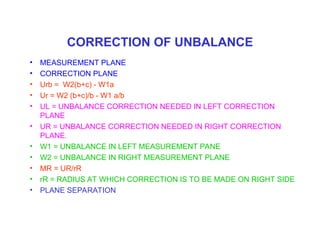

The document discusses equipment balancing and the concept of unbalance, which occurs when a rotor has an uneven mass distribution, leading to vibrations. It describes different types of unbalance such as static, couple, and combined, and explains the principle of balancing machines that measure and correct unbalance using centrifugal forces. Additionally, it outlines the categorization of dynamic balancing machines based on their behavior concerning resonance during operation.