlines the system's fundamentals including work breakdown structure, routing operations, shop design and training. It describes what the card system does and does not do in production planning and control.

![Card Based Production

Planning &Control (PPC)

System

Presented by [Ibrahim Mohammed]](https://image.slidesharecdn.com/cardsystemforppc-190924060833/75/WIP-Flow-A-Card-system-for-Production-Planning-and-Control-1-2048.jpg)